Stator winding iron core and winding method thereof

A technology of stator winding and winding method is applied in the field of stator winding iron core and its winding, and can solve the problems of complicated manufacture of motor windings and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] At present, mechanical equipment is usually used in the manufacturing method of the iron core of the motor for the winding operation. In order to improve the current-carrying capacity of the winding copper wire of the motor, the current-carrying load of the armature winding can be reduced by increasing the diameter of the copper wire or winding multiple copper wires in parallel. However, the existing winding method is relatively difficult to implement for the existing rapping equipment, and the effect of winding is not very good.

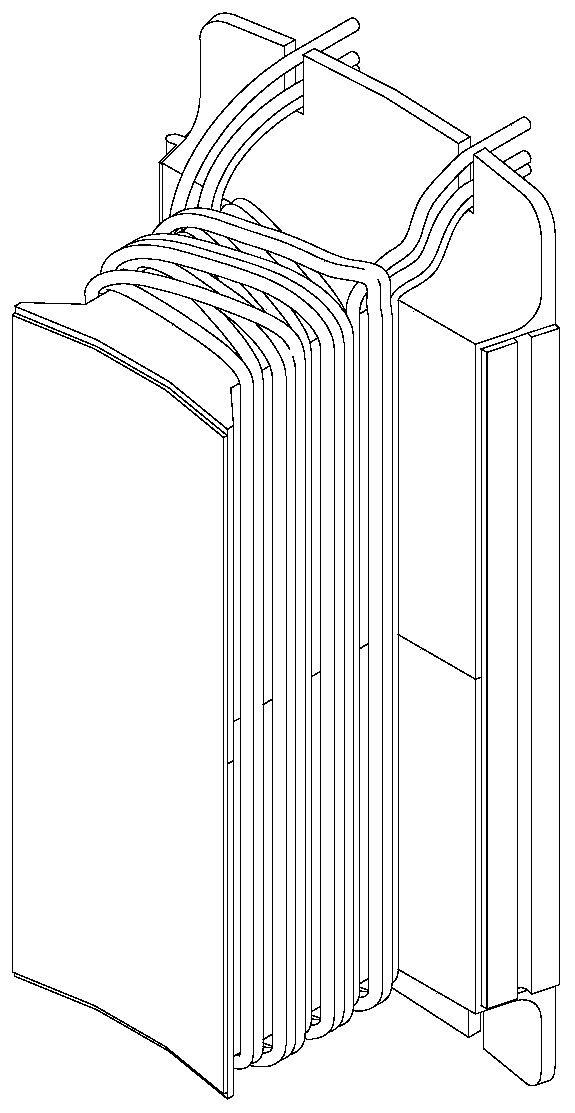

[0044] For example, in research, the inventors have attempted to implement a method such as Figure 1a Copper wire winding shown. It winds multi-strand coils as the same set of armatures on an insulating skeleton.

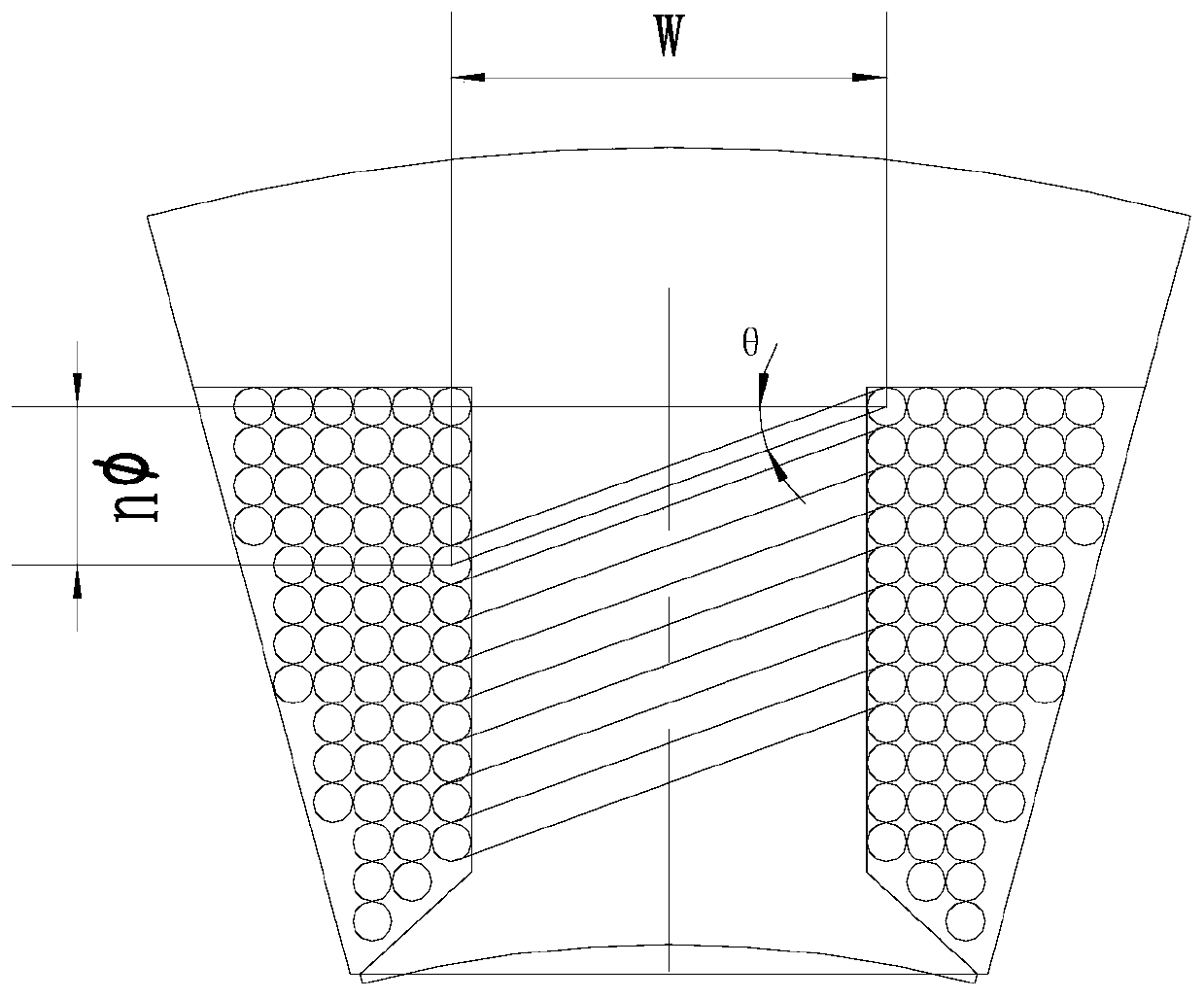

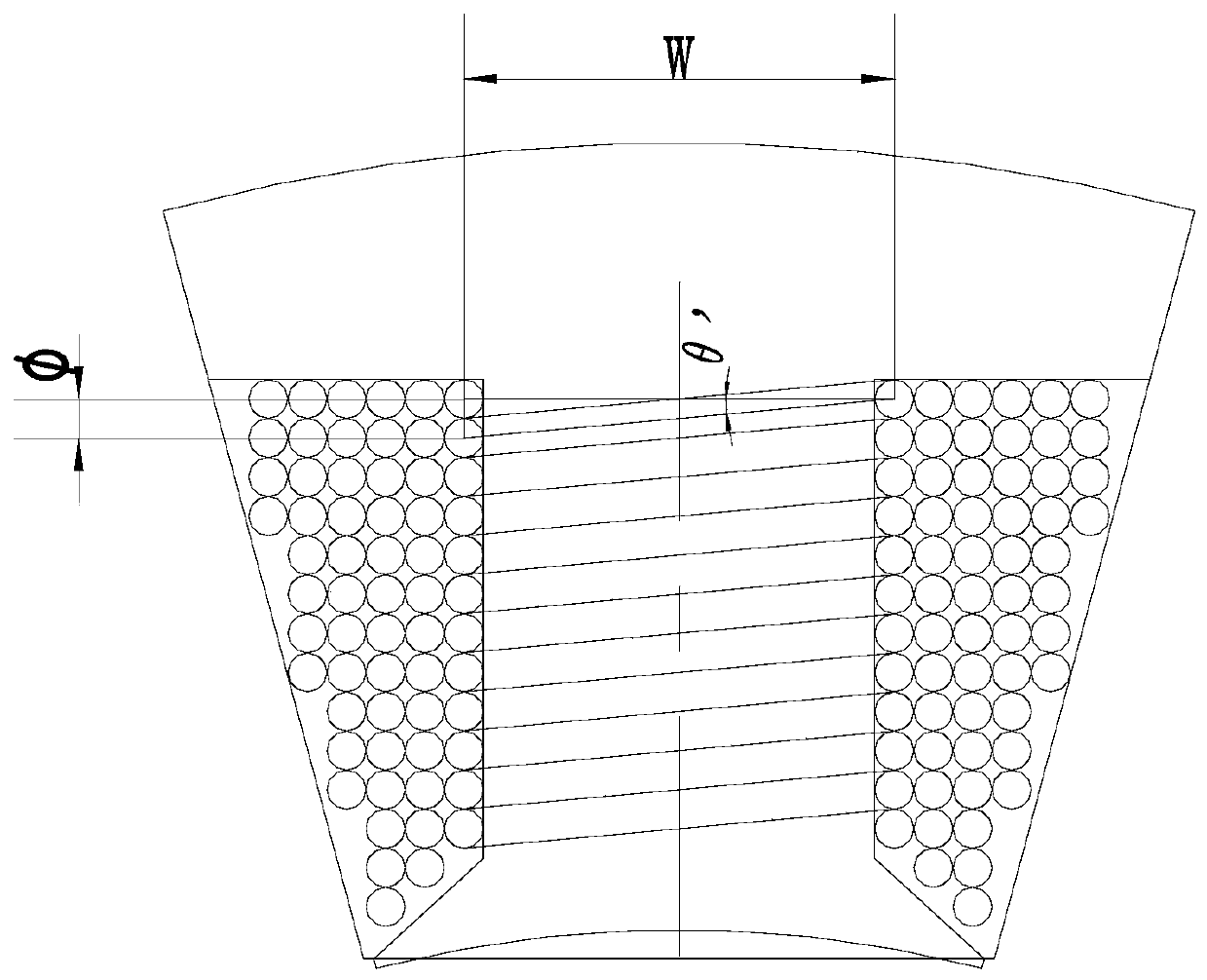

[0045] From the final result of winding, in order to achieve the ideal winding effect, at least the following conditions must be met at the same time: such as Figure 1a As shown, the multi-strand coils pass through multiple wire...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com