Gear shaping stator and assembling technology thereof

A tooth-shaping stator and assembly process technology, applied in electromechanical devices, magnetic circuit shape/style/structure, manufacturing of motor generators, etc., can solve the problems of large motor notch, decreased motor efficiency, and increased tooth harmonics, etc. To achieve the effect of simple off-line process, improve motor performance, and improve slot full rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

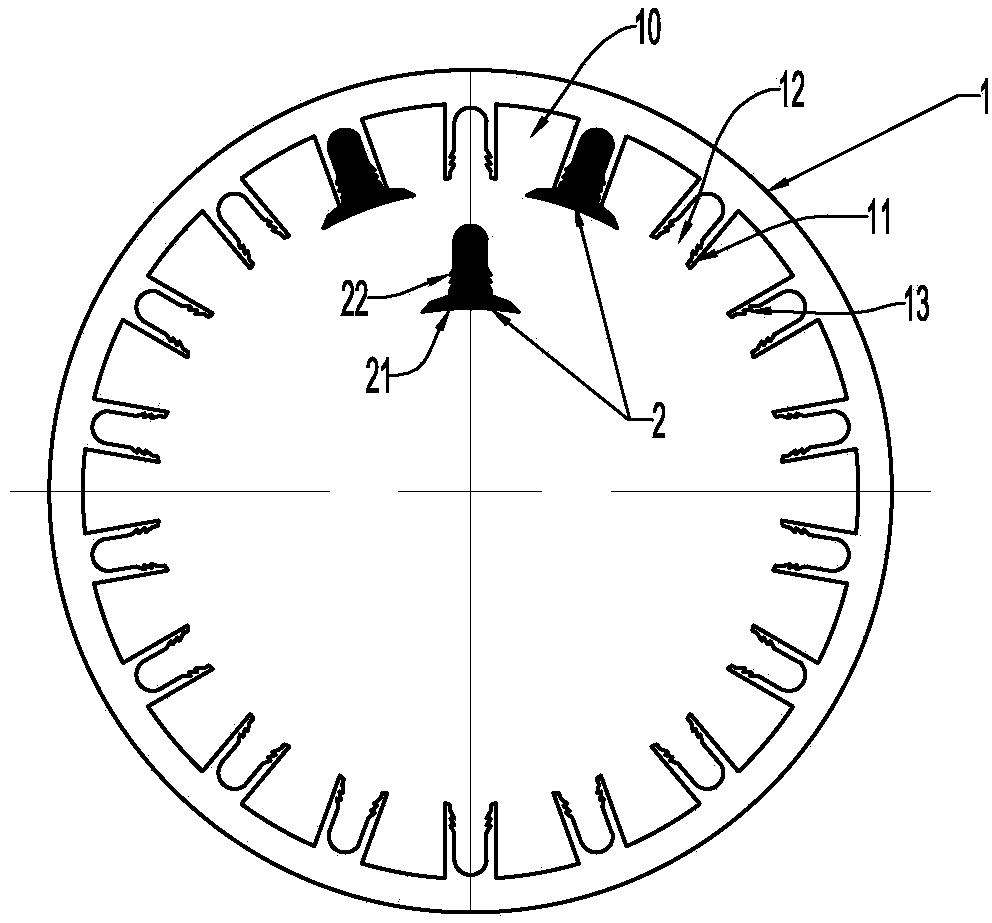

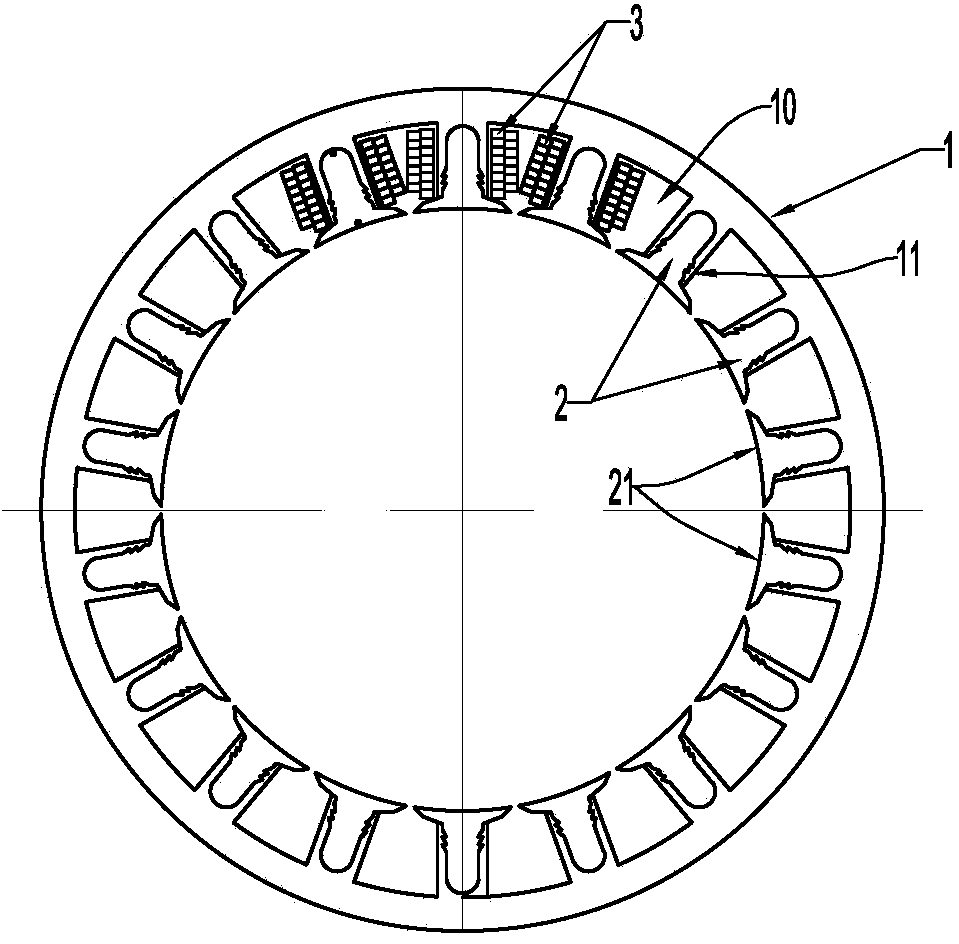

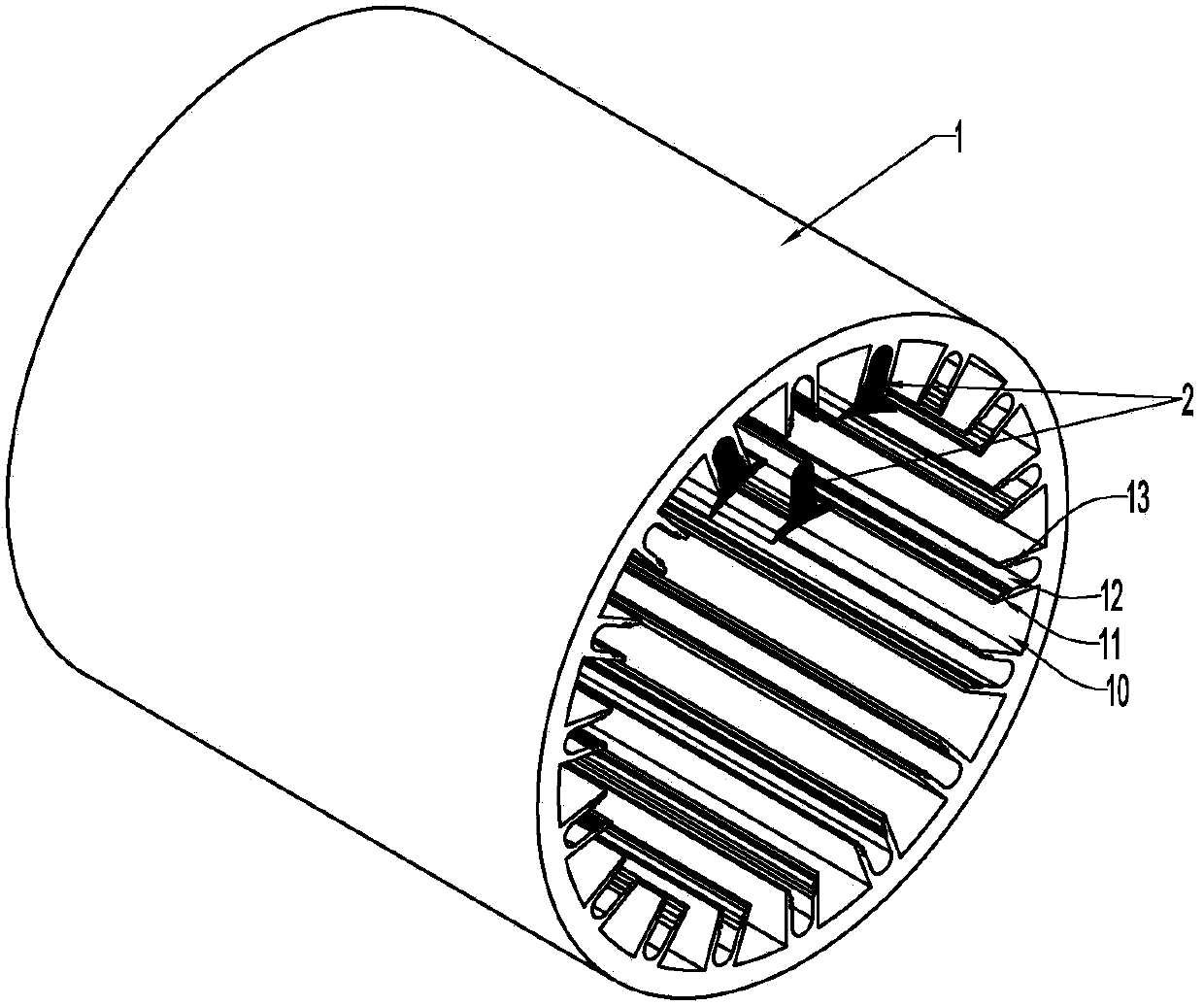

[0020] refer to figure 1 , figure 2 and image 3 , a gear-shaping stator, each stator tooth 11 of the stator 1 is provided with a cog slot 12, and the two sides of the cog slot 12 are respectively processed with anti-falling teeth 13; each cog slot 12 is equipped with a slot 2 , the shaper 2 has a T-shaped head 21 with a circular arc surface, the outer contours on both sides match the cog groove 12, and the position of the corresponding anti-falling tooth 13 is provided with a tooth 22, and the shaper 2 is embedded with the help of the anti-falling tooth 13 cooperates with the inverted tooth 22 to form the anti-off structure of the slotted tooth 2; the slotted tooth 2 is embedded in the cog groove 12, and the T-shaped head 21 blocks the wire grooves 10 on both sides respectively, and the T-shaped head 21 of the adjacent slotted tooth There are gaps between them, forming notches, and the arc surfaces of the plurality of T-shaped heads 21 form the inner circle structure of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com