Electric automobile modular stator and rotor motor

An electric vehicle, modularization technology, applied in the direction of electric vehicles, motors, synchronous machines, etc., can solve problems that have not yet been retrieved, and achieve the effects of improving generator efficiency, reducing iron loss, and reducing the length of flux linkage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The invention will be described in further detail below in conjunction with the accompanying drawings.

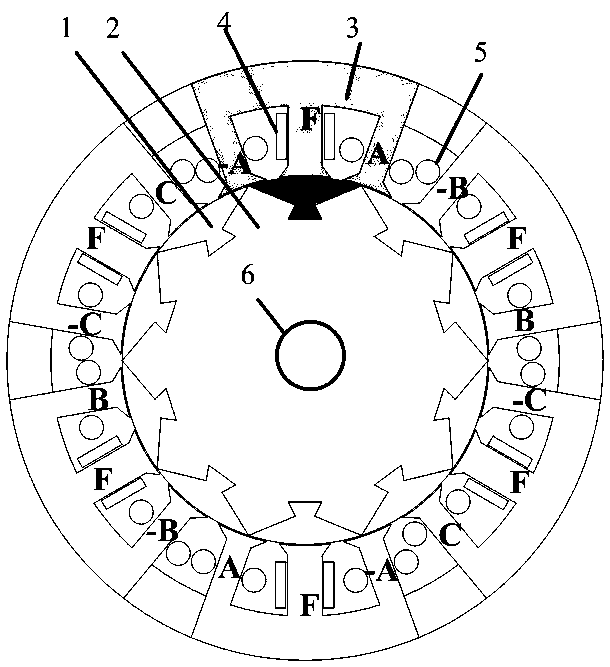

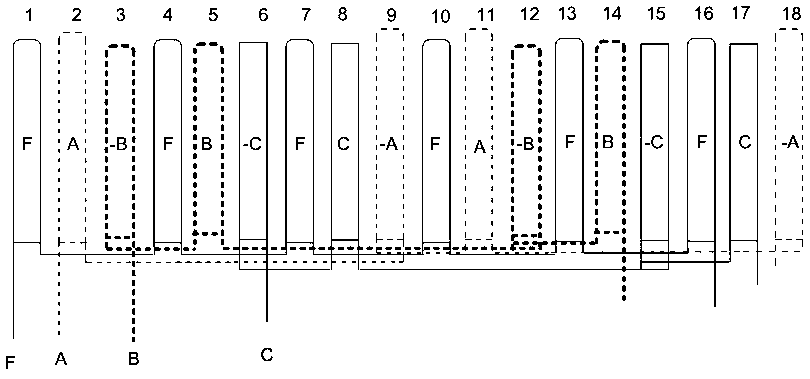

[0036] figure 1 It is a structural schematic diagram of the electric vehicle modular stator-rotor motor of the present invention. Among them, F, A, B and C represent the excitation winding and the A-phase armature winding, the B-phase armature winding and the C-phase armature winding respectively, and the negative sign indicates that the winding direction is opposite.

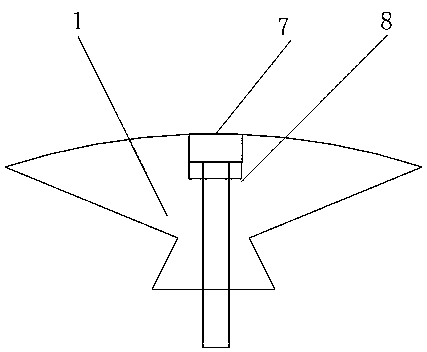

[0037] The electric vehicle modular stator-rotor motor includes a sector core, a non-magnetic rotor core, a stator core, an excitation winding, an armature winding and a shaft;

[0038] The stator core is divided into 6 E-shaped stator modules, and each stator module has 3 stator poles with different widths inside, the middle one is the field pole, and the two sides with equal width are the armature poles. The field pole width is greater than 1.2 times of the armature pole and less than 1.5 times of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com