Stator, motor with stator and compressor

A motor and stator technology, applied in the field of electric motors, can solve problems such as affecting the quality of the motor, disordered wiring at the starting position, and easy loosening of windings, etc., and achieves the effect of solving the disordered initial wiring and improving the full rate of the stator slots.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in detail below with reference to the accompanying drawings and examples.

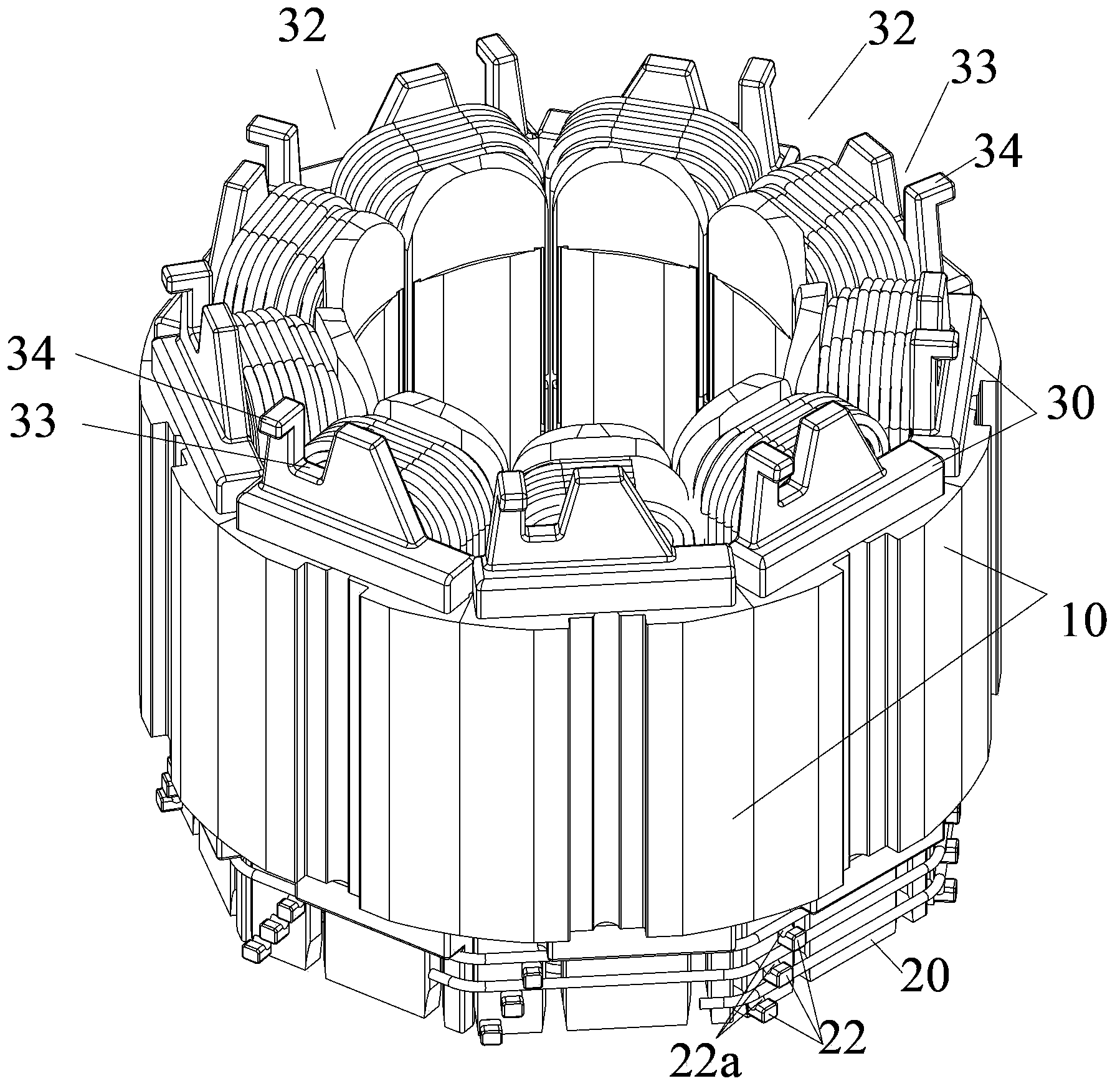

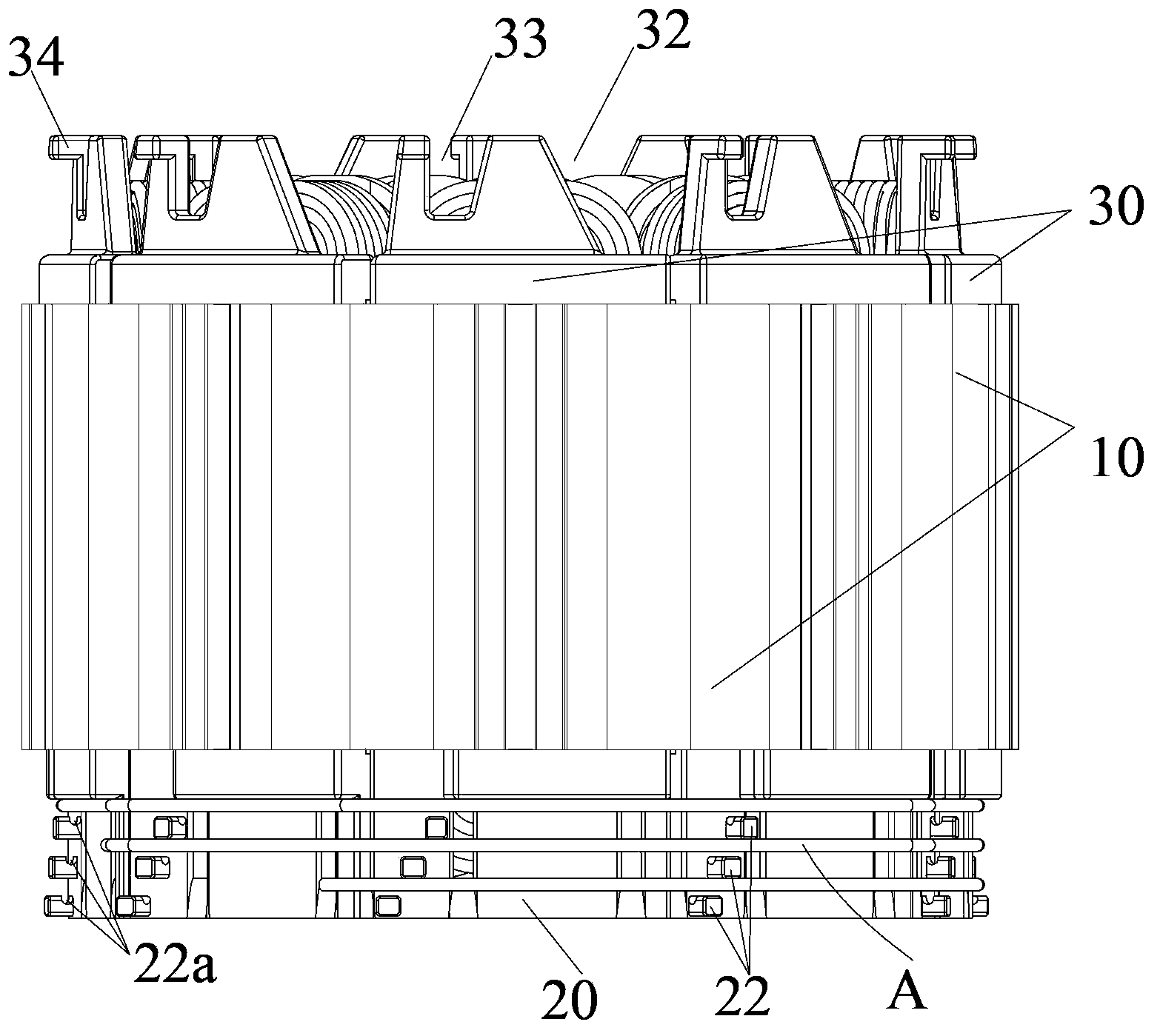

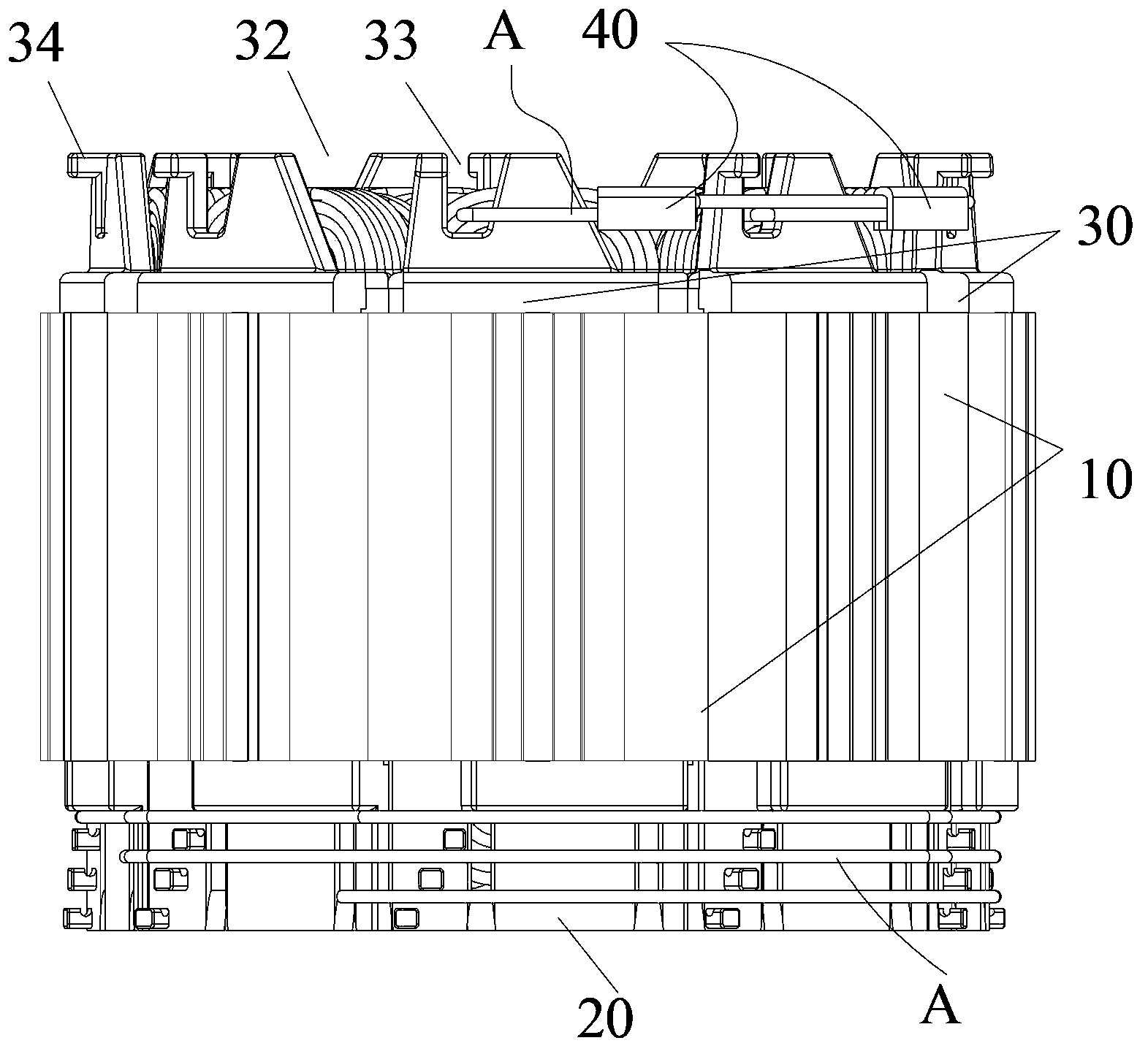

[0025] Such as figure 1 as well as Figures 4 to 7 As shown, the stator according to the present invention includes a plurality of stator core blocks 10, a first insulating frame 20 fixed at the first end of each stator core block 10, and a first insulating skeleton 20 fixed at the second end of each stator core block 10. Two insulating frames 30; the first insulating frame 20 has a first winding portion 21, and the first winding portion 21 has a first winding groove 21a; the second insulating frame 30 has a second winding portion 31, and the second winding A second winding groove 31a corresponding to the position of the first winding groove 21a in the axial direction of the stator is provided on the portion 31 . In the present invention, a first winding slot 21a is provided on the first winding portion 21 of the first insulating frame 20, and a wire tha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com