A drip irrigation belt retracting device

The technology of drip irrigation belt and pole is applied in the field of drip irrigation belt retracting device, which can solve the problems of high cost, time-consuming, laborious, and easy scaling of the dripper, and achieve the effects of low cost, avoidance of clutter, and easy disassembly.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Below by non-limiting embodiment and in conjunction with accompanying drawing, invention is further described:

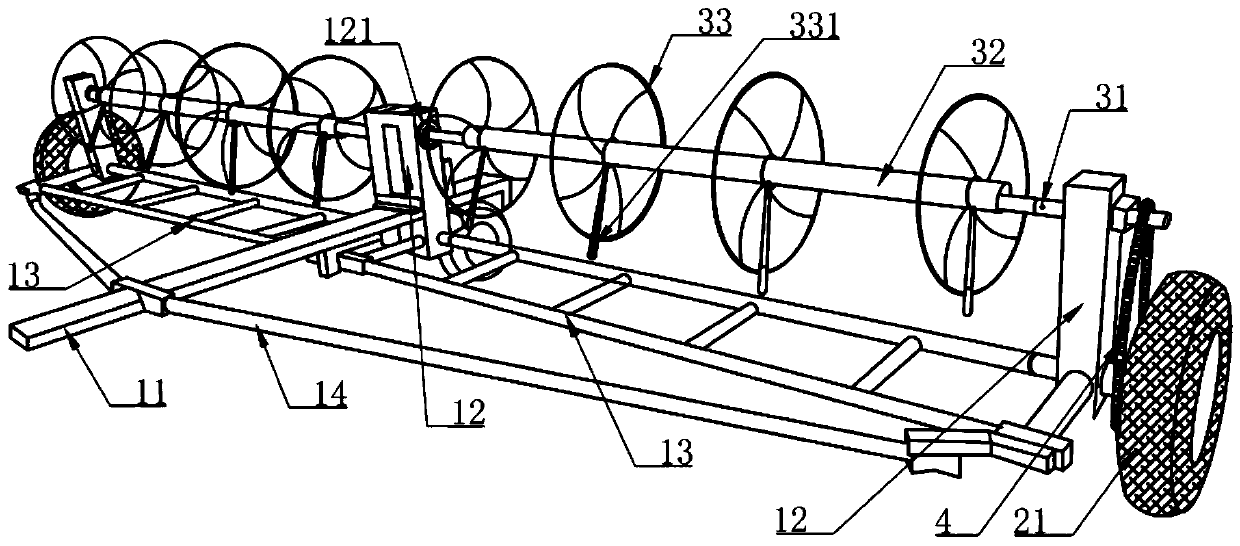

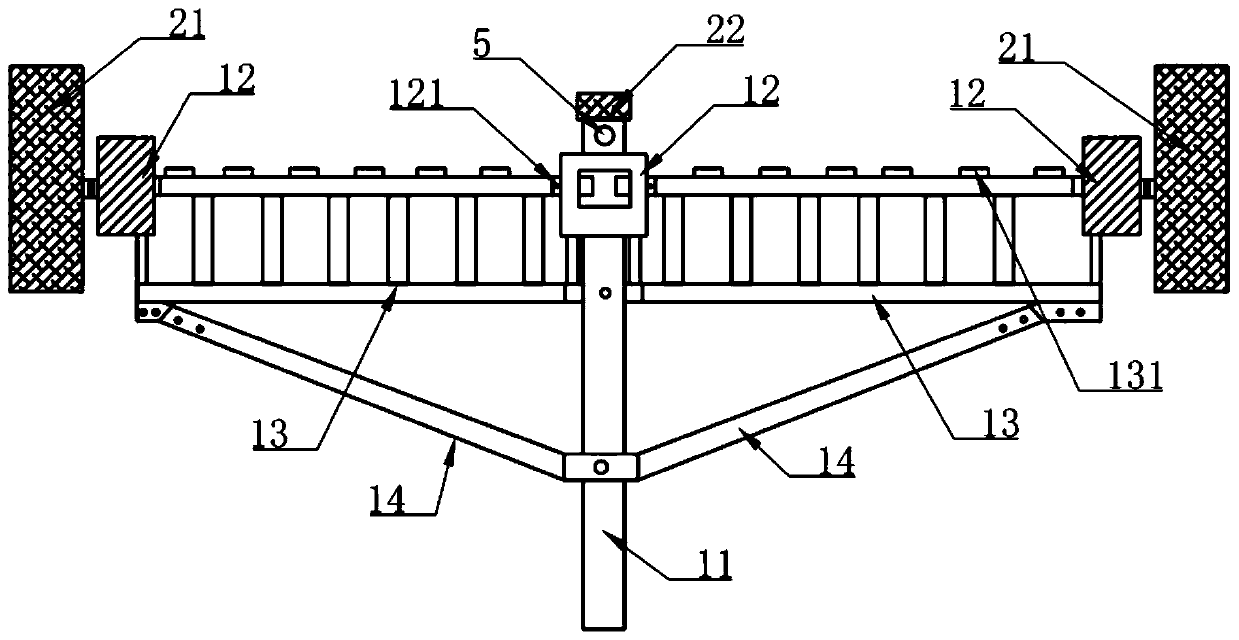

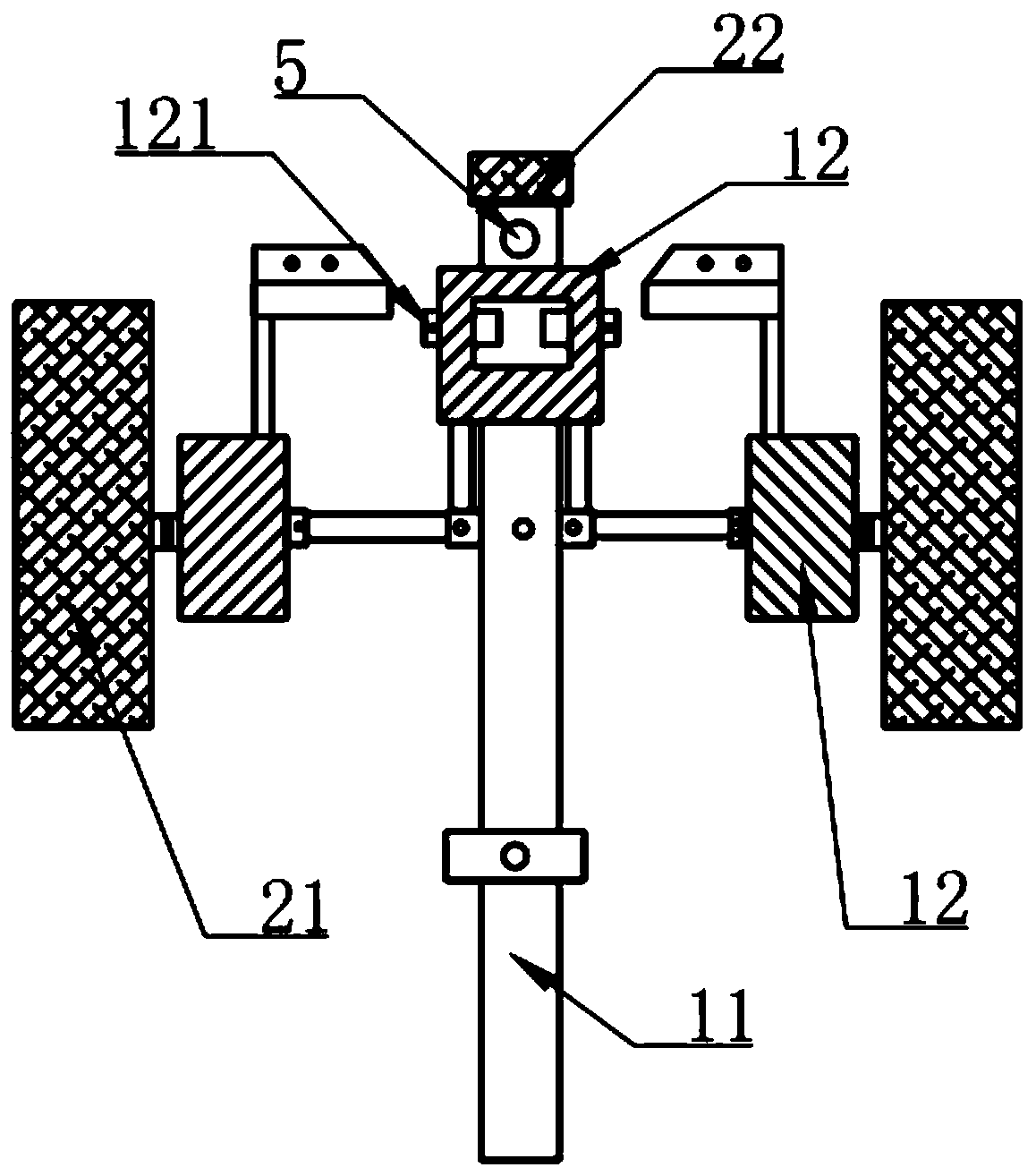

[0024] Such as Figure 1-4 As shown, a drip irrigation belt retracting device is driven by a tractor output power and the structure is composed of a support mechanism, a retracting mechanism and a walking mechanism, the retracting mechanism and the traveling mechanism are arranged horizontally, and the total width is 6.5- 7.5 meters; the supporting mechanism is to be used to connect the main rod 11 of the traction mechanism tractor, three vertical rods 12, two secondary rods 13 connected and fixed with the bottom ends of the three vertical rods 12 and for the main rod 11, the left and right two The connecting rod 14 that side vertical rod 12 is connected is made of; The retracting mechanism is to be made of rotating screw rod 31, retracting rod 32 and several circular fixed catches 33 that are arranged horizontally on the supporting mechanism vertical rod 12;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com