Coiling method of steel coil

A technology for steel coils and coilers, applied in metal rolling, manufacturing tools, metal processing equipment, etc., can solve the problems of inability to carry out packaging, easy to wrinkle strips, and loose steel coils and strips. Difficulty in operation, saving unwinding time and improving production speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

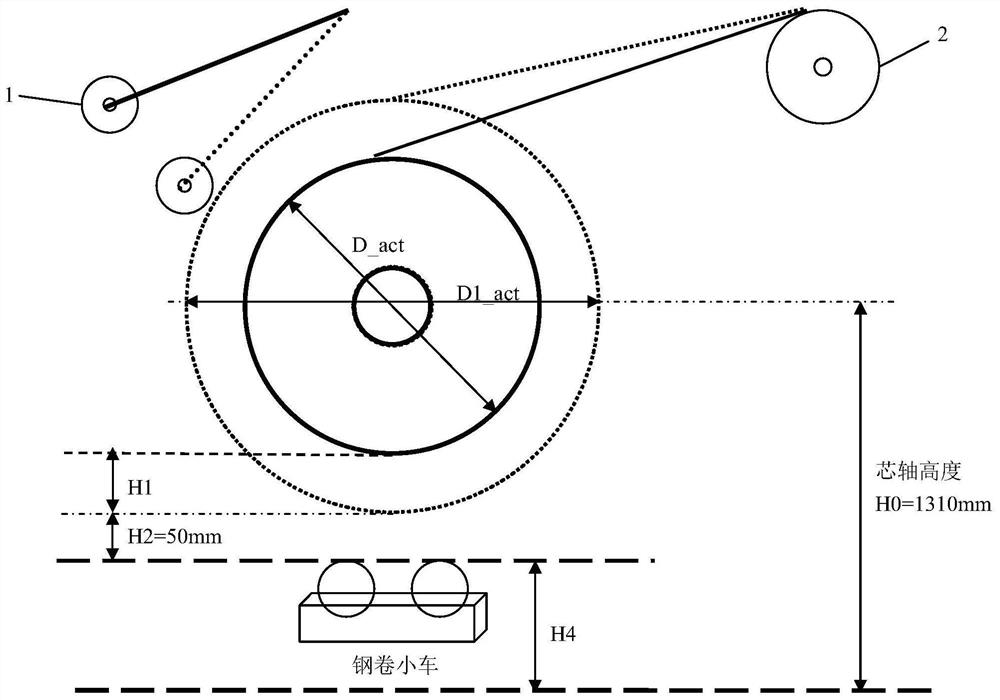

[0039] When the outer diameter of the steel coil on the coiler is larger than (inner diameter + 50 mm), the steel coil trolley is allowed to automatically pick up the coil. When the strip cutting point is 200 meters away from the exit cutting shear L=200 meters, trigger the steel coil trolley to automatically lift to the waiting position. Depending on the thickness of the strip and the inner diameter of the coil, the setting value of the waiting position is different.

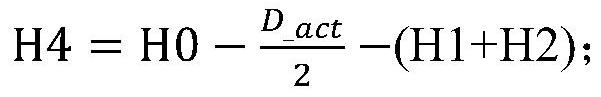

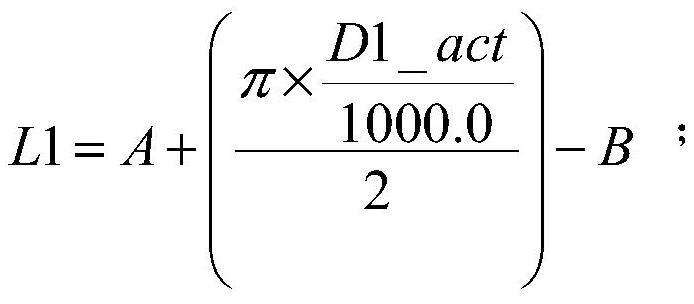

[0040] The change value H1 of the steel coil radius corresponding to the L meter strip steel can be calculated by the following formula:

[0041] H1≈H3×L×1000.0÷(π*D_act)

[0042] Among them, H3 is the strip thickness, the unit is mm, D_act is the actual outer diameter of the steel coil on the coiler, the unit is mm.

[0043] The strip thickness of the production line is 0.3-2.5mm. The maximum coil diameter is 2.1m. Taking the minimum finished coil diameter of 1.0m as an example, calculate the maximum radiu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com