Digital control edgefold sewing machine

A sewing machine and sewing machine technology, applied in the direction of program-controlled sewing machines, sewing machine components, sewing equipment, etc., can solve the problems of poor processing effect of complex curved stitches, increased management difficulty, production cost, and large stitch length error, etc. The effect of saving feeding time, saving management costs and production costs, and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

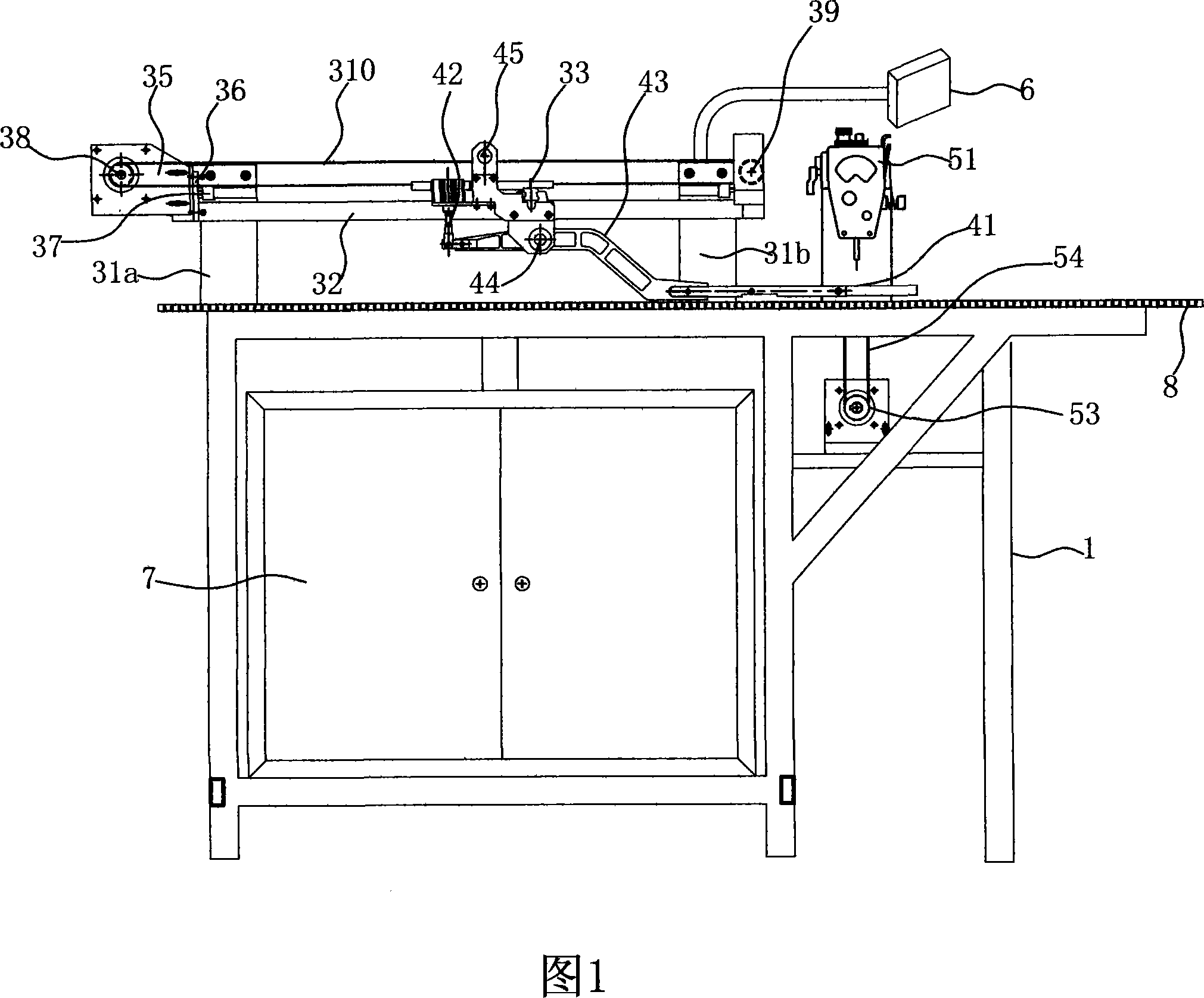

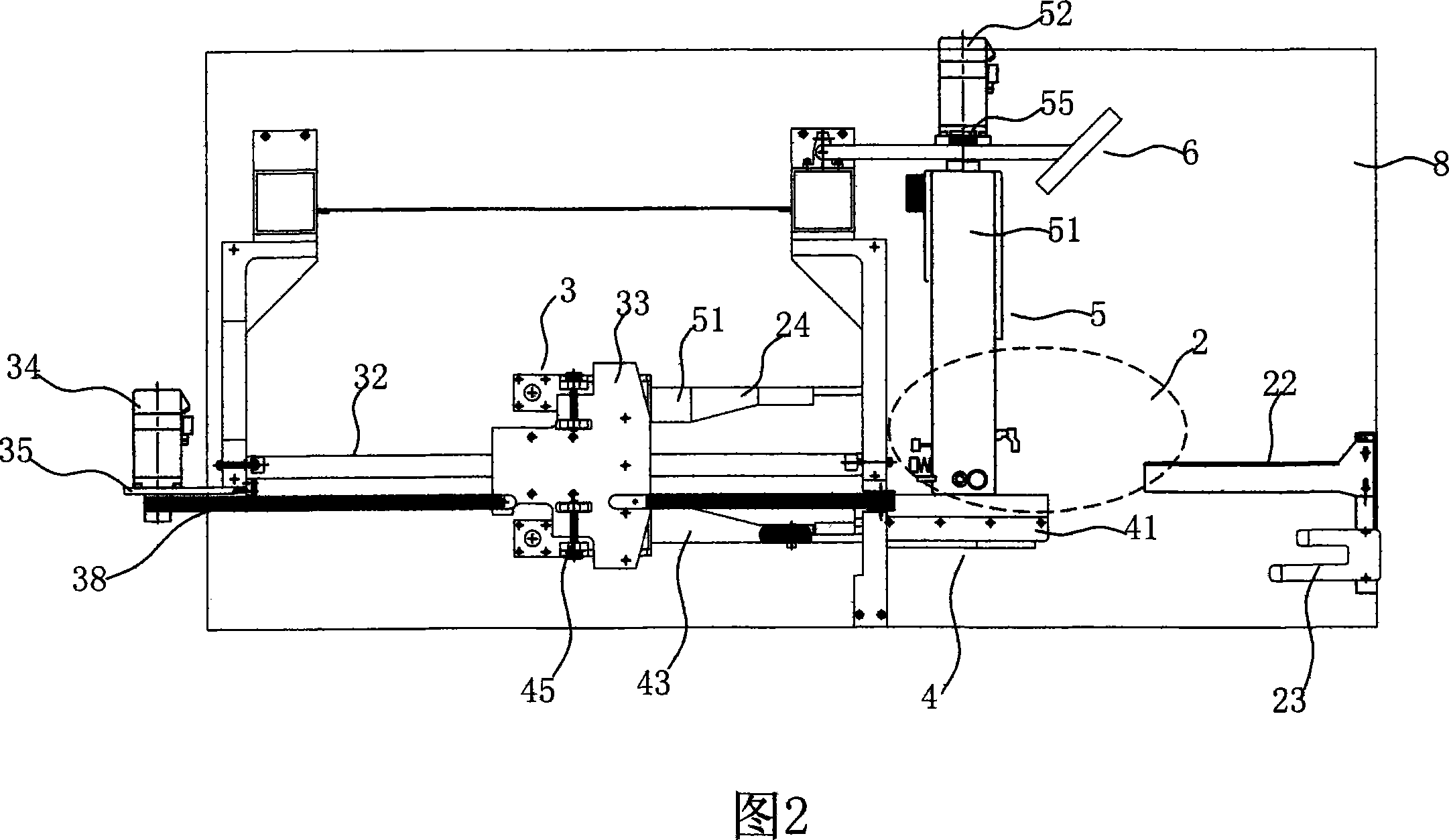

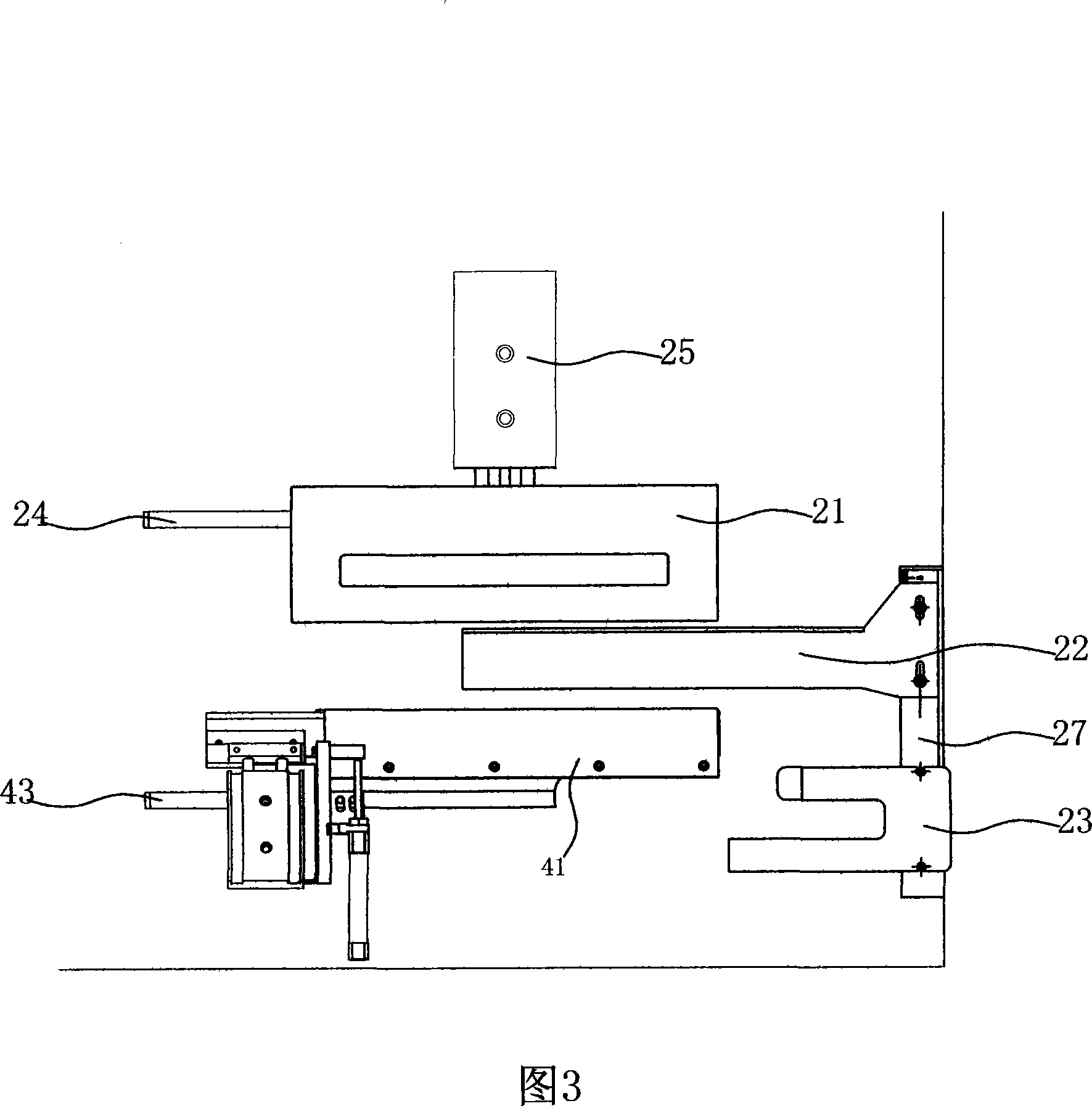

[0015] As shown in Fig. 1 and Fig. 2, the present invention mainly consists of a working platform 8 installed on the frame 1, a sewing machine body assembly 5 installed on the working platform 8, an operation panel 6, a transmission mechanism 3, a hemming mechanism 2, a press Foot mechanism 4 is formed, and distribution box 7 is installed in the below of frame 1.

[0016] The sewing machine body assembly 5 includes a sewing machine body 51 with a body motor 52, the body motor 52 is connected with the distribution box 7, and the body motor driving wheel 53 placed on the main shaft of the body motor 52 passes through the body timing belt 54 and is placed on the sewing machine body 51. The body main shaft belt pulley 55 on the upper body is connected to realize transmission.

[0017] Transmission mechanism 3 comprises right support frame 31a, left support frame 31b installed on the working platform 8, guide rail 32 is installed between right support frame 31a, left support frame ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com