Novel wire cutting machine

A wire cutting machine, a new type of technology, applied in the direction of shearing device, shearing machine accessories, shearing machine equipment, etc., can solve the problems of low cutting speed, poor cutting surface quality, etc., to control the wire feeding length and ensure the quality of the section , the effect of accurate wire feeding length

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

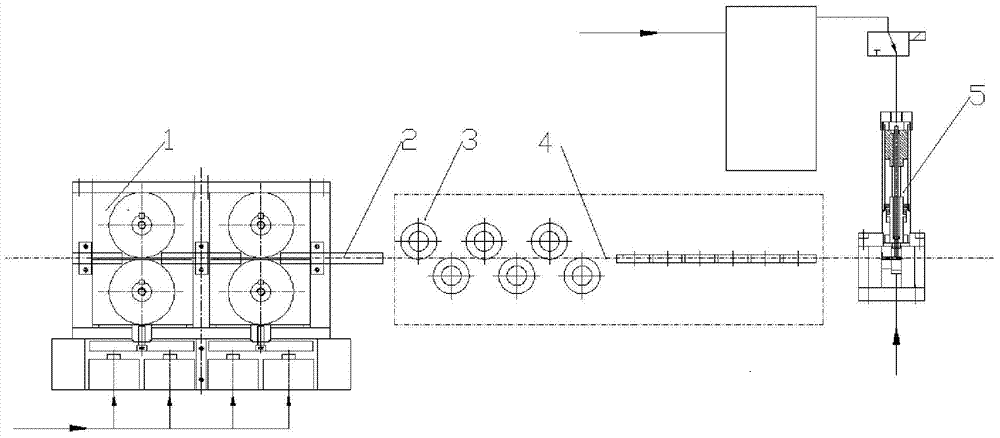

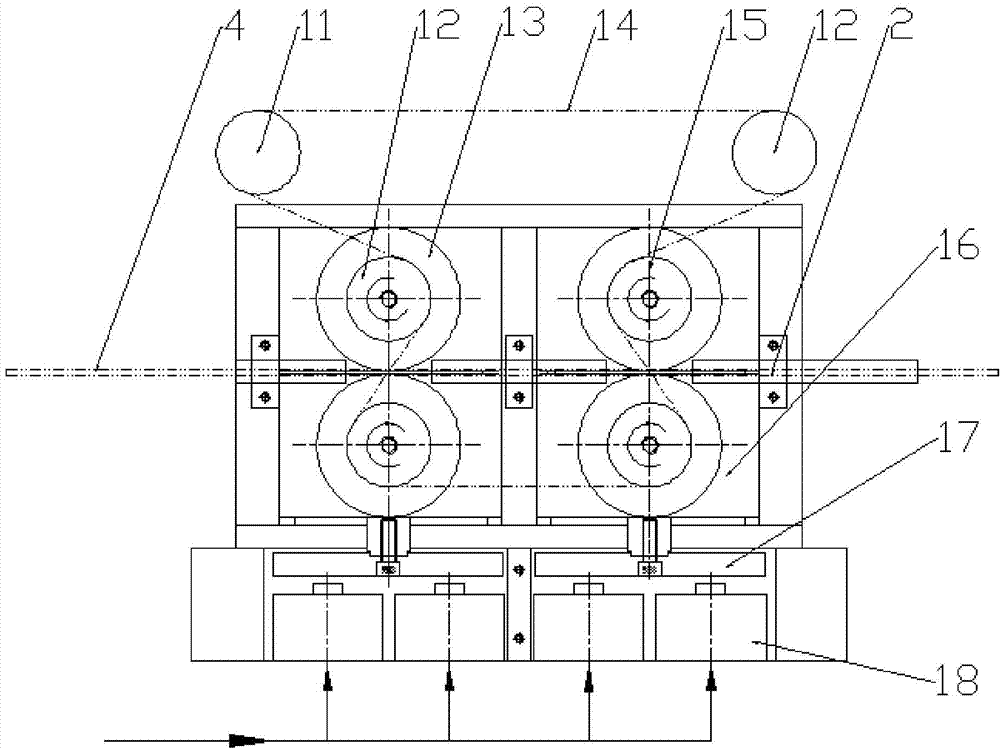

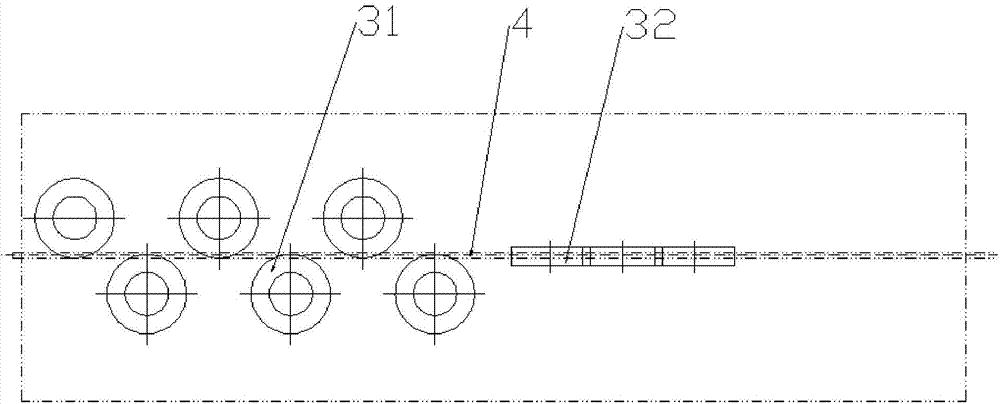

[0020] like Figure 1-4 As shown, the novel wire cutting machine of the present invention includes a wire feeding mechanism 1, a straightening mechanism 3, a wire cutting mechanism 5 and a control system, and the wire feeding mechanism 1, the straightening mechanism 3 and the wire cutting mechanism 5 are arranged in sequence. work, the control system controls the wire feeding mechanism 1 and the wire cutting mechanism 5, and the described wire cutting mechanism 5 includes a pneumatic control device, an impact hammer 53, a spring 54, a cylinder 55, a collision block 56, a guide rod 57, a static knife 58, the moving knife 59 and the plate frame, the impact hammer 53, the spring 54 and the impact block 56 are sequentially connected and arranged in the cylinder 55, and the guide rod 56 is connected with the impact hammer 53 and the impact block respectively. The block 56 is slidingly connected, and the impact hammer 53 and the collision block 56 can move up and down along the guid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com