Single screw rod type blanking machine driven by alternating-current servo motor and asynchronous motor in hybrid way

An asynchronous motor and hybrid drive technology, applied in metal processing equipment, feeding devices, manufacturing tools, etc., can solve the problems of low material utilization, low production efficiency, and reduced production efficiency, and achieve stable expansion of structural design and structural layout Stable expansion and the effect of ensuring the quality of the section

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described in detail below in conjunction with the accompanying drawings.

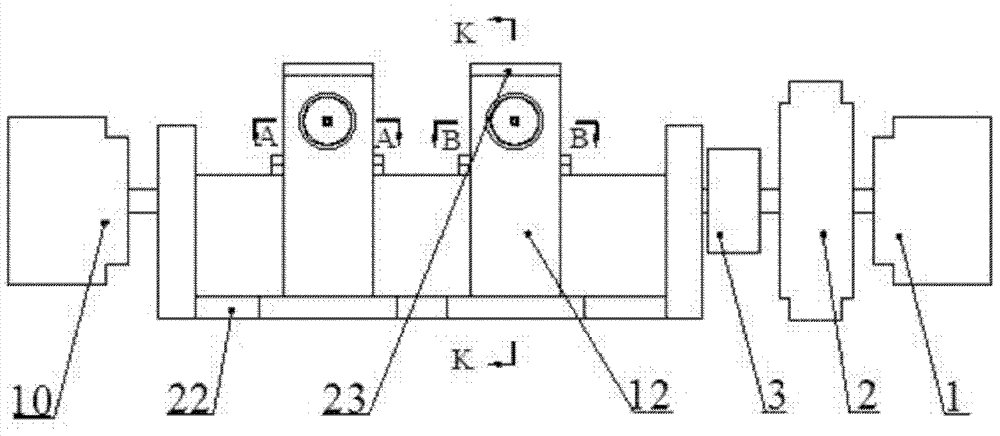

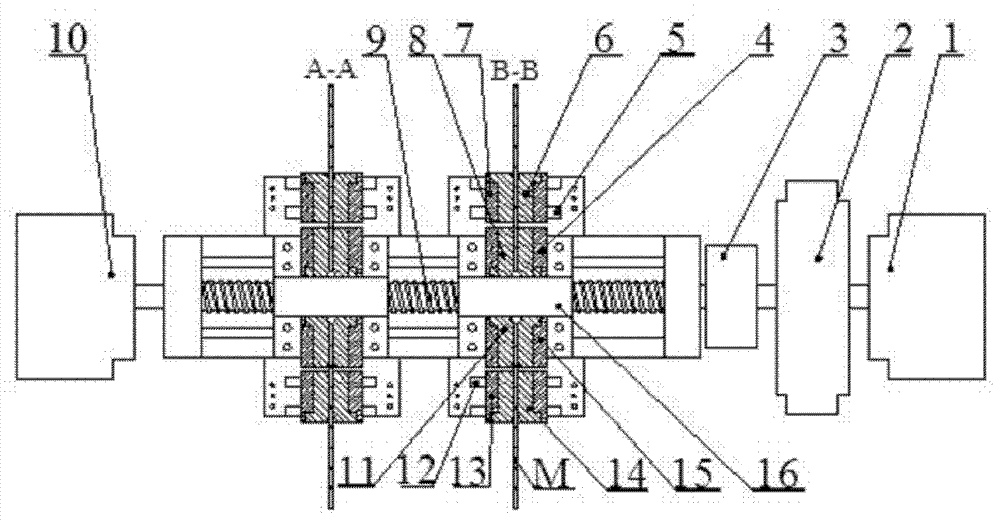

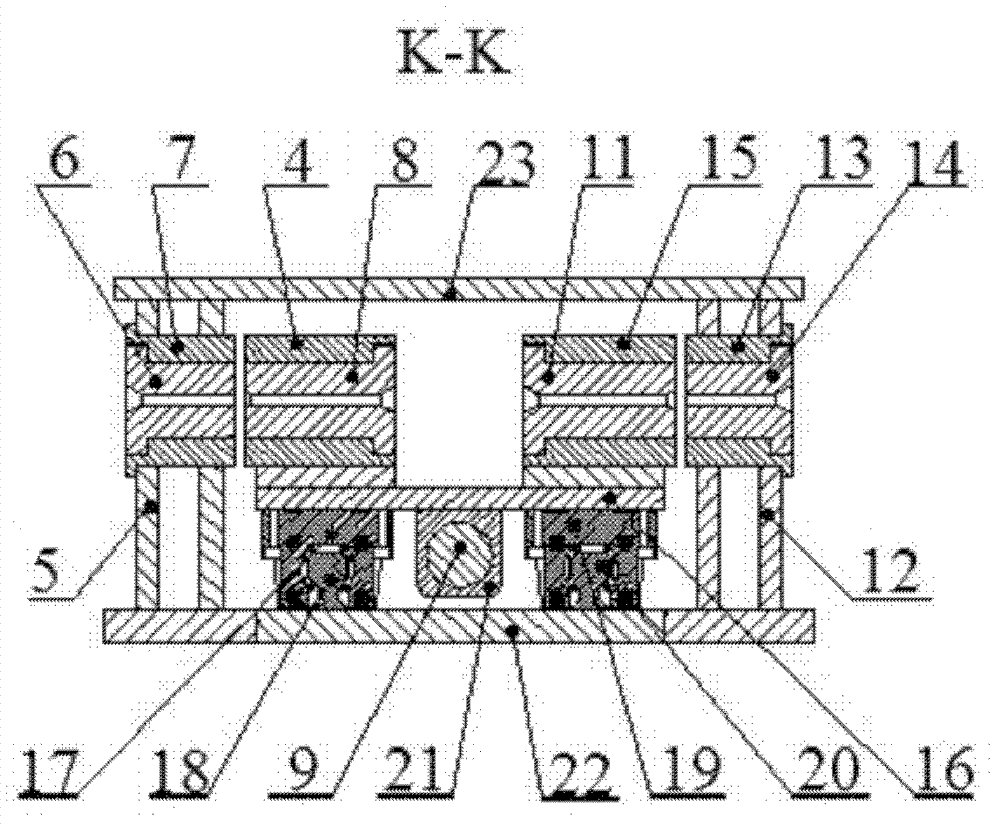

[0018] refer to figure 1 , figure 2 and image 3 , an AC servo and asynchronous motor hybrid drive single screw type blanking machine, including a driving mechanism, a moving mold blanking mechanism and a static mold blanking mechanism,

[0019] The driving mechanism includes an AC asynchronous frequency conversion motor 1, which provides sufficient power for cutting materials, the AC asynchronous frequency conversion motor 1 is connected to the flywheel 2, the flywheel 2 is connected to the input end of the clutch 3, and the output end of the clutch 3 is connected to the input end of the clutch 3. The ball screw 9 is connected, and the ball screw 9 is connected to the bearing fast 16 through the nut 21. The two ends of the bearing block 16 are respectively connected to the first slider 17 and the second slider 19, and the bearing block 16 drives the first...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com