Novel process for blanking of arc-shaped part of component

A new technology, arc technology, applied in the new technology field of punching arc parts, can solve problems such as slump angle, secondary fracture, high burr, etc., to ensure the quality of the section, prolong the life of the knife edge, and reduce the maintenance cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

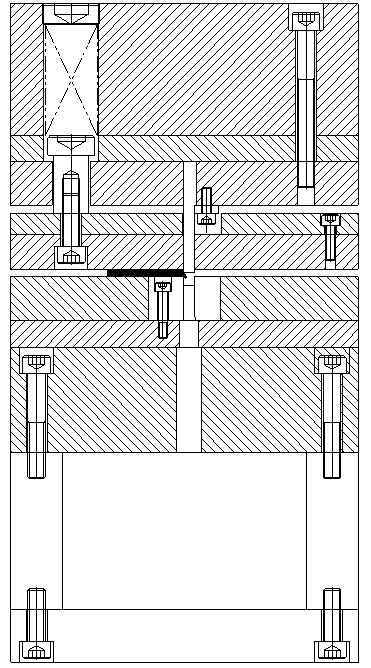

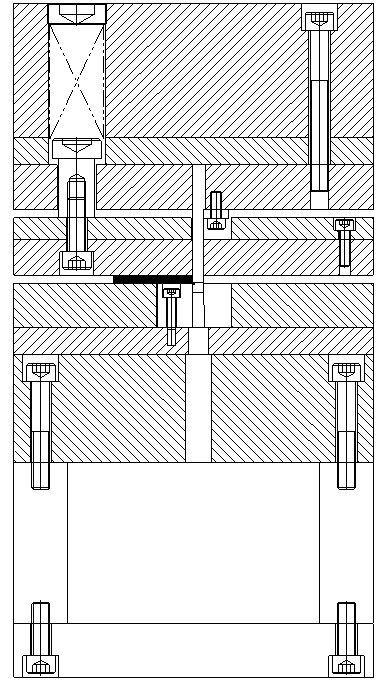

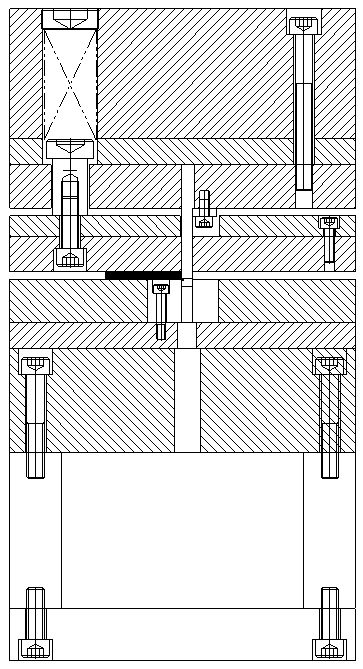

[0026] The present invention will be further described below in conjunction with the accompanying drawings.

[0027] Such as Figure 6-9 As shown, the mold structure of the blanking process of the arc part of the lower part is introduced in detail below: from top to bottom, there are: upper die base 1, upper backing plate 3, punch fixing plate 4, unloading backing plate 5, unloading Plate 6, concave module 7, lower backing plate 8, lower mold base 9, lower pad 10, lower supporting plate 11. A spring is arranged on the top of the unloading ejector pin 2, and the spring is connected to the inner side wall of the upper die base 1, and the bottom of the unloading ejector pin 2 passes through the upper die base 1, the upper backing plate 3, the punch fixing plate 4, The discharge backing plate 5 enters the discharge plate 6 .

[0028] A die insert 14 is arranged in the die plate 7 , and a plate 13 to be processed is placed on the die insert 14 . The bottom of the upper backing p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com