Preparation method of deciduous leaf activated carbon

A technology of activated carbon and fallen leaves, applied in chemical instruments and methods, inorganic chemistry, non-metallic elements, etc., can solve the problems of polluted environment, excellent adsorption effect of activated carbon, etc., achieve the effects of regulating soil properties, reducing residual pesticides, and simple preparation methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] A preparation method of deciduous activated carbon, comprising the following steps:

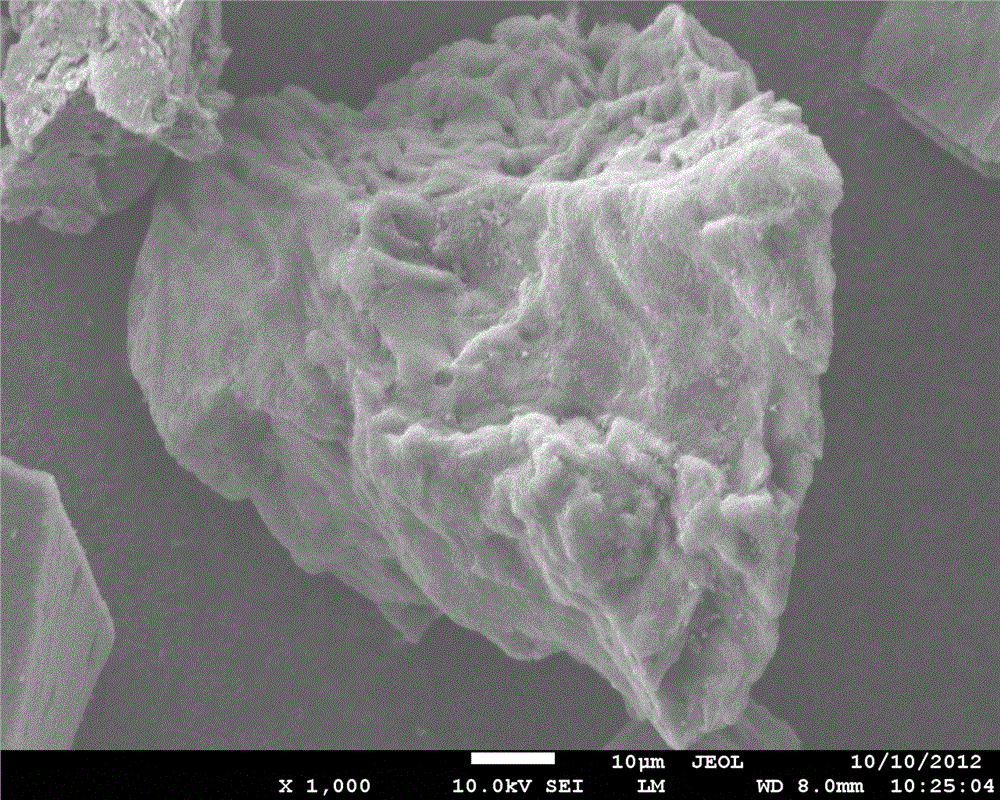

[0040] (1) Pulverization: Wash the fallen leaves of the sycamore tree with water to remove impurities, and after drying, use a plant tissue pulverizer to pulverize to obtain fallen leaf powder;

[0041] (2) Impregnation: impregnate the fallen leaf powder in step (1) with a phosphoric acid solution with a mass fraction of 20% at 40°C for 4 hours and then dry to obtain a block material. The solid-to-liquid ratio of the fallen leaf powder to the phosphoric acid solution is 1:3 g / mL;

[0042] (3) Carbonization: carbonize the bulk material in step (2) into a carbon block, wherein the carbonization temperature is 400°C, and the carbonization time is 0.5h;

[0043] (4) Crushing: Break the cooled carbon block to a particle size of 10mm to obtain an amorphous granular carbon block;

[0044] (5) Activation: activate the amorphous granular carbon block in step (4) into crude activated carbon, w...

Embodiment 2

[0049] A preparation method of deciduous activated carbon, comprising the following steps:

[0050] (1) Pulverization: Wash the fallen leaves of poplar with water to remove impurities, and after drying, crush them with a plant tissue pulverizer to obtain fallen leaf powder;

[0051] (2) Impregnation: Immerse the fallen leaf powder in step (1) with a phosphoric acid solution with a mass fraction of 40% at 50°C for 2 hours and then dry to obtain a lumpy material. The solid-to-liquid ratio of the fallen leaf powder to the phosphoric acid solution is 1:7 g / mL;

[0052] (3) Carbonization: carbonize the bulk material in step (2) into a carbon block, wherein the carbonization temperature is 600°C, and the carbonization time is 1.5h;

[0053] (4) Crushing: crush the cooled carbon block to a particle size of 9mm to obtain an amorphous granular carbon block;

[0054] (5) Activation: activate the amorphous granular carbon block in step (4) into crude activated carbon, wherein the activ...

Embodiment 3

[0059] A preparation method of deciduous activated carbon, comprising the following steps:

[0060] (1) Pulverization: Wash the fallen leaves of the paulownia tree with water to remove impurities, and after drying, use a plant tissue pulverizer to pulverize to obtain fallen leaf powder;

[0061] (2) Impregnation: Immerse the fallen leaf powder in step (1) with a phosphoric acid solution with a mass fraction of 30% at 45°C for 3 hours and then dry to obtain a block material. The solid-to-liquid ratio of the fallen leaf powder to the phosphoric acid solution is 1:5 g / mL;

[0062] (3) Carbonization: carbonize the bulk material in step (2) into carbon blocks, wherein the carbonization temperature is 500°C, and the carbonization time is 1h;

[0063] (4) Crushing: Break the cooled carbon block to a particle size of 6mm to obtain an amorphous granular carbon block;

[0064] (5) Activation: activate the amorphous granular carbon block in step (4) into crude activated carbon, wherein...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Iodine adsorption value | aaaaa | aaaaa |

| Adsorption value | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com