Titanium surface casting modification method for reinforcing titanium-porcelain combination strength

A technology of bonding strength and modification, which is applied in the fields of pharmaceutical formulation, medical science, dentistry, etc., and can solve problems such as affecting the bonding of titanium porcelain and poor adhesion of oxide film

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

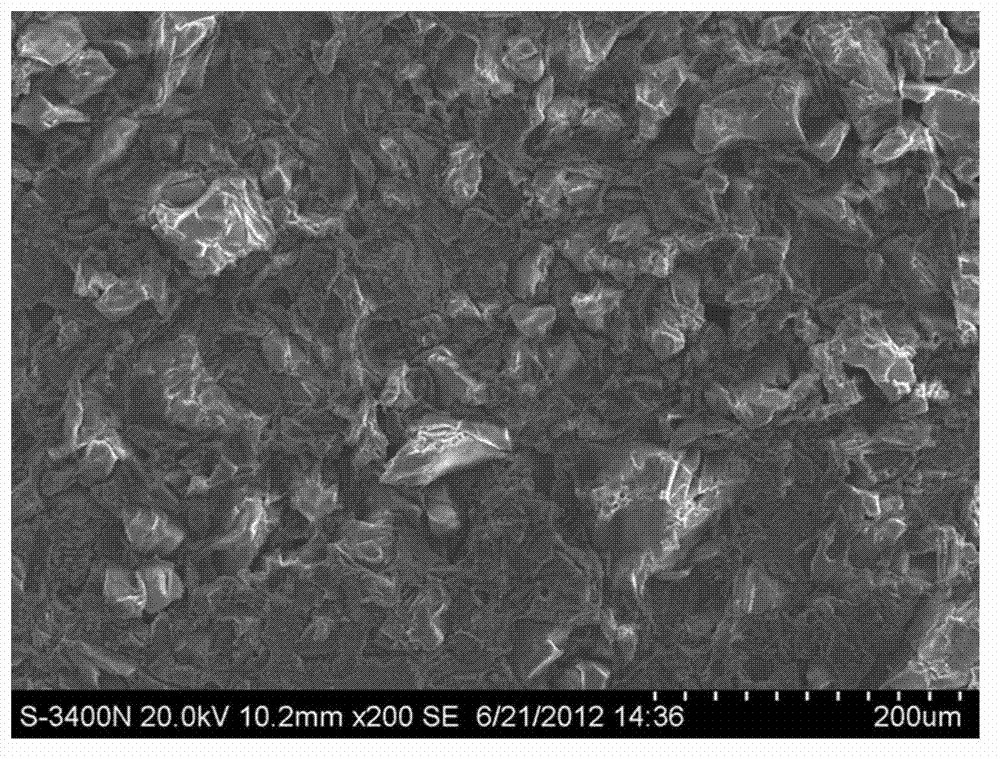

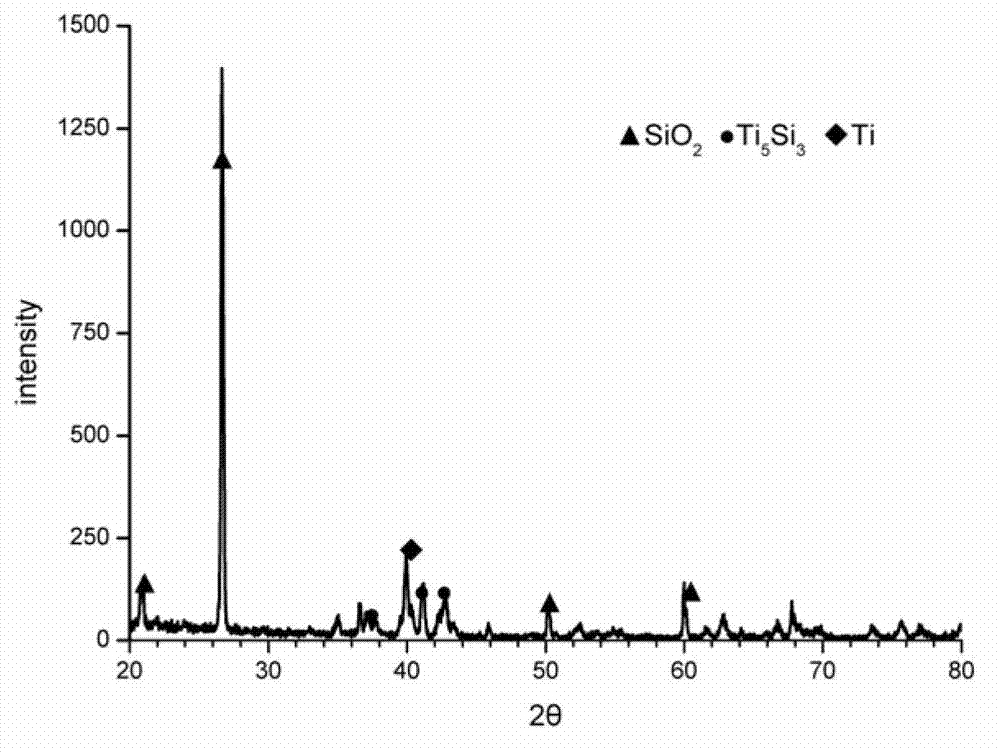

Embodiment 1

[0031] Take SiO 2 5g, ground and placed in a porcelain cup for later use; inject 35% hydrochloric acid and distilled water into the same beaker at a volume ratio of 1:1, mix well, and at the same time inject tetraethyl orthosilicate into another beaker, acidify with the mixed hydrochloric acid The volume ratio of water to ethyl orthosilicate is 1:10, then slowly drop the acidified water with hydrochloric acid into the ethyl orthosilicate beaker, and stir well. SiO is continuously added to the stirred mixture of tetraethyl orthosilicate and acidified water 2 Powder (SiO 2 The amount of powder is 3.9-4 times of the mass of tetraethyl orthosilicate), after adding all of them, continue to stir for 10-15 minutes to make SiO 2 Powder and mixture can be fully reconciled. Apply a suitable inner embedding material on the side of the wax-type that has been treated with affinity mist, and let it solidify naturally at room temperature. Embed the cast wax-type with the titanium professi...

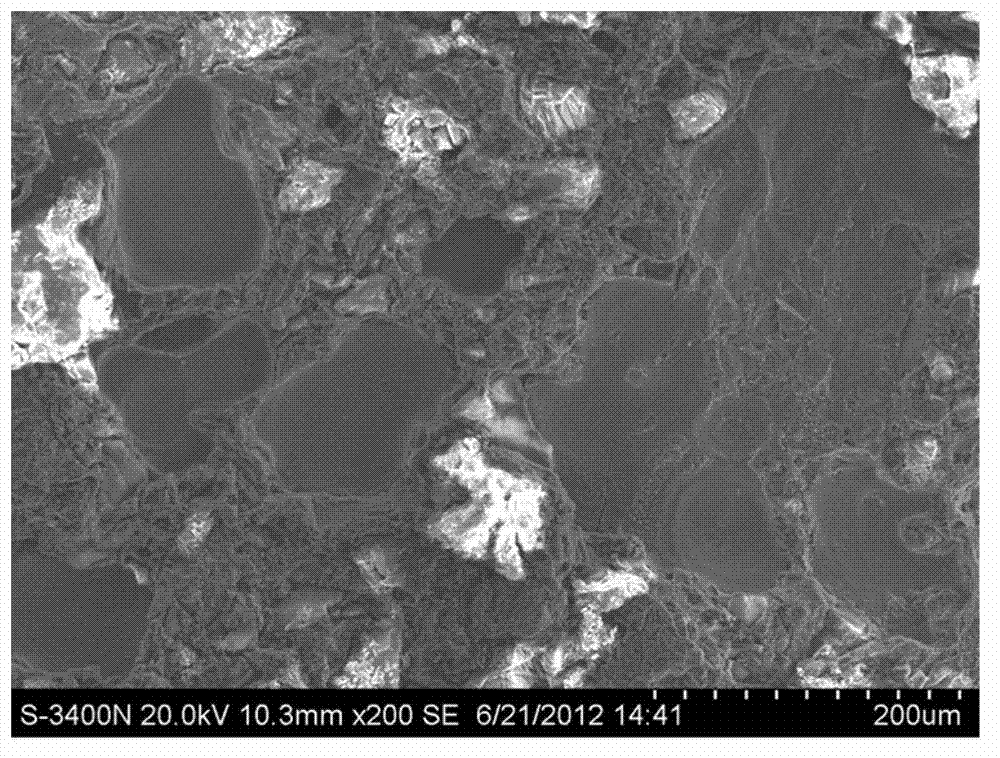

Embodiment 2

[0035] Take SiO 2 powder and Al with a particle size of 2 μm 2 o 3 Add 2.5g of each powder into the ball mill jar, grind for 5 minutes until the two powders are fully mixed; pour 35% hydrochloric acid and distilled water into the same beaker at a volume ratio of 1:1, mix well, and at the same time inject aluminum acid into another beaker Calcium cement, the ratio of mixed hydrochloric acid acidified water to calcium aluminate cement is 1:1, then slowly drop hydrochloric acid acidified water into the calcium aluminate cement, and fully stir. The stirred calcium aluminate cement and acidified water mixture is continuously added with mixed SiO 2 Powder and Al 2 o 3Mix the powder and powder, after adding all the powder, continue to stir for 10-15 minutes, so that the powder and the mixture can be fully reconciled. Apply a suitable inner embedding material on the side of the wax-type that has been treated with affinity mist, and let it solidify naturally at room temperature. E...

Embodiment 3

[0039] Take SiO 2 Powder and ZrO 2 Add 2.5g of each powder into the ball mill jar and grind for 5-10 minutes until the grinding is uniform; inject 35% hydrochloric acid and distilled water into the same beaker at a volume ratio of 1:1, mix well, and inject orthosilicic acid into another beaker at the same time Ethyl ester, the volume ratio of the mixed hydrochloric acid acidified water to tetraethyl orthosilicate is 1:10, slowly drop the hydrochloric acid acidified water into the tetraethyl orthosilicate beaker, and stir well. The stirred mixture of tetraethyl orthosilicate and acidified water is continuously added with the mixed SiO 2 powder and ZrO 2 After all the powder is added, continue to stir for 10-15 minutes to fully reconcile the powder and the mixture. Apply a suitable inner embedding material on the side of the wax-type that has been treated with affinity mist and let it dry naturally at room temperature. Embed the casting wax-type with the titanium professional...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com