Thermosetting resin composition as well as prepreg, laminated board and circuit carrier containing same

A technology of resin composition and circuit carrier, which is applied in the fields of laminates and circuit carriers, thermosetting resin composition, and prepreg, can solve the problems of affecting the quality of signal transmission, difficulty in roughening the surface of the substrate, and the influence of circuit conduction, etc. Achieve the effect of improving activation rate, specific surface area, and enhancing adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

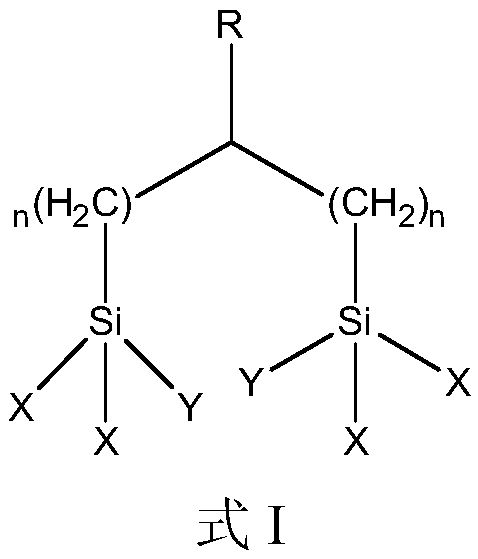

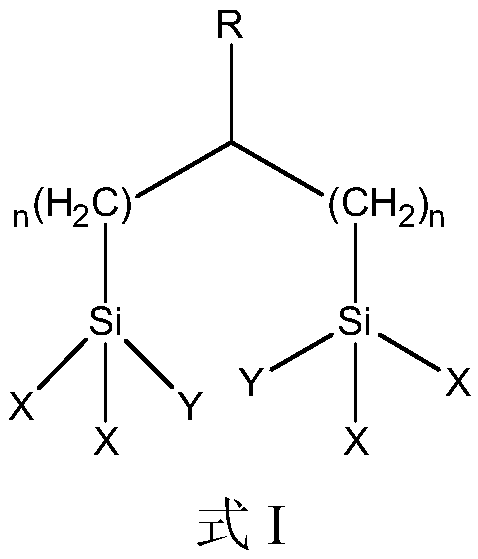

Method used

Image

Examples

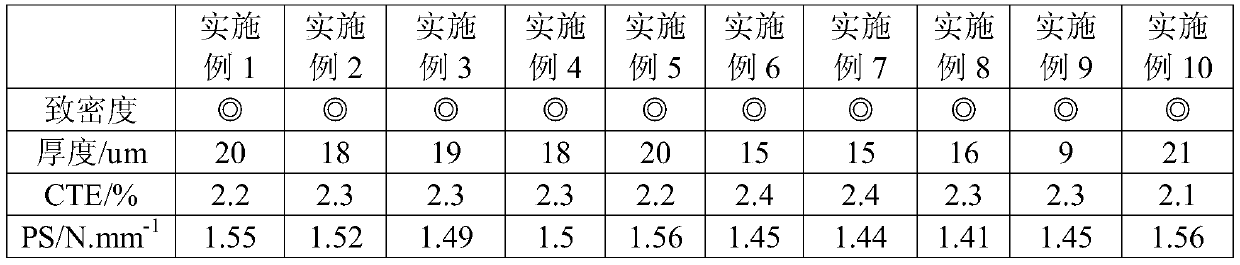

Embodiment 1

[0073] The composition of 100 parts of epoxy resin DER530, 3 parts of dicyandiamide, 0.05 part of 2-methylimidazole, silicon dioxide and zinc molybdate (accounting for 30% of the resin composition mass fraction, wherein silicon dioxide:molybdic acid Zinc=90:10 (mass ratio)), basic copper phosphate (accounting for 2% of resin composition mass fraction) and accounting for 1% of resin composition content hexaalkoxysilane coupling agent (SIB1817) are dissolved in organic solvent 65wt% glue is prepared by mechanical stirring, then impregnated with glass fiber cloth, heated and dried to form a prepreg (prepreg), pressurized and heated to form a laminated board.

Embodiment 2

[0075] The implementation mode of the present embodiment is the same as that of Example 1, and the difference is that in Example 2, the inorganic filler is a composition of silicon dioxide and zinc molybdate, wherein, silicon dioxide: zinc molybdate=99:1 (mass ratio) .

Embodiment 3

[0077] The implementation mode of the present embodiment is the same as that of Example 1, and the difference is that in Example 3, the inorganic filler is a composition of silicon dioxide and zinc molybdate, wherein, silicon dioxide: zinc molybdate=80:20 (mass ratio) .

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com