Composite multi-layer crucible for induction melting of bismuth aluminum alloy and preparation method thereof

A beryllium aluminum alloy, induction melting technology, applied in the field of composite multi-layer crucible for beryllium aluminum alloy induction melting and its preparation, to achieve the effects of high insulation, long service life and high structural strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

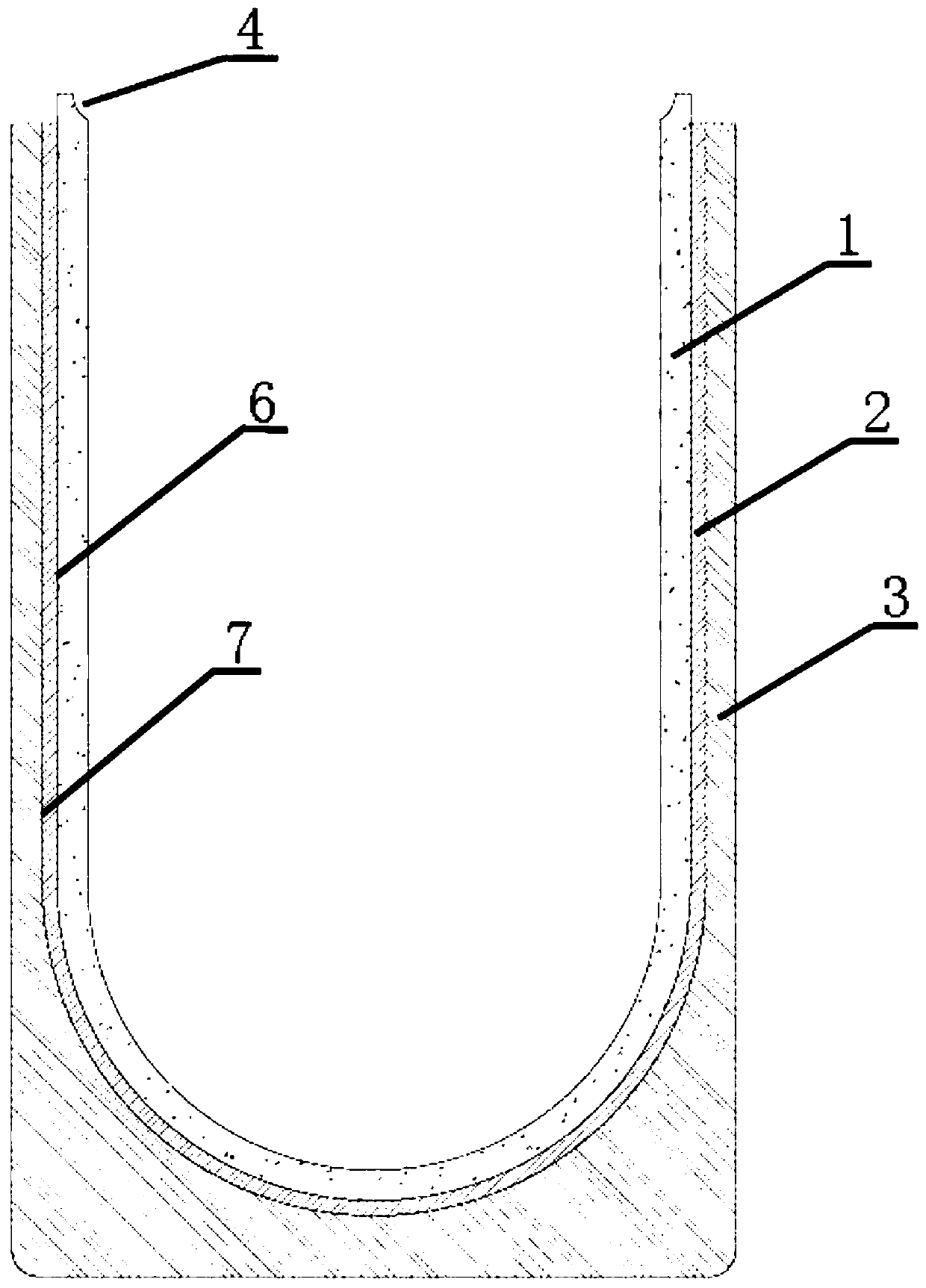

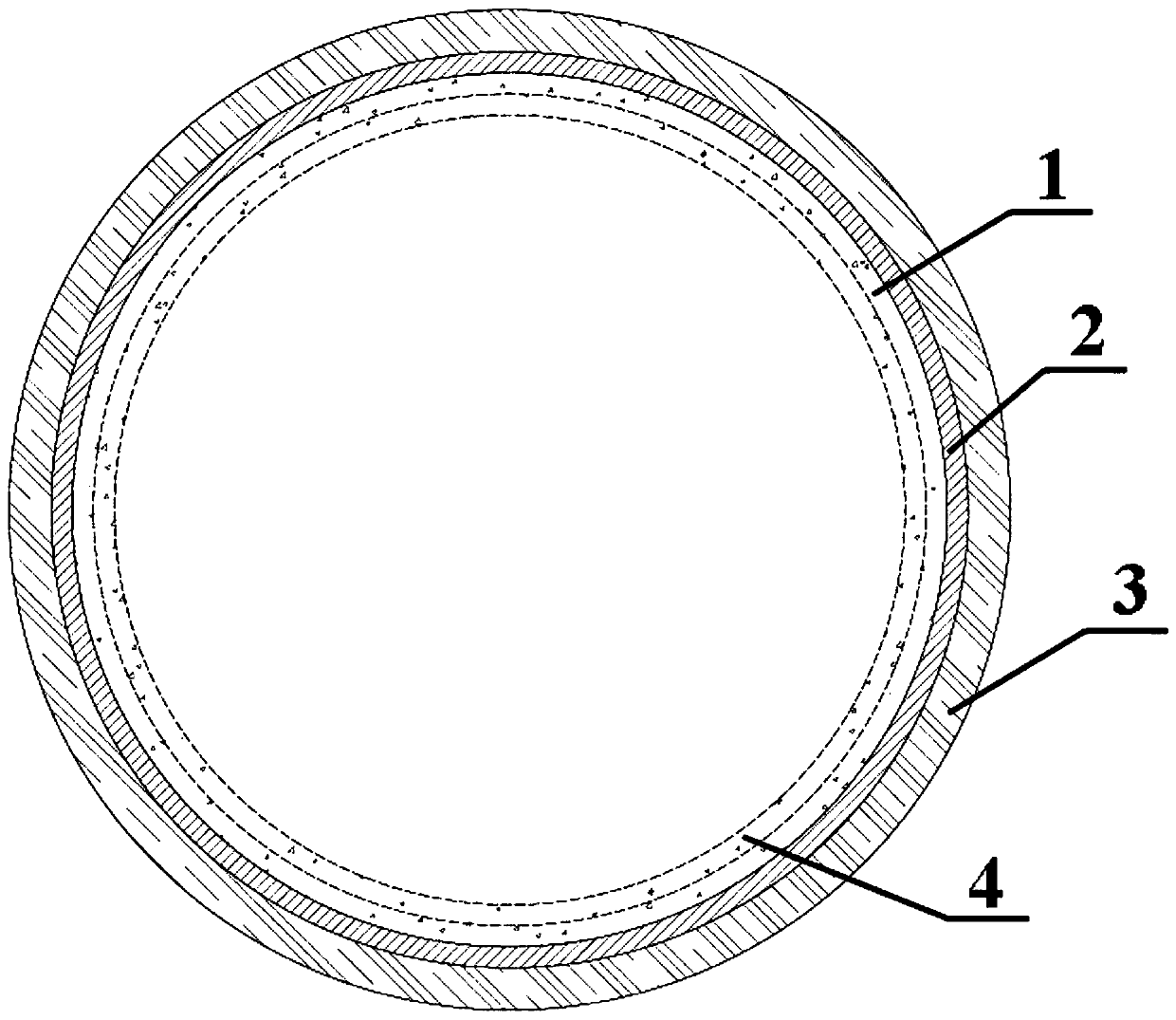

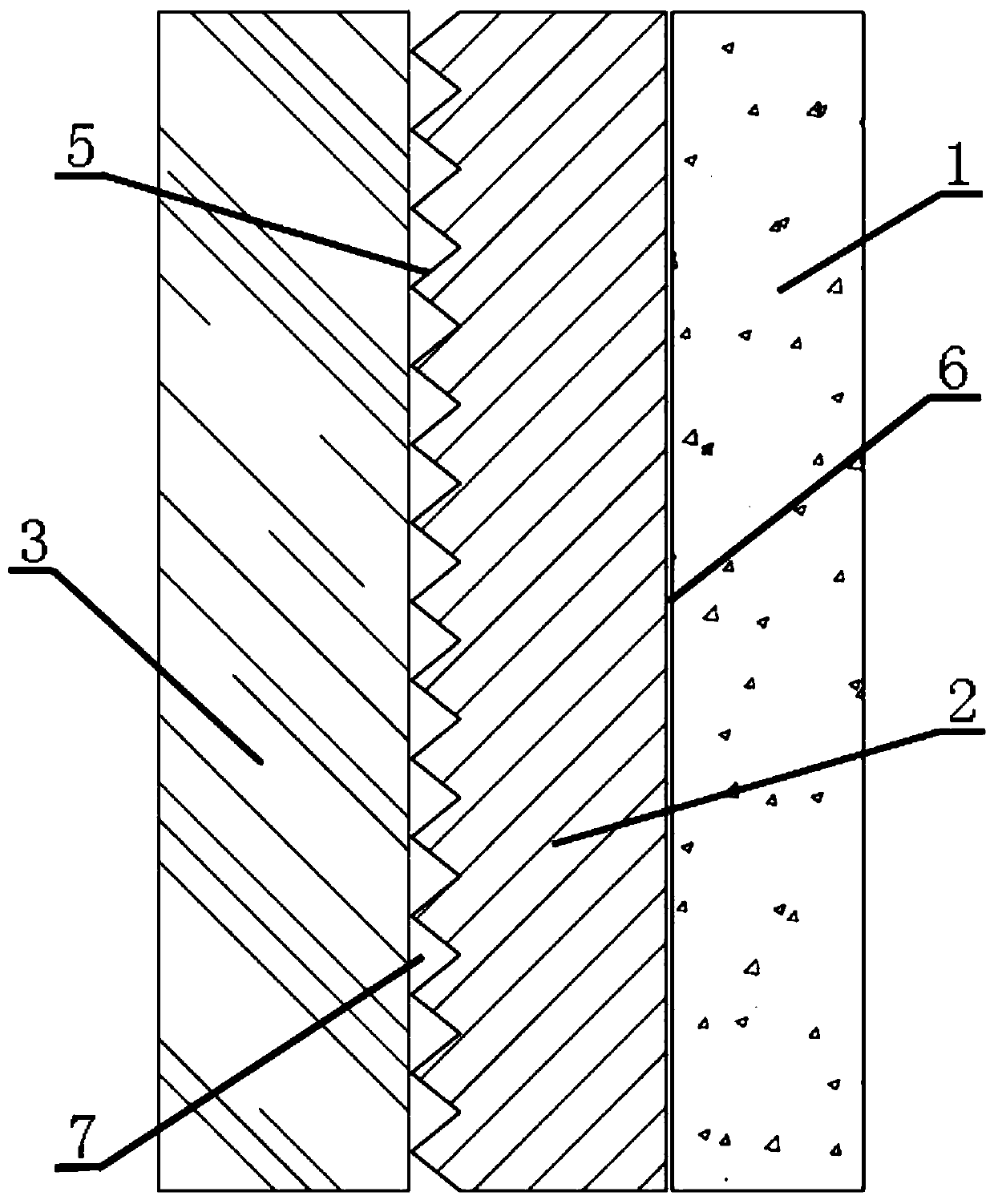

[0060] as attached Figure 1-3 As shown, the present invention provides a composite multilayer crucible for beryllium-aluminum alloy induction melting, comprising an inner crucible 1, a middle crucible 2 and an outer crucible 3 fixedly connected sequentially from the inside to the outside; the inner crucible 1, The tops of the middle crucible 2 and the outer crucible 3 are straight cylindrical; the bottoms of the inner crucible 1 and the middle crucible 2 are hemispherical; the outer surface of the bottom of the outer crucible 3 is Rectangular with a hemispherical bottom inner surface.

[0061] The outer surface of the middle crucible 2 is integrally processed into a threaded surface 5, and its inner surface is a flat surface; the top inner wall of the inner crucible 1 is circumferentially provided with a circle of concave diversion grooves 4, and the inner layer The inner surface of the crucible 1 is a flat surface.

[0062] The composite multi-layer crucible for beryllium ...

Embodiment 2

[0070] This embodiment provides a method for preparing a composite multilayer crucible for beryllium-aluminum alloy induction melting. The structure of the composite multilayer crucible in this embodiment is as shown in Example 1, wherein the thickness of the inner layer crucible is 10 mm, and the middle layer The thickness of the crucible is 6mm, and the thickness of the outer crucible is 7mm;

[0071] Its specific preparation method is:

[0072] (1) Preparation of inner crucible

[0073] Ingredients: Prepare raw materials according to the following parts by weight: 96.5 parts of beryllium oxide (BeO), with a particle size of 500 mesh; 1.5 parts of calcium oxide (CaO), with a particle size of 350 mesh; 2 o 3 ) 1.0 part, particle size 350 mesh; silicon carbide (SiC) 1.0 part, particle size 500 mesh.

[0074] Add the above-mentioned raw materials and water twice their weight into a ball milling jar. The material of the grinding balls is corundum, and the ball-to-material rat...

Embodiment 3

[0085] This embodiment provides a method for preparing a composite multilayer crucible for beryllium-aluminum alloy induction melting. The structure of the composite multilayer crucible in this embodiment is as shown in Example 1, wherein the thickness of the inner layer crucible is 8mm, and the middle layer The thickness of the crucible is 5mm, and the thickness of the outer crucible is 8mm;

[0086] Its specific preparation method is:

[0087] (1) Preparation of inner crucible

[0088] Ingredients: prepare raw materials according to the following parts by weight: 95 parts of beryllium oxide (BeO), particle size 600 mesh; 1.0 part of calcium oxide (CaO), particle size 300 mesh; yttrium oxide (Y 2 o 3 ) 1.0 parts, particle size 300 mesh; silicon carbide (SiC) 3.0 parts, particle size 550 mesh.

[0089] Add the above-mentioned raw materials and water twice the weight into the ball mill jar. The material of the grinding balls is corundum, and the ball-to-material ratio is 3:1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com