Liquid filling valve and operating method thereof

A filling valve, liquid technology, applied in liquid bottling, liquid processing, packaging and other directions, can solve the problems of high cost and complicated control, and achieve the effect of low cost, no cleaning dead angle, and hygienic structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

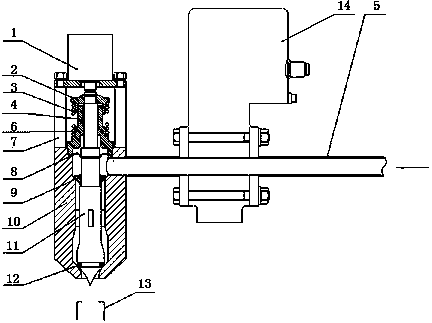

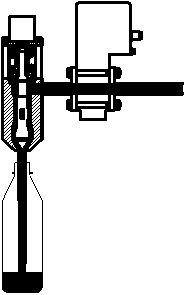

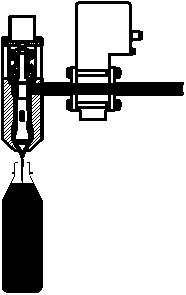

[0026] The liquid filling valve provided by the invention is as figure 1 As shown, it includes a valve body 10 with a valve core 11 inside, the top of the valve body 10 is sealed by the valve core sealing diaphragm 8, the bottom of the valve body 10 is opened with a discharge port aligned with the container, and the inner wall of the valve body 10 and the valve core 11 There is a filling channel in between, and the filling channel is connected to the feed pipe 5 through the flow meter 14; the top of the valve body 10 is provided with a driving device that pushes the valve core sealing diaphragm 8 to move, and it is characterized in that: the valve core 11 is covered with a pre-closing disc 9, there is a gap between the valve core 11 and the pre-closing disc 9, and the pre-closing disc 9 can move up and down freely along the valve core 11; the bottom of the valve core 11 and the lower end of the valve body 10 A valve port sealing ring 12 is arranged between the discharge ports...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com