Patents

Literature

54results about How to "No cleaning dead angle" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

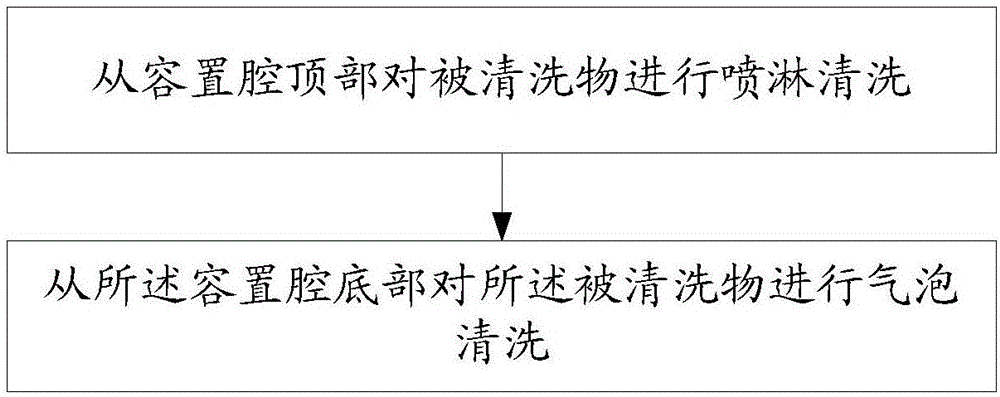

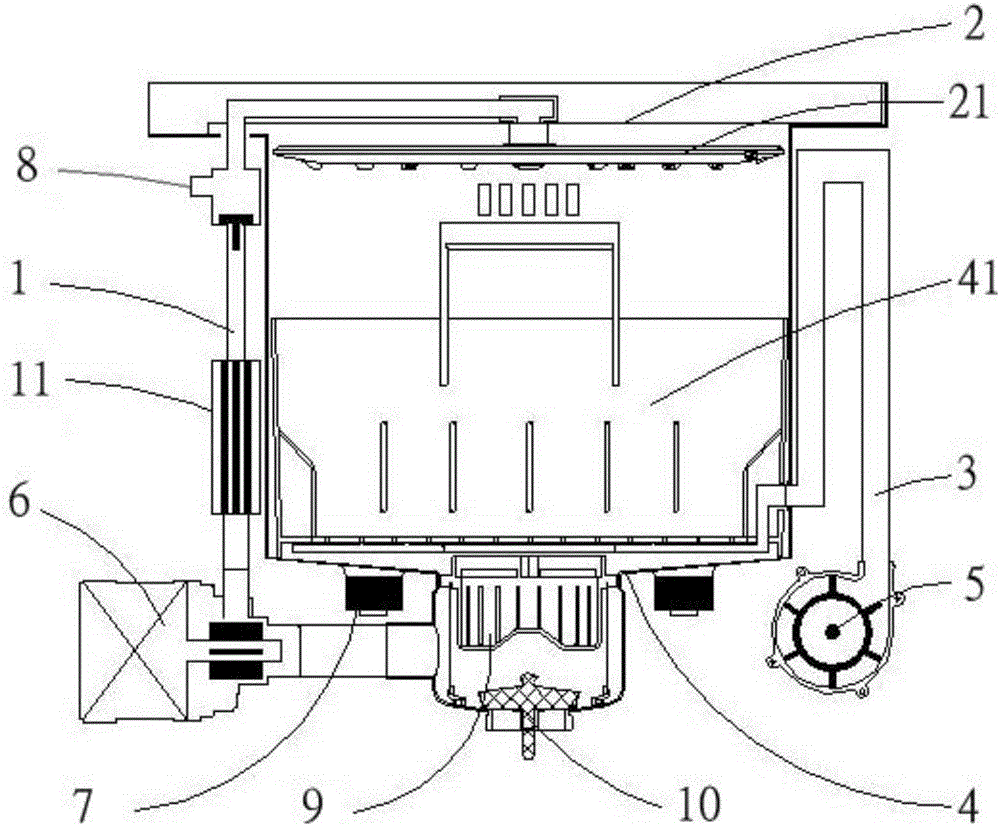

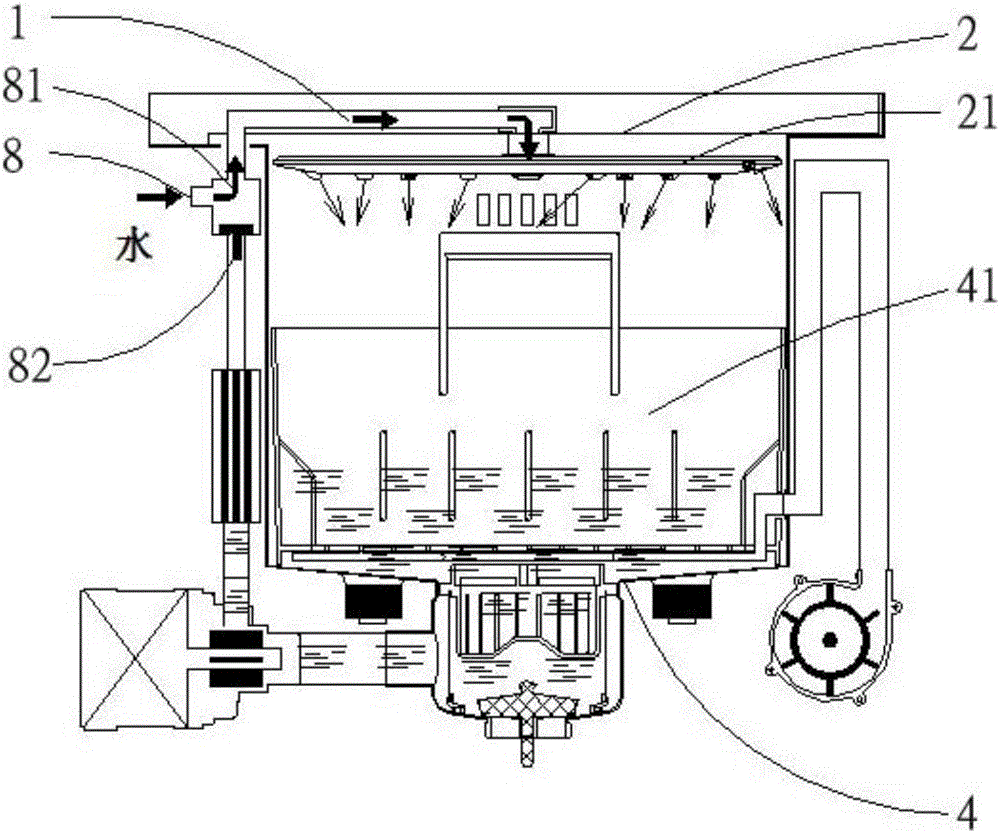

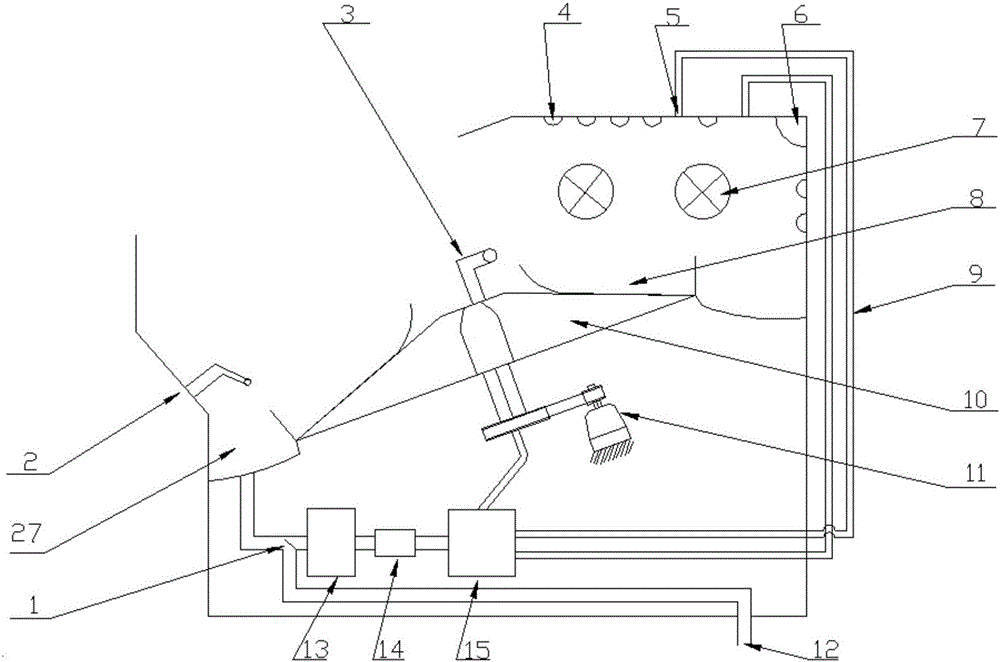

Intelligent water tank washing method and device

The present invention provides an intelligent water tank washing method and a device, and relates to the field of kitchen washing. The intelligent water tank comprises: a main body and an upper cover rotatably connected to the main body, a containing cavity consists of the main body and upper cover, and a rotary and water flow spraying arm driven by water flow is arranged on the upper cover; an air pump is arranged at outside of the containing cavity and connected to an air path, the air path is arranged closing to a bottom part of the containing cavity, and when the air pump works, air is blew into the bottom part of the containing cavity via the air path. A washing method comprises a kneading and washing step: a spraying washing for materials to be washed is conducted from a top part of the containing cavity and a bubble washing for the materials to be washed is conducted from the bottom part of the containing cavity.

Owner:JOYOUNG CO LTD

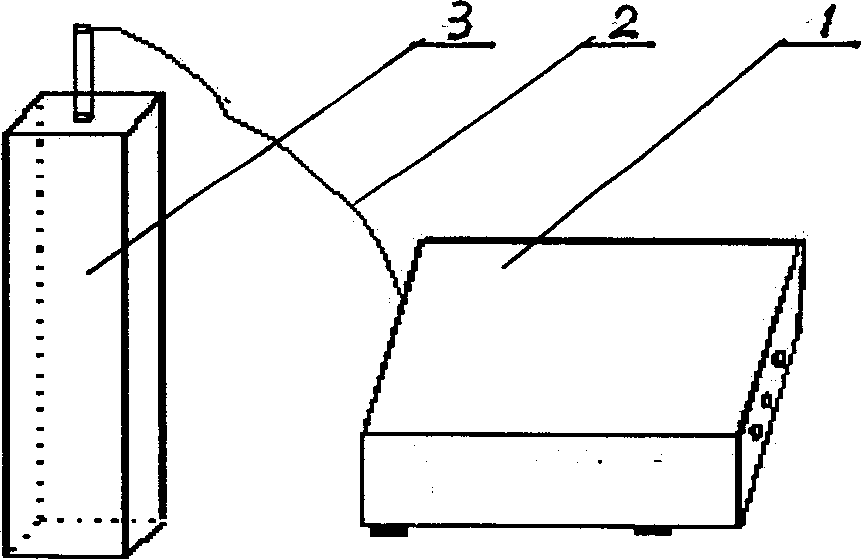

Ultrasonic wave cleaning processor

InactiveCN1422707ANo cleaning dead angleShorten the timeHollow article cleaningCleaning using liquidsMegasonic cleaningUltrasonic vibration

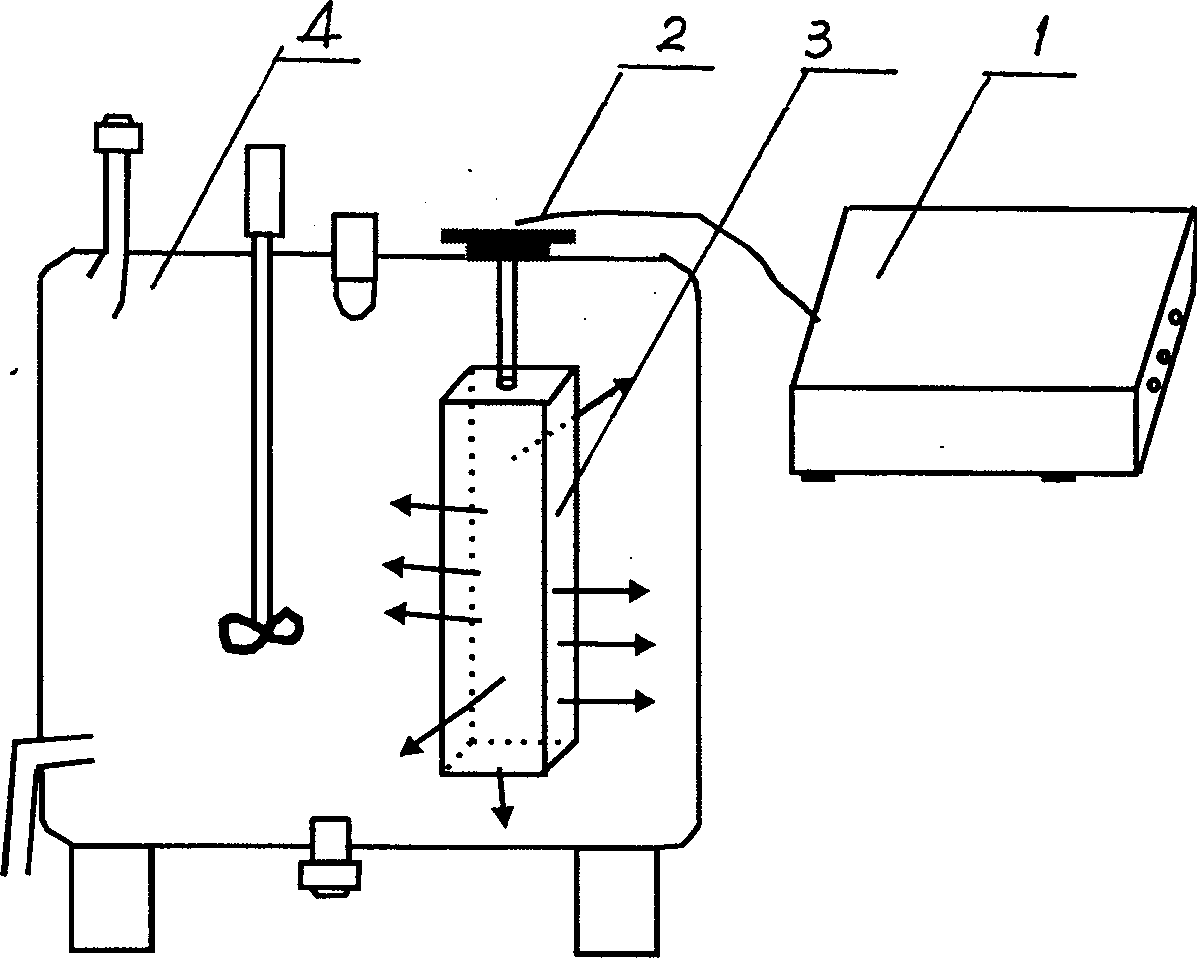

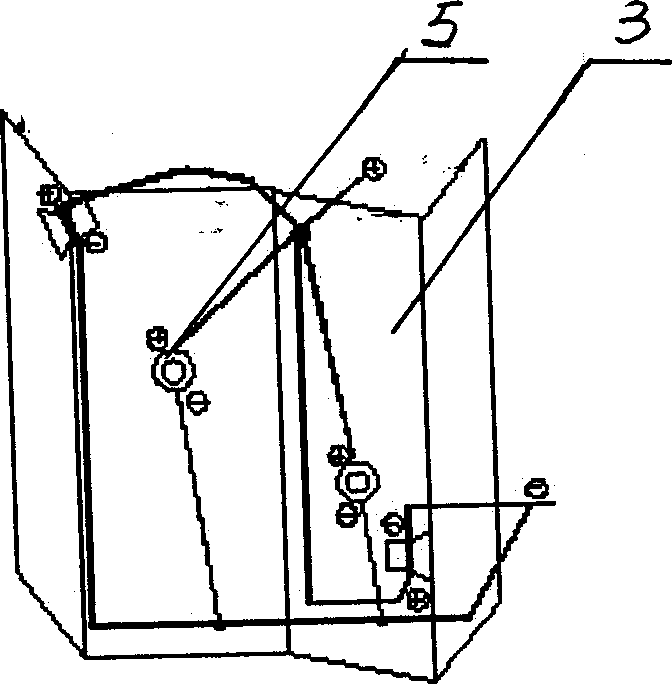

The present invention relates to an ultrasonic cleaning treatment equipment, it is formed from ultrasonic generator connected with ultrasonic vibration board via signal wire, on one surface of the described ultrasonic vibration board an ultrasonic transducer is mounted. In the presence of washing liquor of water, etc. proceed from central space of groove cavity container to be cleaned it can make ultrasonic wave stereo-irradiate all the inner walls of said container and produce cavitition function to implement high-quality cleaning operation under the moderate condition.

Owner:SOUTH CHINA UNIV OF TECH

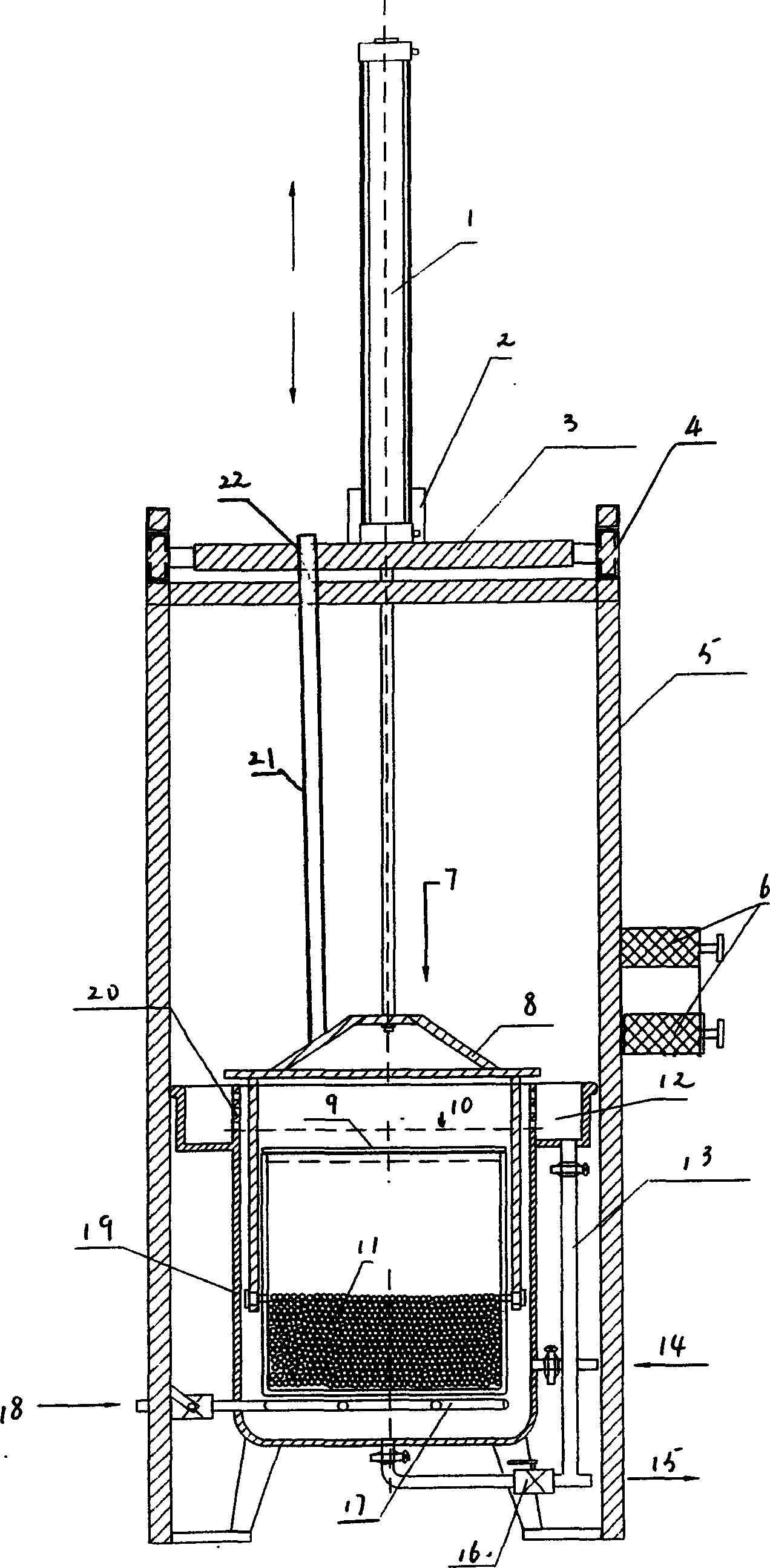

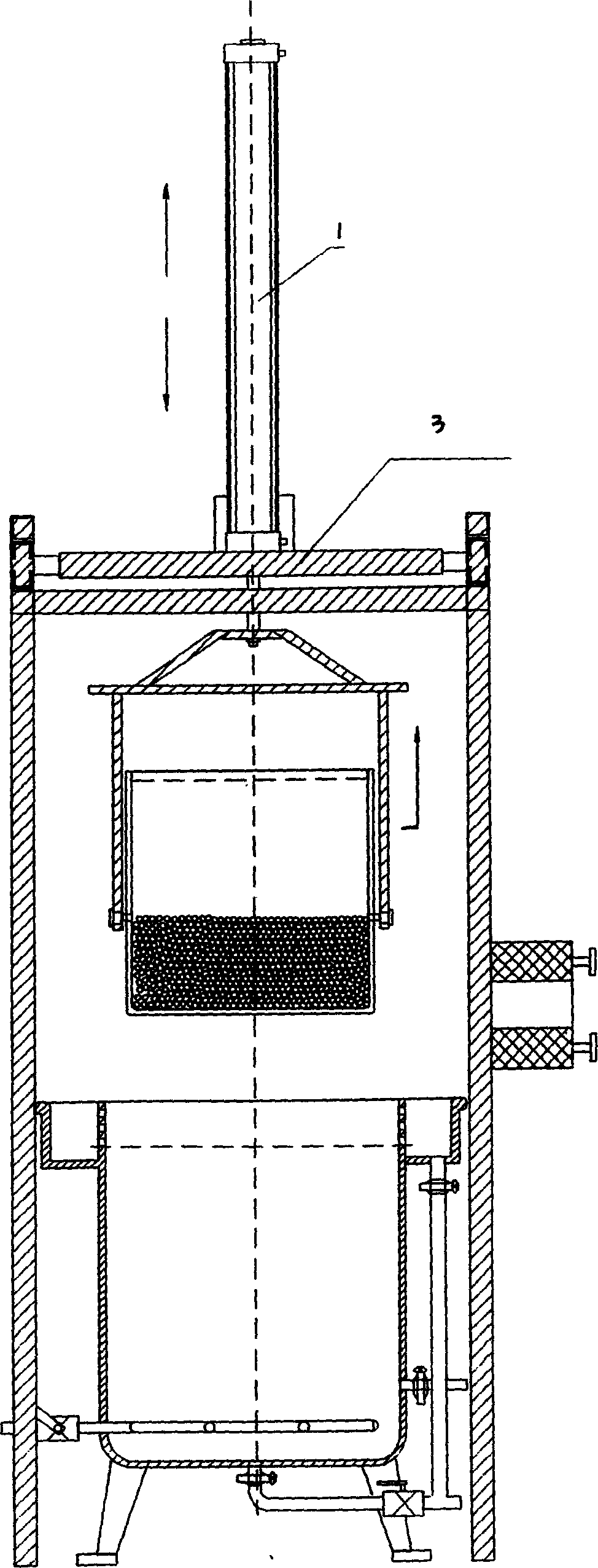

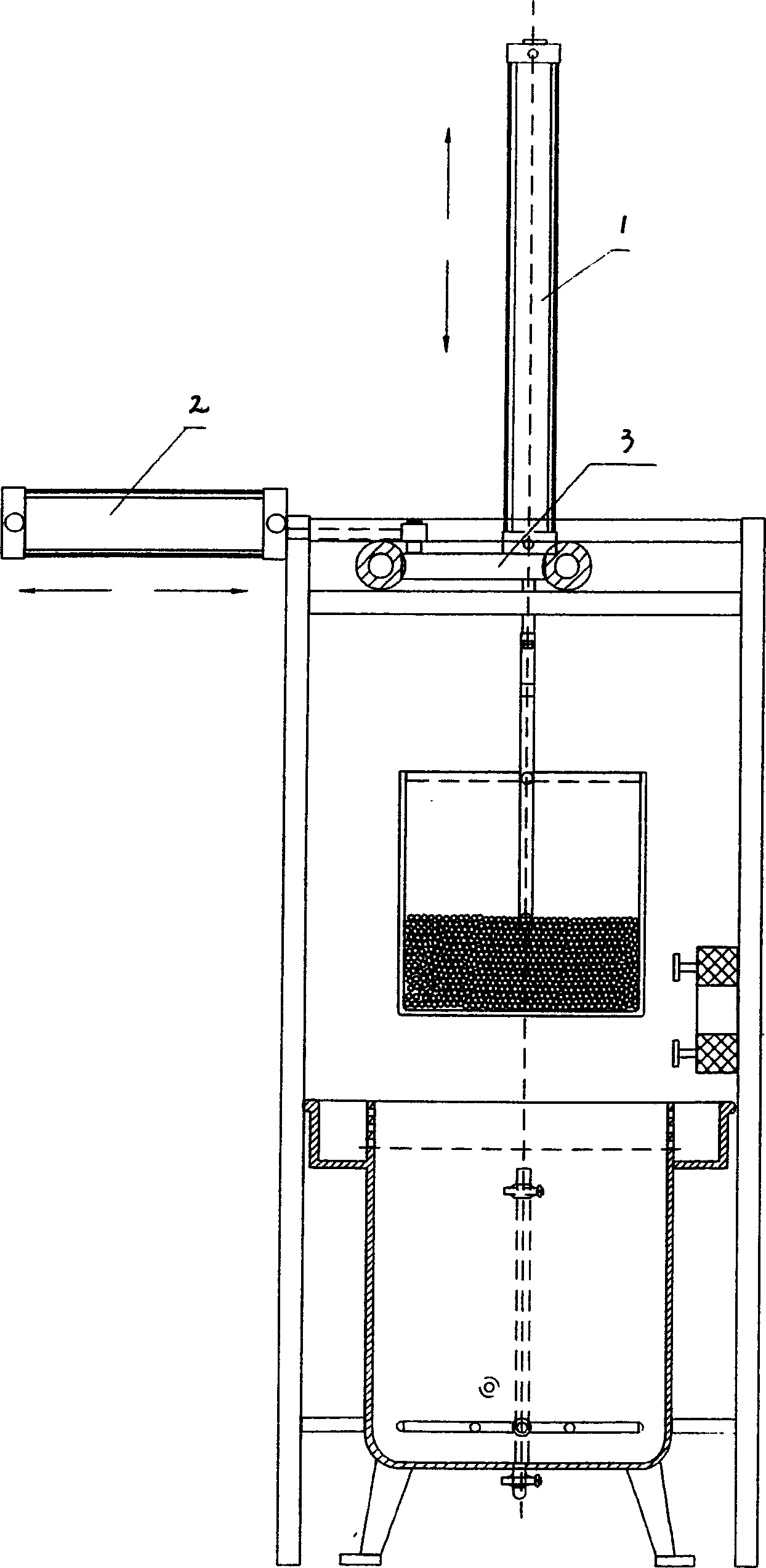

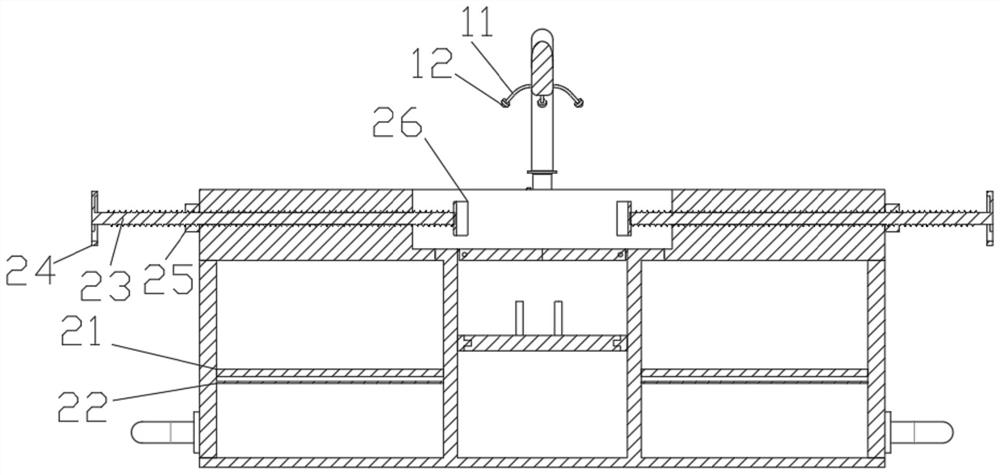

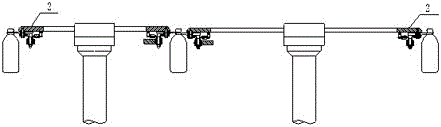

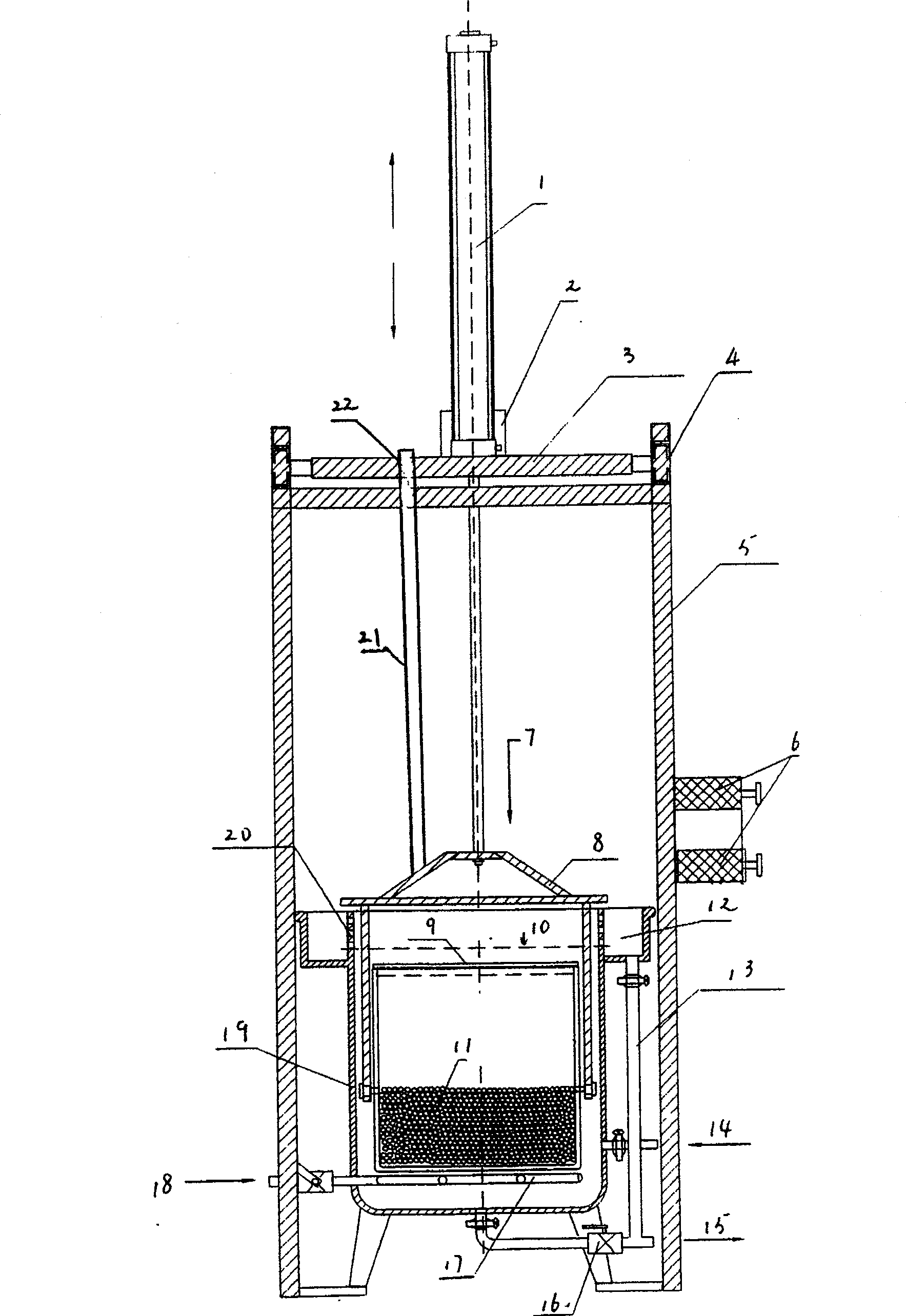

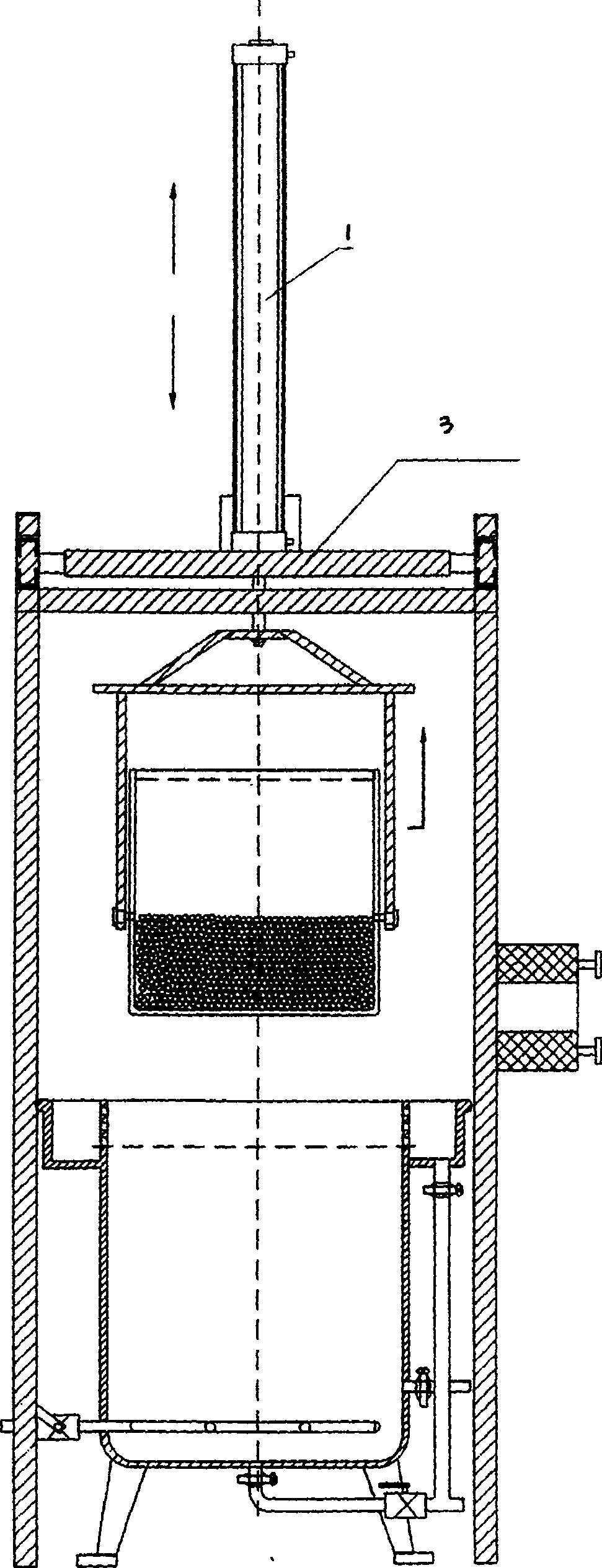

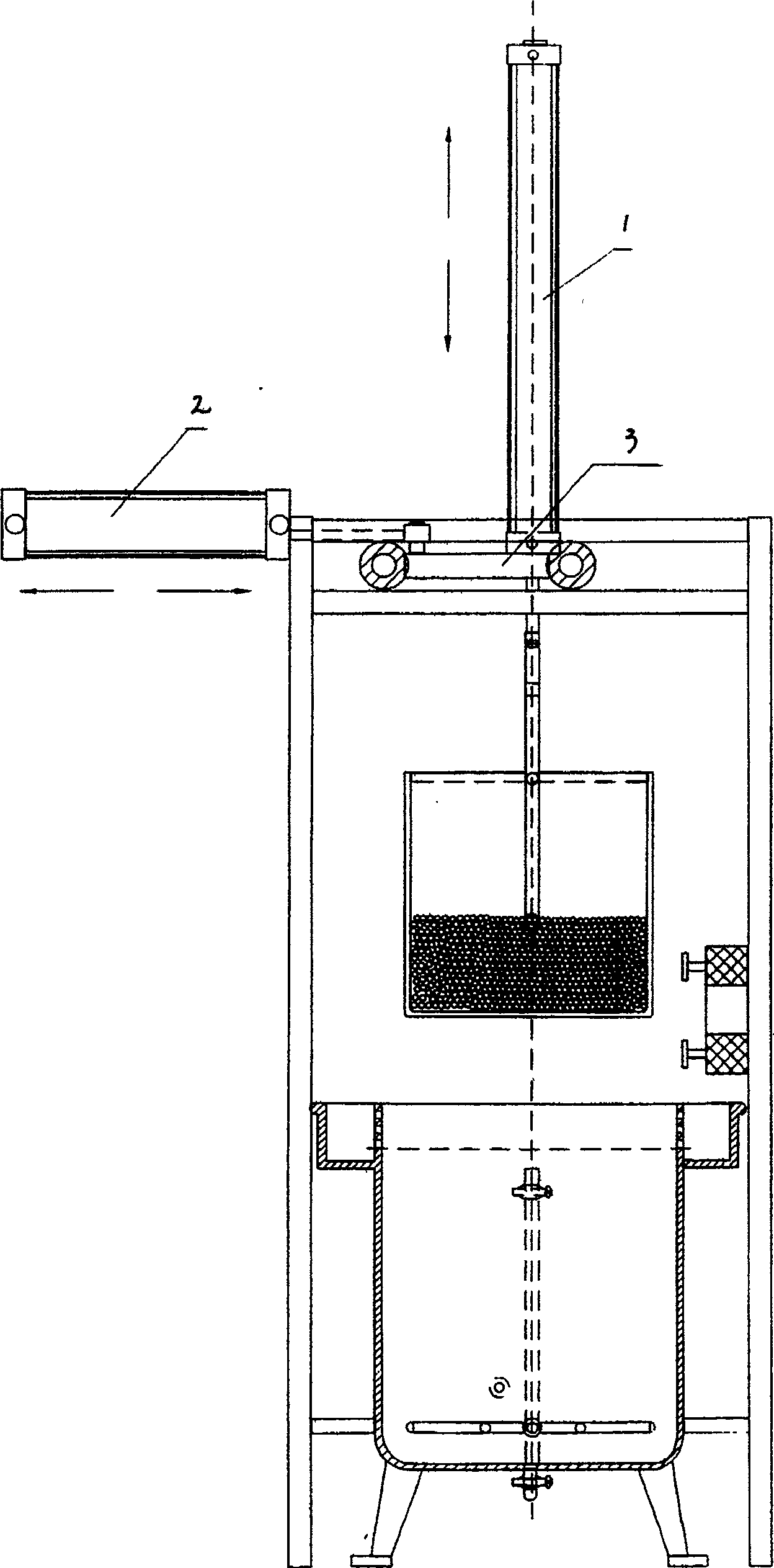

Semi-automatic rubber cork rinsing machine

InactiveCN1864873AClean upImprove cleaning efficiencyCleaning using liquidsSemi automaticEngineering

The invention relates to a semi-automatic plug poacher, used to scavenge the medical large transfusion butyl rubber plug. It comprises: a frame (5), a poaching cylinder (19), a lift basket (8), a lift cylinder (1), a transverse cart (3) and a transverse cylinder (2). Wherein, the poaching cylinder is at the middle of lower part of frame; the wall of poaching cylinder has water inlet tube (14) at its lower side, while its bottom has water outlet tube (13); the lower part of poaching cylinder has air injection coil tube (17); the upper cylinder wall has annular overflow groove (12); the lift basket (8) is inside the poaching cylinder (19); two sides of the top of frame (5) have the track (4) of cart; the transverse cart (3) is on said track (4); the lift cylinder (1) is fixed at the center of transverse cart (3), while its piston rod is connected to the top of lift basket (8); the transverse cylinder (2) is fixed at the back of the top of frame (5), while its piston rod is connected to the back of transverse cart (3). The inventive plug can float upwards and turn over inside the lift basket, while there is no space between plugs; it has high clean efficiency, with simple structure, non cleaning dead angle, and lower energy consumption.

Owner:JIANGSU HUA LAN PHARMA NEW MATERIALS LTD BY SHARE LTD

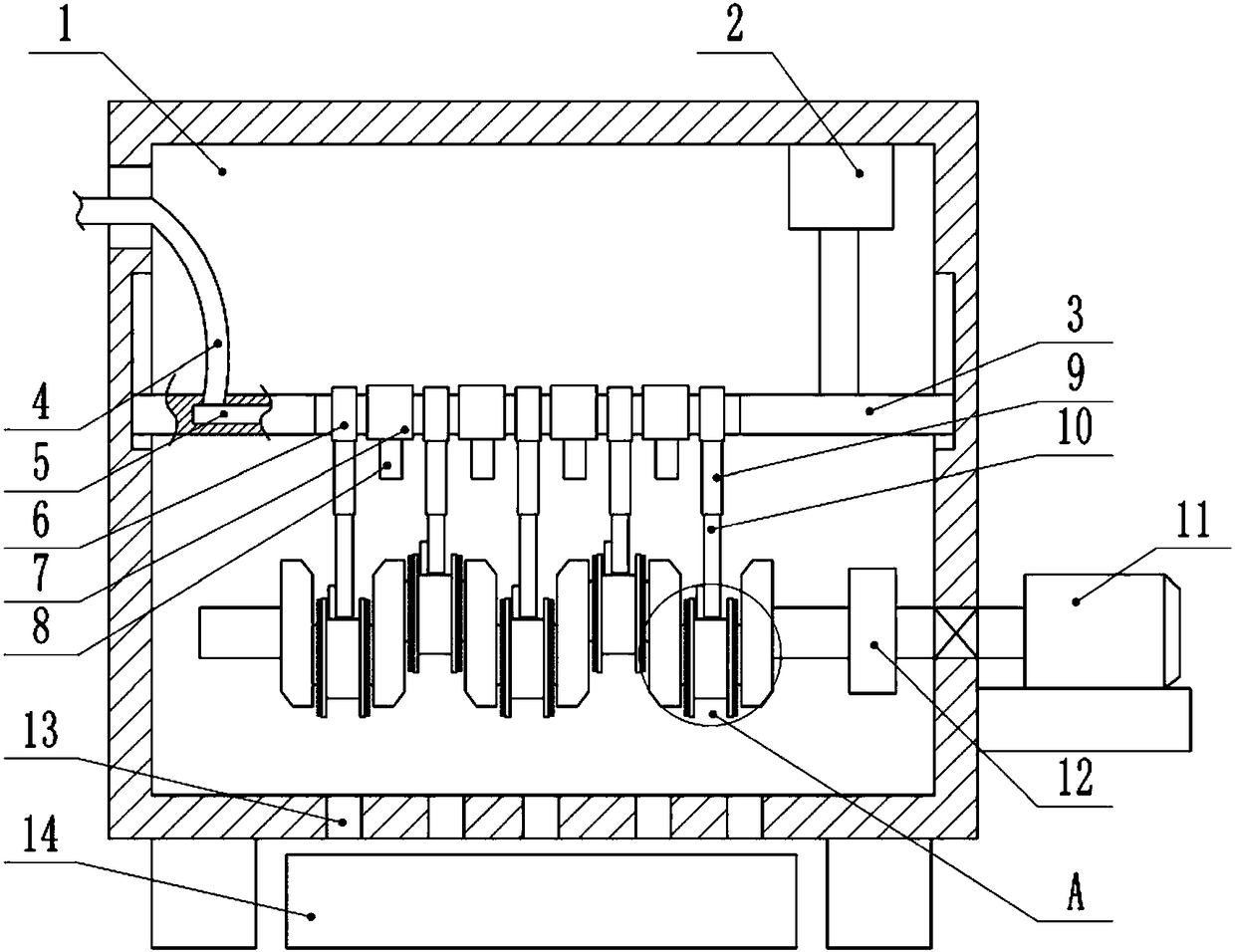

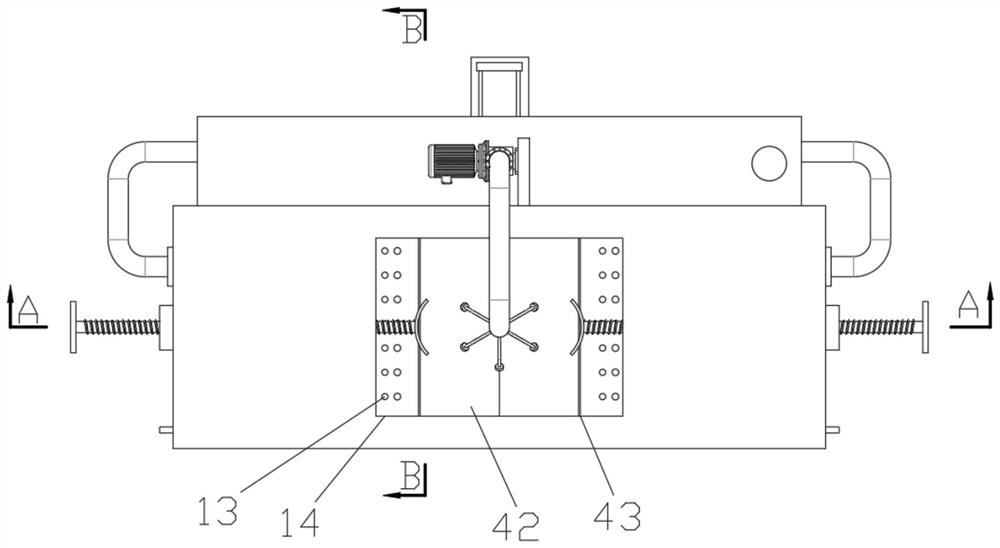

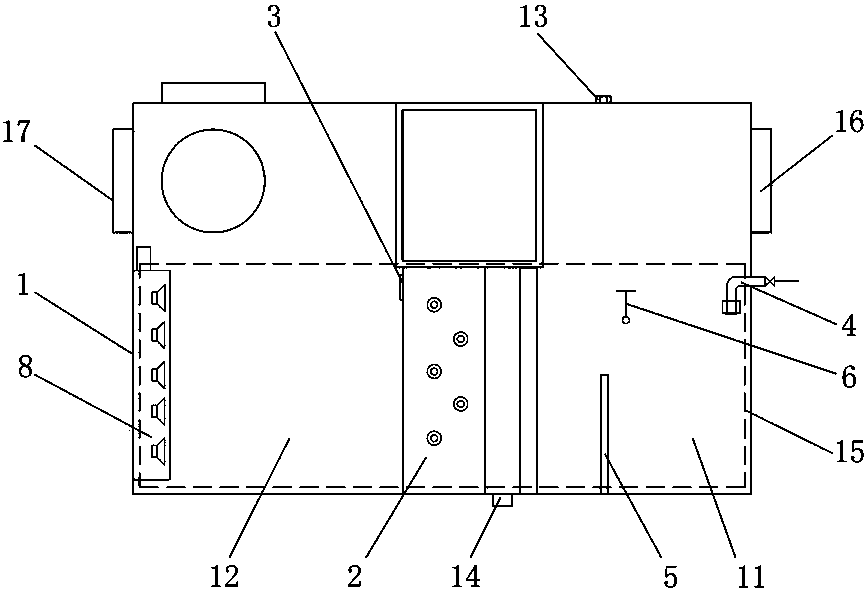

Crankshaft surface cleaning device

PendingCN108405449AEasy to cleanComprehensive cleaningCleaning using toolsCleaning using liquidsBristleSurface cleaning

The invention belongs to the technical field of cleaning equipment, and particularly discloses a crankshaft surface cleaning device. The crankshaft surface cleaning device comprises a box body. The box body is internally provided with a clamping mechanism for clamping a crankshaft, a power mechanism for driving the clamping mechanism to rotate, and a cleaning mechanism for cleaning the crankshaft.The cleaning mechanism comprises a horizontally-arranged support rod, a lifting mechanism for driving the support rod to lift and lower is arranged on the box body, the support is provided with a plurality of screws, and the screws are provided with elastic telescopic rods. Screw holes matched with the screws are formed in the upper ends of the elastic telescopic rods, and holding claw mechanismscapable of holding a journal of the crankshaft are arranged at the lower ends of the elastic telescopic rods. Brushing bristles are arranged on the inner sides and the left and right sides of the holding claw mechanisms, and the box body is internally provided with a plurality of spraying mechanisms for spraying water on the crankshaft. The crankshaft is cleaned by the brushing bristles moving back and forth, the cleaning dead angle is avoided and the cleaning effect is better.

Owner:重庆伟福机械有限公司

Bubble washing and water flow washing combined type shoe-washing machine and shoe-washing method thereof

The invention provides a bubble washing and water flow washing combined type shoe-washing machine and a shoe-washing method thereof. The bubble washing and water flow washing combined type shoe-washing machine comprises a machine box, a cleaning assembly, a drying device, a sterilizing lamp and a turntable, wherein the cleaning assembly, the drying device, the sterilizing lamp and the turntable are arranged in the machine box. The cleaning assembly comprises a water spraying nozzle, a water flow jet device and a bubble generator. The water spraying nozzle is located at the center of the turntable, and the outer side of the water spraying nozzle is provided with a plurality of shoe clamps connected with the upper surface of the turntable. The sterilizing lamp, the drying device, the water flow jet device and the bubble generator are arranged above the turntable. The bubble washing and water flow washing combined type shoe-washing machine is relatively simple in structure and convenient to operate, does not damage shoes and saves water.

Owner:SHAANXI UNIV OF SCI & TECH

Negative pressure adsorbing type plastic product multi-water-injection-nozzle washing device

PendingCN111921952AEasy to operateNo cleaning dead angleTreatment involving filtrationMultistage water/sewage treatmentWater circulationProcess engineering

The invention discloses a negative pressure adsorbing type plastic product multi-water-injection-nozzle washing device. The negative pressure adsorbing type plastic product multi-water-injection-nozzle washing device comprises a workbench, a washing groove, a washing component, a water circulating component, clamping components and a driving component; the washing groove is formed in the middle part of the workbench; the clamping components are arranged on the two sides of the washing groove and rotationally connected to the interior of the workbench; the driving component is arranged at the bottom of the washing groove; a water tank is fixed on one side of the workbench; the water tank is connected with the workbench through a water circulating component; the upper end of the water tank is connected with the washing component; and a washing end of the washing component is opposite to the washing groove. According to the negative pressure adsorbing type plastic product multi-water-injection-nozzle washing device, the washing device drives a plastic product through pressure to be washed in a rotating manner; under cooperation of a multi-angle adjusting washing nozzle, the washing efficiency is greatly enhanced; and meanwhile, as the sewage after washing is treated and cleaned and is used in circulation, water resources are sufficiently utilized, and the water resources are saved.

Owner:LINAN LEILUO PLASTIC FACTORY

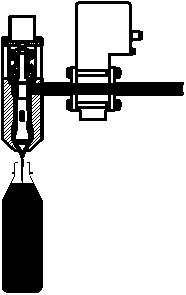

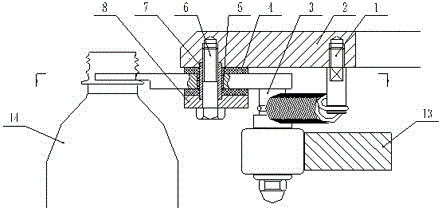

Liquid filling valve and operating method thereof

The invention provides a liquid filling valve and an operating method thereof. The liquid filling valve comprises a valve body, wherein a valve core is arranged in the valve body, the top of the valve body is sealed by a sealing diaphragm of the valve core, a discharge opening which is aligned with a container is formed in the bottom of the valve body, a filling channel is formed between the inner wall of the valve body and the valve core, the filling channel is connected to a feed pipe by virtue of a flowmeter, and a push device which is used for pushing the sealing diaphragm of the valve core to move is arranged on the top of the valve body. The liquid filling valve is characterized in that a pre-closed valve clack sleeves the upper part of the valve core, a clearance is left between the valve core and the pre-closed valve clack, the pre-closed valve clack can freely move up and down along the valve core, and a valve port sealing ring is arranged between the bottom of the valve core and the discharge opening in the lower end of the valve body. The liquid filling valve has the advantages of sanitation, no cleaning dead angle and low cost, and the splashing phenomenon is fully eliminated when the filling valve is closed.

Owner:南京保立隆包装机械有限公司

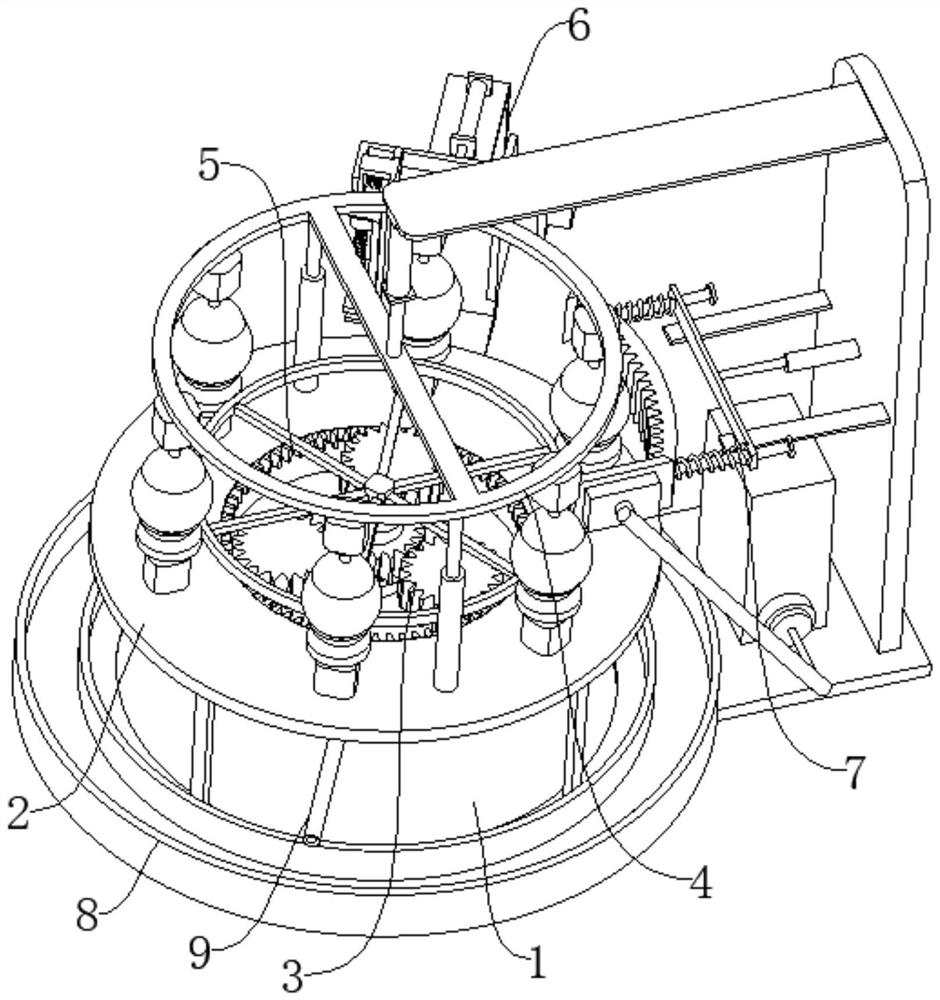

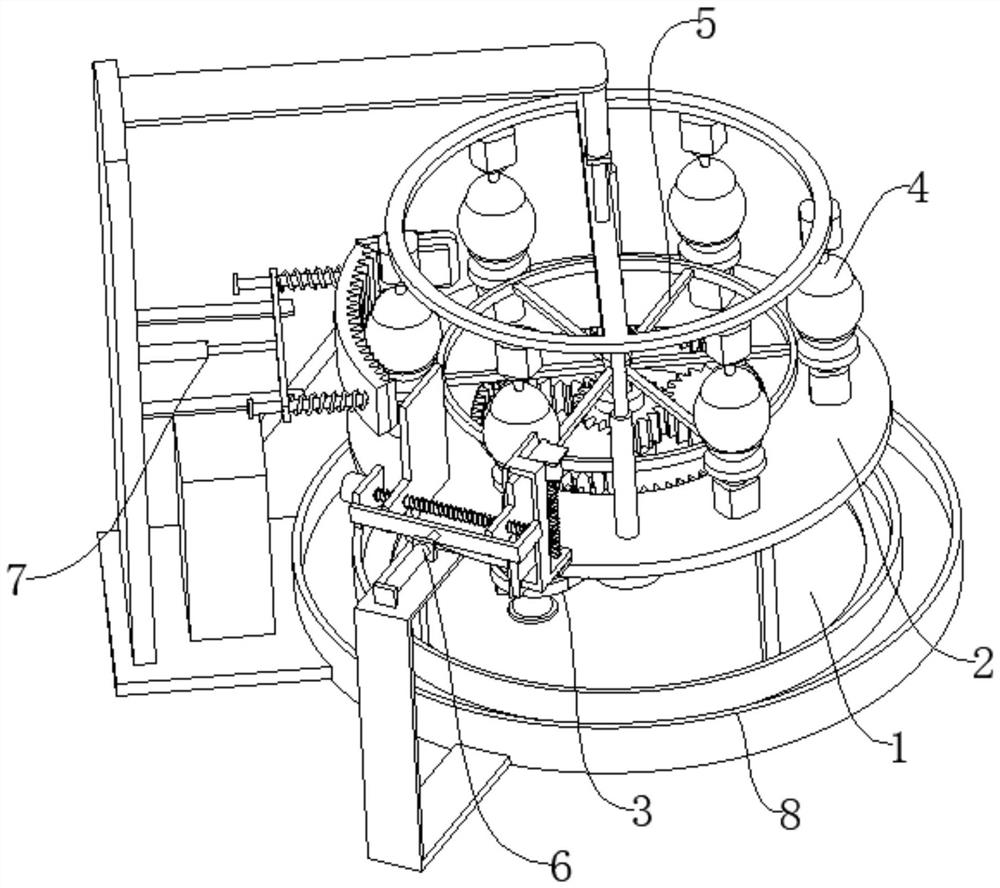

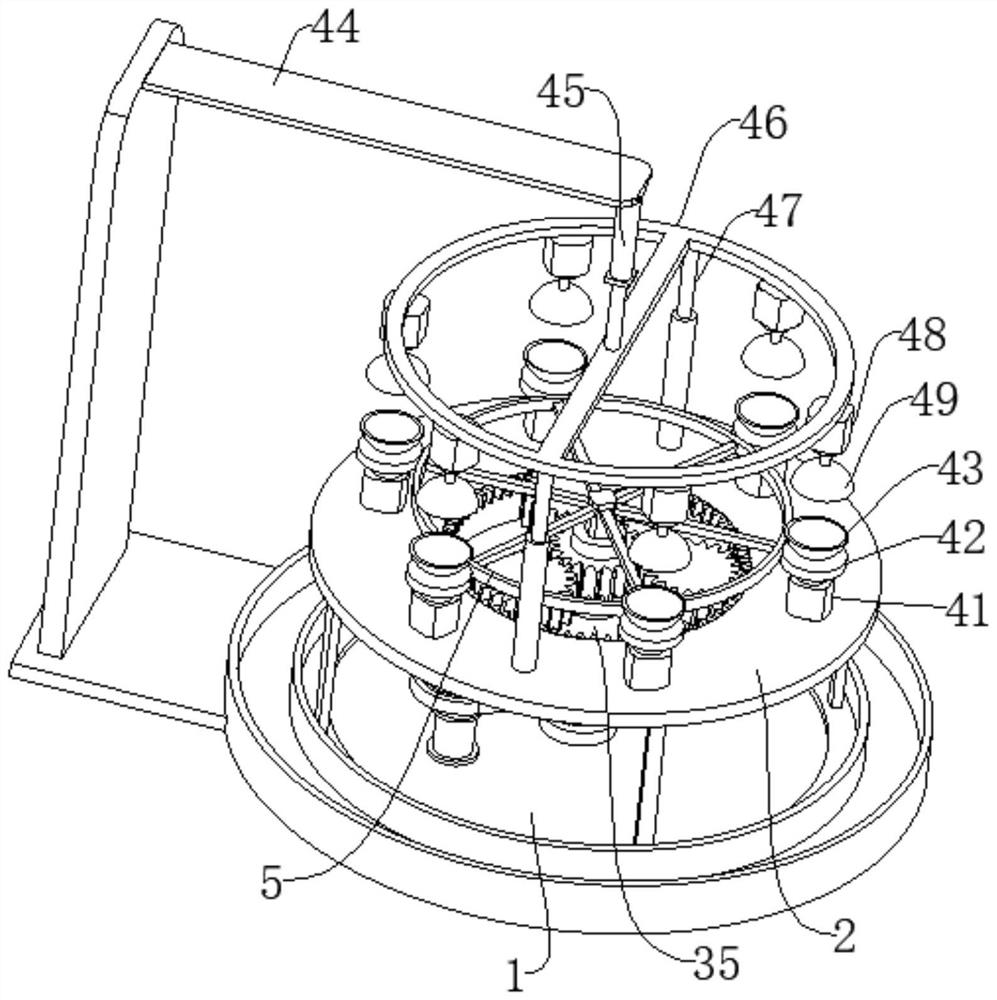

Automatic reversing and cleaning device of spherical catalyst for coke oven flue gas desulfurization

ActiveCN113500027AFull rinseEasy to cleanCatalyst regeneration/reactivationCleaning using toolsPtru catalystEngineering

The invention discloses an automatic reversing and cleaning device of a spherical catalyst for coke oven flue gas desulfurization. The device comprises a base and an annular rotating plate rotationally connected to the top of the base, wherein a driving mechanism used for driving the rotating plate to rotate is arranged at the top of the base, a fixing mechanism used for fixing the spherical catalyst is arranged above the rotating plate, a cleaning mechanism and a reversing mechanism are arranged on one side of the base, the cleaning mechanism sprays water to clean the catalyst, the reversing mechanism reverses the cleaned spherical catalyst, and the fixing mechanism comprises a plurality of first fixing seats fixed to the top of the rotating plate and evenly distributed, rotating discs rotationally connected to the tops of the first fixing seats, containing seats rotationally connected to the tops of the rotating discs, a mounting frame fixed to one side of the base, and a first air cylinder mounted on the mounting frame and vertically arranged. The cleaning device is capable of automatically reversing the catalyst, free of cleaning dead angles, good in cleaning effect, high in automation degree and convenient to use.

Owner:安徽紫朔环境工程技术有限公司

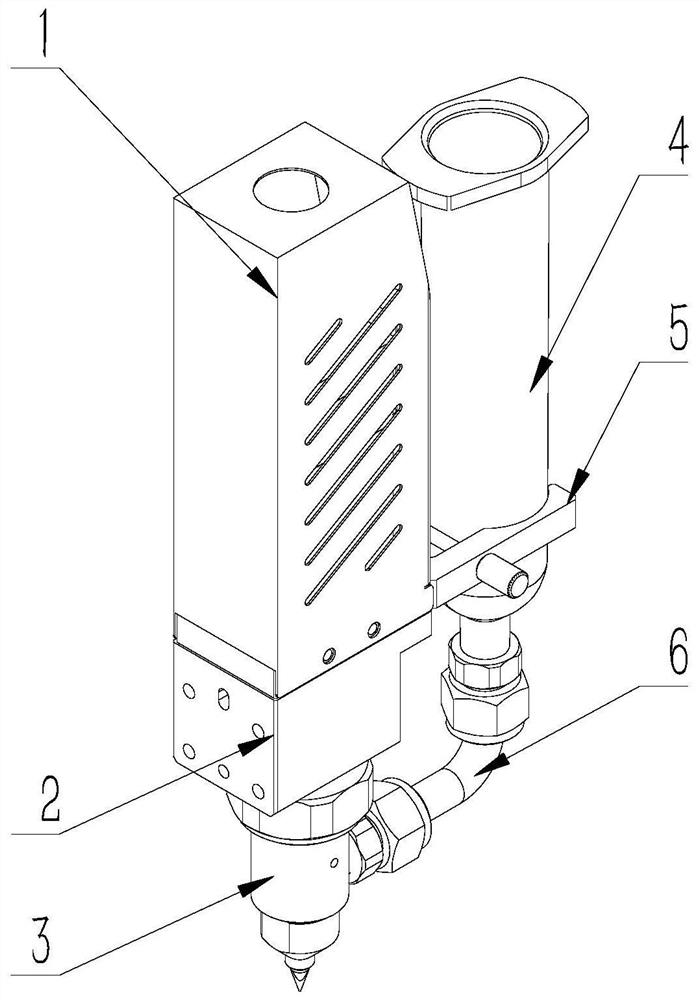

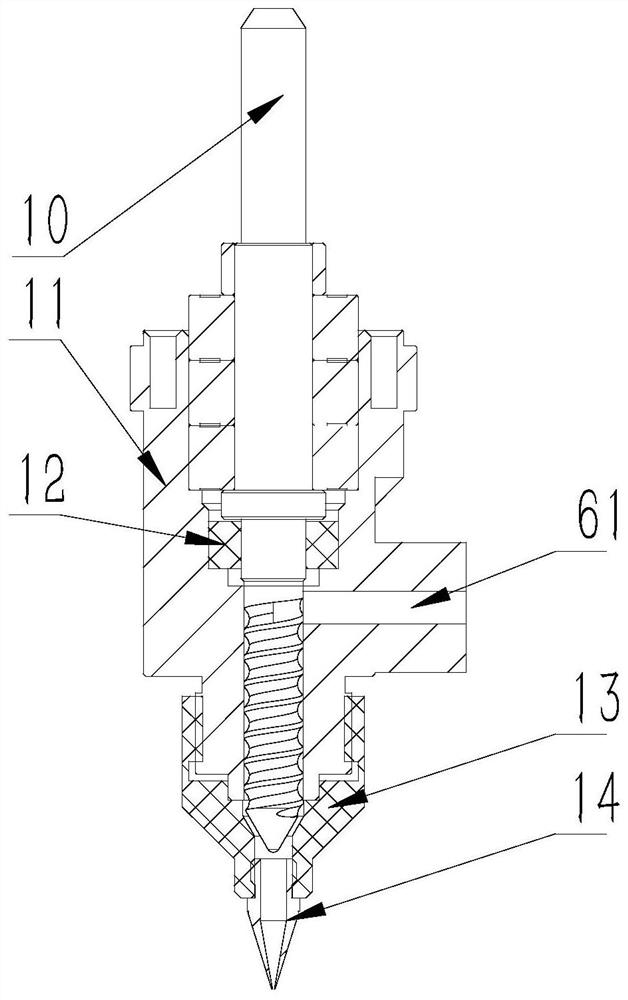

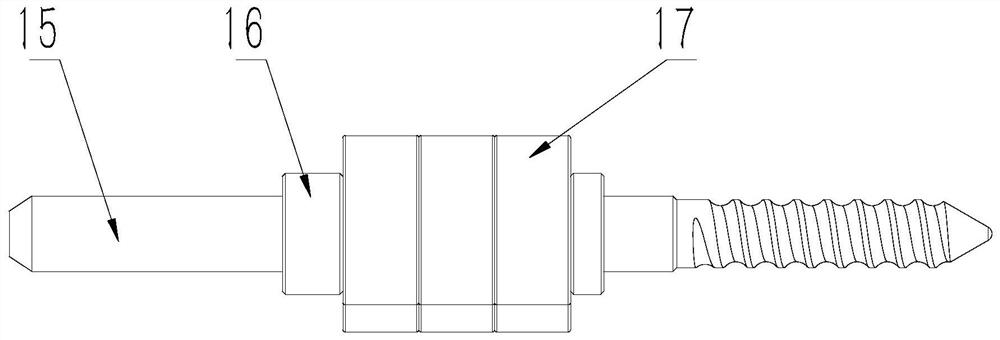

Single-liquid screw valve

ActiveCN112403834AHigh ergonomicsZero BacklashPretreated surfacesCleaning using gasesPhysicsEngineering

The invention discloses a single-liquid screw valve. The single-liquid screw valve comprises a shell, a valve body upper assembly, a valve body assembly, a glue barrel, a fixing piece and a glue conveying assembly. The shell is arranged on the valve body upper assembly, the bottom of the valve body upper assembly is connected with the valve body assembly, and the glue barrel is fixed to one side of the shell through the fixing piece. By the adoption of the structure, the number of parts is minimized when the screw valve is disassembled, assembled and cleaned, disassembly and assembly are convenient and rapid, and the man-machine efficiency is high.

Owner:SHENZHEN TENSUN IND EQUIP

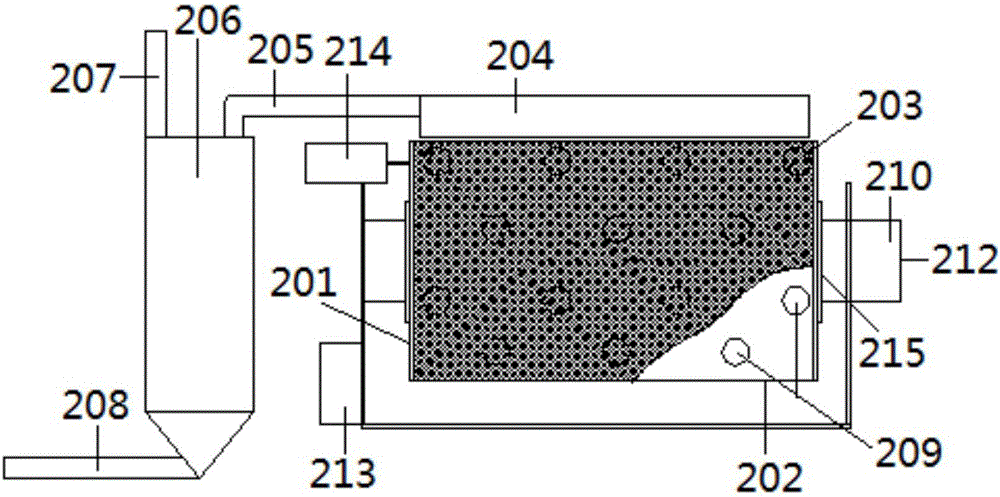

Adsorption type rotary drum filter for water treatment

InactiveCN106731152ASmooth filter surfaceAvoid damageMoving filtering element filtersTreated waterPollution

The invention provides an adsorption type rotary drum filter for water treatment. The filtering direction of the adsorption type rotary drum filter is from outside to inside. The filtering surface of a filter screen is smooth and is not affected by blocking of a supporting wall, and is large in filtering area and free of cleaning dead angle. No pollution discharge component is arranged in the filter screen. The structure is simple. The immersion rate can be increased to 80% or more, so that the open area is large, and the treated water flow in unit area is large. The surface of the filter screen is cleaned through negative pressure, cleaning action is moderate, damage to the filter screen is small, and accordingly the service life of the filter screen is long. Filtered solid can be collected completely through a pollution suction nozzle, and accordingly the situation that filtered substances are splashed and leaked and then pollute a system secondarily is avoided.

Owner:张家港纽艾农业科技有限公司

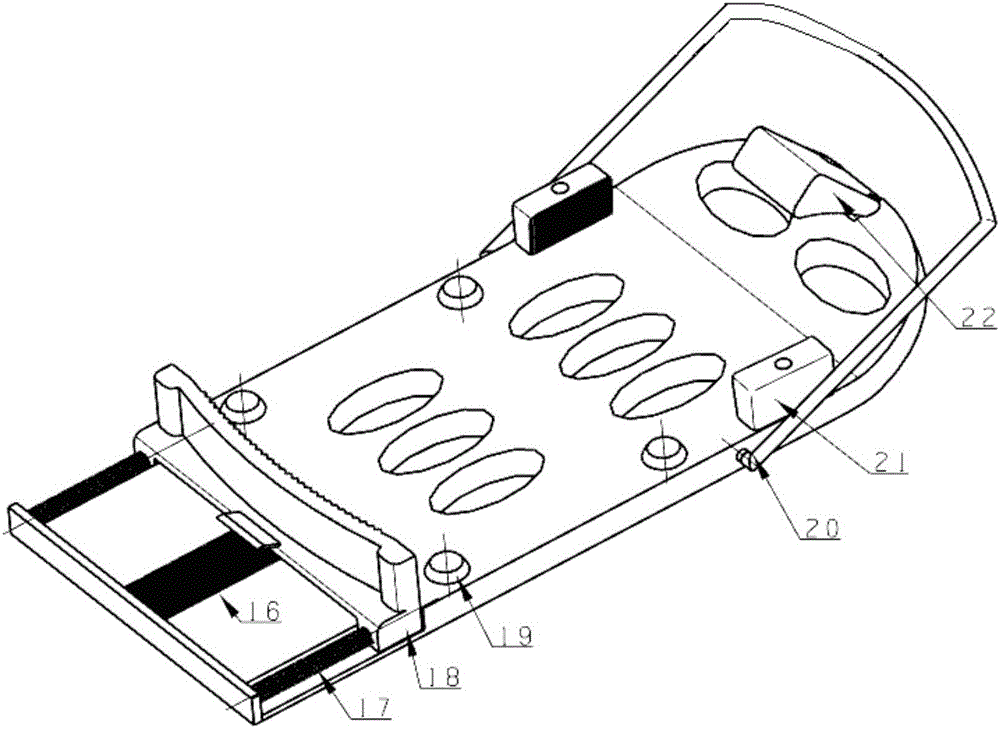

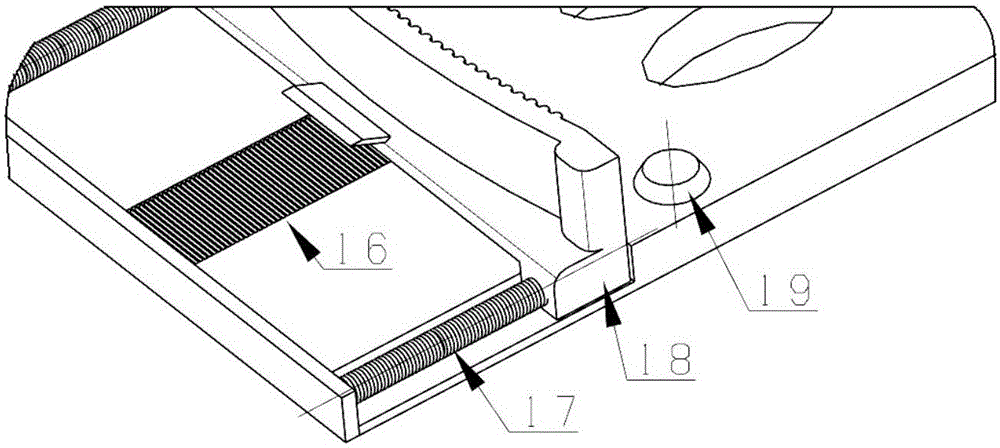

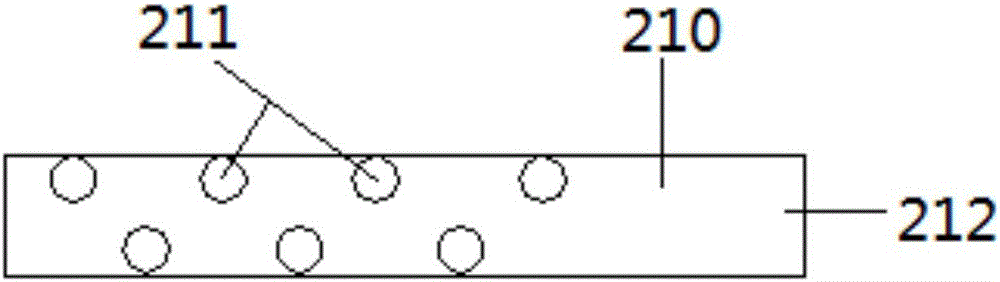

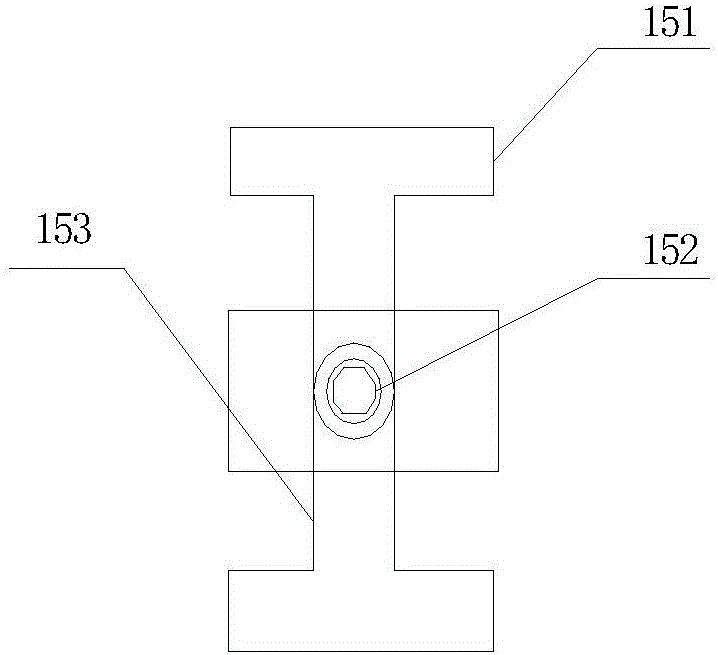

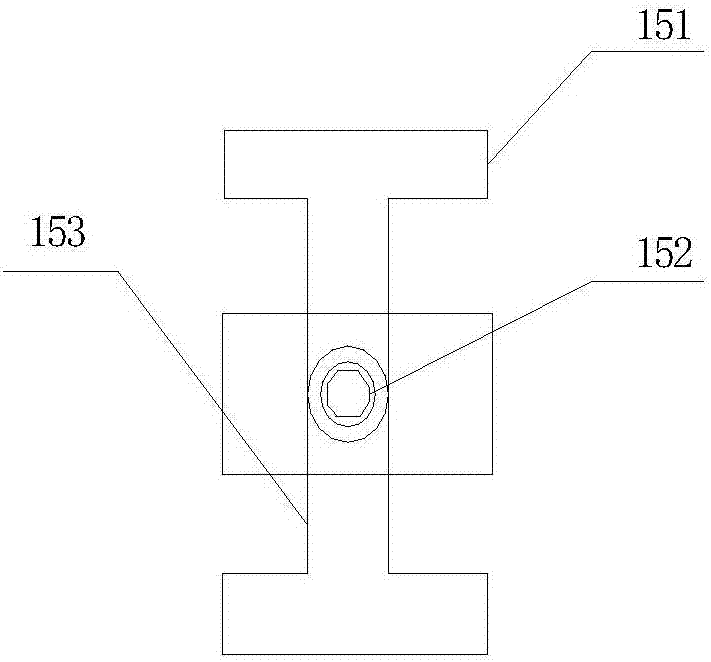

Bio-electricity signal collecting device

ActiveCN105997061ANo cleaning dead angleSimple production and processing technologyDiagnostic recording/measuringSensorsElectrical resistance and conductanceMechanical engineering

The invention discloses a bio-electricity signal collecting device. The bio-electricity signal collecting device comprises a support body, as well as an electrode mounted on the support body, and a lead, wherein an electrode positioning hole is formed in the support body; the electrode comprises a fixing ring, and a conducting resin cavity having two open ends and being communicated is formed in the middle of the fixing ring; an electrode sensing layer is arranged on the inner wall of the conducting resin cavity, is an annular face with a gap, and is connected with the lead; a fixing groove is formed in the outer cylindrical surface of the fixing ring, and is used for embedding the periphery of the electrode positioning hole and fixing the electrode and the support body; the electrode sensing layer is the annular face with the gap, and is serially connected with a safety resistor, thus being safe to the human body; the electrode sensing layer is positioned on the inner wall of the conducting resin cavity, therefore, no cleaning dead angle exists, and the cleaning is convenient.

Owner:段晏文

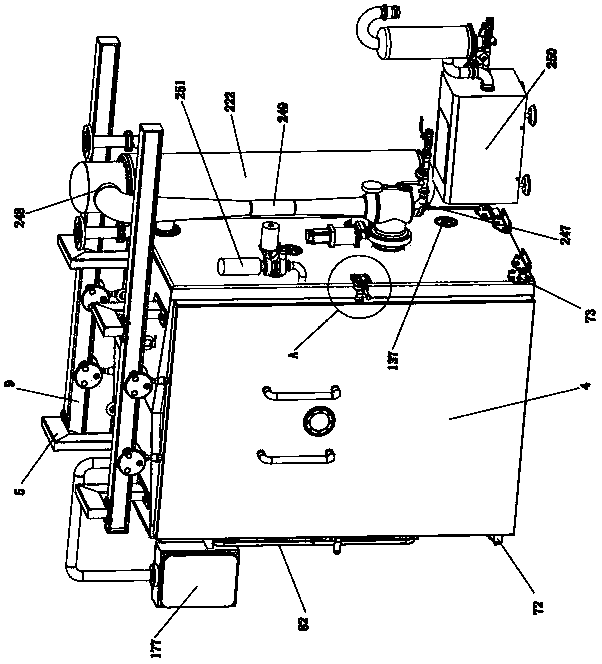

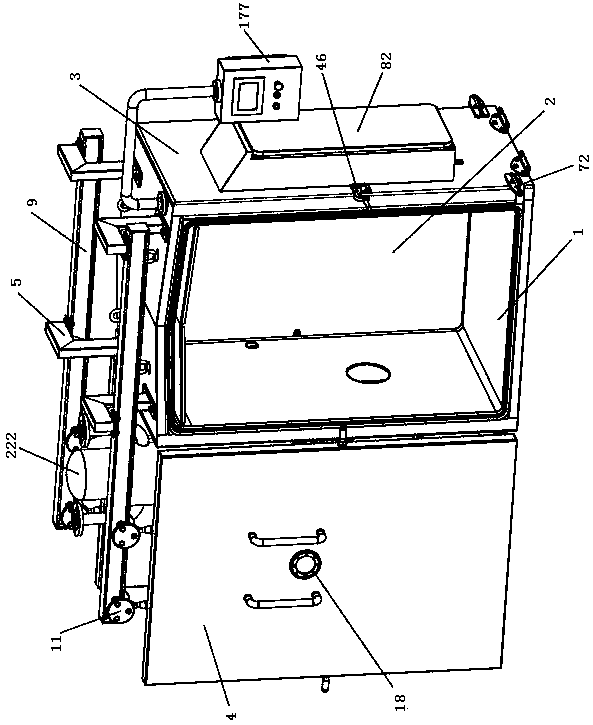

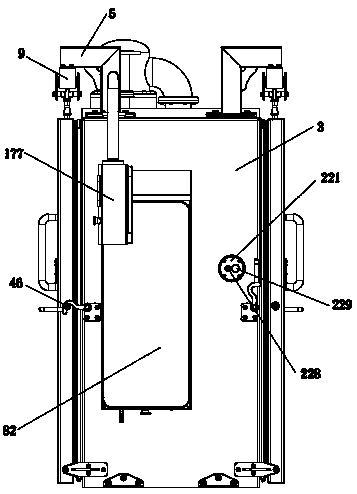

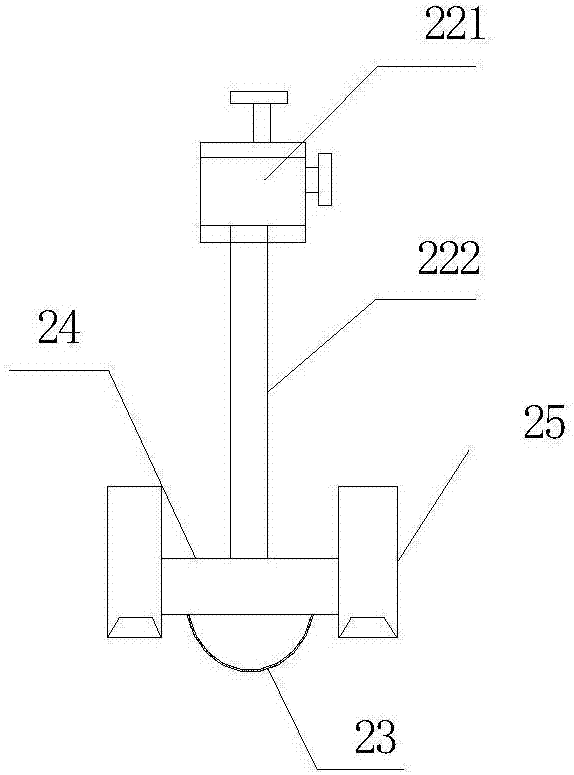

Vacuum cooling machine capable of solving food safety hygienic problems

PendingCN107960590AImprove sealingGood hygiene levelDomestic cooling apparatusLighting and heating apparatusFood safetyElectrical control

The invention discloses a vacuum cooling machine capable of solving food safety hygienic problems. The vacuum cooling machine comprises a tank body with a charging opening and a discharging opening, and a sealing door for sealing the charging opening and the discharging opening, wherein a waterproof door lock for locking the sealing door at the charging opening and the discharging opening is arranged on the tank body and the sealing door; a guiding and positioning mechanism is arranged on the tank body; a waterproof electrical control cabinet with electrical apparatus elements, and a waterproof junction box for leading out wires buried in the tank body are arranged on the side surface of the tank body; a temperature sensor connected with the electrical apparatus elements is arranged in thetank body; an electric control tank with a buzzer, which is rotatably connected with the tank body, is hung on the outer side of the tank body; a controller which cooperates with the electric controltank to facilitate loading and unloading and a heat exchanger connected with the tank body are arranged on the side surface of the tank body; a jet device with a steam inlet and a steam outlet communicates with the heat exchanger and the tank body; and the vacuum cooling machine also comprises a repressing mechanism which is connected with the tank body and is used for balancing the pressure difference in the tank body after cooling is completed so that the sealing door is convenient to open. According to the vacuum cooling machine disclosed by the invention, charging and discharging are convenient; the vacuum cooling machine is convenient to operate, and good in waterproof sealing properties; the waterproof grade can achieve an IP68 grade; the protection grade of steam washing can achieve an IP69K grade; the number of bacterial colonies is small; and the vacuum cooling machine is safe and hygienic.

Owner:QINGDAO FRESH FOOD TECH CO LTD

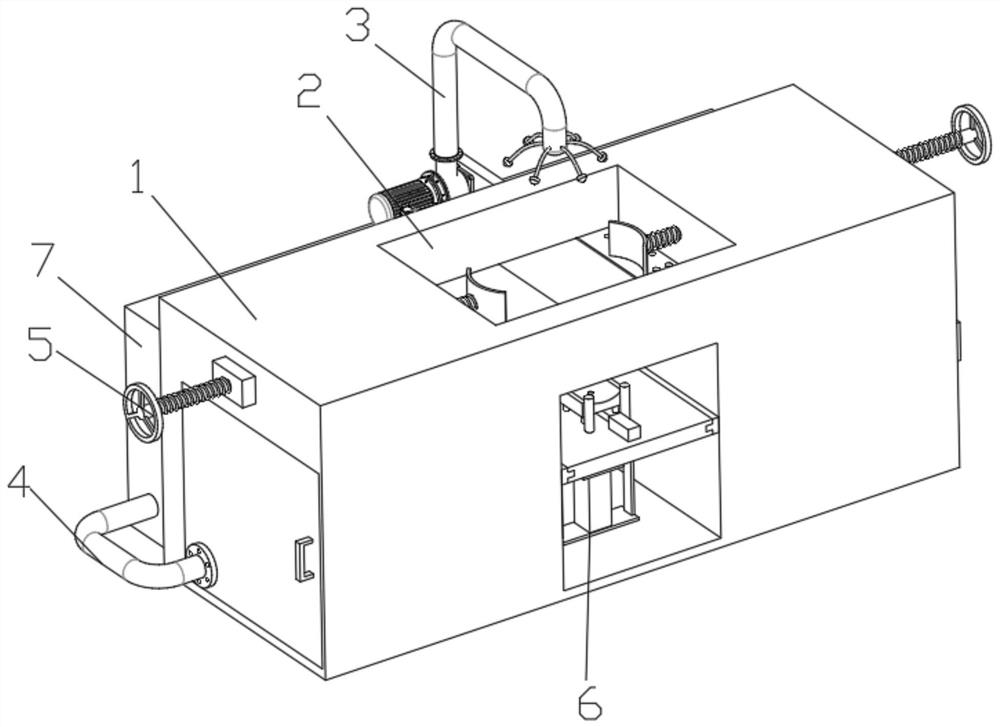

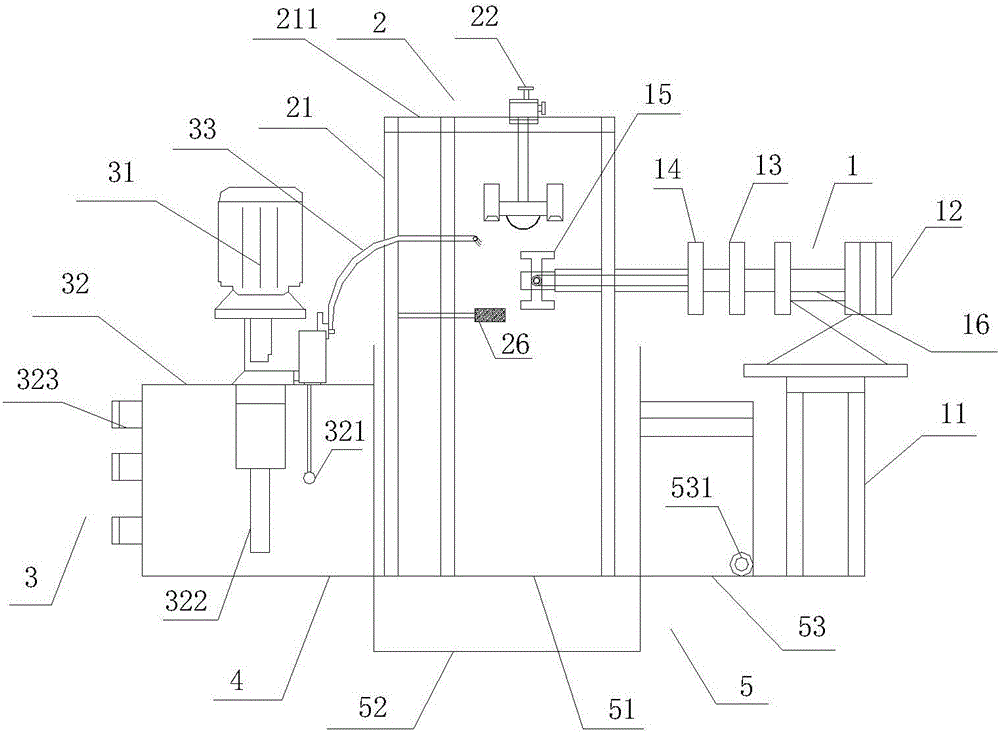

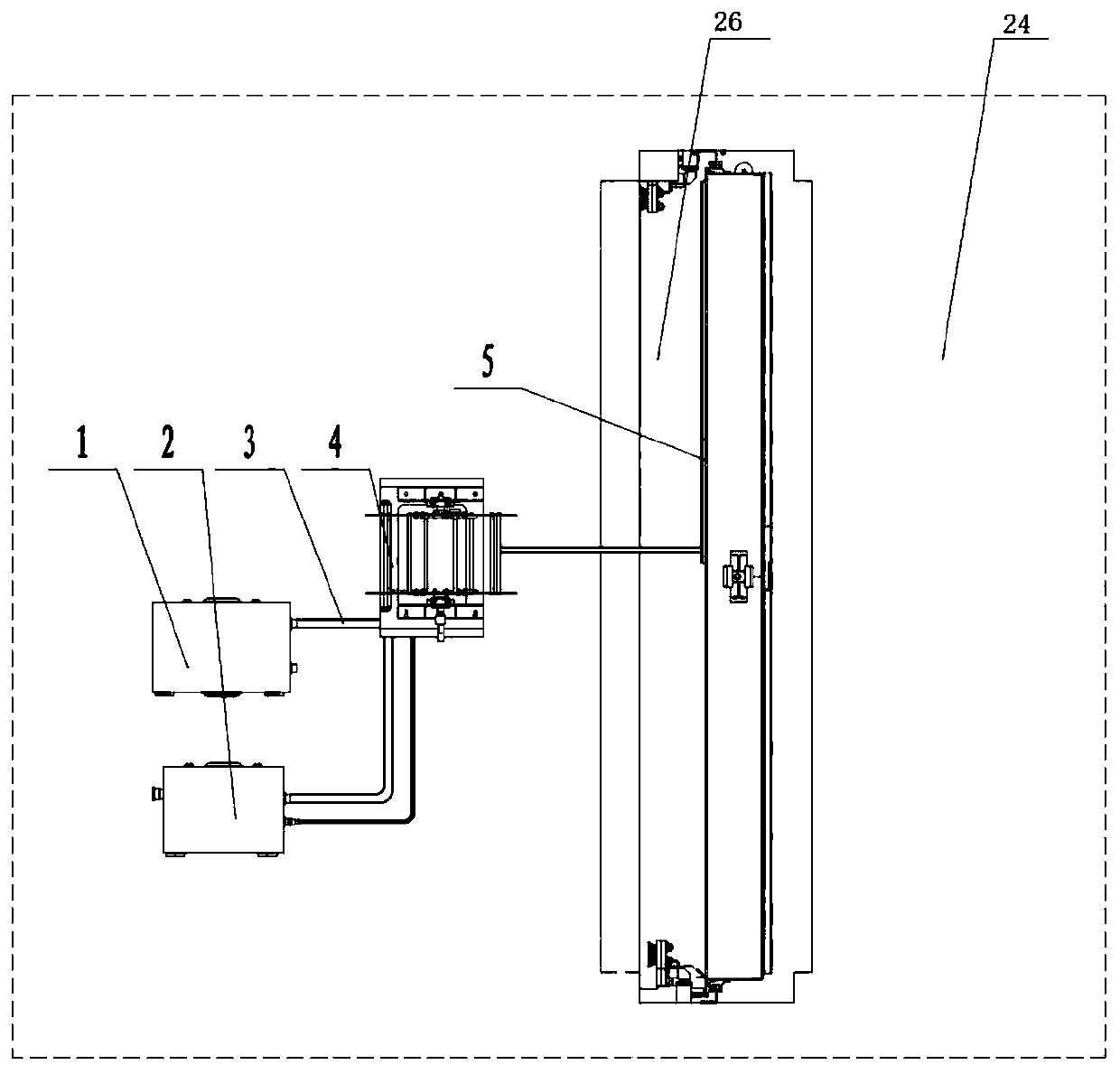

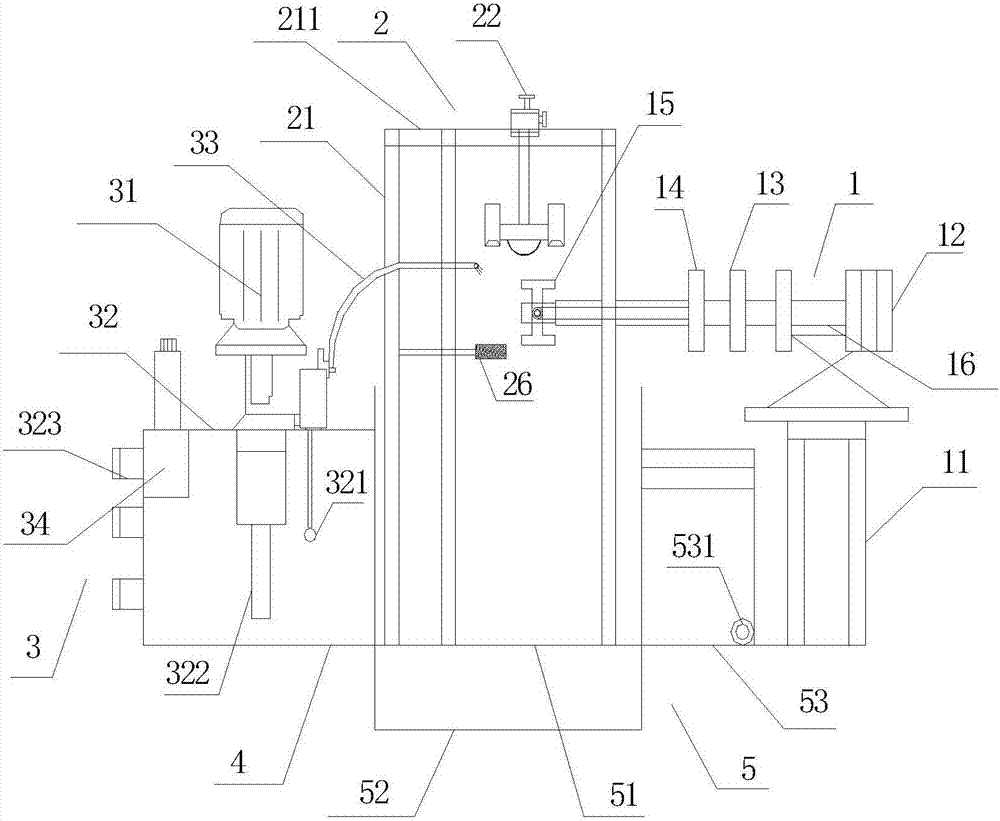

Cleaning machine for cylinder barrel of oil cylinder

The invention provides a cleaning machine for a cylinder barrel of an oil cylinder. The cleaning machine comprises a drive part, a cleaning part, a cleaning liquid supply part, a base and a sewage collecting and treating device. The drive part and the cleaning liquid supply part are located on the two sides of the cleaning part correspondingly. The drive part, the cleaning part, the cleaning liquid supply part and the sewage collecting and treating device are located at the upper end of the base and fixedly connected with the base. The sewage collecting and treating device is located under the cleaning part. The cleaning part comprises a stand column, a cleaning brush telescopic device, a spherical cleaning brush, a fixed trough, drying devices and an inner cleaning brush. The stand column is fixedly connected with the base. The cleaning brush telescopic device is fixedly connected with the upper end of the stand column. The spherical cleaning brush and the fixed trough are located at the lower end of the cleaning brush telescopic device and fixedly connected with the cleaning brush telescopic device. The spherical cleaning brush is located in the fixed trough and movably connected with the fixed trough. The drying devices are located on the two sides of the fixed trough and fixedly connected with the fixed trough. The inner cleaning brush is fixedly connected with the stand column. The cleaning machine is high in cleaning efficiency and good in cleaning effect.

Owner:江苏昊阳传动科技有限公司

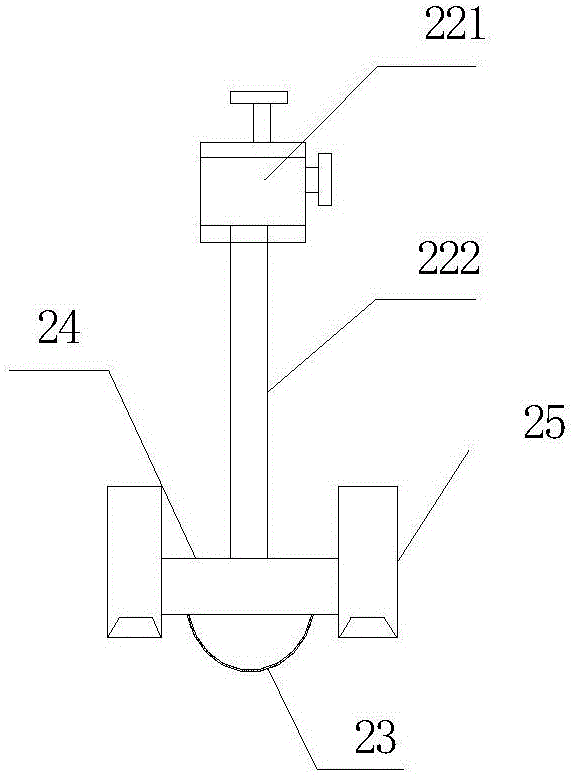

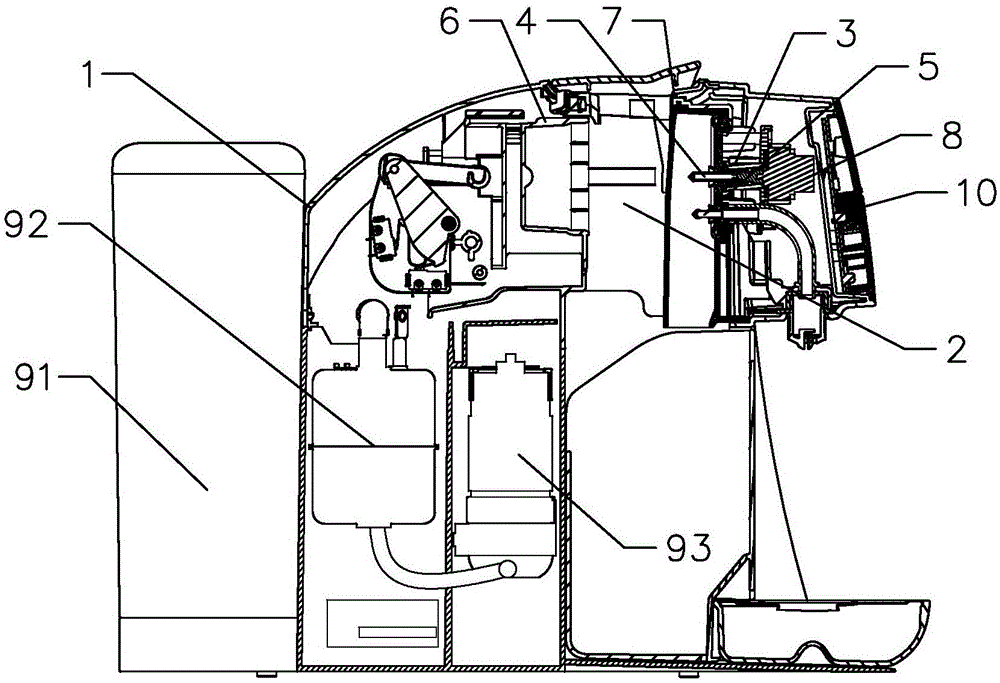

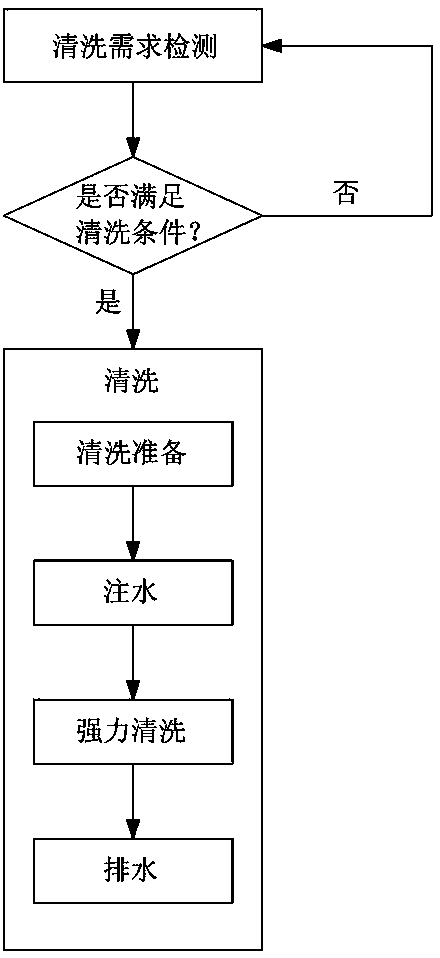

Washing method of capsule beverage machine

ActiveCN106583378AStrong stickinessEasy to cleanHollow article cleaningProcess engineeringIdentification device

The invention provides a washing method of a capsule beverage machine. The machine comprises a machine base, a brewing cavity and a control panel which are arranged in the machine base, a brewing head, a water inlet pricking pin, a water outlet pricking pin, a liquid supply mechanism for providing a liquid for the brewing head, a brewing cup for accommodating capsules and an identifying device for identifying the capsules. Multiple washing modes are set, the washing method comprises an identification step and a washing step, and the identification step is added before the washing step, so that the different washing modes can be selected according to the different identified capsules; with the washing method, the machine is washed clean without water wasting, is more convenient to use and more intelligent and conforms to the modern way of life.

Owner:杭州九创家电有限公司

Water storage type cleaning method applicable to electrostatic filter

InactiveCN103639055AImprove cleaning efficiencyImprove cleanlinessElectrodes cleaningWater storageEngineering

Owner:若夫智能科技(上海)有限公司

Sanitation brush capable of avoiding producing clearing and sweeping dead corners

The invention discloses a sanitation brush capable of avoiding producing clearing and sweeping dead corners. The sanitation brush comprises a rotating shaft, wherein two sets of limiting protrusions are integrally and symmetrically arranged on the surface of the rotating shaft along the axial direction of the rotating shaft, and the surface of the rotating shaft is slidably connected with a clearing and sweeping assembly in an sleeved mode; the clearing and sweeping assembly comprises a mounting disc, wherein the surface of the outer ring of the mounting disc is fixedly provided with a brush wire body, and the surface of the mounting disc is further provided with a shell in a sleeved mode; the outer end of the surface of the shell abuts against the surface of the brush wire body, a limiting groove is formed in the joint of the shell and the brush wire body, and the groove bottom of the limiting groove inclines 40 - 70 degrees from inside to outside; and the two ends of the rotating shaft are movably connected with end covers, and the inner sides of the end covers are connected with the clearing and sweeping assembly in an attached mode. The sanitation brush is simple and reasonablein structural design, convenient to operate, convenient to dismount and replace, capable of effectively avoiding producing the clearing and sweeping dead corners, safe and stable, cost-saving, wide in application range and beneficial to promotion and popularization.

Owner:安徽名扬刷业有限公司

Urine power operating system support

The invention discloses a urine power operating system support. The urine power operating system support comprises a fixing clamp, a supporting arm and a supporting clamp which are sequentially connected, wherein the supporting arm comprises a supporting arm main branch and a plurality of supporting arm branches, which are detachably connected; the end, away from the supporting arm branches, of the supporting arm main branch is connected with the fixing clamp; the end, away from the supporting arm main branch, of each supporting arm branch is connected with the supporting clamp; the supportingclamp is used for fixing a urethra piezometric tube or a rectum piezometric tube; the supporting arm branches and the supporting arm main branch are in threaded connection or inserted connection or are connected through pipe hoops; the supporting arm is a flexible supporting arm which can be bent and deformed and has a supporting effect; and the supporting clamp is a sheet-shaped magnetic clamp.The urethra piezometric tube and the rectum piezometric tube are fixed and supported when urodynamics analysis and examination are carried out on a urinary patient, and after the urethra piezometric tube and the rectum piezometric tube are placed into the human body, the urethra piezometric tube and the rectum piezometric tube are clamped by the supporting clamp to be positioned.

Owner:BEIJING CHAOYANG HOSPITAL CAPITAL MEDICAL UNIV

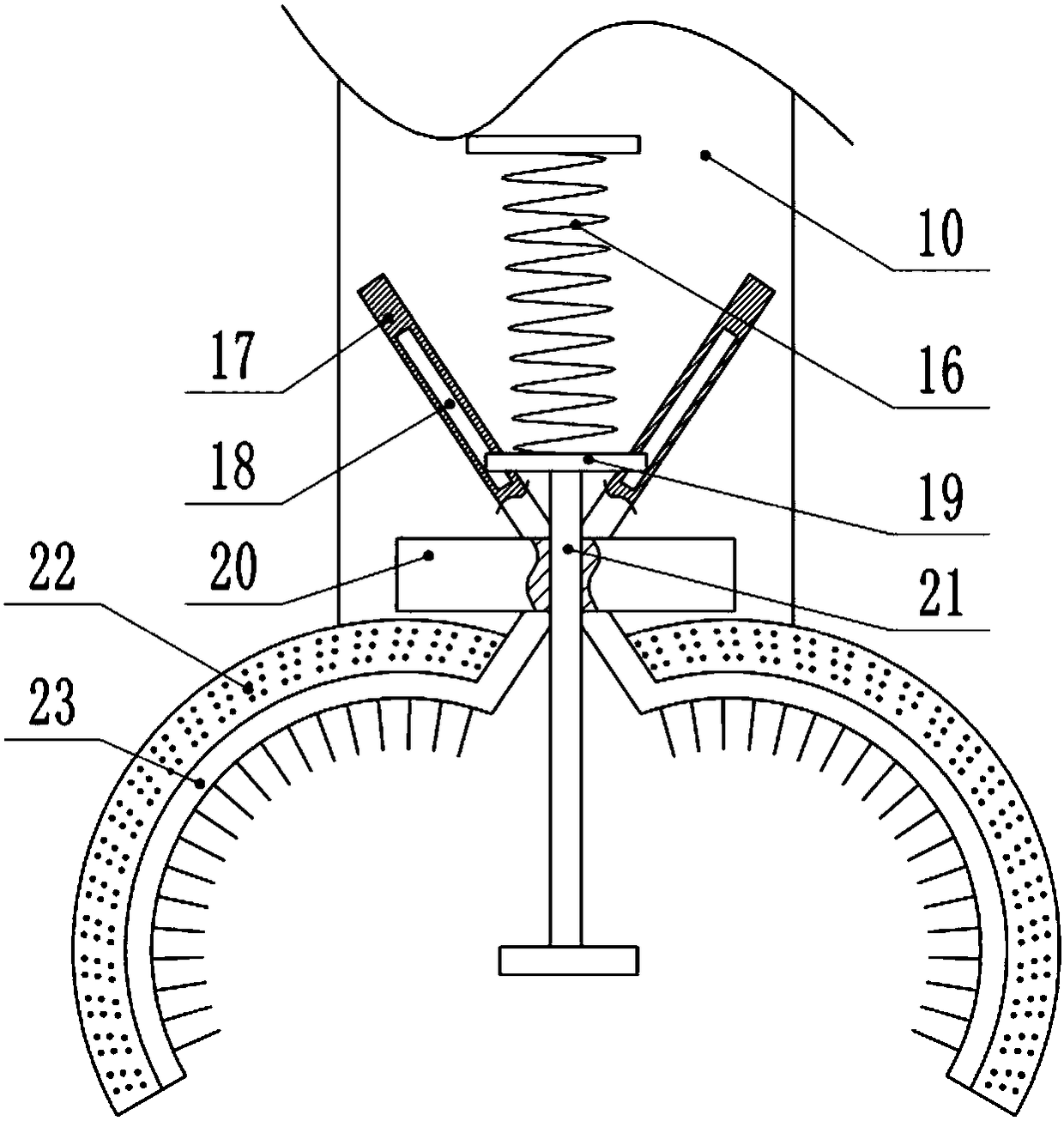

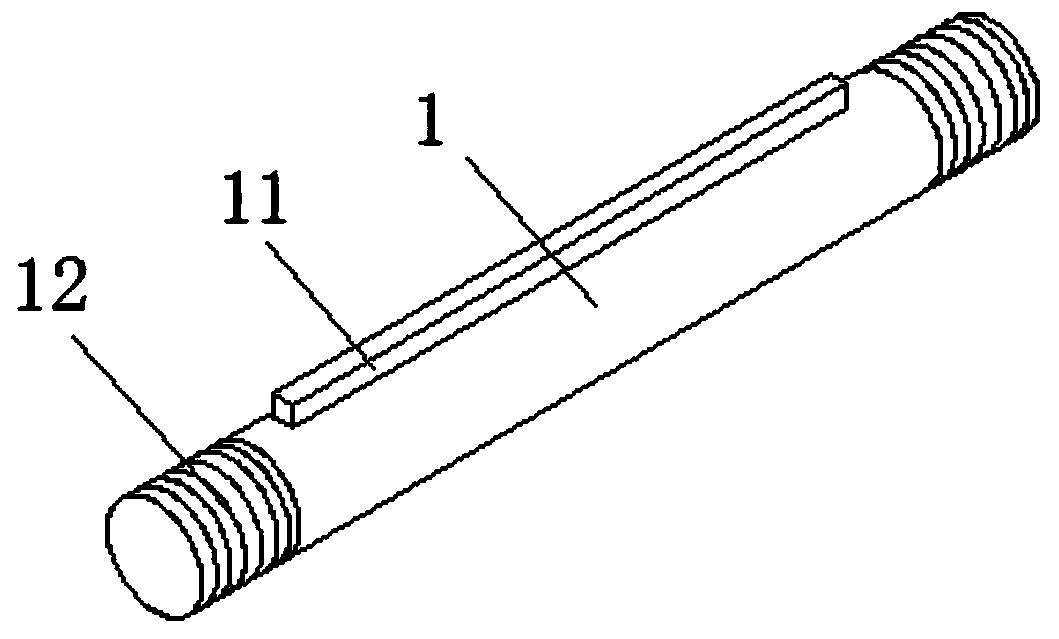

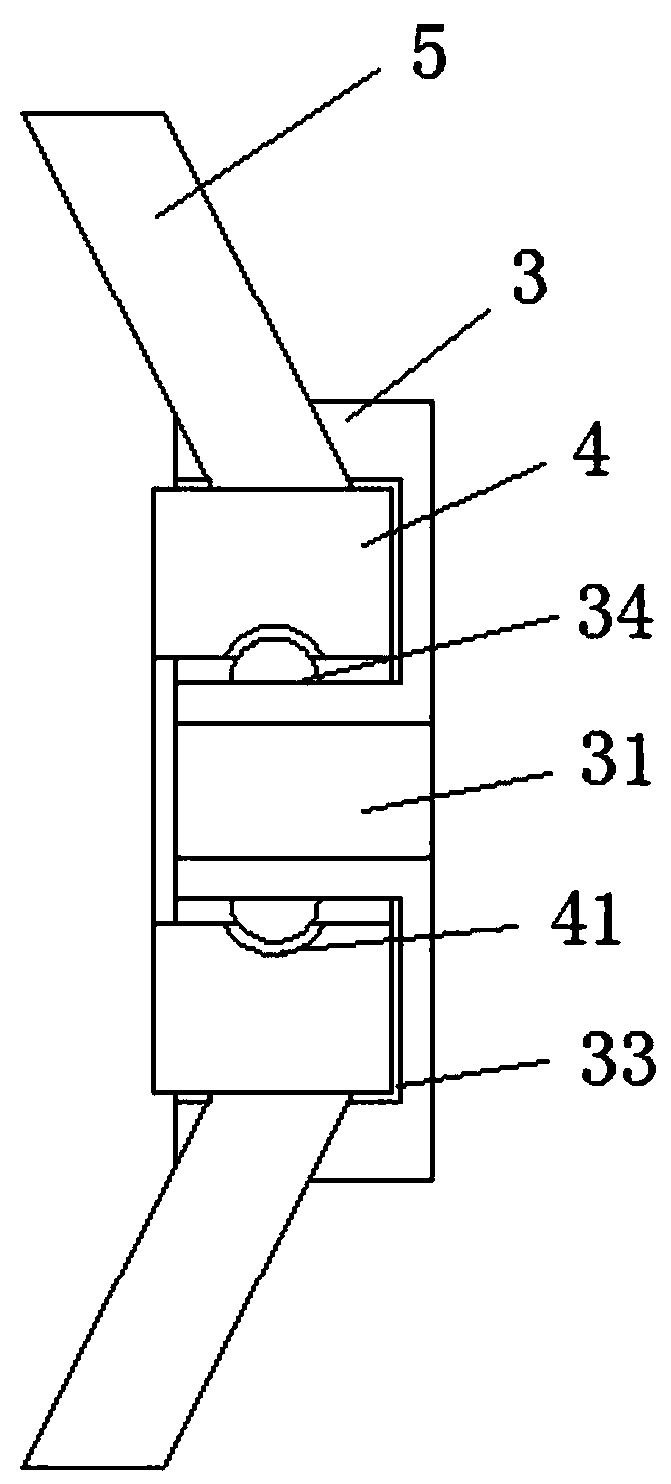

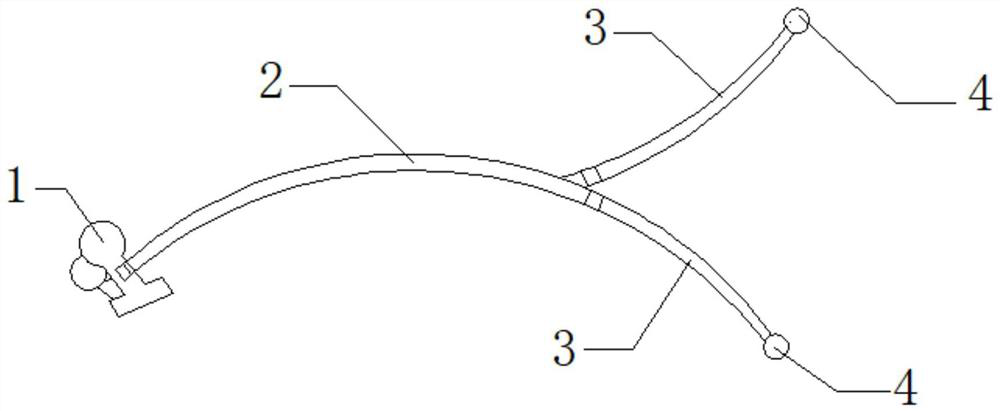

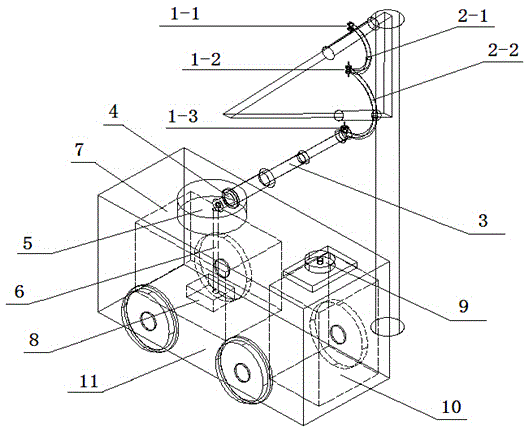

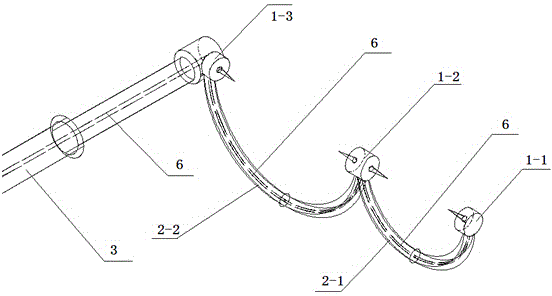

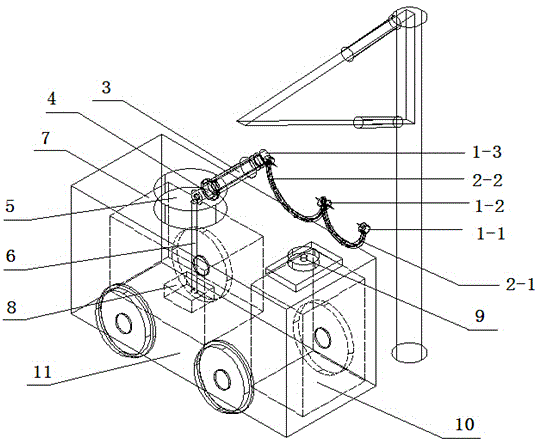

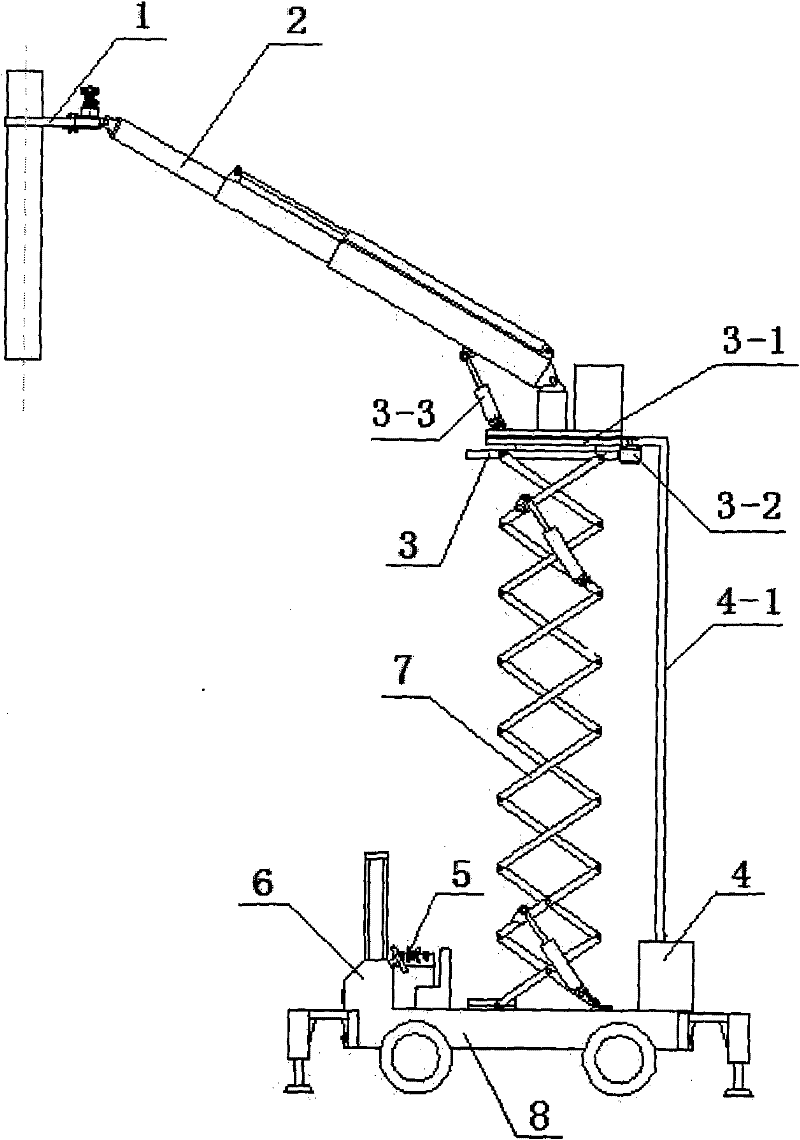

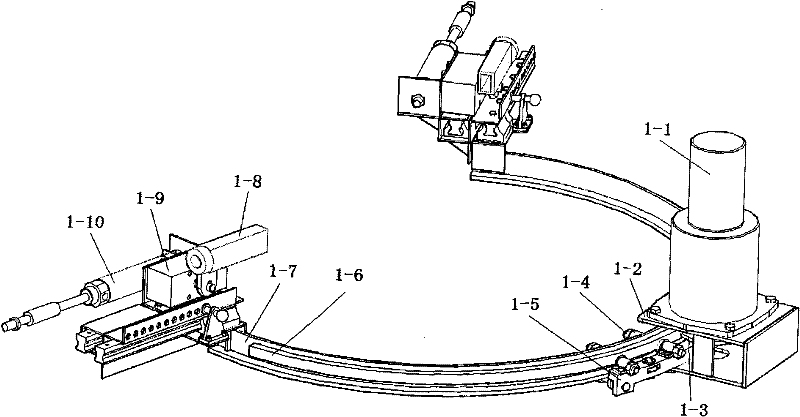

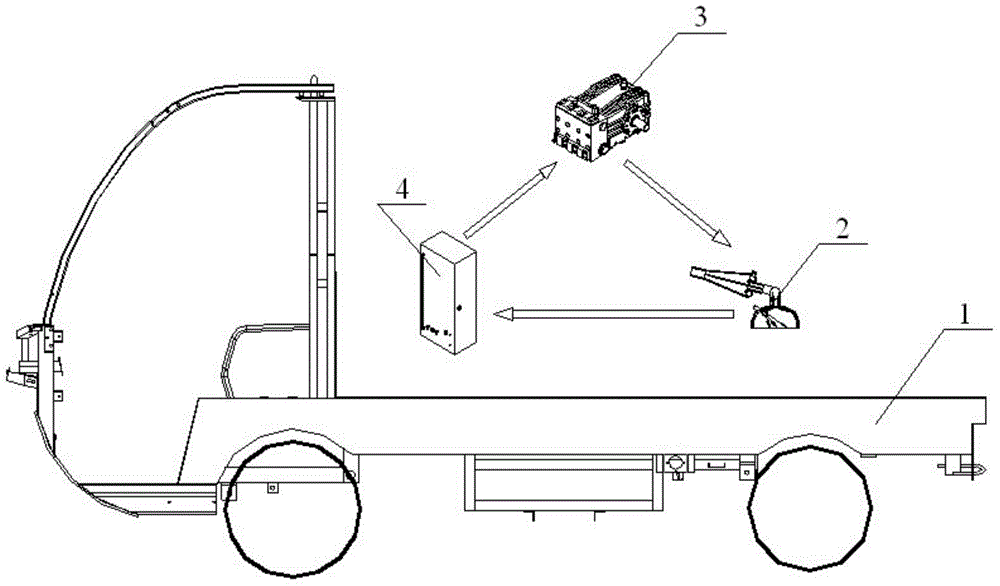

Cleaning vehicle for contact network insulators

ActiveCN106140673ALarge containment areaAdjustable distanceCleaning using liquidsHydraulic motorContact network

A catenary insulator cleaning vehicle belongs to catenary insulator cleaning equipment. The top high-pressure nozzle (1-1), the middle high-pressure nozzle (1-2) and the bottom high-pressure nozzle (1-3) are respectively installed on the upper semicircular arm (2-1) and the lower semicircular arm ( 2-2) The bottom ends of the upper and lower semicircular arms (2-2) are connected to one end of the insulating rotating telescopic arm (3), and the other end of the insulating rotating telescopic arm (3) is connected to the hydraulic motor (4). The hydraulic motor is installed Inside the rotating platform (5), the rotating platform (5) is placed on the top of the vehicle body (11); there is a cleaning fluid storage tank (7) inside the vehicle body (11), and a high-pressure water pump (8) is installed in the cleaning fluid storage tank (7) , the high-pressure water pump (8) is connected to the cleaning fluid delivery pipe (6); a controller (10) is installed in the car body (11), and a distance measuring sensor (9) is installed on the top. The invention aims at the specific structural design of the catenary insulator, basically has no cleaning dead angle, is convenient to operate, has a high degree of automation, and is safe and reliable.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

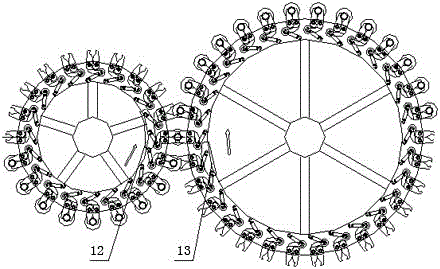

Plastic bottle conveying clamping finger mechanism and operating method thereof

InactiveCN106315488AExtended service lifeEasy to manufacture and processLiquid bottlingTorsion springEngineering

The invention provides a plastic bottle conveying clamping finger mechanism and an operating method thereof. The plastic bottle conveying clamping finger mechanism comprises a plurality of star wheel discs and a plurality of clamping fingers installed on the circumferences of the star wheel discs, wherein when the plastic bottle conveying clamping fingers need clamping, clamping tension springs pull roller shafts, so that driving clamping fingers rotate clockwise, and meanwhile, driven clamping fingers are driven by drive pins to rotate counterclockwise, and thus the plastic bottle conveying clamping fingers are closed; when the plastic bottle conveying clamping fingers need opening, expansion cams press rollers, so that the roller shafts overcome the tension of the clamping tension springs, thus the driving clamping fingers rotate counterclockwise, and meanwhile, the driven clamping fingers are driven by the drive pins to rotate clockwise, and then the plastic bottle conveying clamping fingers are opened. The plastic bottle conveying clamping finger mechanism provided by the invention is long in service life, is safe and reliable, has a hygienic structure, does not have cleaning dead space, is convenient to manufacture and is low in cost.

Owner:南京保立隆包装机械有限公司

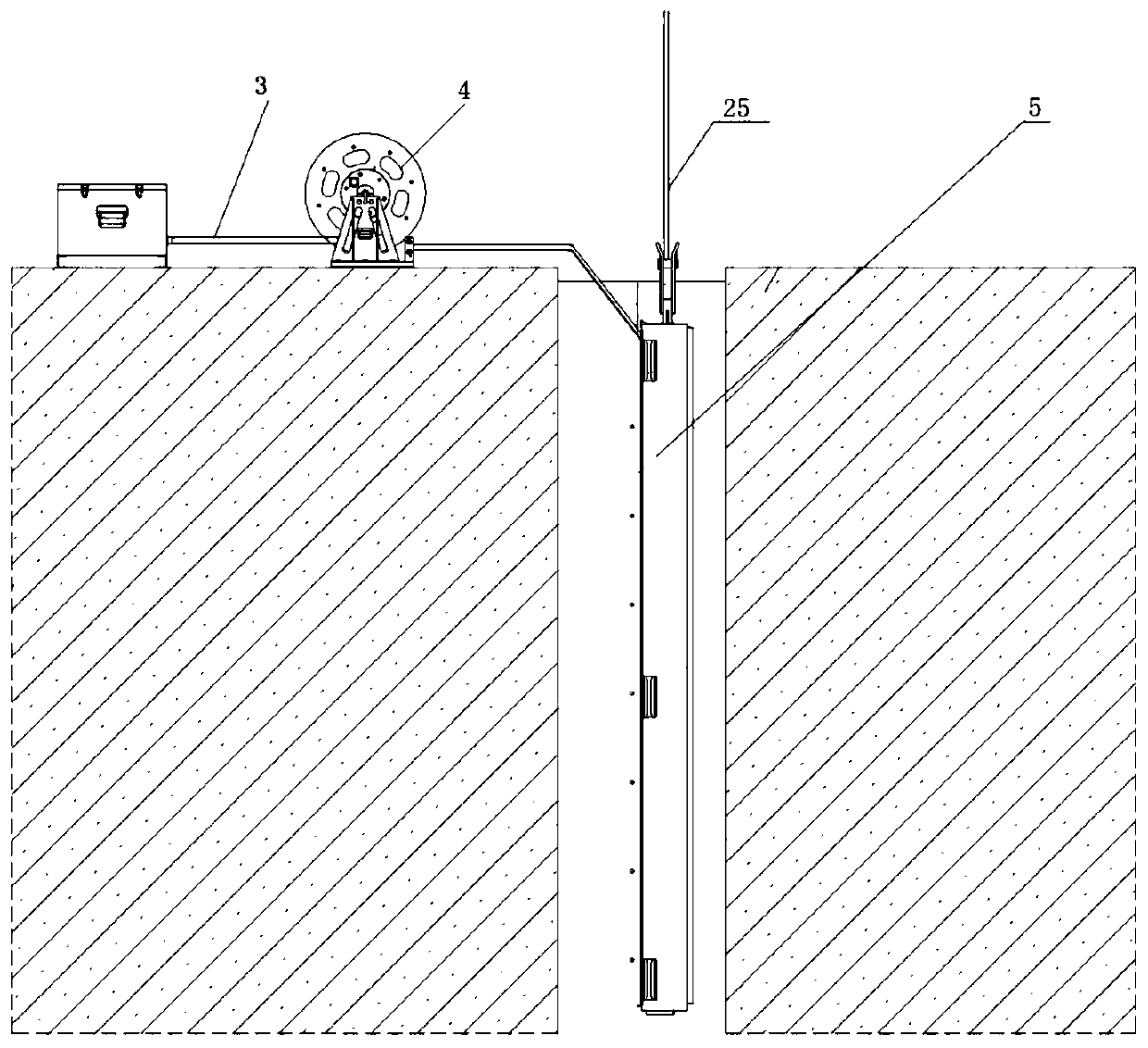

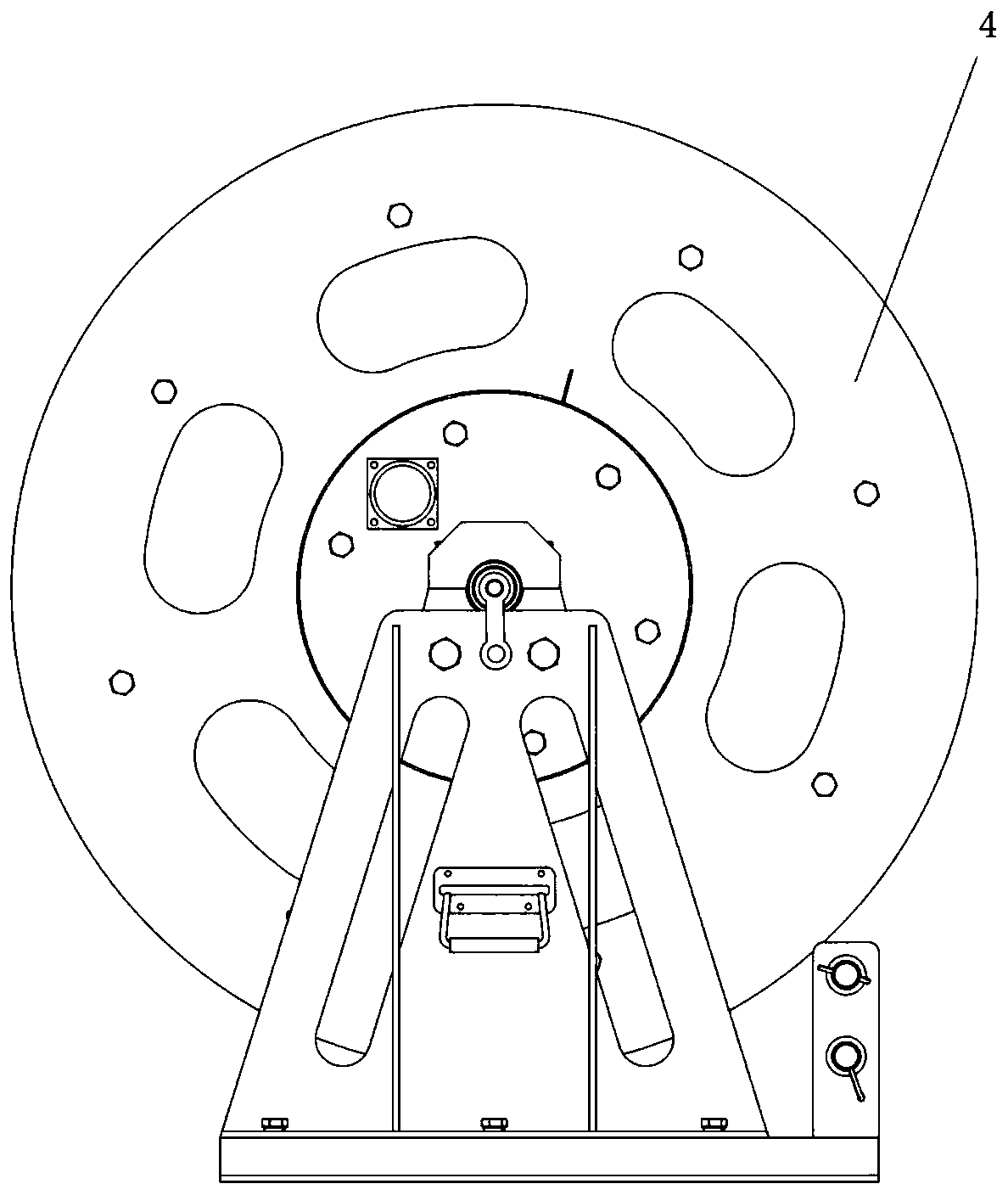

Automatic clearing system for sealing surface of underwater gate

InactiveCN111451200AImprove cleaning efficiencyNo cleaning dead angleCleaning using toolsCleaning using liquidsPortable powerControl theory

The invention discloses an automatic clearing system for a sealing surface of an underwater gate. The automatic clearing system comprises a portable power box, a portable control box, a manual take-upand pay-off device used for taking up and paying off a cable, and an underwater clearing mechanism, wherein the underwater clearing mechanism comprises a clearing mechanism body and a frame body, theclearing mechanism body is movably arranged on the frame body and is connected with the portable power box and the portable control box through the cable, the clearing mechanism body comprises a brush head assembly, a high-pressure water pump, a brush head rotation driving assembly and a brush head feeding driving assembly, the brush head assembly is connected with the brush head rotation drivingassembly and the brush head feeding driving assembly, and aquatic organisms on the sealing face of the underwater gate are cleared through rotation feeding. The automatic clearing system is high in clearing efficiency, free of clearing dead corners and good in clearing effect, and the safety risk of manual clearing is avoided.

Owner:GUANGXI FANGCHENGGANG NUCLEAR POWER +1

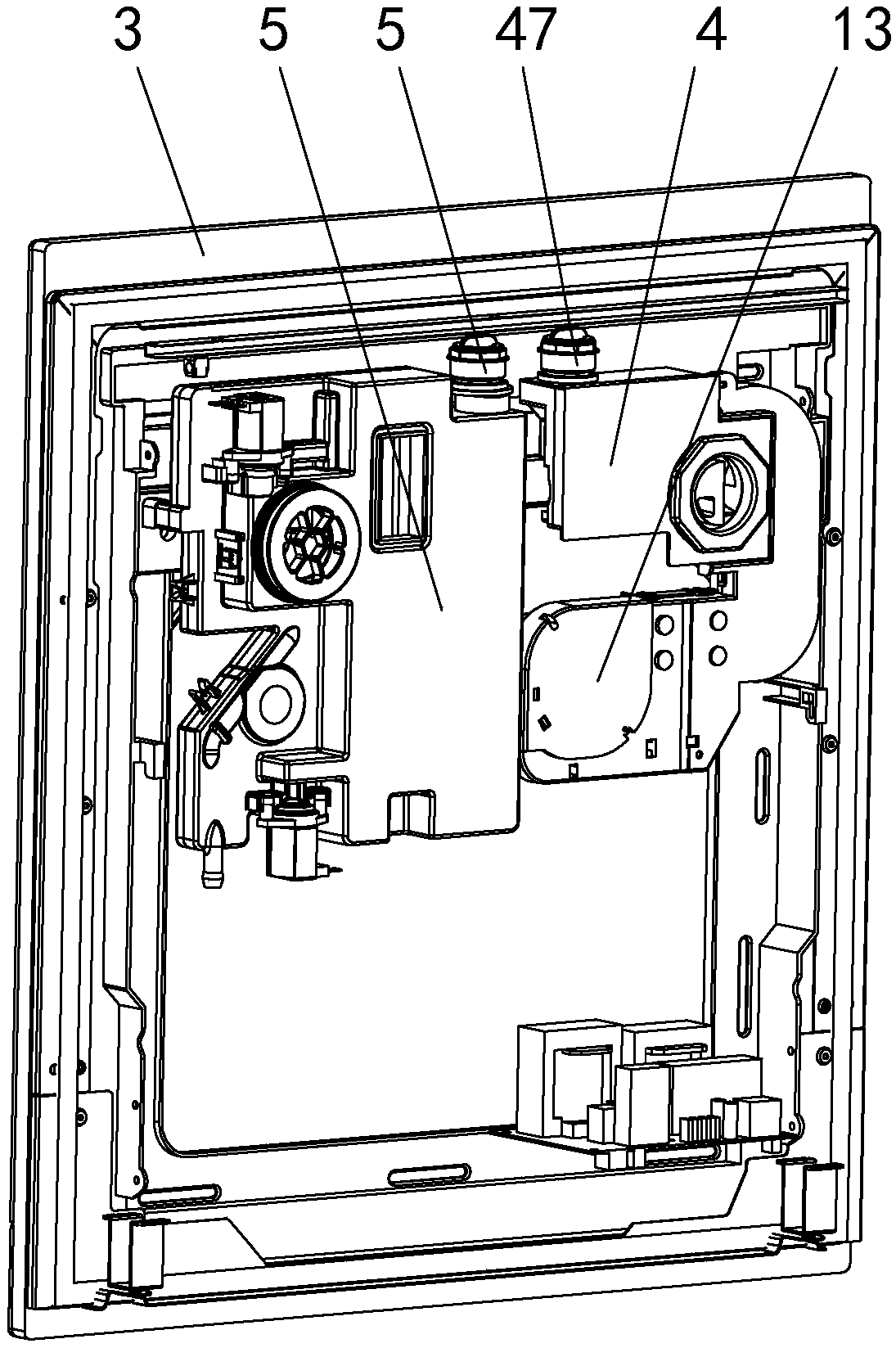

Ultrasonic dish washer

InactiveCN104510427ANo cleaning dead angleImprove cleanlinessTableware washing/rinsing machine detailsUltrasonic generatorEngineering

Disclosed is an ultrasonic dish washer. An ultrasonic transducer is placed in an inner cavity of a dish rack and connected to an ultrasonic generator, liquid filled into the dish rack by the ultrasonic transducer provides ultrasonic vibration energy, dish holding grids are arranged in the dish rack, and the ultrasonic transducer is mounted at the bottom of the dish rack. The ultrasonic dish washer has the advantages that stains on tableware are shaken off by the aid of ultrasonic vibration, the tableware is further cleaned with water, cleaning dead space is omitted, cleanness is high, and the tableware is cleaner by cleaning.

Owner:南京乐汉东智能设备有限公司 +1

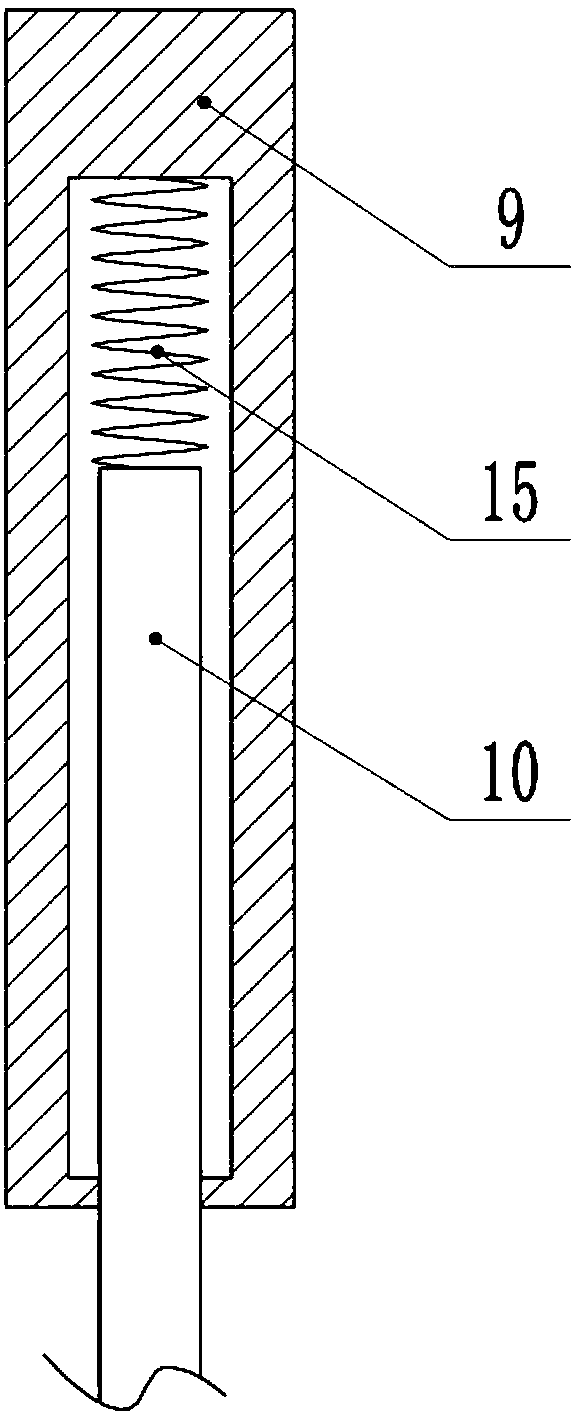

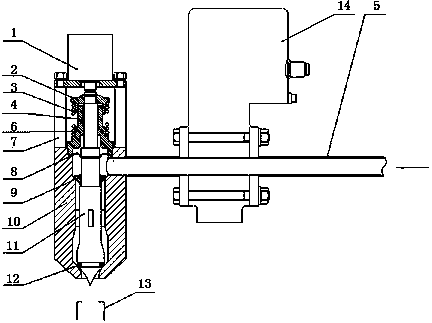

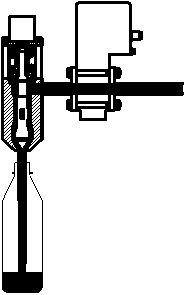

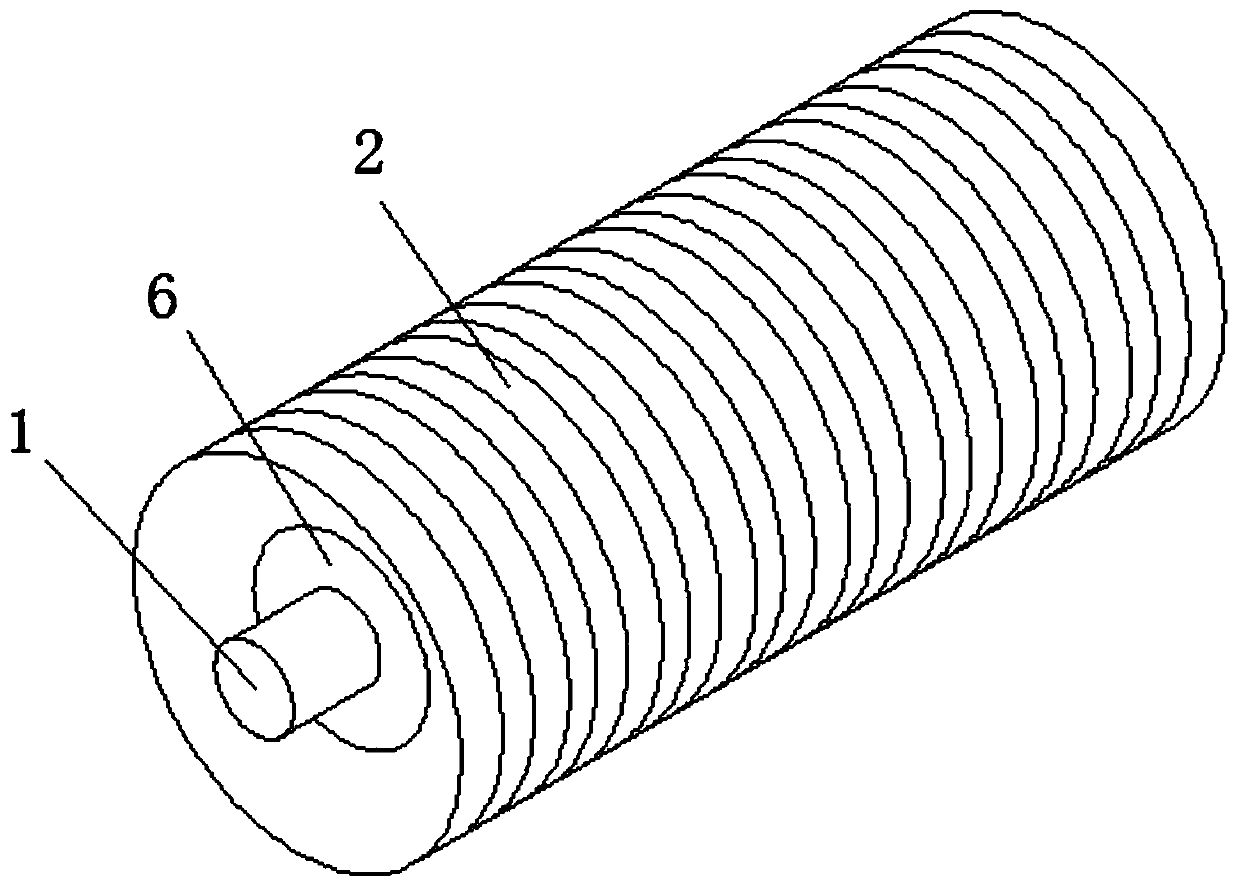

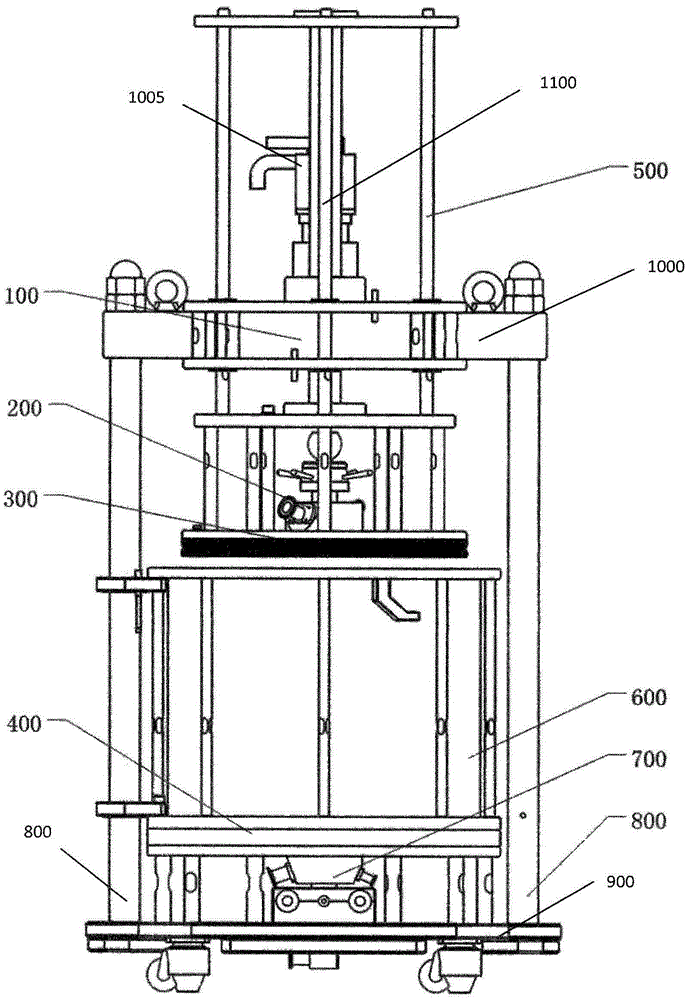

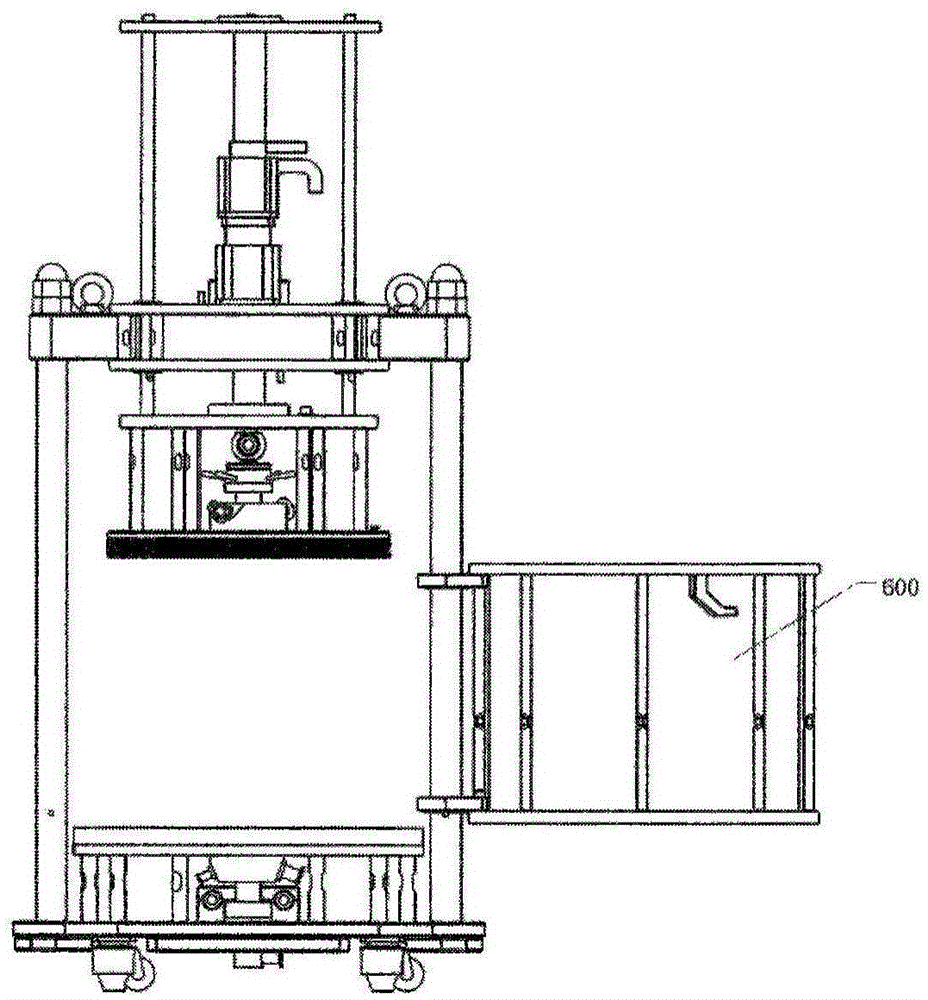

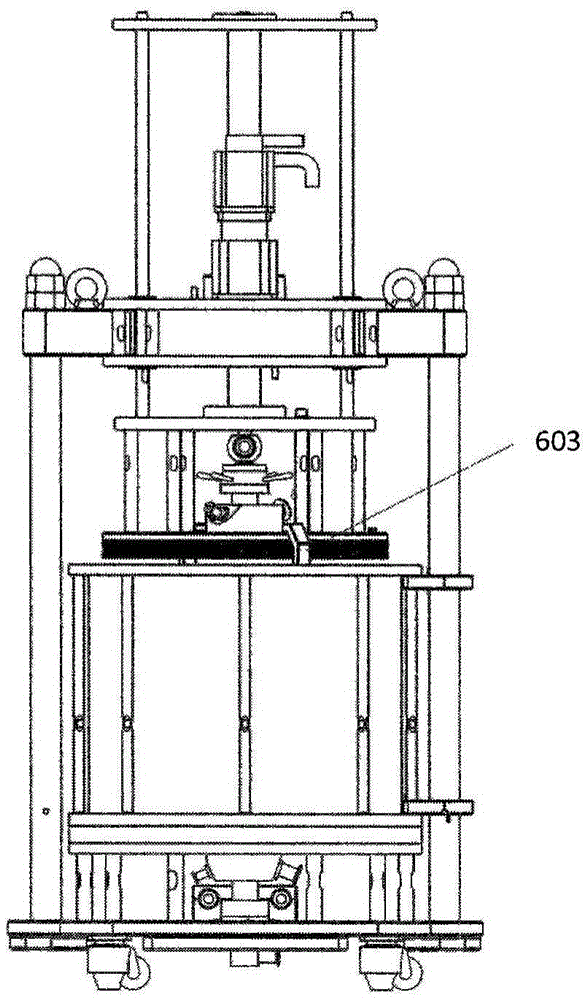

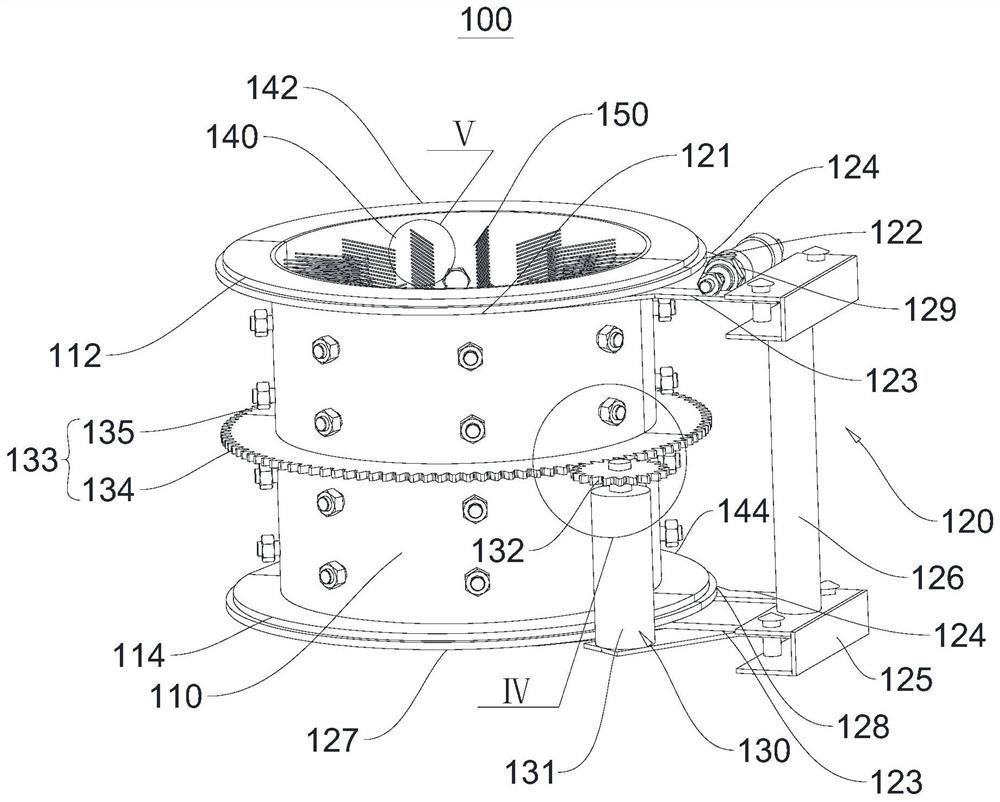

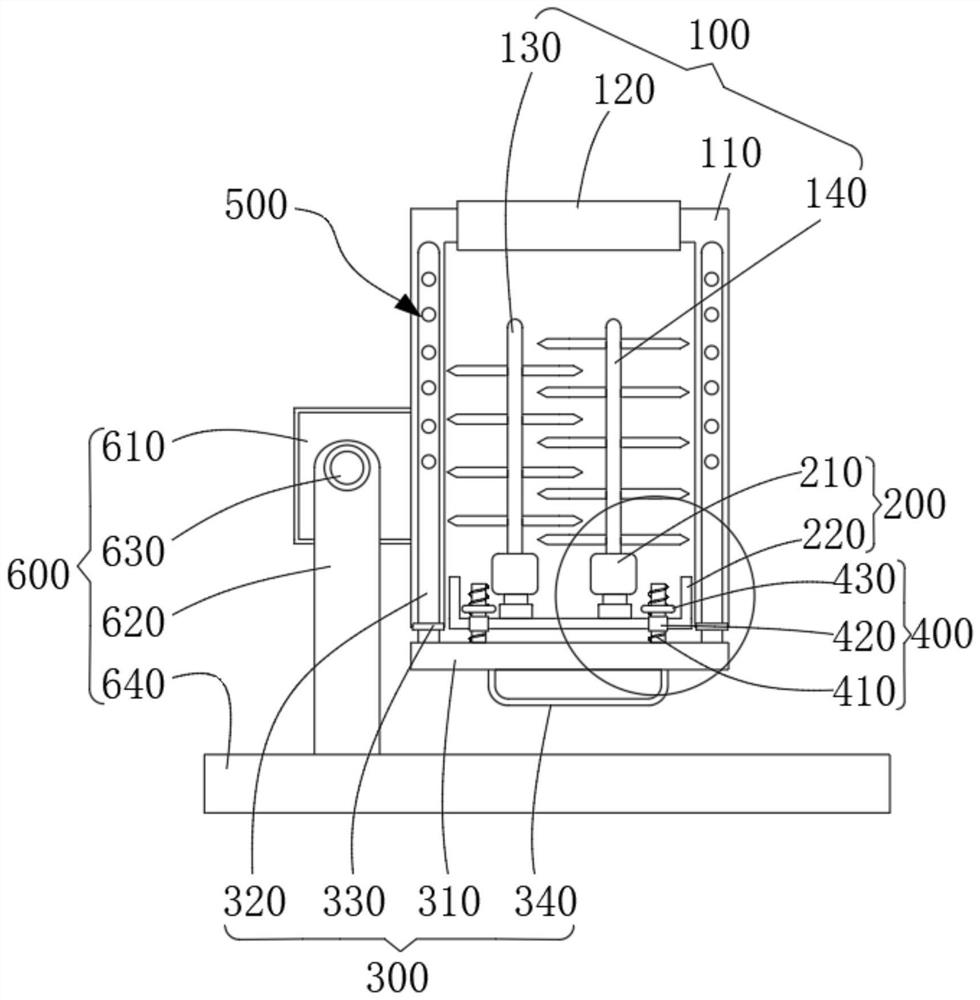

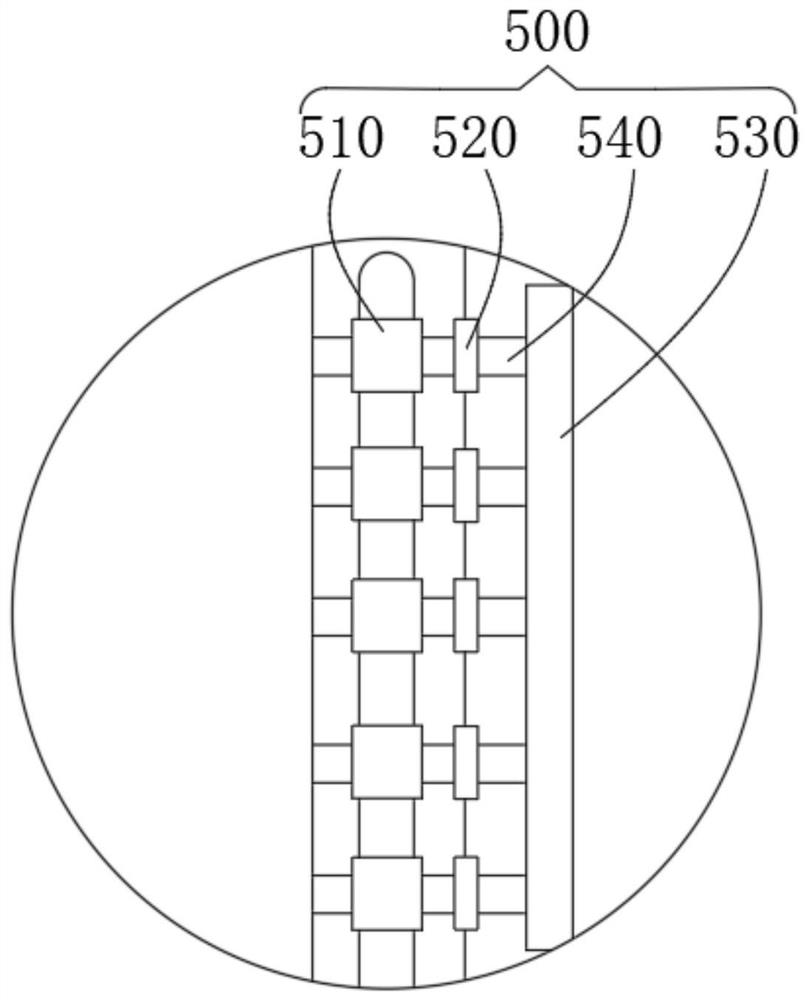

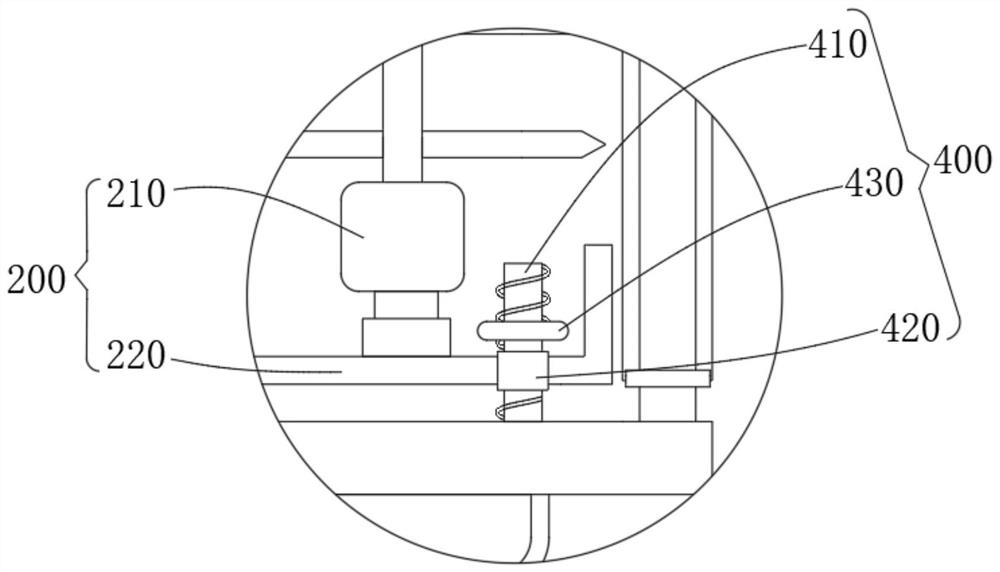

A fully automatic chromatographic column

InactiveCN104307207BSimple structureImprove reliabilitySolid sorbent liquid separationSprayerEngineering

A fully-automatic chromatographic column, comprising a liftable column head portion (300), a tubular column portion (600), a drive portion (100) and a fixed chassis (900); a top plate (1000) is fixedly connected to the fixed chassis (900) via two support rods (800) to form a box-shaped fixed structure, the box-shaped fixed structure providing overall support; the automatic chromatographic column further comprises a multi-channel upper sprayer portion (200); the drive portion (100) is fixedly connected to the top plate (1000), allowing automatic lifting of the column head portion (300) installed at the lower end of a screw (1100); a moving mechanism connects the tubular column portion (600) to the support rods (800) or to other components fixed relative to the fixed chassis (900), allowing the tubular column portion (600) to move horizontally relative to the fixed chassis (900) under the action of the moving mechanism.

Owner:YUANCHUANG JINGKE BIOTECH CHANGSHA CO LTD

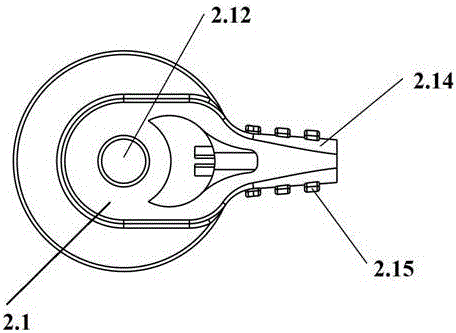

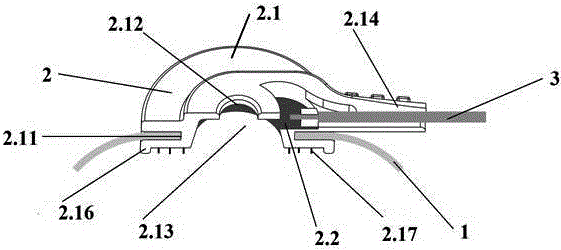

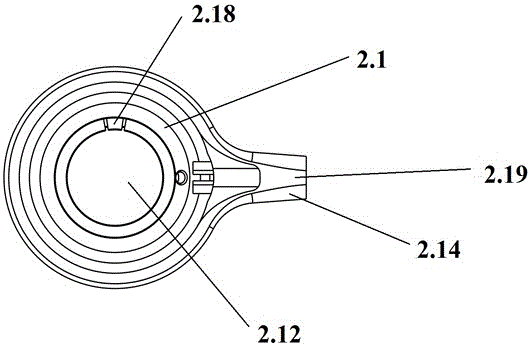

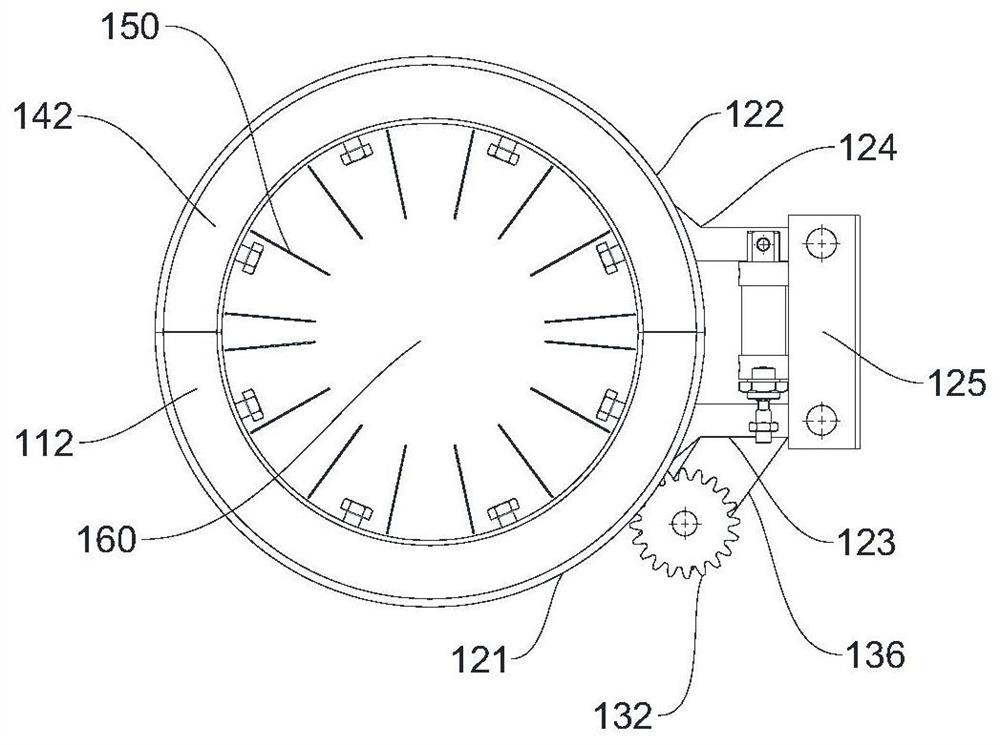

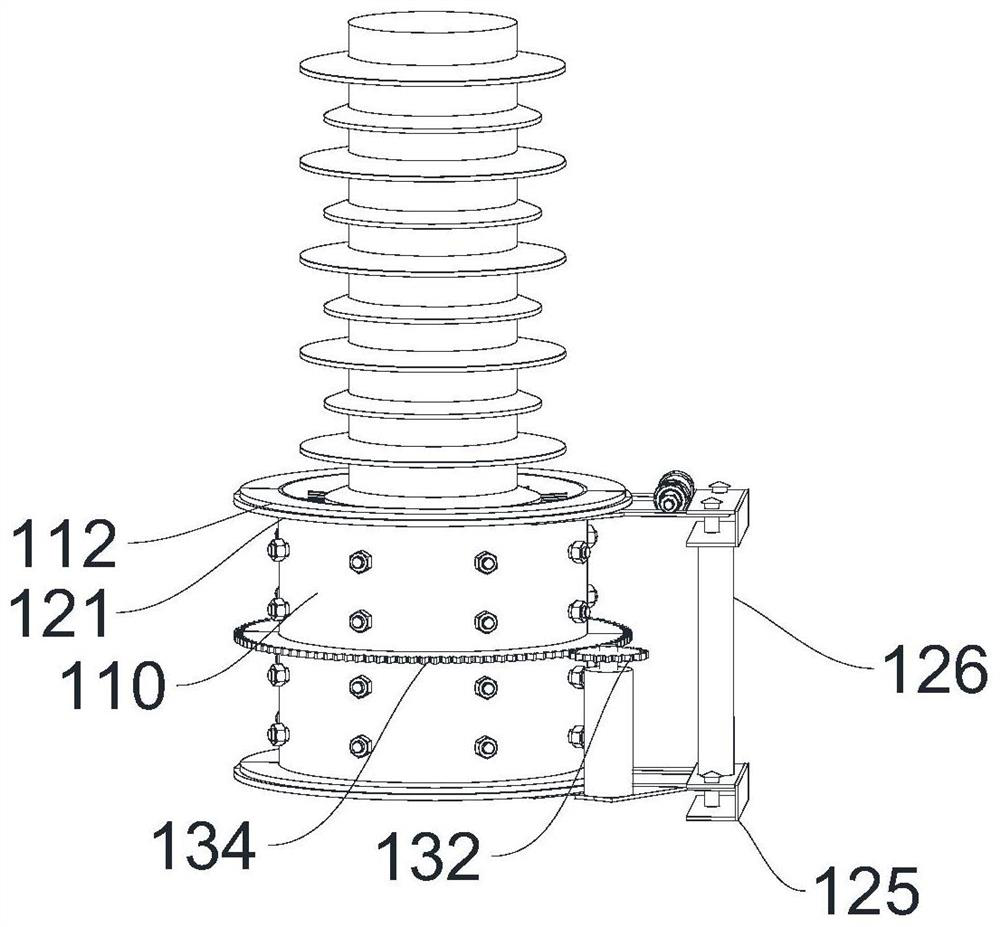

A cleaning device and power equipment

ActiveCN109821790BEasy to cleanNo cleaning dead angleCleaning using toolsCleaning using liquidsElectric power equipmentEngineering

The invention provides a cleaning device and power equipment and relates to the field of cleaning of power external insulation equipment. The cleaning device comprises a first semi-cylinder body, a first drive piece, a second drive piece and a second semi-cylinder body matched with the first semi-cylinder body. The inner walls of the first semi-cylinder body and the second semi-cylinder body areboth provided with multiple cleaning pieces. The first drive piece is used for enabling the first semi-cylinder body and the second semi-cylinder body to be relatively closed or separated. When in therelatively closed state, the first semi-cylinder body and the second semi-cylinder body form a cleaning space used for containing devices to be cleaned, so that the cleaning pieces are in contact with the devices to be cleaned in the cleaning space. The second drive piece is used for driving the first semi-cylinder body and the second semi-cylinder body to rotate. The power equipment comprises insulators and the cleaning device. In the use process of the power equipment, the cleaning device can rapidly and conveniently clean the insulators and effectively avoid a cleaning dead angle.

Owner:BEIJING GUODIAN FUTONG SCI & TECH DEV

Semi-automatic rubber cork rinsing machine

InactiveCN100496771CClean upImprove cleaning efficiencyCleaning using liquidsSemi automaticEngineering

The invention relates to a semi-automatic plug poacher, used to scavenge the medical large transfusion butyl rubber plug. It comprises: a frame (5), a poaching cylinder (19), a lift basket (8), a lift cylinder (1), a transverse cart (3) and a transverse cylinder (2). Wherein, the poaching cylinder is at the middle of lower part of frame; the wall of poaching cylinder has water inlet tube (14) at its lower side, while its bottom has water outlet tube (13); the lower part of poaching cylinder has air injection coil tube (17); the upper cylinder wall has annular overflow groove (12); the lift basket (8) is inside the poaching cylinder (19); two sides of the top of frame (5) have the track (4) of cart; the transverse cart (3) is on said track (4); the lift cylinder (1) is fixed at the center of transverse cart (3), while its piston rod is connected to the top of lift basket (8); the transverse cylinder (2) is fixed at the back of the top of frame (5), while its piston rod is connected to the back of transverse cart (3). The inventive plug can float upwards and turn over inside the lift basket, while there is no space between plugs; it has high clean efficiency, with simple structure, non cleaning dead angle, and lower energy consumption.

Owner:JIANGSU HUA LAN PHARMA NEW MATERIALS LTD BY SHARE LTD

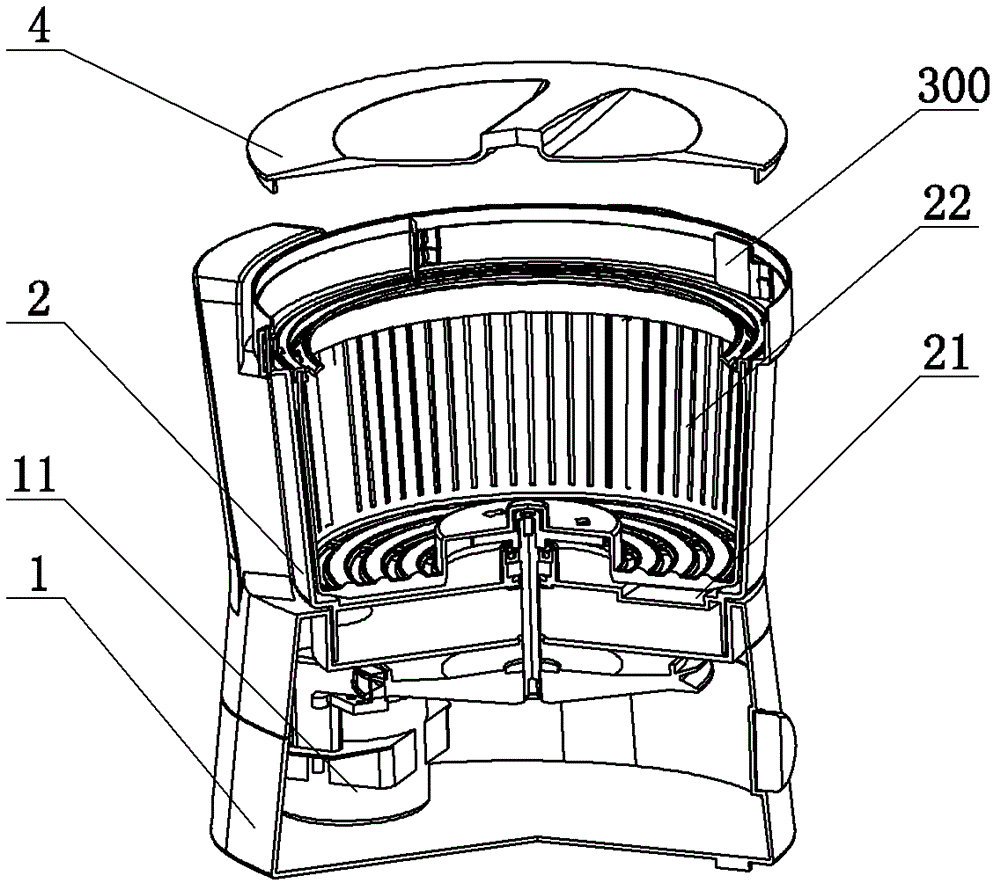

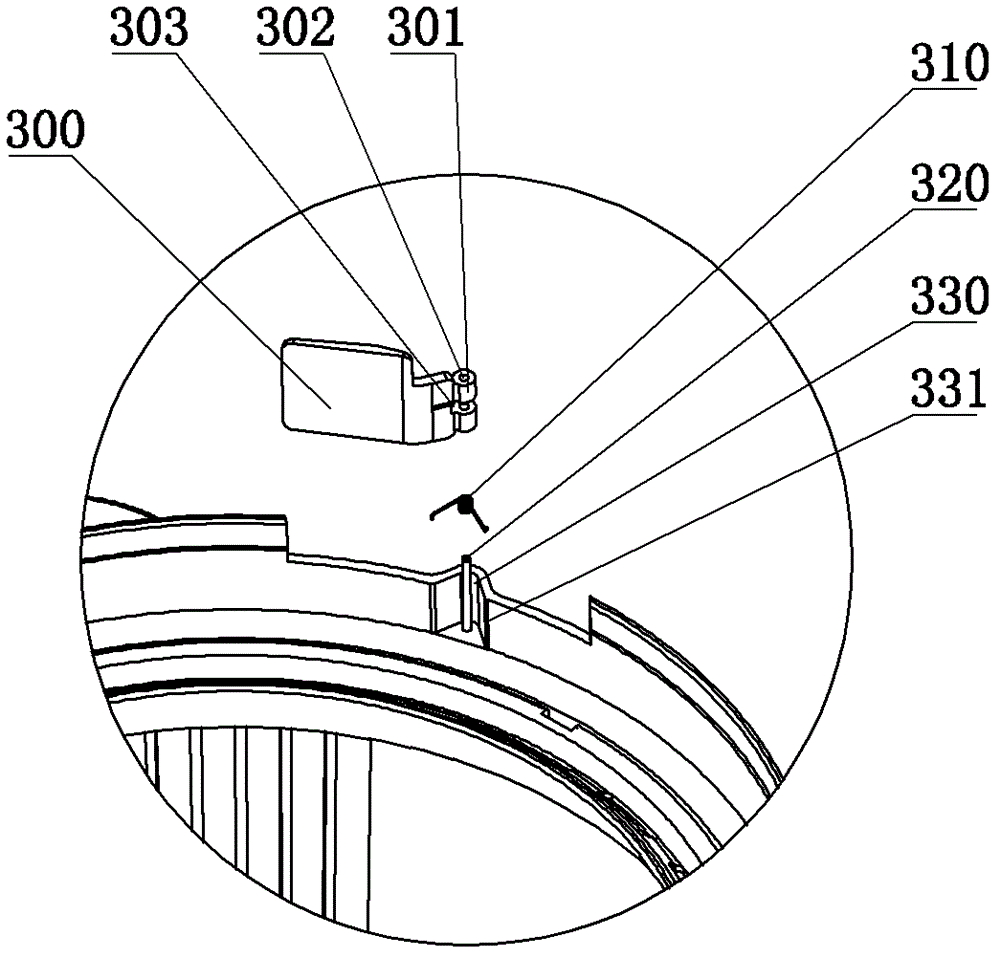

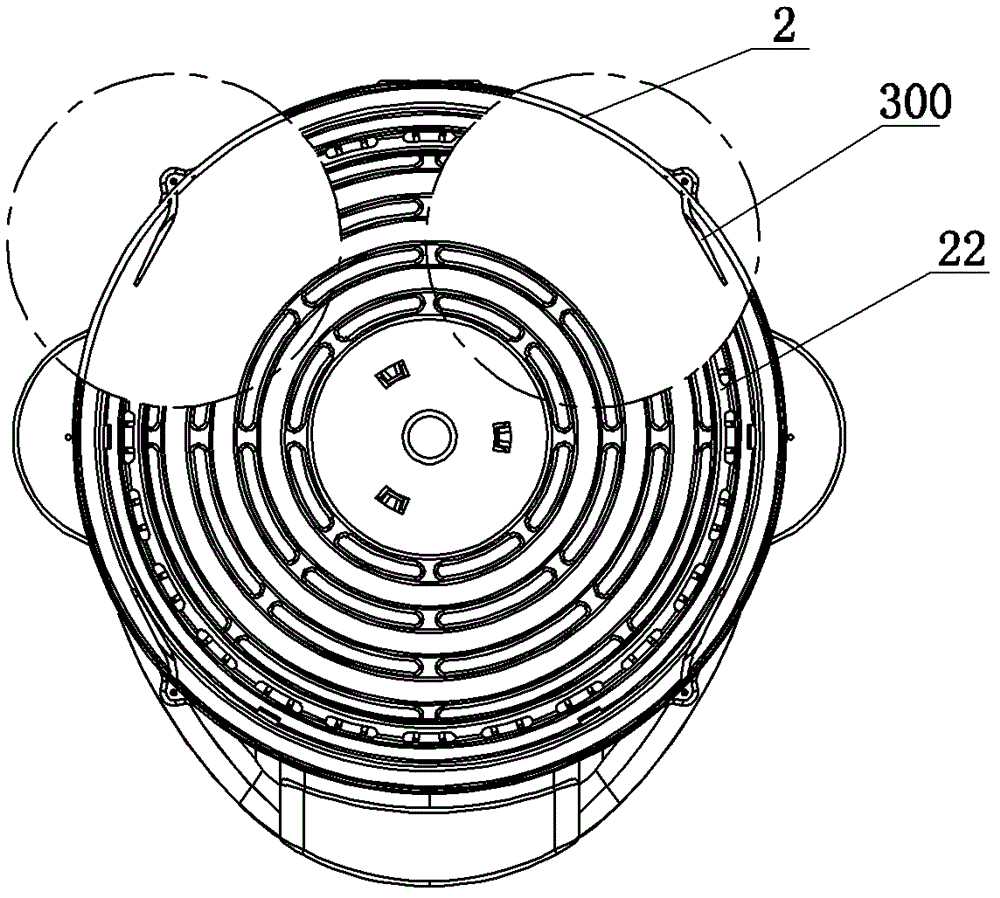

Washer easy for washing fruits and vegetables

ActiveCN102578931BEven and effective cleaningClean evenly and thoroughlyKitchen equipmentWater flowEngineering

A washer easy for washing fruits and vegetables comprises a body, a washing barrel, a washing basket and a top cap, wherein the washing basket is arranged in the washing barrel, and the top cap caps the mouth of the washing barrel. The washer is characterized by further comprising a turbulator which acts under impaction of water flow and extends into the washing barrel to realize turbulence. By the aid of the turbulator, water in the washing barrel is turbulent during washing and capable of washing fruits and vegetables uniformly and effectively. During operation, the turbulator extends into the washing barrel to realize water turbulence under action of water flow, is excellent in turbulence effect, and is attached onto the washing barrel and occupies no space and has no affection onto use and storage of the washing basket when in an idling state. In addition, the turbulator has no affection on the appearance of the washer, and accordingly the washer is smaller in structure.

Owner:JOYOUNG CO LTD

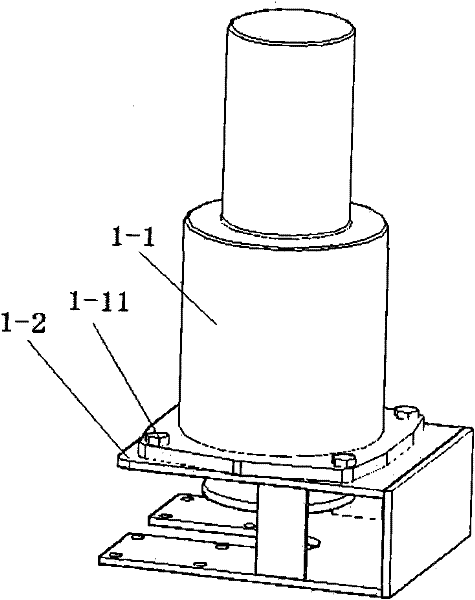

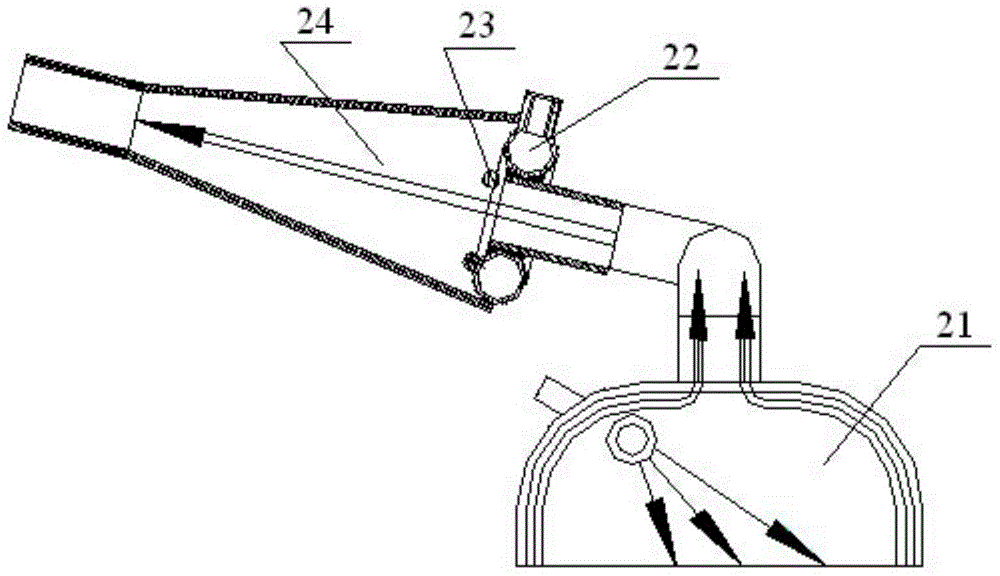

Dry ice cleaning vehicle of electrical equipment external insulation

ActiveCN101716904BExtended service lifeAbrasiveness of dry ice particlesItem transportation vehiclesCleaning processes and apparatusEconomic benefitsElectrical devices

The invention relates to a dry ice cleaning vehicle of electrical equipment external insulation, belonging to the cleaning equipment of the electrical equipment external insulation. A lifter (7) is fixed on a vehicle body (8); the top end of the lifter (7) is provided with a lift platform (3) on which an insulation telescopic arm (2) is arranged; the telescopic end of the insulation telescopic arm (2) is connected with an automatic dry ice particle track sprinkler head assembly (1); and a dry ice conveying insulation duct (4-1) on a dry ice conveying device (4) is communicated with a sprinkler head (1-8) on the automatic dry ice particle track sprinkler head assembly (1). The invention has the advantages of compact structure, larger inclusive area for cleaned objects, almost no cleaning dead corner, large one-step cleaning surface, high cleaning quality, convenient operation and high dirt removal efficiency, thereby being especially suitable for the cleaning work of vertically arranged cylindrical insulating equipment, such as insulators or sleeve pipes. The invention can be used as high-efficiency cleaning equipment for safe electric power production and electric power supply guarantee and has favorable social and economic benefits.

Owner:CENT CHINA GRID +1

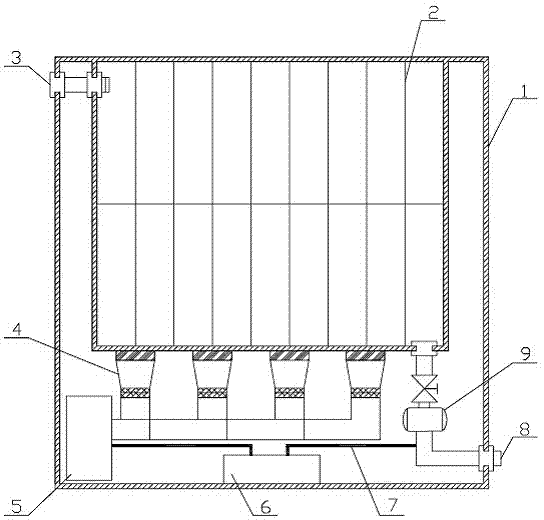

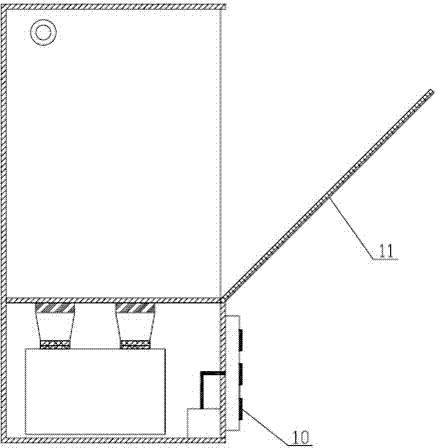

An oil cylinder cylinder cleaning machine with a cleaning liquid self-dispensing device

ActiveCN105798030BEasy to cleanImprove cleaning efficiencyHollow article cleaningDrying gas arrangementsFuel tankSewage

The invention provides an oil cylinder barrel cleaning machine with a cleanout fluid self-preparing device. The oil cylinder barrel cleaning machine comprises a drive part, a cleaning part, a cleanout fluid supply part, a base and a waste water collecting and processing device. The cleaning part comprises a stand column, a cleaning brush telescopic device, a spherical cleaning brush, a fixing tank, drying devices and an inner cleaning brush. The stand column is fixedly connected with the base. The cleaning brush telescopic device is fixedly connected with the upper end of the stand column. The spherical cleaning brush and the fixing tank are located at the lower end of the cleaning brush telescopic device and fixedly connected with the cleaning brush telescopic device. The spherical cleaning brush is located in the fixing tank and movably connected with the fixing tank. The drying devices are located on the two sides of the fixing tank and fixedly connected with the fixing tank. The inner cleaning brush is fixedly connected with the stand column. The cleanout fluid supply part is provided with the cleanout fluid self-preparing device, and the cleanout fluid self-preparing device comprises a cleaning agent storage bottle, a cleaning agent control valve, a solvent control valve, a cleanout fluid mixing tank and a flow-out port. The oil cylinder barrel cleaning machine is high in cleaning efficiency, good in cleaning effect and capable of achieving automatic cleanout fluid preparing, and automatic operation can be better achieved.

Owner:江苏昊阳传动科技有限公司

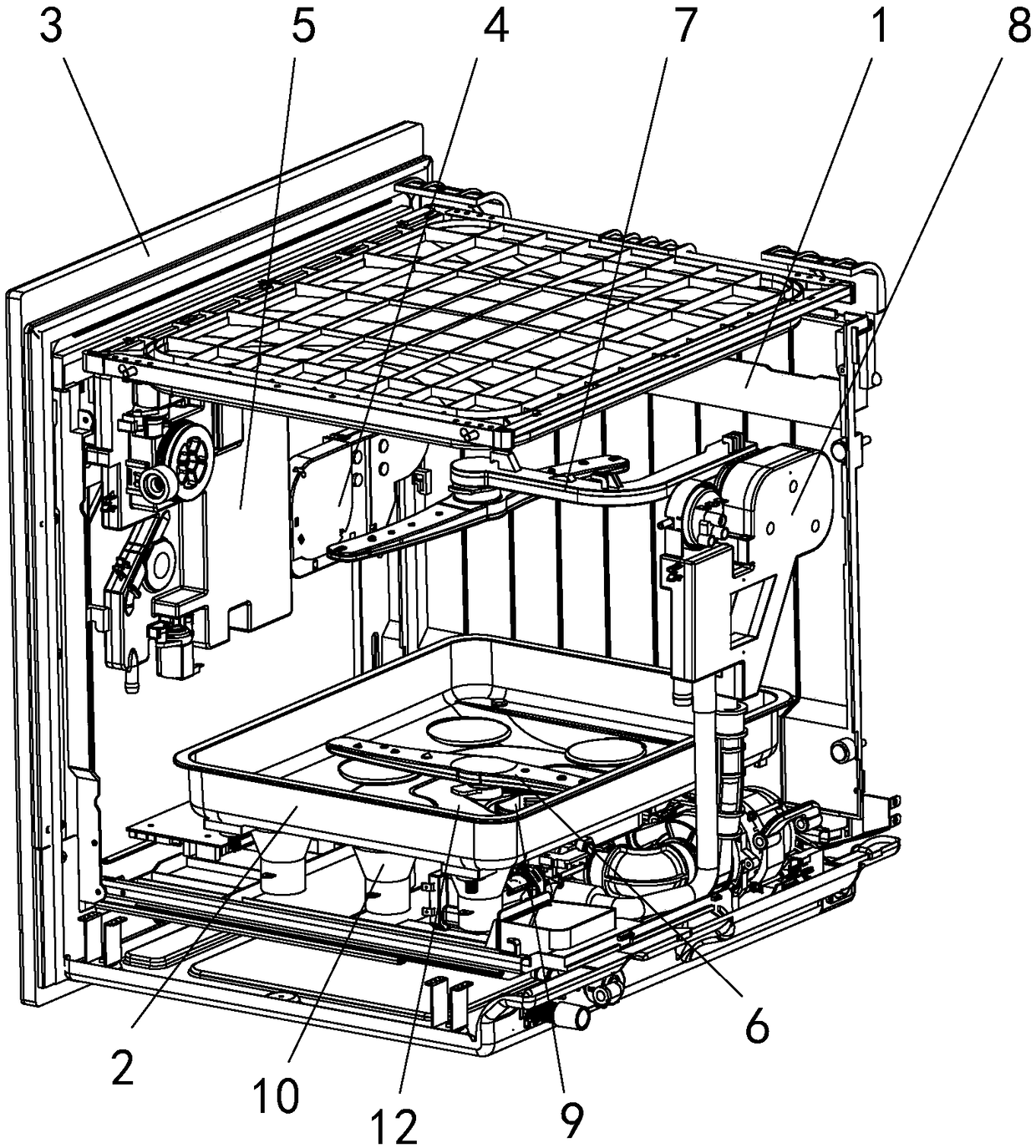

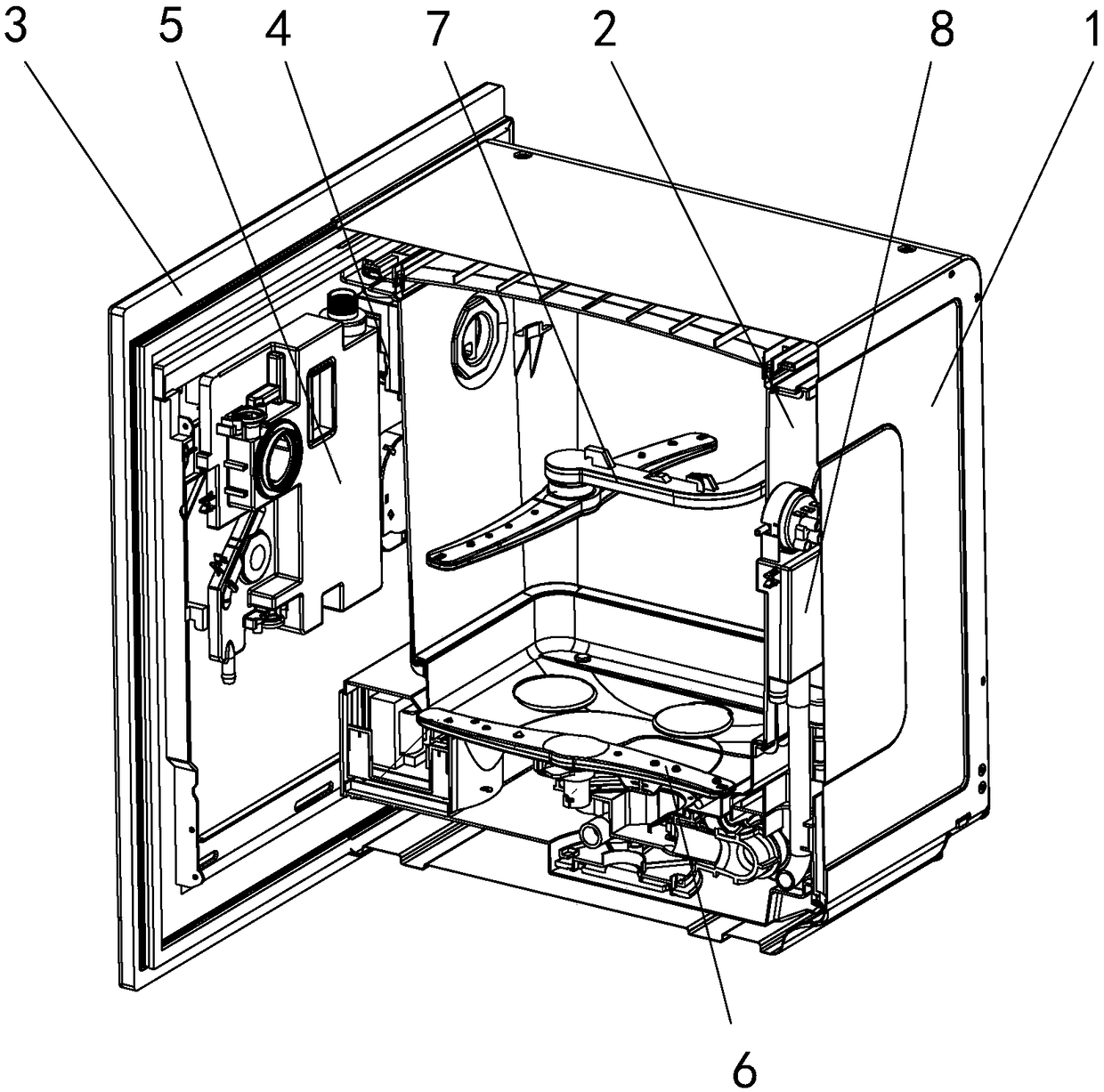

Ultrasonic dishwasher

PendingCN108903875AAvoid secondary pollutionNo cleaning dead angleTableware washing/rinsing machine detailsHome appliance efficiency improvementUltrasonic generatorPush and pull

The invention discloses an ultrasonic dishwasher. The ultrasonic dishwasher comprises a casing, a inner container mounted in the casing, and a door connected to the inner container; the inner container can horizontally move in the casing by pushing and pulling the door; a lower spraying arm located on the bottom of the inner cavity and an upper spraying arm located on the top of the inner cavity are arranged in the inner container; a drainage circulation device connected to the upper spraying arm is arranged on a back side wall of the inner container; ultrasonic generators located at the bottom of the inner container are arranged in the casing; in use, the ultrasonic waves generated by the ultrasonic generators arranged on the bottom of the inner container are used to peel off the stain ondishes, spraying water of the upper spraying arm and the lower spraying arm are used to wash the dishes; the washing water is recycled by the drainage circulation device, and oil on a surface of thewashing water is filtered to avoid secondary pollution of the washed dishes. The dishwasher does not have cleaning dead angles, has high cleanness degree, and can ensure cleaner tableware.

Owner:广东海伦宝家用电器有限公司

Food crusher capable of effectively guaranteeing edible safety and use method thereof

The invention discloses a food crusher capable of effectively guaranteeing edible safety. The food crusher capable of effectively guaranteeing edible safety comprises a crusher assembly, a driving assembly, a detaching assembly and a connecting assembly, wherein the crusher assembly comprises a crushing treatment frame, a charging port formed in the top surface of the crushing treatment frame, as well as a first rotating shaft and a second rotating shaft which are arranged in the crushing treatment frame; and the driving assembly comprises a driving motor connected with the second rotating shaft, and a concave storage frame connected with the driving motor. A use method of the food crusher capable of effectively guaranteeing edible safety comprises the following steps of S1, S2 and S3. According to the invention, through mutual cooperation of a detaching structure and a connecting structure, the effect of quickly moving crushing blades and the motor out of the treatment frame integrally is achieved, so that no cleaning dead angle is ensured during cleaning, the cleaning speed is increased, the cleanliness is improved, and the food crushing quality and the food safety are ensured; and moreover, all the blades can be integrally detached, washed and replaced quickly through the connecting structure, so that the replacement speed is increased.

Owner:姜棋桐

Integrated high-pressure cleaning and recovering cleaning tanker

InactiveCN104923506ASave waterEasy to moveCleaning using liquidsBiochemical engineeringHigh pressure

The invention discloses an integrated high-pressure cleaning and recovering cleaning tanker. The integrated high-pressure cleaning and recovering cleaning tanker comprises a tanker body, and a cleaning and recovering device, a high-pressure pump and a filtering and recovering water tank which are arranged on the tanker body, wherein the cleaning and recovering device, the high-pressure pump and the filtering and recovering water tank are respectively communicated; the high-pressure pump transports water into the cleaning and recovering device, and the cleaning and recovering device recovers and filters the used water through the filtering and recovering water tank; because the whole integrated high-pressure cleaning and recovering cleaning tanker is arranged on one tanker, so that the cleaning tanker is convenient to move, is suitable for flow and cycle operation in various places, and is very convenient. The cleaning tanker disclosed by the invention has multiple functions, so that a great quantity of tanker purchasing funds are saved, special operations can also be performed, the cleaning range is extended, and a cleaning dead angle does not exist; the cleaning efficiency is improved, the cost expense is reduced, the structure is simple, the practicality is high, and the cleaning tanker is suitable for generalization and application in relevant technical fields.

Owner:TIANJIN TONGJIE HIGH PRESSURE PUMP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com