Crankshaft surface cleaning device

A surface cleaning and crankshaft technology, applied in cleaning methods and utensils, cleaning methods using tools, cleaning methods using liquids, etc., can solve the problems of incomplete cleaning, light labor, etc., and achieve no cleaning dead ends and comprehensive cleaning , good cleaning effect

Pending Publication Date: 2018-08-17

重庆伟福机械有限公司

View PDF0 Cites 9 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The engine crankshaft needs to be cleaned after manufacture and before assembly to ensure good work after assembly to the engine. Now it is usually cleaned manually, but manual cleaning has the disadvantages of incomplete cleaning and light labor.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

[0016] The present invention will be described in further detail below by means of specific embodiments:

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

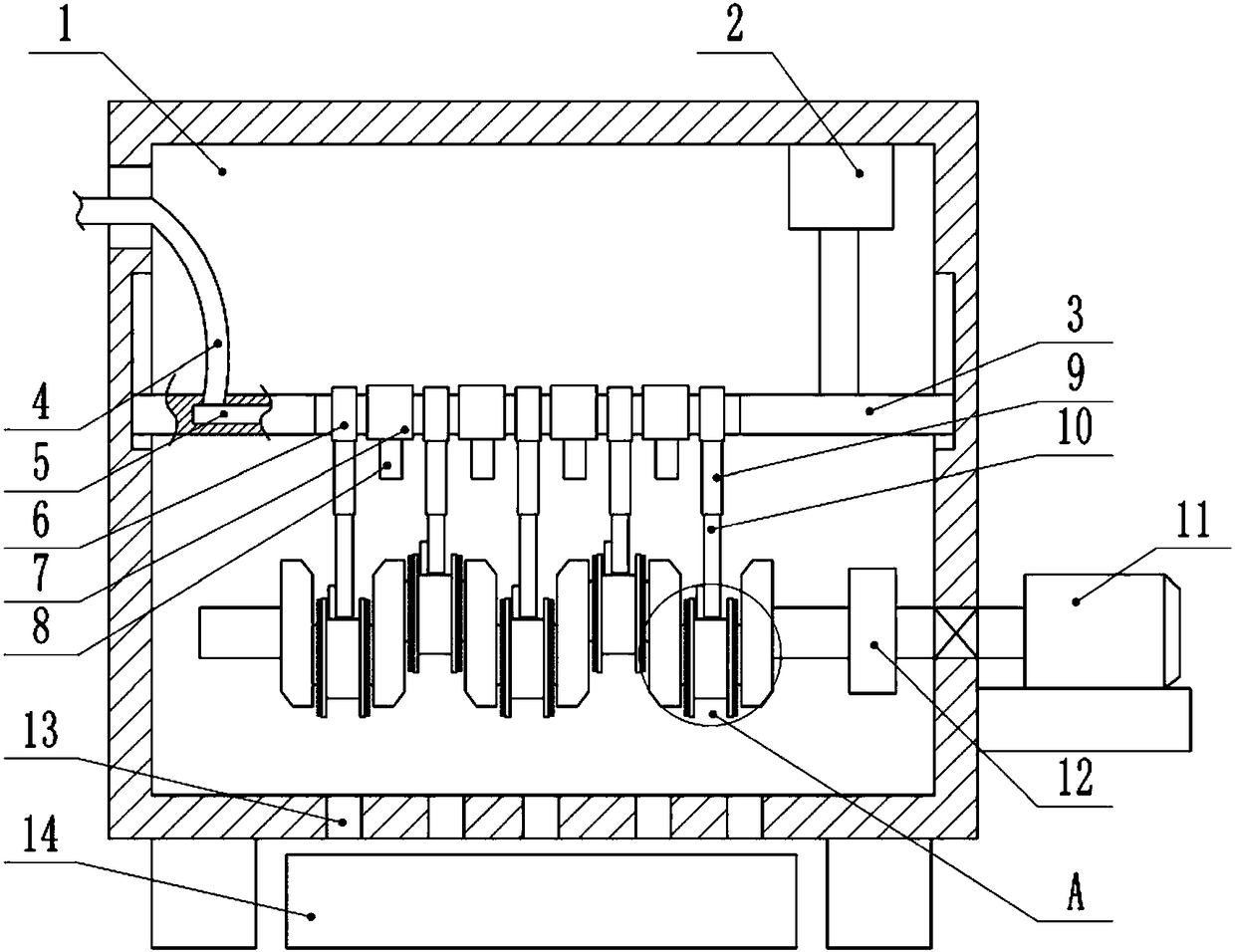

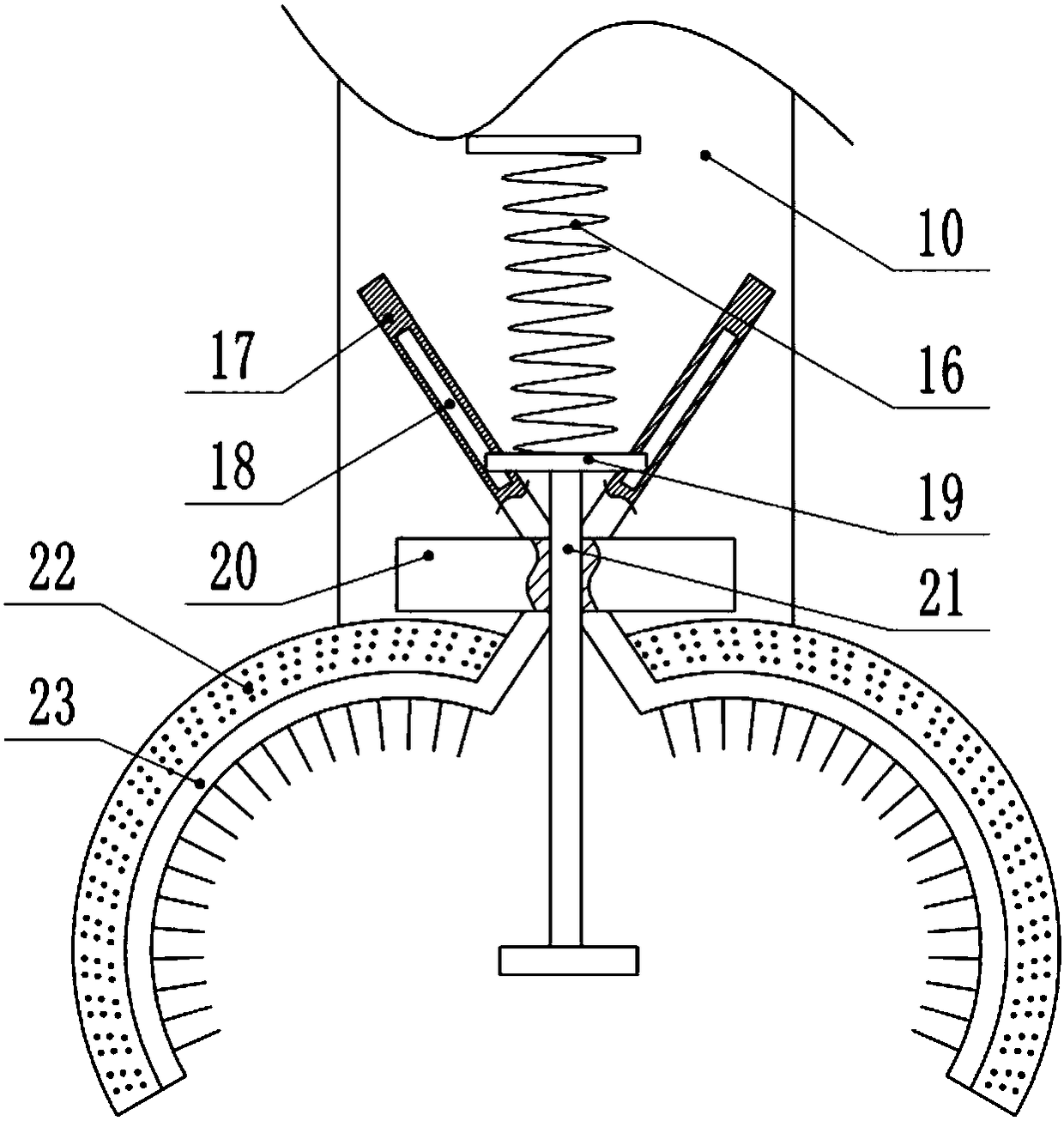

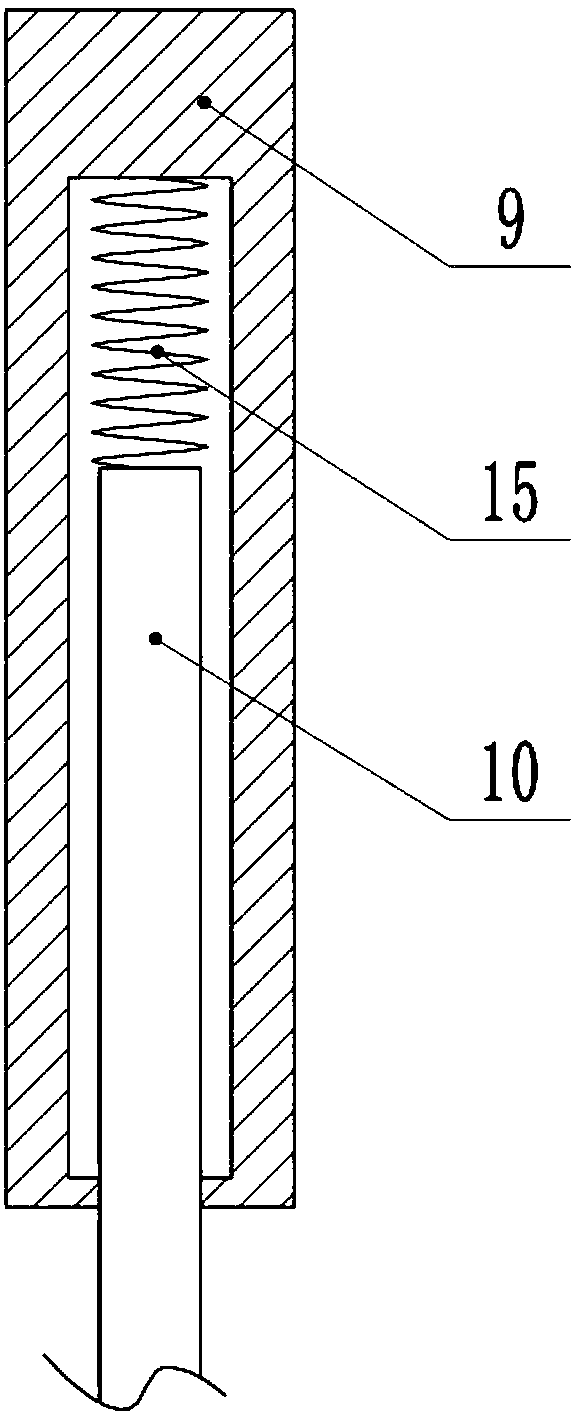

The invention belongs to the technical field of cleaning equipment, and particularly discloses a crankshaft surface cleaning device. The crankshaft surface cleaning device comprises a box body. The box body is internally provided with a clamping mechanism for clamping a crankshaft, a power mechanism for driving the clamping mechanism to rotate, and a cleaning mechanism for cleaning the crankshaft.The cleaning mechanism comprises a horizontally-arranged support rod, a lifting mechanism for driving the support rod to lift and lower is arranged on the box body, the support is provided with a plurality of screws, and the screws are provided with elastic telescopic rods. Screw holes matched with the screws are formed in the upper ends of the elastic telescopic rods, and holding claw mechanismscapable of holding a journal of the crankshaft are arranged at the lower ends of the elastic telescopic rods. Brushing bristles are arranged on the inner sides and the left and right sides of the holding claw mechanisms, and the box body is internally provided with a plurality of spraying mechanisms for spraying water on the crankshaft. The crankshaft is cleaned by the brushing bristles moving back and forth, the cleaning dead angle is avoided and the cleaning effect is better.

Description

technical field [0001] The invention belongs to the technical field of cleaning equipment, in particular to a crankshaft surface cleaning device. Background technique [0002] The crankshaft is the most important component in the engine. It bears the force transmitted by the connecting rod and converts it into torque through the crankshaft output and drives other accessories on the engine to work. The crankshaft is subjected to the joint action of the centrifugal force of the rotating mass, the periodically changing gas inertial force and the reciprocating inertial force, so that the crankshaft is subjected to the bending torsional load. Therefore, the crankshaft is required to have sufficient strength and rigidity, and the surface of the journal needs to be wear-resistant, work evenly, and have good balance. The engine crankshaft needs to be cleaned after manufacture and before assembly to ensure good work after assembly to the engine. Nowadays, it is usually cleaned manu...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): B08B3/02B08B1/02B08B3/08B08B13/00

CPCB08B3/022B08B3/08B08B13/00B08B1/12B08B1/20

Inventor 黄伟

Owner 重庆伟福机械有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com