Water storage type cleaning method applicable to electrostatic filter

A filter and water storage technology, applied in the direction of electrostatic separation, electrode cleaning, etc., can solve the problems of low cleaning efficiency, large water consumption, and large space, and achieve high cleaning efficiency, reduced water consumption, and high cleanliness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

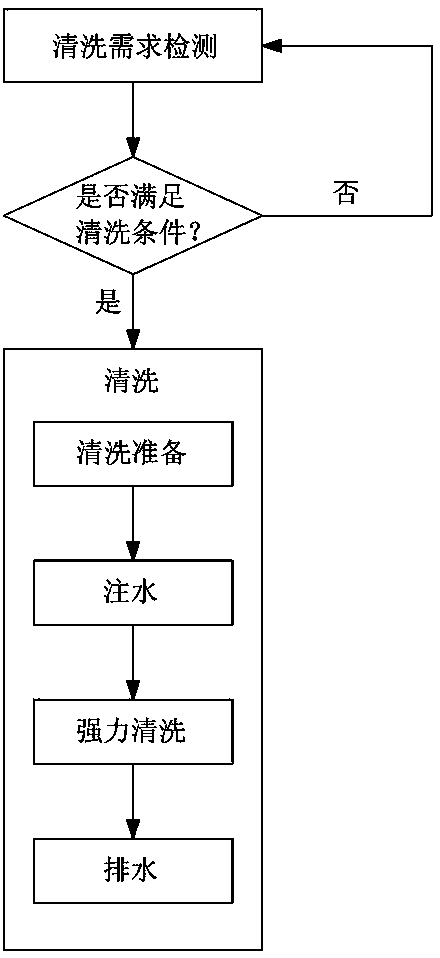

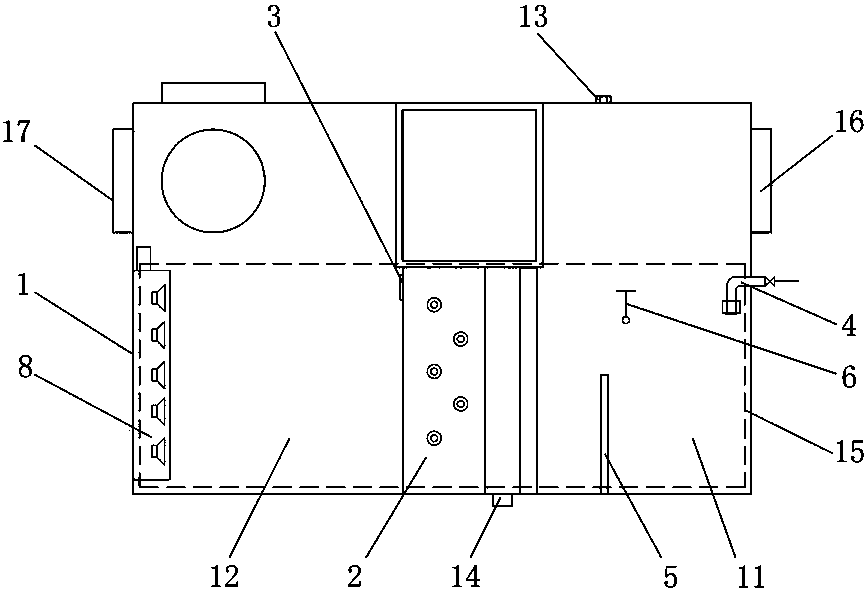

[0027] The water storage type cleaning method that is used for electrostatic filter of the present invention is by such as figure 2 The water storage type electrostatic filter shown is realized, the water storage type electrostatic filter includes a box body 1, an electrostatic precipitator assembly 2 and a cleaning demand detection device 3, the electrostatic precipitator assembly 2 is installed in the box body 1, and the box body The inner cavity of 1 is provided with a water storage area 15 for immersing the electrostatic precipitator assembly 2. The electrostatic precipitator assembly 2 divides the inner cavity of the cabinet 1 into a horizontally arranged air inlet chamber 11 and an exhaust chamber 12. The air inlet 16 communicating with the air chamber 11 and the air outlet 17 communicating with the exhaust chamber 12, the air inlet 16 and the air outlet 17 are all higher than the water storage area 15, and the air inlet 16 is connected to the air inlet fan (not shown in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com