Ultrasonic wave cleaning processor

A technology of ultrasonic waves and processors, applied in the field of ultrasonic cleaning processors, which can solve the problems of easy damage to the inner wall of the container and failure to clean, and achieve the effect of saving manpower, saving time and being easy to realize

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

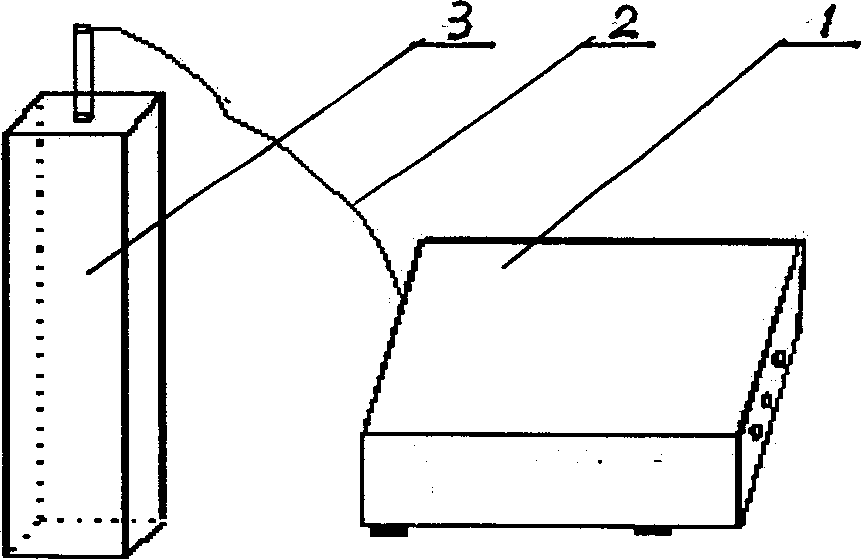

[0022] figure 1 It is a schematic diagram of the structure of the ultrasonic cleaning processor of the tetrahedral vibration plate, which is composed of an ultrasonic generator 1 connected to a tetrahedral ultrasonic vibration plate 3 through a signal line 2. When the power switch of the ultrasonic generator 1 is turned on, the ultrasonic waves generated are transmitted from the signal line 2 to the transducer in the ultrasonic vibration plate 3 for cleaning.

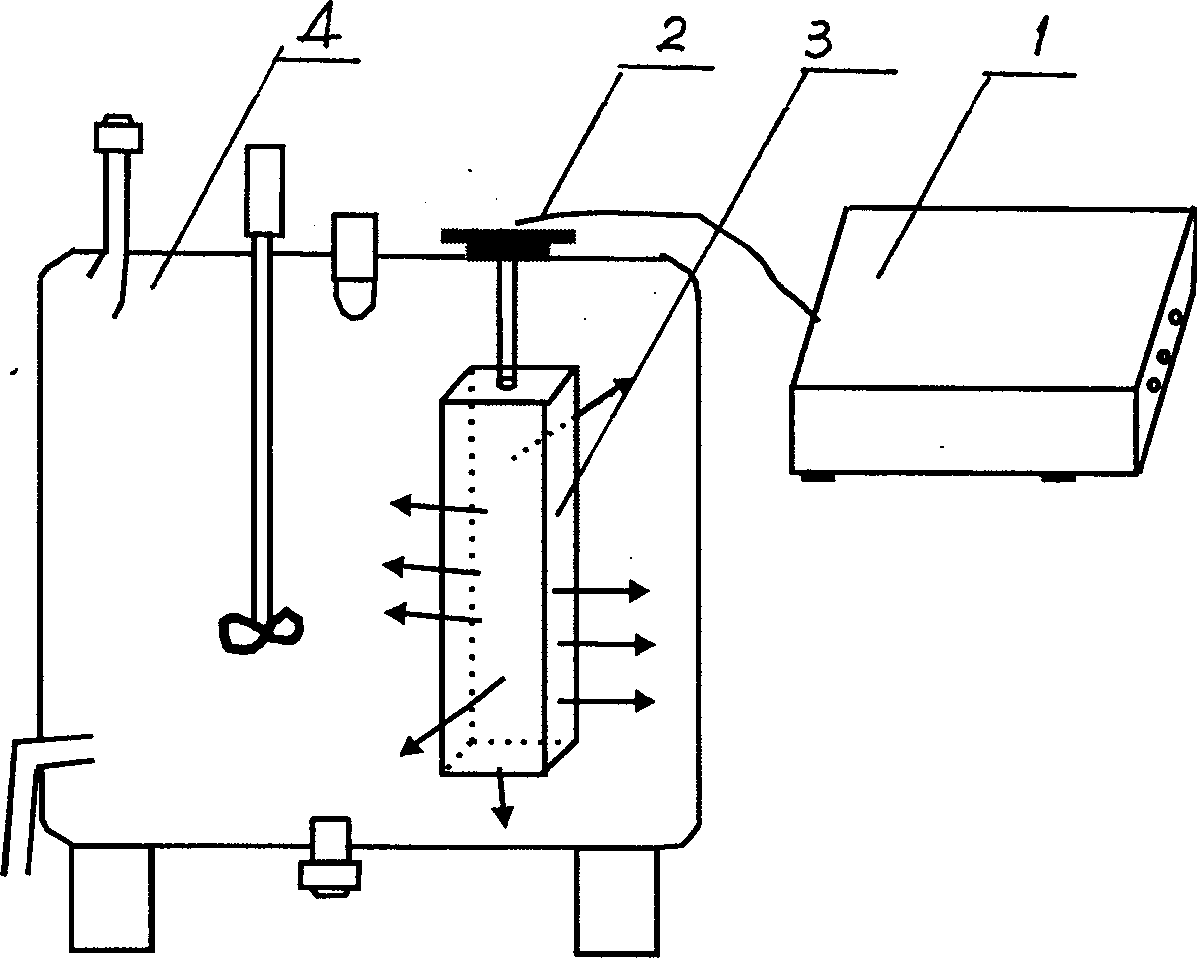

[0023] figure 2 Yes figure 1 The structure diagram of the ultrasonic vibration plate 3 in the container 4 to be cleaned. Open the sight glass hole 4(1) of the container 4 to be cleaned, and insert the ultrasonic vibration plate 3 into the container 4 through the sight glass hole 4(1). The container 4 is filled with cleaning liquid, and the cleaning liquid immerses the entire ultrasonic vibration plate 3 , Turn on the ultrasonic generator 1 switch for ultrasonic cleaning. At that time, the ultrasonic wave strength and u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com