Semi-automatic rubber cork rinsing machine

A rubber stopper rinsing machine, semi-automatic technology, applied in chemical instruments and methods, cleaning methods and utensils, cleaning methods using liquids, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

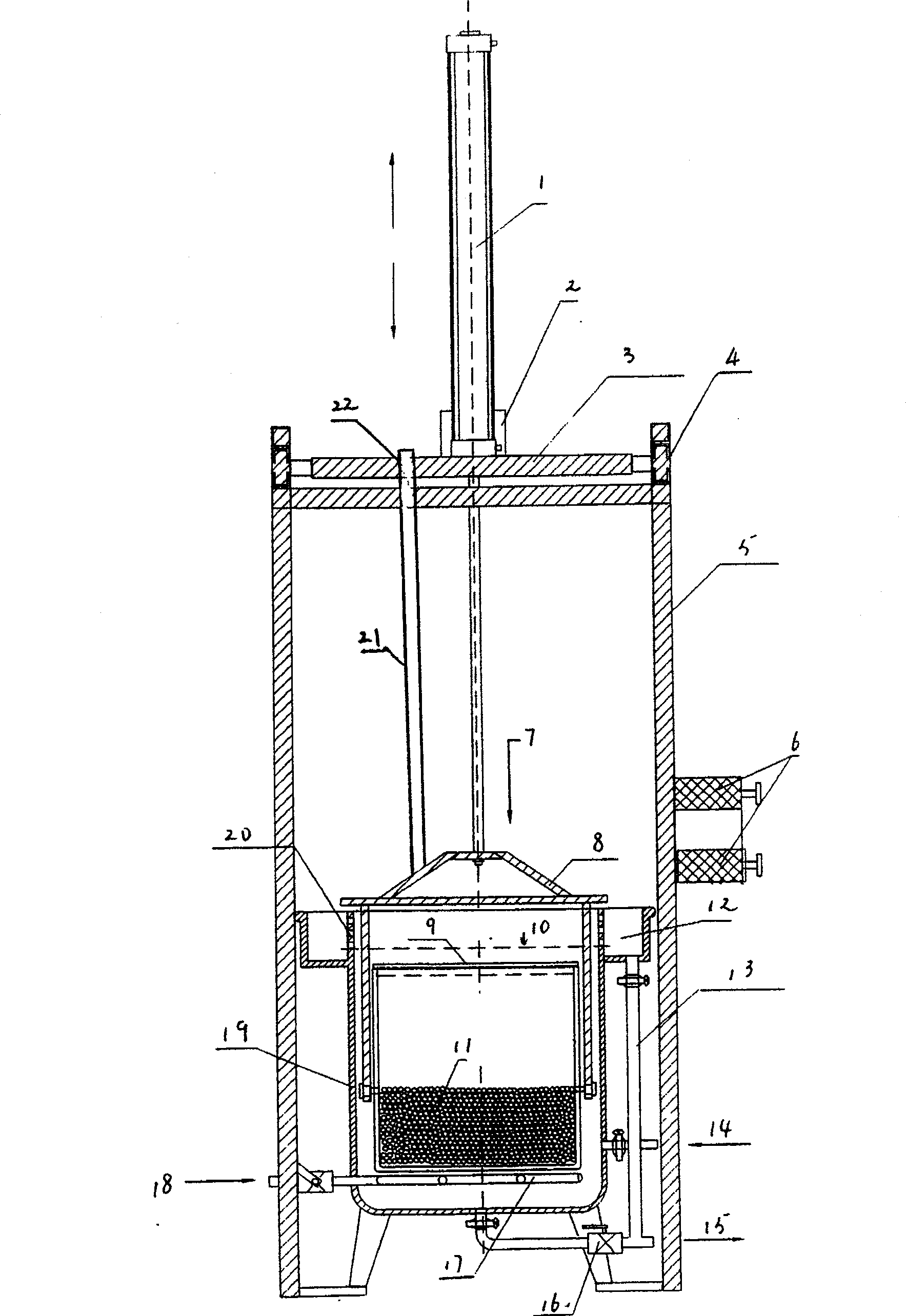

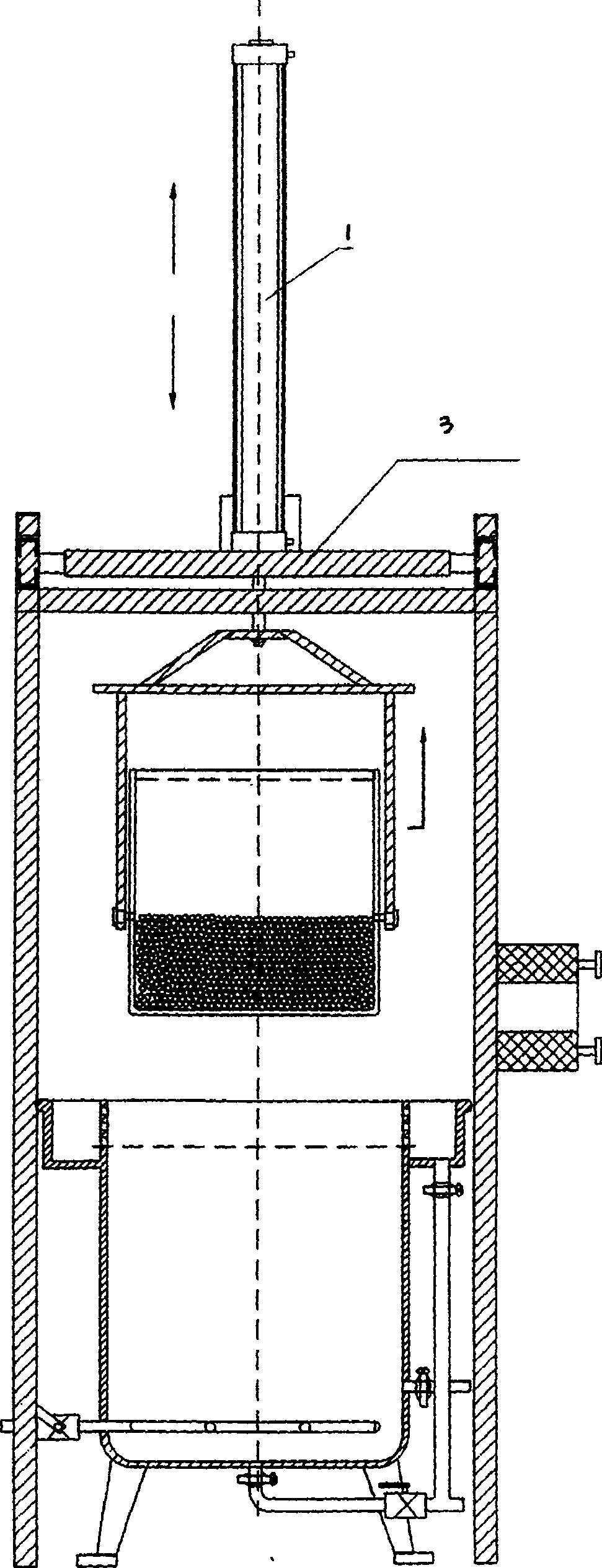

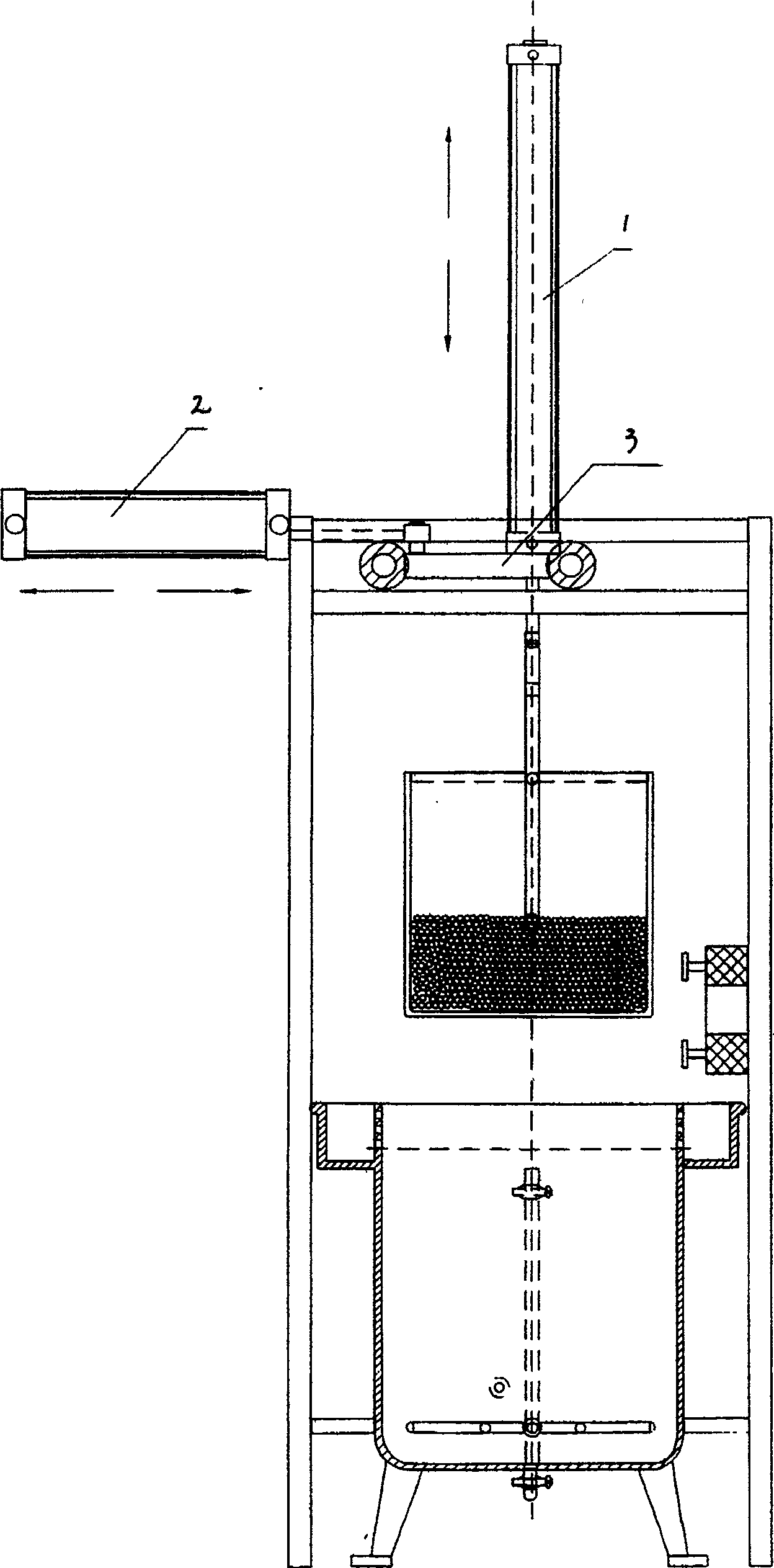

[0016] Such as figure 1 , The invention is a semi-automatic rubber stopper rinsing machine. It mainly consists of frame 5, rinsing cylinder 19, overflow hole 20, overflow tank 12, drain pipe 13, water inlet pipe 14, air jet coil 17, basket 8, basket cover 9, lifting cylinder 1, traverse cylinder 2, traverse Move dolly 3 and dolly guide rail 4 to form.

[0017] The rinsing cylinder 19 is placed in the middle of the lower part of the frame 5, and the upper wall of the rinsing cylinder 19 is evenly distributed with overflow holes 20, and the periphery of the overflow hole 20 is provided with an overflow groove 12 outwardly, and the overflow groove 12 and the overflow hole 20 Link to each other, overflow tank 12 bottoms are connected with drainpipe 13 downwards, drainpipe 13 inserts rinse tube 19 bottoms, drain valve 16 is housed on drainpipe 13, water inlet pipe 14 is arranged on rinse tube 19 tube wall downsides. The jet coil 17 is placed horizontally at the lower part of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com