Water-retention water-water-permeable concrete utilizing construction waste and preparation method of water-retention water-permeable concrete

A technology of permeable concrete and construction waste, applied in the direction of climate sustainability, sustainable waste treatment, solid waste management, etc., can solve the problems of poor water retention performance and non-conforming to recycling, and achieve waste reduction, artistic and ornamental , Color can be diversified effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] Prepare the first water-retaining permeable concrete for the sand layer of the water-retaining and permeable ground structure, as follows:

[0043] (1) Weigh each raw material component according to the following parts by weight: 1-30 parts by weight of cement, 1-3 parts by weight of mineral admixture, 50-90 parts by weight of aggregate, 0-3 parts by weight of colorant, special admixture SZ -BS-02 0.1 to 3 parts by weight and 4 to 9 parts by weight of water;

[0044] The above cement is ordinary portland cement P.O 42.5, P.O 52.5;

[0045] Above-mentioned aggregate is made up of the component of following percentage by weight:

[0046] Waste concrete particles with a particle size of 2-8mm 30%

[0047] Waste clay brick particles with a particle size of 2-8mm 50%

[0048] Lightweight ceramsite with particle size not greater than 4mm 20%

[0049] The above-mentioned mineral admixtures are made by using the specific surface area ≥ 550m2 generated during the constructio...

Embodiment 2

[0053] Prepare the second water-retaining pervious concrete for the graded cushion of the water-retaining permeable ground structure, as follows:

[0054] (1) Weigh each raw material component according to the following parts by weight: 1-30 parts by weight of cement, 1-3 parts by weight of mineral admixture, 50-90 parts by weight of aggregate, 0-3 parts by weight of colorant, special admixture SZ -BS-02 0.1 to 3 parts by weight and 4 to 9 parts by weight of water;

[0055] The above cement is ordinary portland cement P.O 42.5, P.O 52.5;

[0056] Above-mentioned aggregate is made up of the component of following percentage by weight:

[0057] Waste concrete particles with a particle size of 2 to 30mm 30%

[0058] Waste clay brick particles with a particle size of 2-30mm 50%

[0059] Lightweight ceramsite with a particle size of 0.1-15mm 20%;

[0060] The above waste concrete particles are composed of first concrete particles and second concrete particles in a weight ratio ...

Embodiment 3

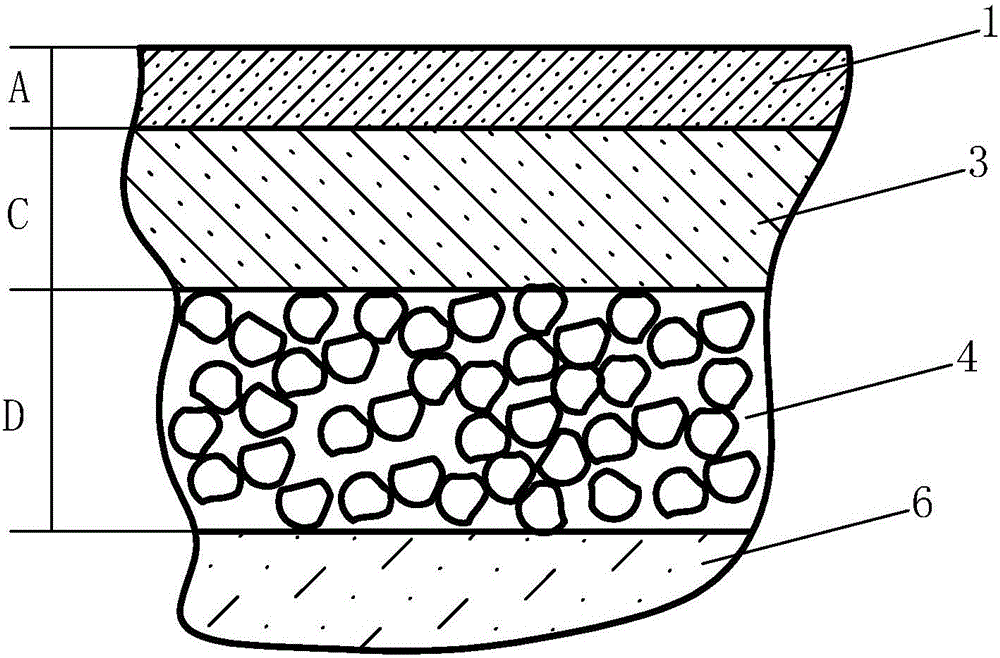

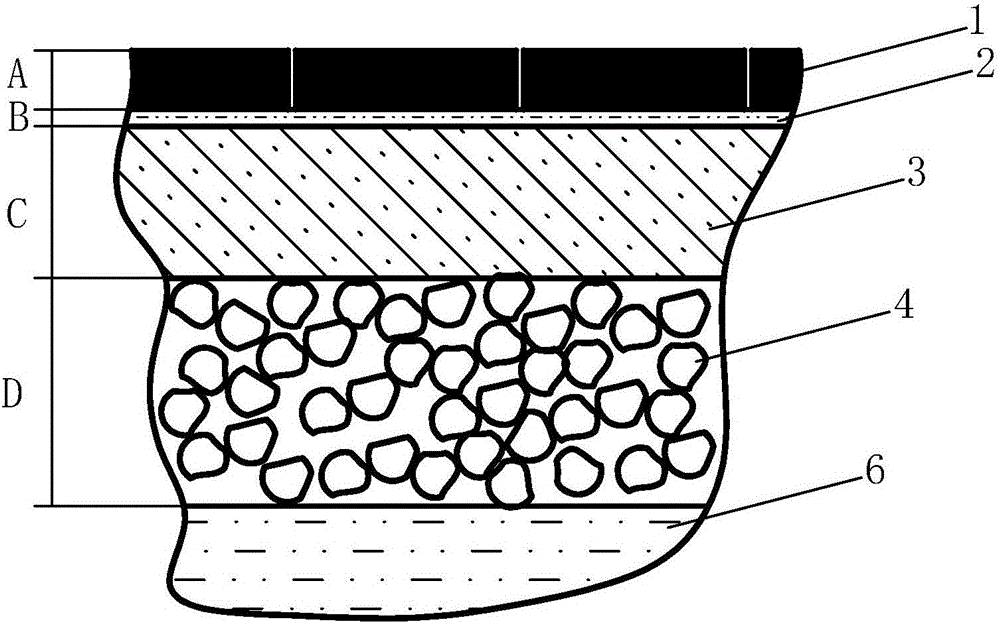

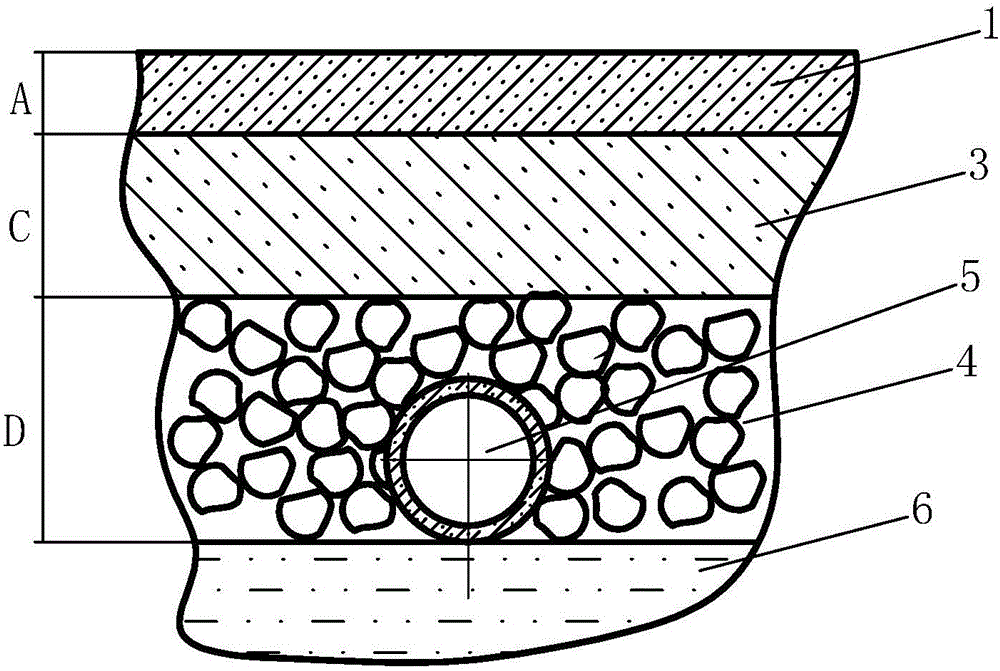

[0067] Such as figure 1 As shown, a water-retaining permeable ground structure, the pavement structure includes from top to bottom: permeable surface layer 1 (the basic formula is: 25-35 parts of cement, 45-55 parts of waste concrete particles with a particle size of 5.0-10.0mm , 10-20 parts of waste concrete particles with a particle size of 2.0-5.0 mm, 1-3 parts of colorant determined according to the design and color matching, 1-3 parts of special admixture SZ-BS-02 and 2-4 parts of water, paving Thickness A=10~60mm), sand layer 2 (paving the first water-retaining permeable concrete in Example 1, paving thickness B=80~200mm, specific formula is shown in the table below), graded cushion layer 3 (paving The second water-retaining permeable concrete in Example 2, the pavement thickness D=100-200mm, the specific formula is shown in the table below) and the base layer 6.

[0068]

[0069] The pavement method of this embodiment is:

[0070] 1. The base layer 6 plain soil is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com