Air equalizing structure for heat pump module of heat pump type washing-drying integrated machine

A heat pump module, integrated machine technology, applied in household dryers, washing devices, textiles and papermaking, etc., can solve the problems of evaporator design waste, prolonging drying time, affecting drying efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

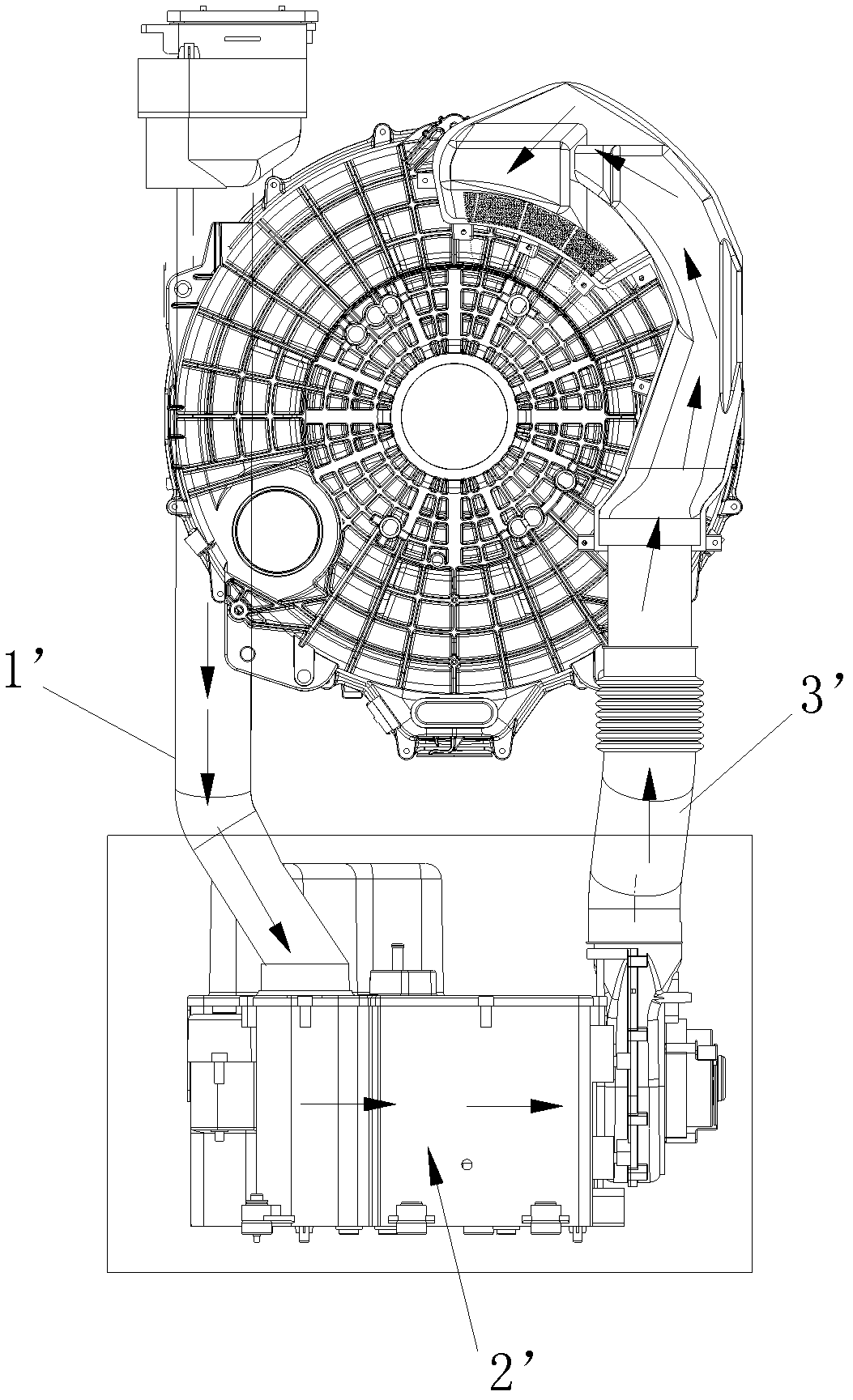

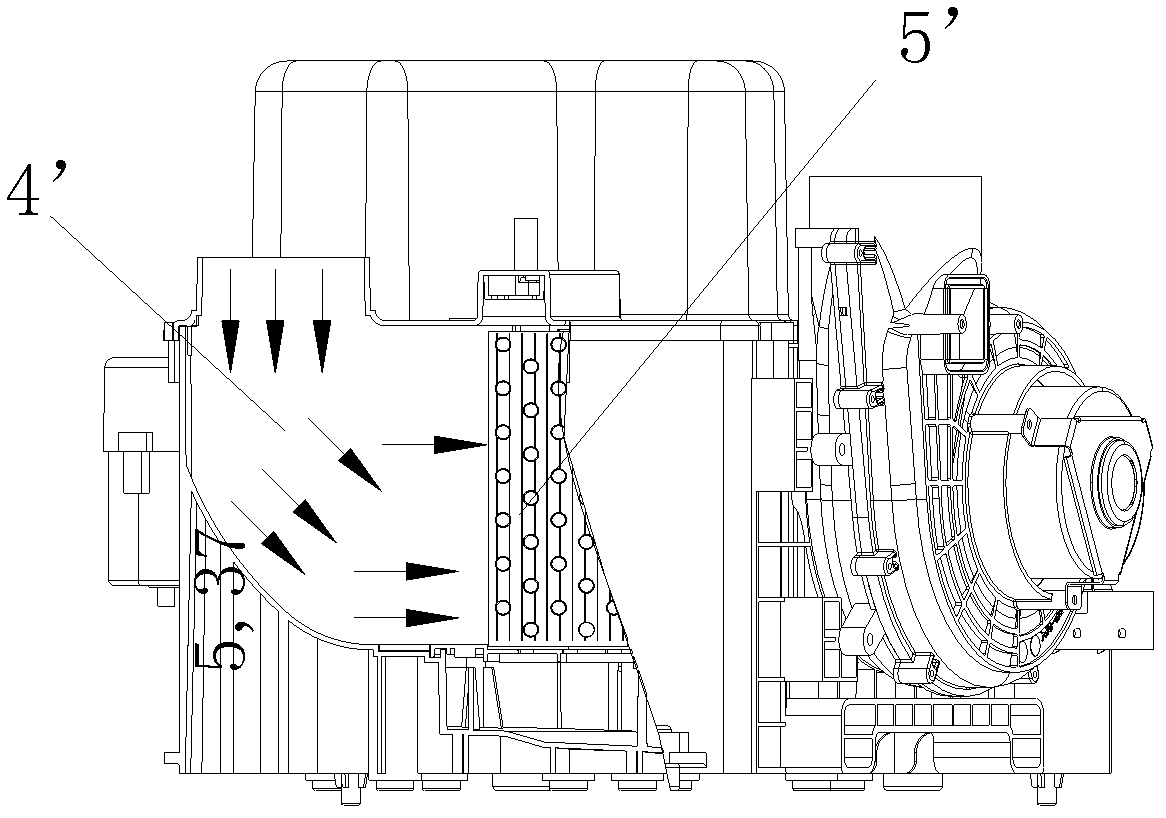

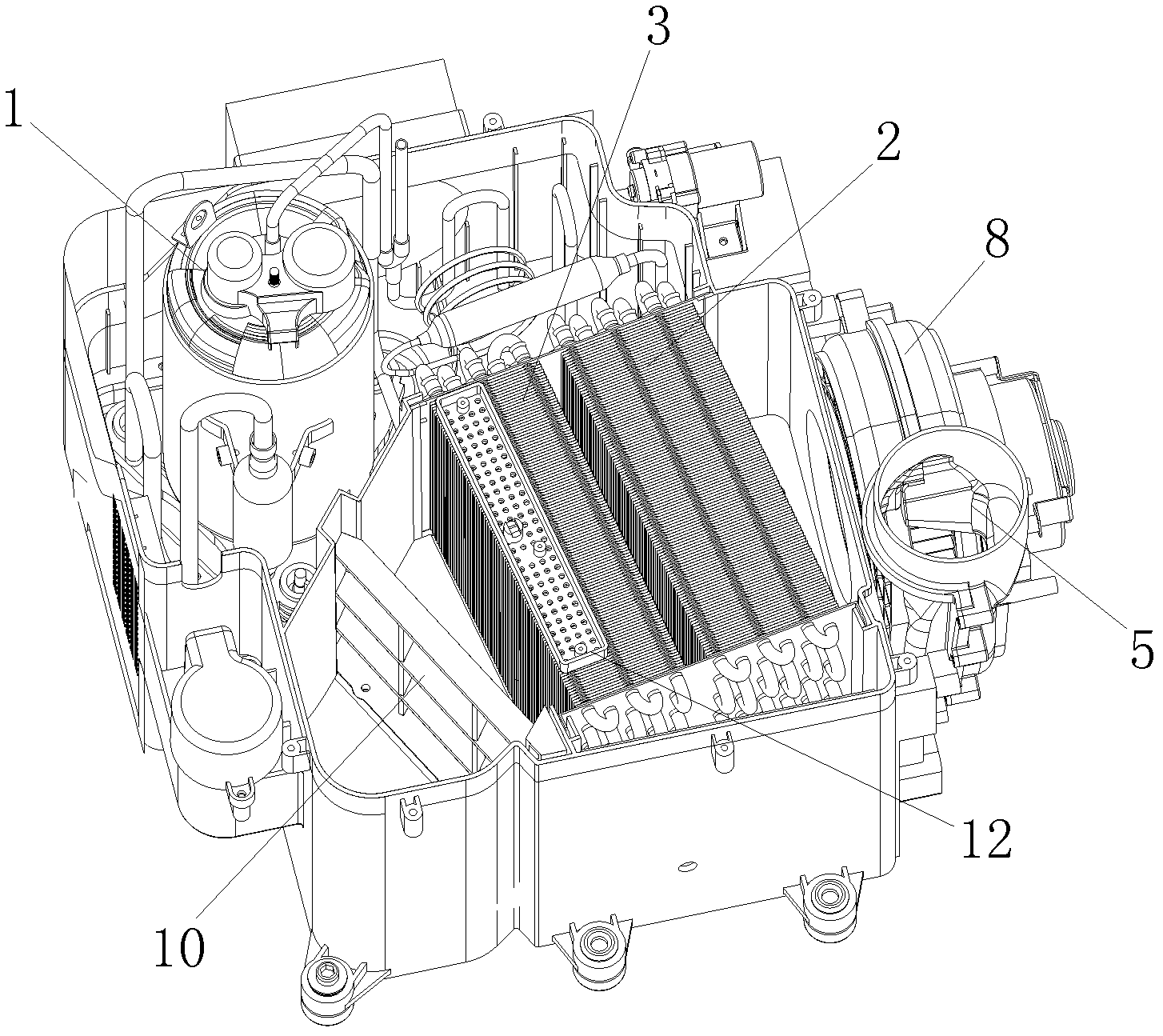

[0034] like Figure 3 to Figure 7 As shown, the integrated drum washing and drying machine of the present invention includes a heat pump module for drying clothes, an air inlet 4 and an air outlet 5 of the heat pump module respectively connected to the drum where the clothes are placed, and the heat pump module mainly includes compression machine 1, condenser 2, throttling device and evaporator 3, the above-mentioned heat pump module is integrated in the closed space formed by the upper cover plate 6 and the lower cover plate 7, and the compressor 1, condenser 2, The throttling device, the evaporator 3 and then the compressor 1 are connected to form a circulation system. The heat pump module is integrated into an integrated structure through the upper cover plate 6 and the lower cover plate 7. The air inlet 4 of the heat pump module, the flow equalization structure, and the evaporation The heat pump dehumidification and heating air path is formed from the device 3, the condens...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com