Loading device specially for silicon material square section pickling

A loading device and silicon material technology, applied in cleaning methods and utensils, chemical instruments and methods, cleaning methods using liquids, etc., can solve problems such as lack of cleaning, operator injury, pickling solution splashing, etc., to ensure Production safety, ensure cleaning quality, good cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

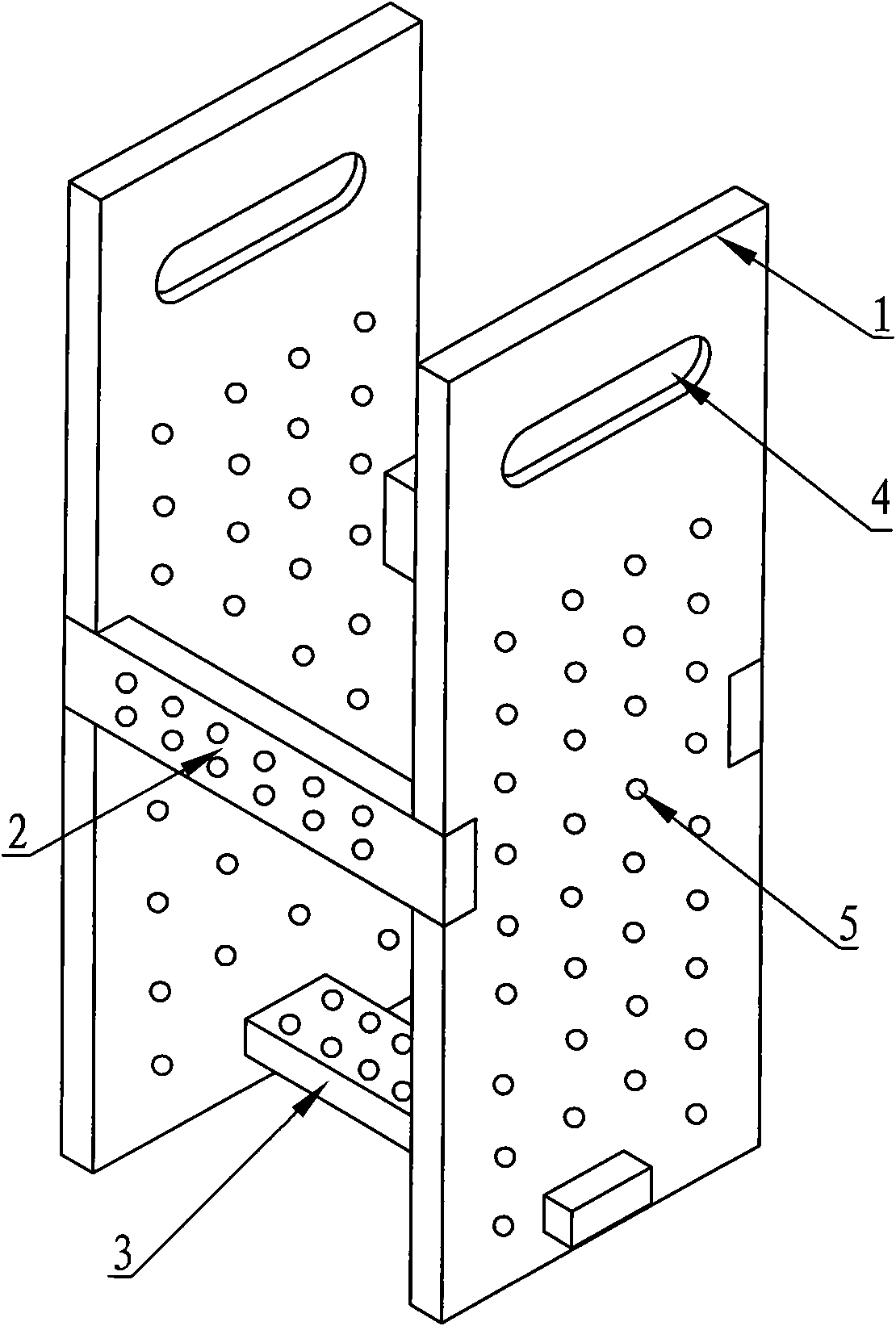

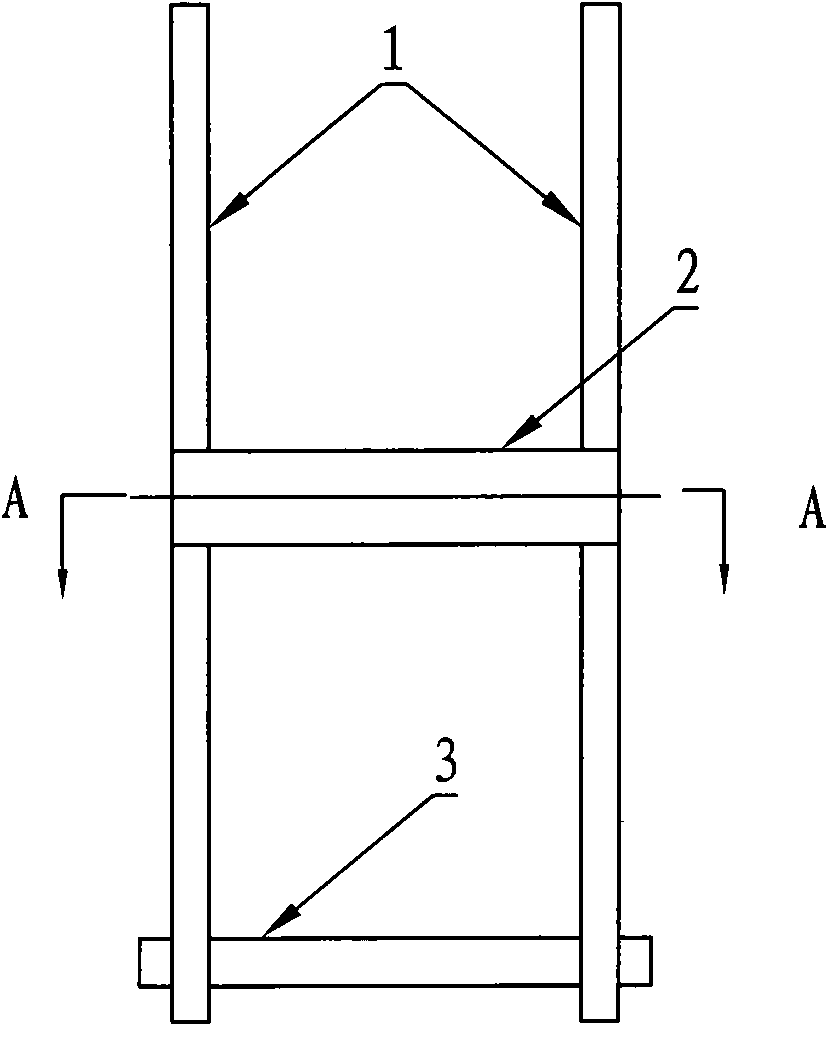

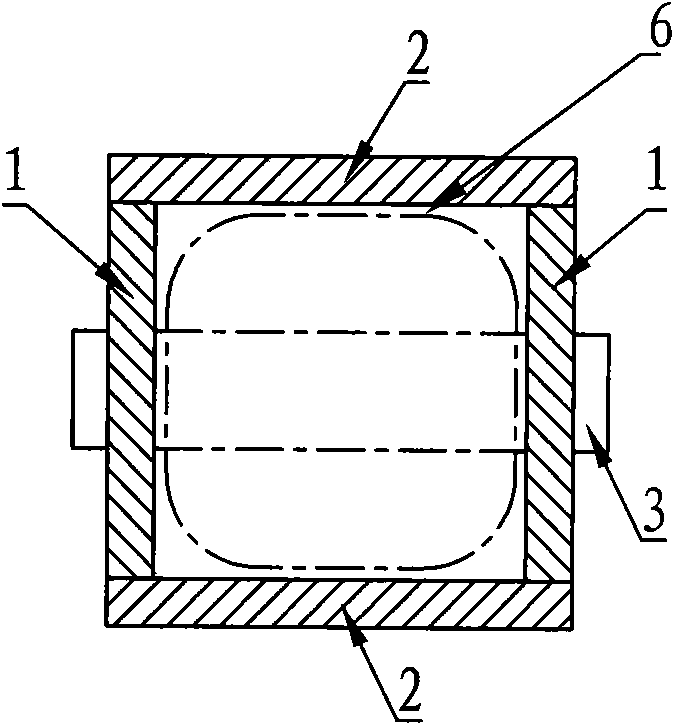

[0016] Embodiment 1: the special loading device for pickling of silicon material square section according to the present invention, such as Figure 1 ~ Figure 3 As shown, it consists of a main support plate 1, a side connecting plate 2 and a bottom connecting plate 3, a side connecting plate 2 is fixed on both sides of the two main supporting plates 1, and the bottom connecting plate 3 is fixed on two main supporting plates In the middle part of the bottom of the plate 1, the distance from the upper end surface of the side connecting plate 2 to the upper end surface of the bottom connecting plate 3 is slightly smaller than the height dimension of the silicon material square section 6 to be cleaned. Two main support plates 1 and two side connecting plates 2. The length of the side of the synthetic square is 8 millimeters larger than the side spacing of the lateral section of the silicon material square section 6 to be cleaned, and the upper ends of the two main support plates 1 ...

Embodiment 2

[0017] Embodiment 2: On the basis of Embodiment 1, a liquid-permeable hole 5 is provided on the main support plate 1, the side connection plate 2 and the bottom connection plate 3, and the main support plate 1, the side connection plate 2 and the bottom connection plate 3 are all made of acid-resistant and high-temperature-resistant PP plastics.

Embodiment 3

[0018] Embodiment 3: On the basis of Embodiment 1, two side connecting plates 2 are fixed on both sides of the two main support plates 1, and the upper end surface of the upper side connecting plate 2 to the upper end surface of the bottom connecting plate 3 The distance is slightly smaller than the height dimension of the silicon material 6 of the square section to be cleaned.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com