High-strength and high-tenacity gas shielded welding wire

A technology of gas-shielded welding wire and high toughness, which is applied in the direction of welding medium, welding equipment, welding/cutting medium/material, etc. It can solve the problems that cannot meet the use requirements of high toughness, expensive Ni elements, poor low-temperature impact toughness, etc., and achieve Excellent welding process performance, stable smelting process, and stable welding arc

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] This embodiment is a gas-shielded welding wire for welding high-strength and high-toughness steel. Its chemical composition and weight percentage (%) are: C: 0.02-0.12, Mn: 1.20-2.10, Si: 0.20-1.00, S: ≤ 0.010, P: ≤0.015, Ni: 2.00~3.50, Mo: 0.20~0.80, Ti: 0.20~0.30, Cr: 0.60~1.20, V≤0.05, B: 0.005~0.010, Al: ≤0.015, Cu: ≤0.35 , the balance is Fe;

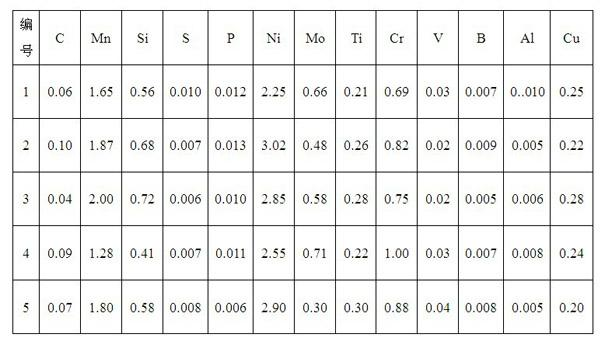

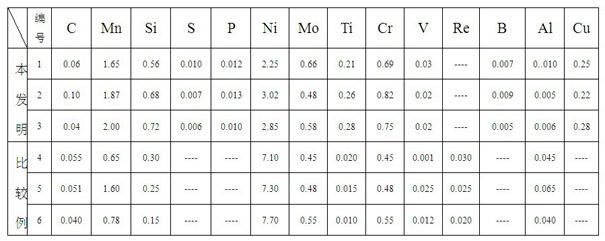

[0025] The preparation process of the welding wire is the same as the prior art. After smelting, rolling and drawing (one heat treatment in the production process) into welding wire, the surface is purified. The diameter of the welding wire is Φ1.2mm. The specific weight percentage of the chemical elements that make up the welding wire is shown in Table 1 (Table 1. A total of 5 Group):

[0026] Table I:

[0027]

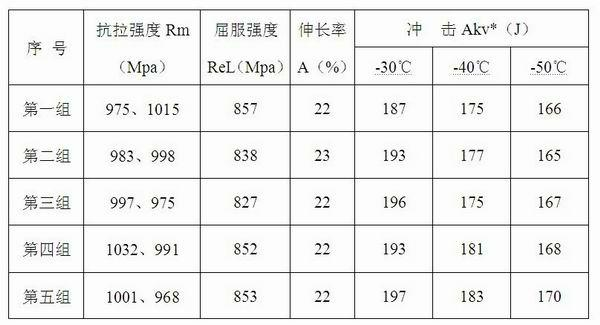

[0028] Test plate: a new generation of engineering machinery structure steel HG80, welded test plate thickness 20mm, groove angle 45o, with 12mm thick backing plate, root gap 12mm, both test plate and backin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com