Aluminium-vanadium-tin-copper-iron intermediate alloy and preparation method thereof

An aluminum-vanadium-tin-copper and master alloy technology is applied in the field of aluminum-vanadium-tin (aluminum-vanadium-tin-based) master alloy and its preparation, and can solve the problems of difficulty in the intermediate process of producing titanium alloy, unstable product performance, complicated production process and the like, To achieve the effect of shortening the production process, convenient preparation and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] 1. Screen the raw materials and determine the composition of the raw materials through analysis; then dry the raw materials at a temperature of 100-120°C and a drying time of 10-12 hours.

[0018] 2. Build the furnace according to the specified ratio, and calculate the alloy ratio.

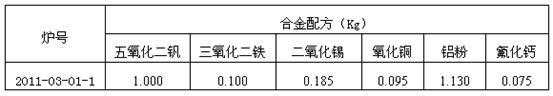

[0019] Table 1 Example 1 alloy formula table

[0020]

[0021] 3. Put the raw materials into the mixing machine for mixing. Mixing requirements: each raw material must be fully mixed evenly to ensure sufficient contact between raw materials.

[0022] 4. Finally, furnace is installed for smelting, and the furnace temperature is 30-60°C. After 24 hours, it was released from the furnace, and the alloy ingot was taken out to obtain the product. Chemical analysis was carried out on the alloy components taken out, and the following results were obtained.

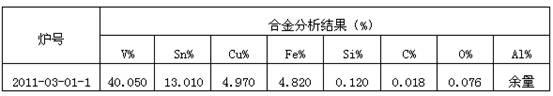

[0023] Table 2 Example 1 Alloy Composition Table

[0024]

[0025] It can be seen from the above results that the alloy compositi...

Embodiment 2-5

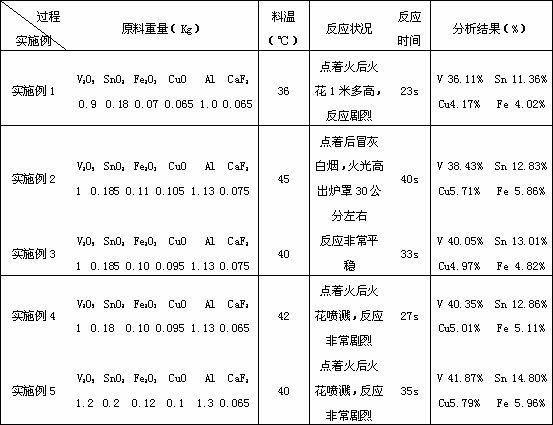

[0026] Embodiment 2-5 is operated according to the method of embodiment 1, and the specific content is shown in Table 3.

[0027] Table 3 Examples of aluminum vanadium tin copper iron alloy

[0028]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com