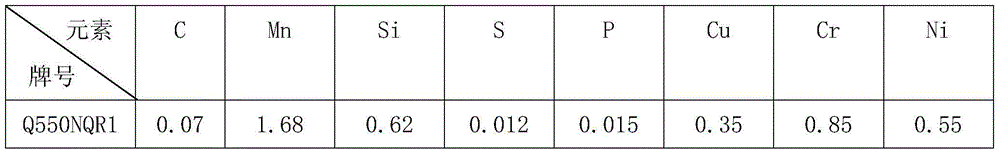

High-strength solid wire made of weathering resistant steel through gas shielded welding

A gas shielding and solid core welding wire technology, applied in welding equipment, welding media, welding/cutting media/materials, etc., can solve the problem of unsatisfactory weather resistance, unsatisfactory ratio of corrosion-resistant alloy elements, and inability to meet strength requirements stably, etc. problems, to achieve excellent welding process performance, good matching effect, and good atmospheric corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] In order to make the object, technical solution and advantages of the present invention more clear, the present invention will be further described in detail below in conjunction with the examples. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

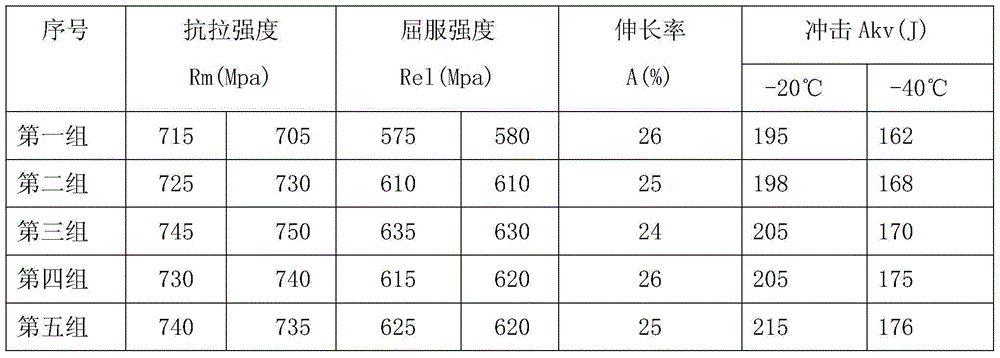

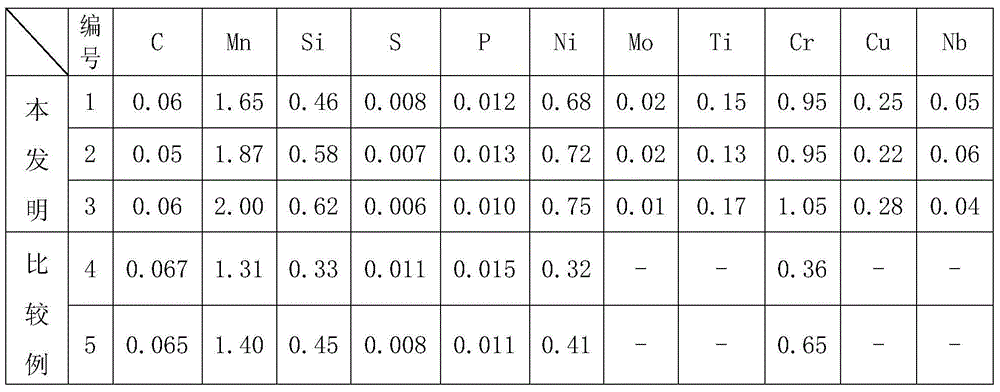

[0013] A high-strength weather-resistant steel gas-shielded solid welding wire, the chemical composition of which is C: 0.05-0.15, Mn: 1.65-2.10, Si: 0.40-0.80, S≤0.010, P≤0.015, Cu: 0.25-0.55, Cr: 0.90-1.25, Ni: 0.65-0.95, Ti: 0.12-0.18, Nb: 0.02-0.10, Mo≤0.1, and the rest are iron and other impurities. The implementation of the present invention is by adopting mixed gas 80%Ar+20%CO2 as protective gas for welding, adding appropriate amount of alloying elements such as Mn, Si, Cu, Cr, Ni, Ti, Nb, Mo in the welding wire, adopting various Strengthen the mechanism to improve the strength and toughness of welded joints, and ha...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com