Gas protection welding wire for high-strength weathering steel and steel for gas protection welding wire

A technology of gas-shielded welding wire and weather-resistant steel, which is applied in the direction of welding medium, welding equipment, welding/cutting medium/material, etc., can solve the problems of high cost and dependence on imports, and achieve beautiful shape, small spatter, and excellent welding process performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

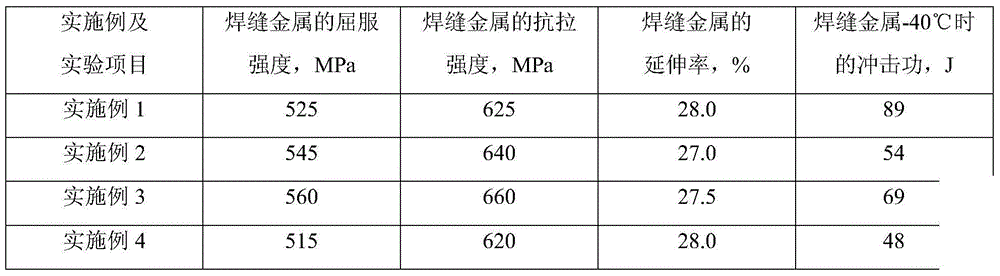

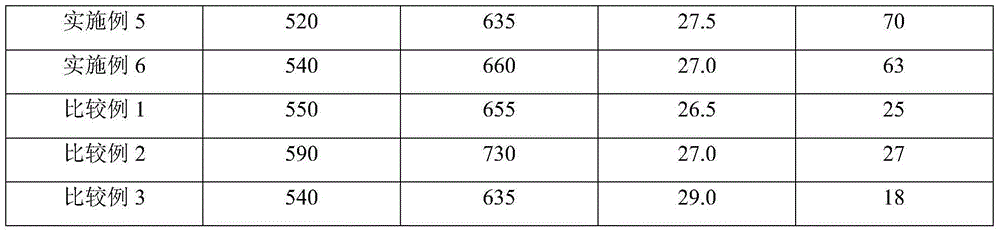

Examples

Embodiment 1

[0018] The basic chemical composition of the steel for gas shielded welding wire for high-strength weathering steel is (weight percent):

[0019] C: 0.02%; Mn: 1.05%; Si: 0.44%; Ni: 0.82%; Cu: 0.25%; Cr: 0.01%; Nb: 0.066%; S: 0.004%; P: 0.011%; unavoidable impurities.

[0020] The basic chemical composition of the gas-shielded welding wire for high-strength weathering steel is (weight percent):

[0021] C: 0.02%; Mn: 1.05%; Si: 0.44%; Ni: 0.82%; Cu: 0.36%; Cr: 0.01%; Nb: 0.066%; S: 0.004%; P: 0.011%; unavoidable impurities.

[0022] The conventional electroless plating technology is used to plate copper on the surface of the above welding wire, and the copper plating layer accounts for 0.11% of the total weight of the welding wire.

Embodiment 2

[0024] The basic chemical composition of the steel for gas shielded welding wire for high-strength weathering steel is (weight percent):

[0025] C: 0.042%; Mn: 1.10%; Si: 0.42%; Ni: 0.85%; Cu: 0.22%; Cr: 0.01%; Nb: 0.056%; S: 0.0034%; P: 0.010%; unavoidable impurities.

[0026] The basic chemical composition of the gas-shielded welding wire for high-strength weathering steel is (weight percent):

[0027] C: 0.042%; Mn: 1.10%; Si: 0.42%; Ni: 0.85%; Cu: 0.35%; Cr: 0.01%; Nb: 0.056%; S: 0.0034%; P: 0.010%; unavoidable impurities.

[0028] Copper is plated on the surface of the above welding wire by conventional electroless plating technology, and the copper plating layer accounts for 0.13% of the total weight of the welding wire.

Embodiment 3

[0030] The basic chemical composition of the steel for gas shielded welding wire for high-strength weathering steel is (weight percent):

[0031] C: 0.044%; Mn: 1.40%; Si: 0.64%; Ni: 0.84%; Cu: 0.19%; Cr: 0.01%; Nb: 0.049%; S: 0.0043%; P: 0.011%; unavoidable impurities.

[0032] The basic chemical composition of the gas-shielded welding wire for high-strength weathering steel is (weight percent):

[0033] C: 0.044%; Mn: 1.40%; Si: 0.64%; Ni: 0.84%; Cu: 0.33%; Cr: 0.01%; Nb: 0.049%; S: 0.0043%; P: 0.011%; unavoidable impurities.

[0034] The conventional electroless plating technology is used to plate copper on the surface of the above-mentioned welding wire, and the copper plating layer accounts for 0.14% of the total weight of the welding wire.

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com