Double-bent-welding-wire narrow-gap gas metal arc welding torch

A technology of melting electrode gas and narrow gap, which is applied to the characteristics of electrodes, welding equipment, arc welding equipment, etc., can solve the problems of increasing the heat input of the side wall, the side wall is not fused, and the actual effect is yet to be verified, so as to improve the utilization rate, Compact structure and good adaptability of groove width

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

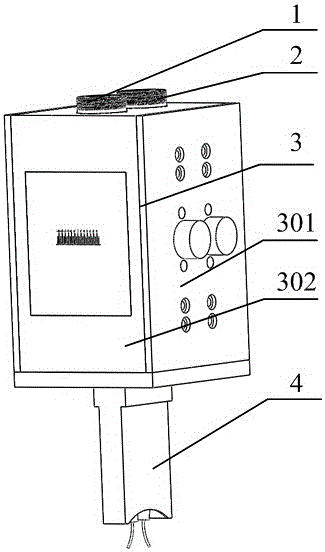

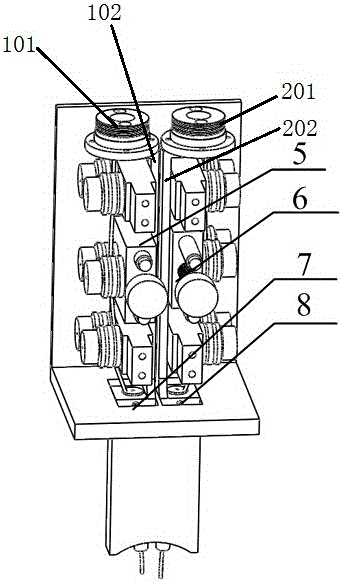

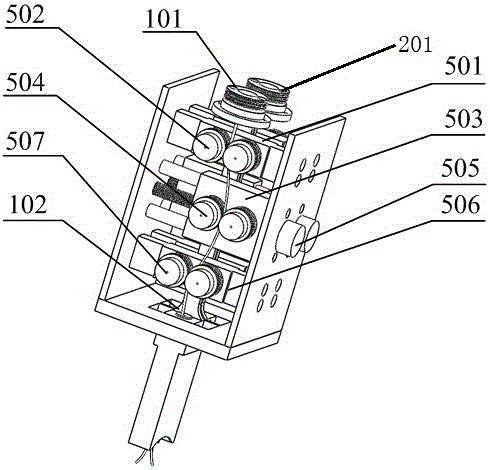

[0042] Such as Figure 1-8 As shown, a double-bent welding wire narrow-gap MIG shielded welding torch includes a front conductive mechanism 1, a rear conductive mechanism 2, a welding torch box 3, a plug-in nozzle 4, a front wire bending mechanism 5, and a rear wire bending mechanism 6. The front conductive mechanism 1, the rear conductive mechanism 2, the front wire bending mechanism 5 and the rear wire bending mechanism 6 are located in the torch box 3, and the front conductive mechanism 1 and the rear conductive mechanism 2 are arranged in parallel; the front The conductive mechanism 1 includes a front conductive connector 101, a front conductive plate 102, a front conductive rod 103, and a front conductive tip 104. The upper end of the front conductive plate 102 is connected with the front cable connector 101, and the lower end is connected with the front conductive rod 103. The mouth 104 is connected to the lower end of the front conductive rod 103; the rear conductive me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com