High-toughness CO2 gas protection welding wire and wire rod and application thereof

A gas shielded welding wire, high toughness technology, applied in welding media, welding equipment, welding equipment and other directions, can solve the problems of large spatter, low gas cost, affecting the mechanical properties of welds, etc., to achieve less spatter, low welding wire cost, forming beautiful effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

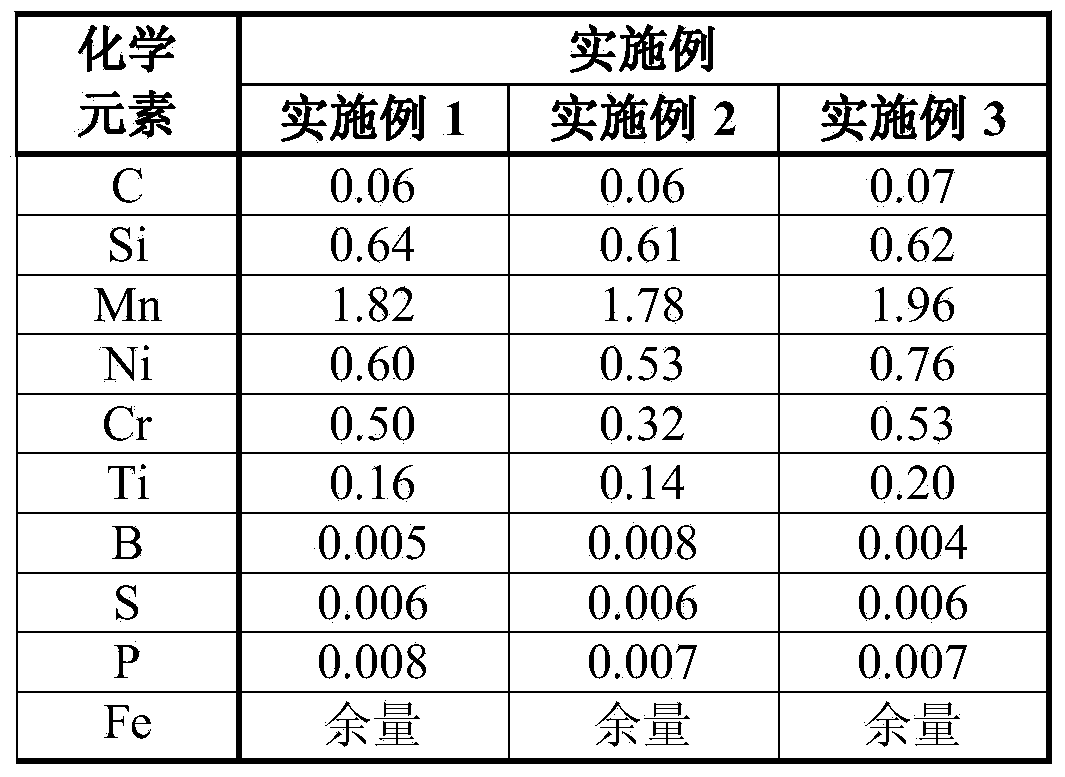

[0026] The embodiment of the present invention is a high-strength CO2 designed according to the above-mentioned design. 2 The composition range of gas shielded welding wire and wire rod has been carried out in 3 groups of embodiments, and the production process is the same: the welding wire steel smelted according to the design composition is rolled into a 5.5mm diameter wire rod, and then drawn into a 1.2mm diameter welding wire, After being plated with copper on the surface, it becomes the welding wire of the present invention.

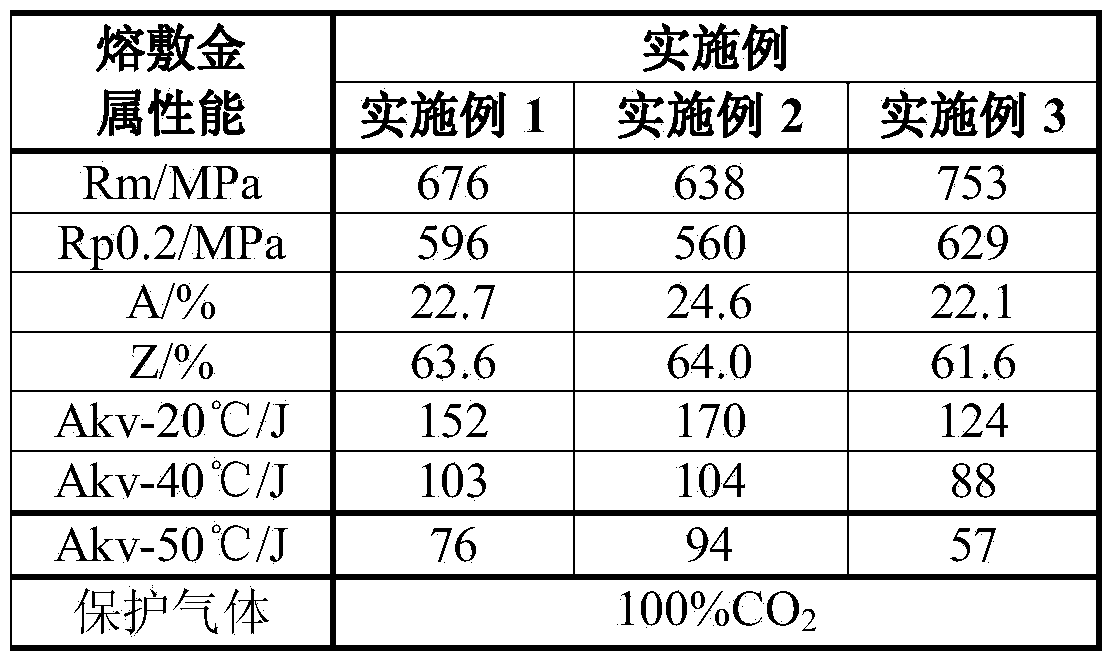

[0027] The welding wire of the present invention is in CO 2 The mechanical properties of the weld metal are inspected under gas shielded welding. The welding specifications are: welding current is 280-320A, welding voltage is 30V, welding speed is 33cm / min, interlayer temperature and preheating temperature are 135-165℃, welding The line energy is 16.4kJ / cm. The thickness of the welding plate is 20mm, the groove angle is 45°, with a 20mm backing pl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com