Preparation method of hyperpure nitride powder

A nitride and powder technology, which is applied in the field of preparation of ultrapure nitride powder, can solve the problems that the quality consistency and stability of the reaction product cannot be guaranteed, and the temperature control of the reaction system is inconvenient, so as to achieve good adhesion and stability. The effect of sintering activity, less impurities and high powder content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

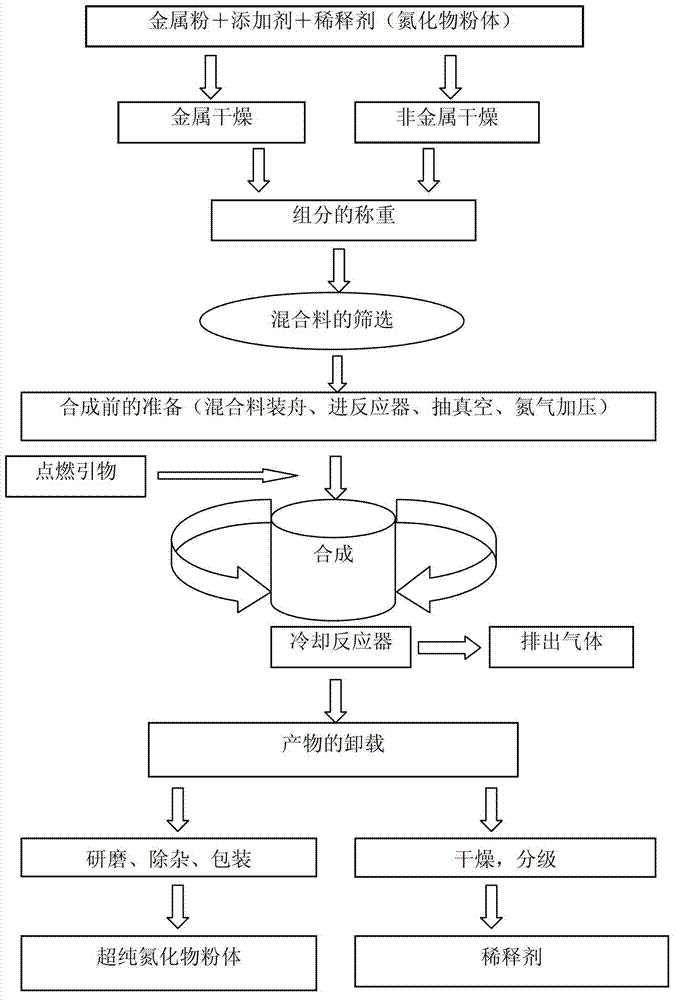

[0030] Such as figure 1 Shown, a kind of preparation method of ultrapure nitride powder comprises the following steps:

[0031] (1) Combine metal powder, diluent and NH 4 Cl is fully mixed in the tank mill to obtain the original mixture;

[0032] (2) After the original mixture is screened, a reaction material is obtained, and the reaction material is evenly packed in a graphite boat;

[0033] (3) Close the reactor where the graphite boat is located, vacuumize it, and then fill it with high-purity nitrogen;

[0034] (4) In the reactor, the primer is ignited by energizing the nickel-chromium wire, and the heat generated by the primer ignites the reaction material to obtain the ultra-pure nitride powder.

[0035] Typically, the primer is ignited by passing a 10 A DC current through the nichrome wire. After the reaction, the reactor is cooled to room temperature, the gas in the reactor is removed, and the product is unloaded from the graphite boat for processing. Among them, ...

Embodiment 1

[0038] Metal silicon powder, silicon nitride powder, NH 4 Cl is weighed at a mass ratio of 43:47:10, and fully mixed with silicon nitride balls in the pot mill for 4 hours. The purpose of using silicon nitride balls is to prevent other impurities from being brought in during the grinding process and reduce the synthesis of powder The impurity content of the mixed material is evenly packed in a porous semicircular graphite boat with a diameter of 150mm and a length of 800mm after passing through a 30-mesh sieve.

[0039] Vacuum after closing the reactor, and the vacuum degree reaches 10 -4 MPa, and then filled with high-purity nitrogen to a pressure of 4MPa. The mixture of Ti and C with a molar ratio of 1:1 is ignited by a direct current of 10A through a nickel-chromium wire, and the heat generated by the mixture ignites the reaction material until the reaction is complete.

[0040] Among them, the silicon nitride powder is synthesized by combustion synthesis method, the puri...

Embodiment 2

[0048] Metal aluminum powder, aluminum nitride powder, NH 4 Cl is weighed at a mass ratio of 40:50:10, and is fully mixed with alumina balls in the pot mill for 4 hours. The purpose of using aluminum nitride balls is to prevent other impurities from being brought into the grinding process and reduce the synthetic powder. Impurity content, the mixed material is evenly packed in a porous semicircular graphite boat with a diameter of 150mm and a length of 800mm after passing through a 30-mesh sieve.

[0049] Vacuum after closing the reactor, and the vacuum degree reaches 10 -4 MPa, and then filled with high-purity nitrogen to a pressure of 4MPa. The mixture of Ti and C with a molar ratio of 1:1 is ignited by a direct current of 10A through a nickel-chromium wire, and the heat generated by the mixture ignites the reaction material until the reaction is complete.

[0050] Among them, the aluminum nitride powder is synthesized by the aluminum powder nitriding method, the purity is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com