Oscillating-arc narrow-gap MIG/MAG (Metal Inert Gas/Metal Active Gas) welding torch

A narrow gap and welding torch technology, which is applied in arc welding equipment, electrode accessories, welding rod characteristics, etc., can solve the problems of unfused side walls, etc., to solve the problems of unfused side walls, large welding plate thickness, and high welding production efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

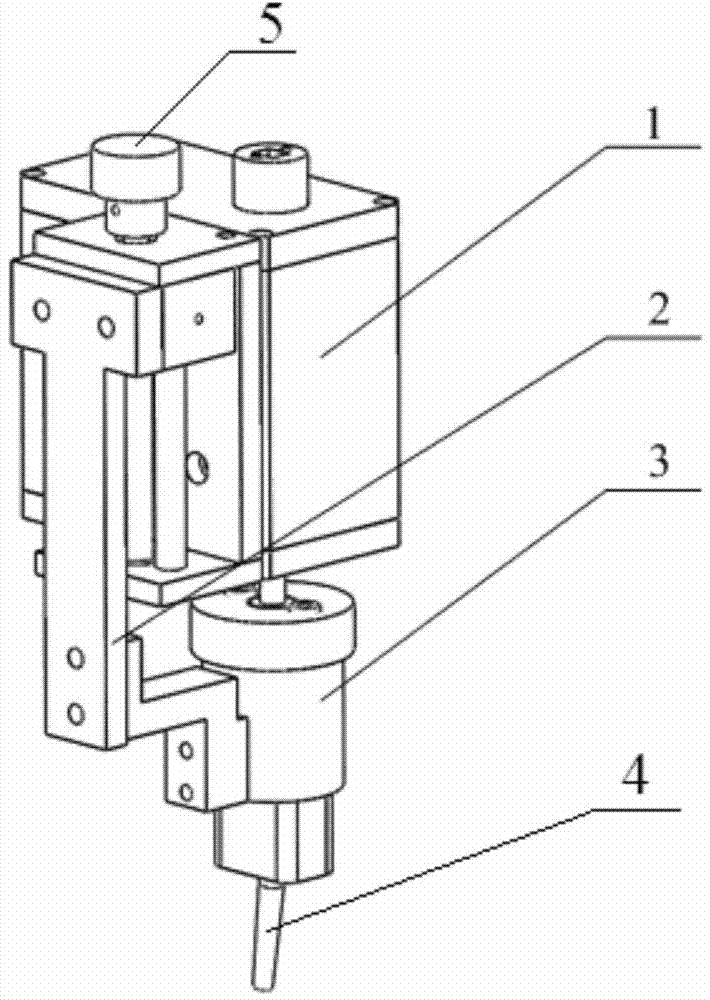

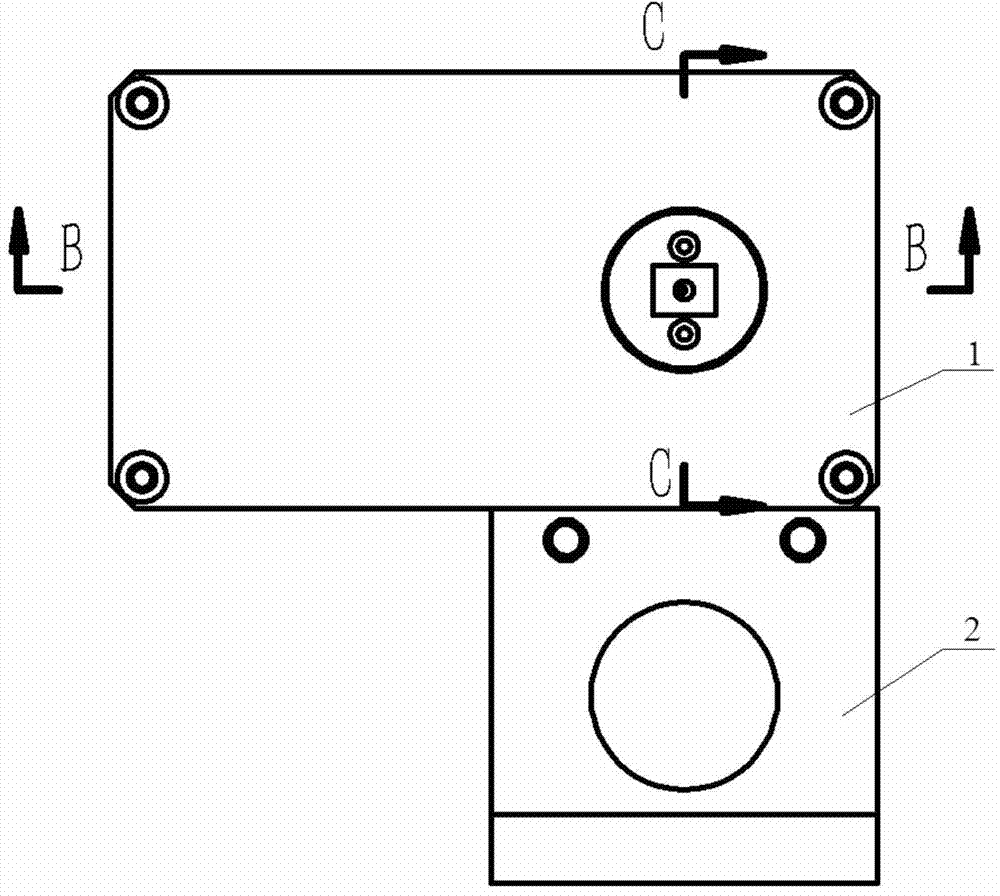

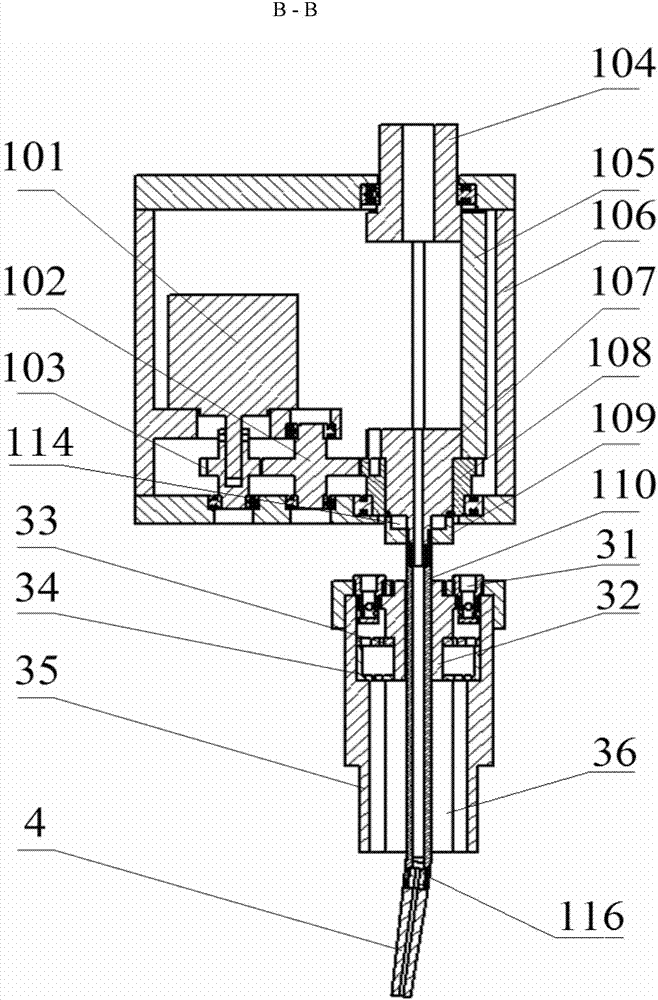

[0012] Specific implementation mode one: combine Figure 1 ~ Figure 4 Describe this embodiment. This embodiment includes a welding torch main body 1, a nozzle height adjustment part 2, an external narrow gap nozzle 3 and a conductive tip 4. The welding torch main body 1 includes a welding torch housing 106, a swing mechanism and a conductive cooling device. The swing mechanism includes a motor 101, motor gear 103, transition gear 102 and swing gear 108, motor gear 103 is fixed on the output shaft of motor 101, transition gear 102 meshes with motor gear 103 and swing gear 108 at the same time, conductive cooling device includes welding torch joint 104, conductive plate 105, conductive shaft 107, conductive shaft sleeve 109, curved conductive rod 110 and two water pipes 112, the two ends of the conductive plate 105 are respectively connected with the welding torch joint 104 and the conductive shaft 107, the conductive shaft 107 is arranged in the center hole of the swing gear 108...

specific Embodiment approach 2

[0014] Specific implementation mode two: combination image 3 Describe this embodiment, the external narrow gap nozzle 3 of this embodiment comprises a nozzle housing 35, a filter screen 33, a secondary filter screen 34 and a central bushing 32, the central bushing 32 is placed in the center of the nozzle, and the central bushing 32 and the Two air inlets 31 are arranged between the nozzle housings 35 , the air inlets 31 communicate with the lower cavity 36 of the nozzle housing 35 , and the primary filter 33 and the secondary filter 34 are arranged below the two air inlets 31 up and down. The protective gas enters the interior of the nozzle 3 through the two air inlets 31 on the upper end of the nozzle shell, is filtered and calmed by the primary filter 33 and the secondary filter 34, and finally exits from the lower end of the nozzle 3. The central bushing 32 is placed in the center of the nozzle and is curved and conductive Rod 110 passes through central hub 32 . Other com...

specific Embodiment approach 3

[0015] Specific implementation mode three: combination image 3 To describe this embodiment, the axis of the bending head 116 and the axis of the conductive shaft 107 in this embodiment form an included angle of 6°. Other components and connections are the same as those in the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com