Gas-shielded flux-cored wire for 20 chromium steel for nuclear power and welding method thereof

A technology of flux-cored welding wire and nuclear power, applied in welding medium, welding equipment, welding equipment and other directions, can solve the problems of continuous automatic welding, lack of flux-cored welding wire, low production efficiency, etc. The effect of good position operation process and stable welding arc

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

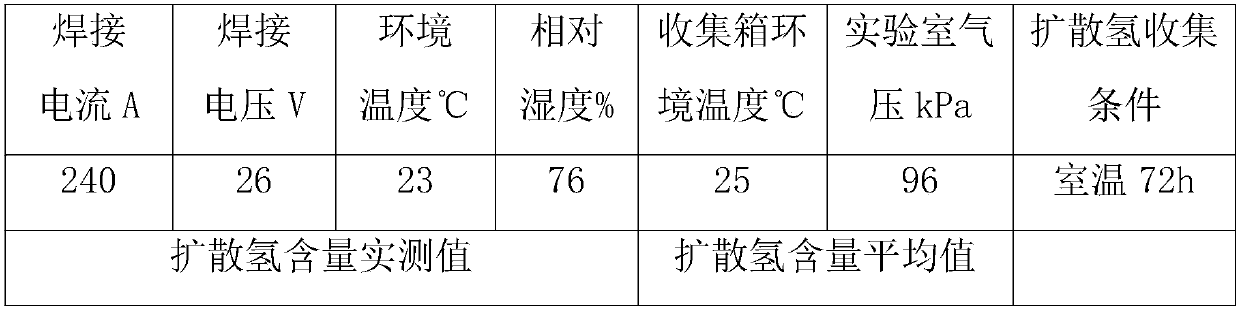

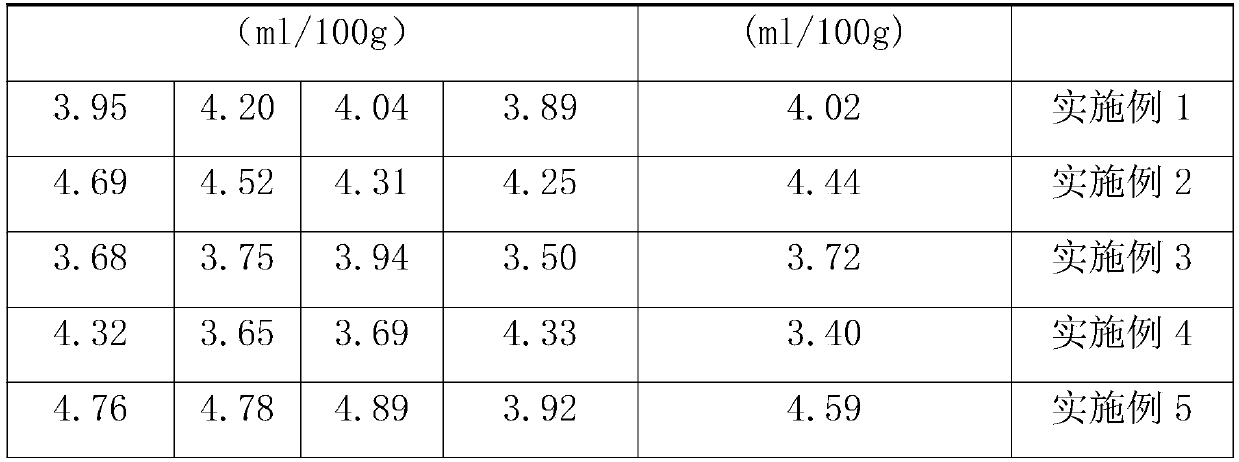

Embodiment 1

[0031] This embodiment provides 20 chromium-controlled steel gas-shielded flux-cored welding wire for nuclear power, including a carbon steel sheath and a flux core. The flux core accounts for 16% of the total mass of the flux-cored welding wire. The composition and content of the flux core account for the total mass percentage of the flux core as follows : Fluorite: 35%, Rutile: 20%, Feldspar: 2%, 45 #Ferrosilicon: 7%, rare earth fluoride: 1%, magnesium powder: 2%, electrolytic manganese: 15%, nickel powder: 1.5%, copper powder: 2%, chromium powder: 2%, the balance is Fe and unavoidable of impurities. Among them, the carbon steel sheath adopts low S, P carbon steel strip, the chemical composition of the carbon steel strip is C: 0.052%, Si: 0.25%, Mn: 0.24%, S: 0.005%, P: 0.006% , and the balance is iron. The preparation method of using the components in this embodiment to prepare the flux-cored wire is the same as that of the prior art, and the diameter of the prepared flux...

Embodiment 2

[0034] This embodiment provides 20 chromium-controlled steel gas-shielded flux-cored welding wire for nuclear power, including a carbon steel sheath and a flux core. The flux core accounts for 20% of the total mass of the flux-cored welding wire, and the composition and content of the flux core account for the total mass of the flux core. The percentages are as follows: Fluorite: 20%, Rutile: 10%, Feldspar: 1%, 45 # Ferrosilicon: 5%, rare earth fluoride: 0.5%, magnesium powder: 1%, electrolytic manganese: 8%, nickel powder: 1%, copper powder: 1%, chromium powder: 1%, the balance is Fe and unavoidable of impurities. Among them, the carbon steel sheath adopts low S, P carbon steel strip, the chemical composition of the carbon steel strip is C: 0.052%, Si: 0.25%, Mn: 0.24%, S: 0.005%, P: 0.006% , and the balance is iron. The preparation method of using the components in this embodiment to prepare the flux-cored wire is the same as that of the prior art, and the diameter of the ...

Embodiment 3

[0037] This embodiment provides 20 chromium-controlled steel gas-shielded flux-cored welding wire for nuclear power, including a carbon steel sheath and a flux core. The flux core accounts for 18% of the total mass of the flux-cored welding wire, and the composition and content of the flux core account for the total mass of the flux core. The percentages are as follows: Fluorite: 28%, Rutile: 15%, Feldspar: 1.5%, 45% # Ferrosilicon: 6%, rare earth fluoride: 0.7%, magnesium powder: 1.5%, electrolytic manganese: 12%, nickel powder: 1.3%, copper powder: 1.5%, chromium powder: 1.5%, the balance is Fe and unavoidable of impurities. Among them, the carbon steel sheath adopts low S, P carbon steel strip, the chemical composition of the carbon steel strip is C: 0.052%, Si: 0.25%, Mn: 0.24%, S: 0.005%, P: 0.006% , and the balance is iron. The preparation method of using the components in this embodiment to prepare the flux-cored wire is the same as that of the prior art, and the diam...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com