Flux-cored wire for gas protection of arc welding

A gas shielded and arc welding technology, which is applied in the direction of arc welding equipment, welding medium, welding equipment, etc., can solve problems such as difficulty in maintaining the shape of the weld bead and easy sagging of welded metal, and achieve the effect of improving strength and ensuring stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

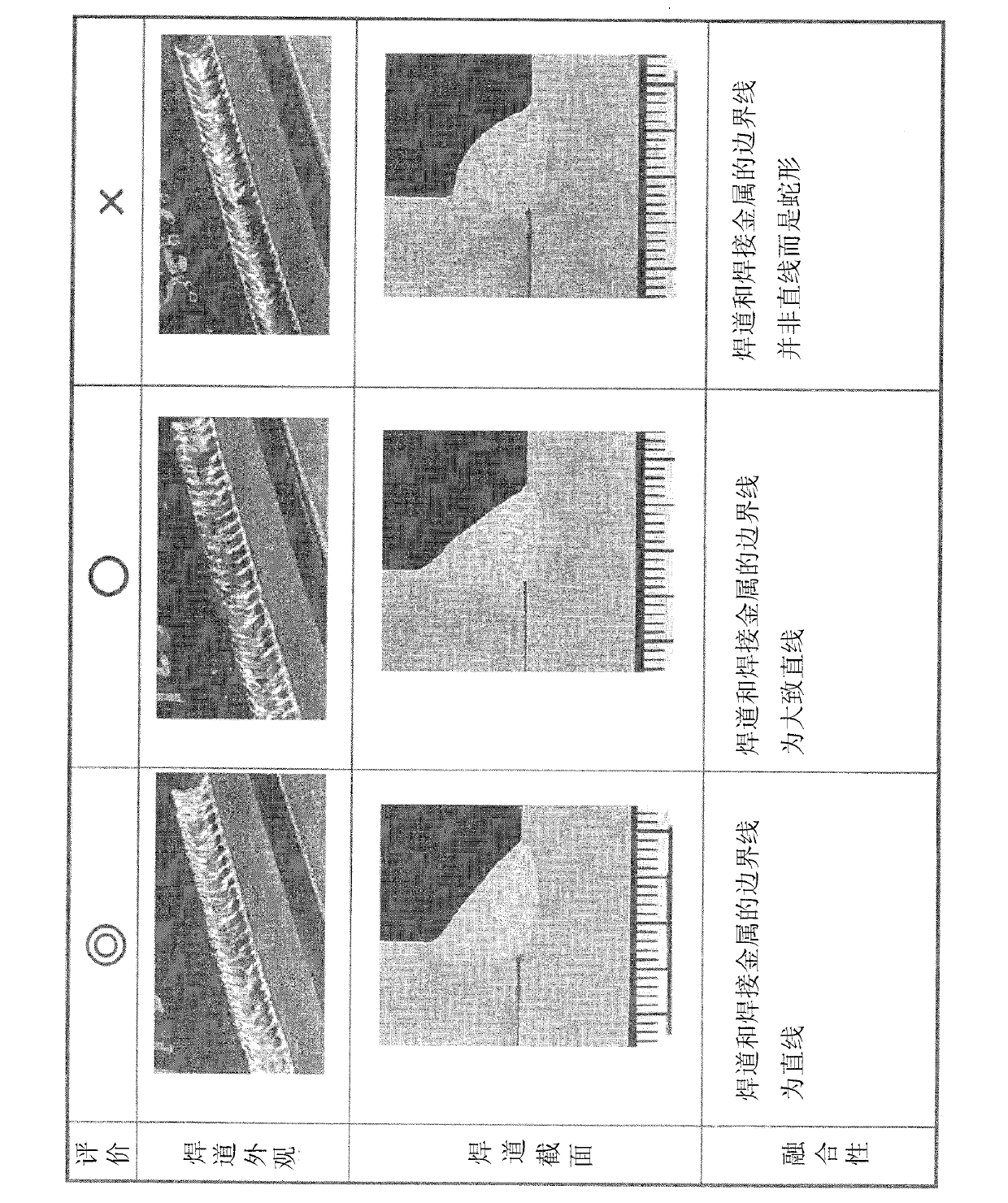

Method used

Image

Examples

no. 1 Embodiment approach 》

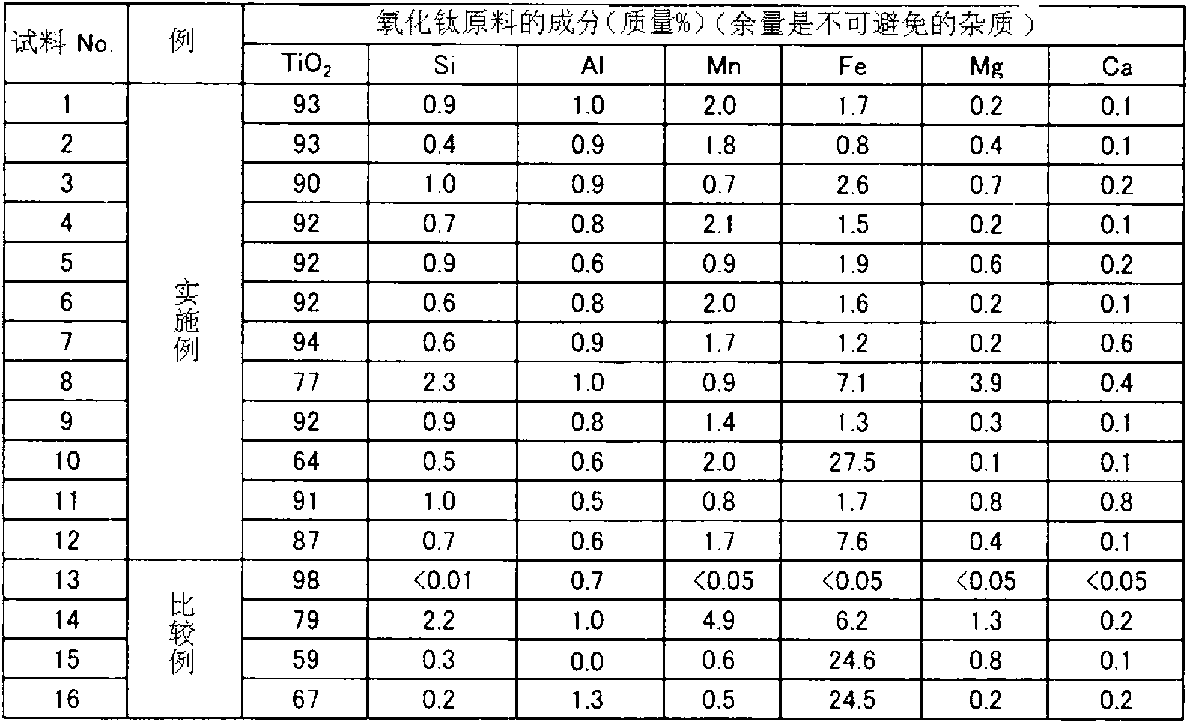

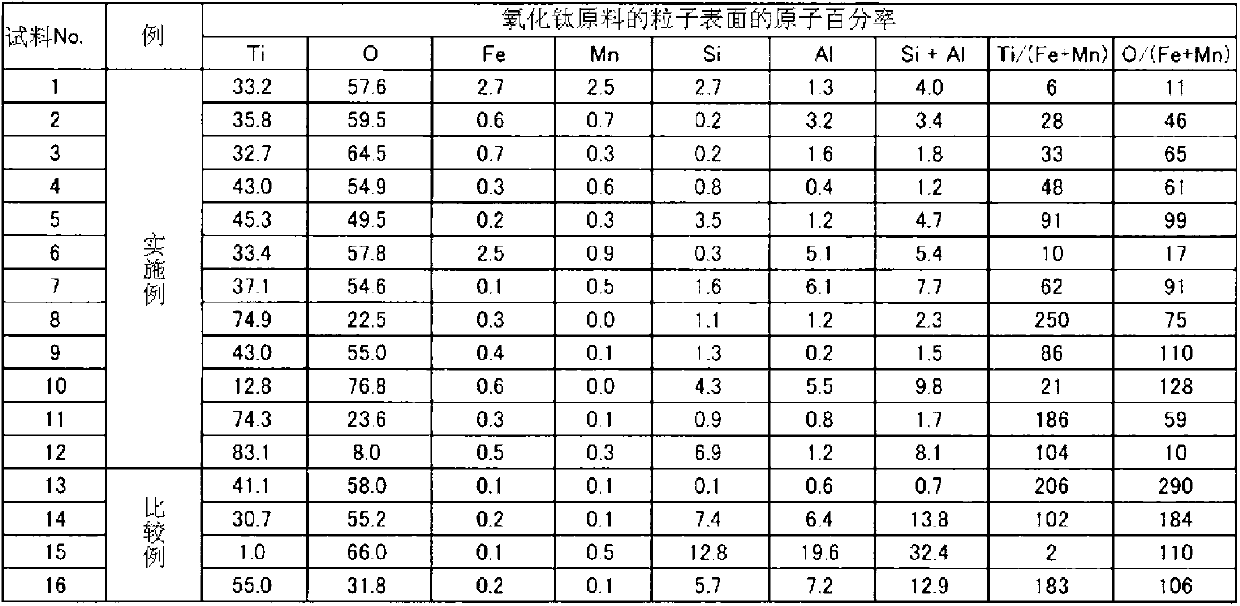

[0022] The first embodiment relates to a mild steel flux-cored welding wire.

[0023] The gas-shielded arc welding flux-cored wire of the present invention contains a specified amount of oxygen that forms particles.

[0024] Titanium oxide raw material, C, the total of the Si-equivalent amount of metal Si and the Si-equivalent amount of Si oxide, the Si-equivalent amount of metal Si, Mn, the total of the Al-equivalent amount of metal Al, and Mg, and the Na-equivalent amount of Na compounds and the total of the K-equivalent amount in the K compound, and the F-equivalent amount in the F compound. In addition, the flux filling rate based on the total mass of the welding wire is a predetermined amount.

[0025] In addition, the titanium oxide raw material has a predetermined amount of TiO2 based on the total mass of the titanium oxide raw material. 2 , Si, Al, Mn, Fe, Mg, Ca, and there is an oxide containing any one or more of Ti, Fe, Mn, Al, and Si on the particle surface of th...

no. 2 Embodiment approach 》

[0075]The second embodiment relates to FCW corresponding to low-temperature toughness. In the second embodiment, in order to achieve low temperature toughness at -40°C, predetermined amounts of B and Ni are added to the flux-cored wire of the first embodiment, and the contents of Cr, Nb, and V are limited to predetermined amounts.

[0076]

[0077] B segregates at the γ grain boundary, has the effect of suppressing the formation of proeutectoid ferrite, and is effective for improving the toughness of the weld metal. When the B content based on the total mass of the wire is less than 0.0003% by mass, most of B is immobilized as nitrides as BN, the effect of suppressing the formation of proeutectoid ferrite disappears, and no improvement in toughness can be recognized. On the other hand, when it exceeds 0.0130% by mass, the strength of the weld metal increases remarkably and the toughness decreases.

[0078] Therefore, the B content is 0.0003 to 0.0130% by mass.

[0079]

...

no. 3 Embodiment approach 》

[0086] The third embodiment relates to FCW corresponding to ultra-low temperature toughness. In the third embodiment, predetermined amounts of B and Ni, and Cr and Nb are added to the flux-cored wire of the first embodiment. The content of V is limited to a predetermined amount, and by adding a predetermined amount of metal Ti, toughness can be ensured even at an extremely low temperature of -60°C. In addition, Mo may be contained in a predetermined amount.

[0087]

[0088] Metal Ti refers to one or more of "pure metal Ti" and "alloy Ti".

[0089] Ti refines crystal grains and has a deoxidizing effect and an effect of improving toughness. When the Ti-equivalent amount of metal Ti based on the total mass of the welding wire is less than 0.05% by mass, the effect cannot be confirmed. On the other hand, when it exceeds 0.40% by mass, a large amount of Ti compounds such as TiC precipitates, the strength increases remarkably, and the toughness decreases. Therefore, the Ti eq...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com