Flux cored wire for gas-shielded arc welding

A gas shielded and arc welding technology, applied in arc welding equipment, welding media, welding equipment, etc., can solve the problems of weld metal performance research, unclearness, and inability to meet the requirements of NACE, and achieve good low temperature toughness and welding operability good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

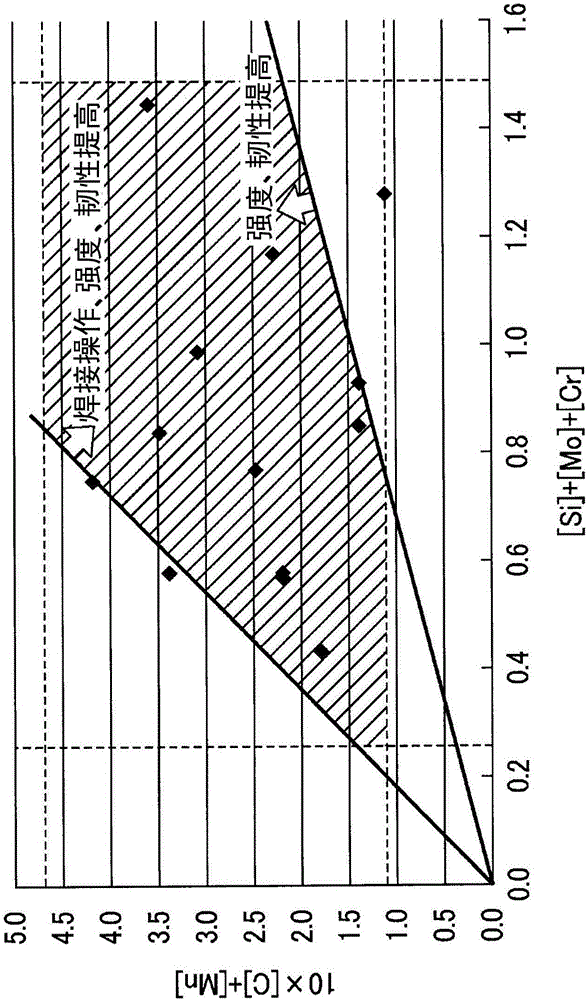

Image

Examples

Embodiment

[0087] Hereinafter, examples and comparative examples of the present invention will be given, and the effects of the present invention will be specifically described. In this example, the steel sheath made of mild steel was filled with 13 to 20% by mass of flux, and each flux-cored wire of Examples and Comparative Examples having the compositions shown in Table 1 and Table 2 below was produced. At this time, the wire diameter was 1.2 mm. In addition, welding wire Nos. 1 to 13 shown in Table 1 below are examples within the scope of the present invention, and welding wire Nos. 14 to 28 shown in Table 2 below are comparative examples outside the scope of the present invention.

[0088] [Table 1]

[0089]

[0090] [Table 2]

[0091]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Yield strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com