Flux-cored wire for stainless steel arc welding

一种药芯焊丝、不锈钢的技术,应用在焊接/焊接/切割物品、焊接介质、焊接设备等方向,能够解决熔渣剥离性和耐点蚀性劣化、不能适应耐点蚀性和低温韧性、含量少等问题,达到焊接操作性良好、良好熔渣包覆性、优异耐点蚀性的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

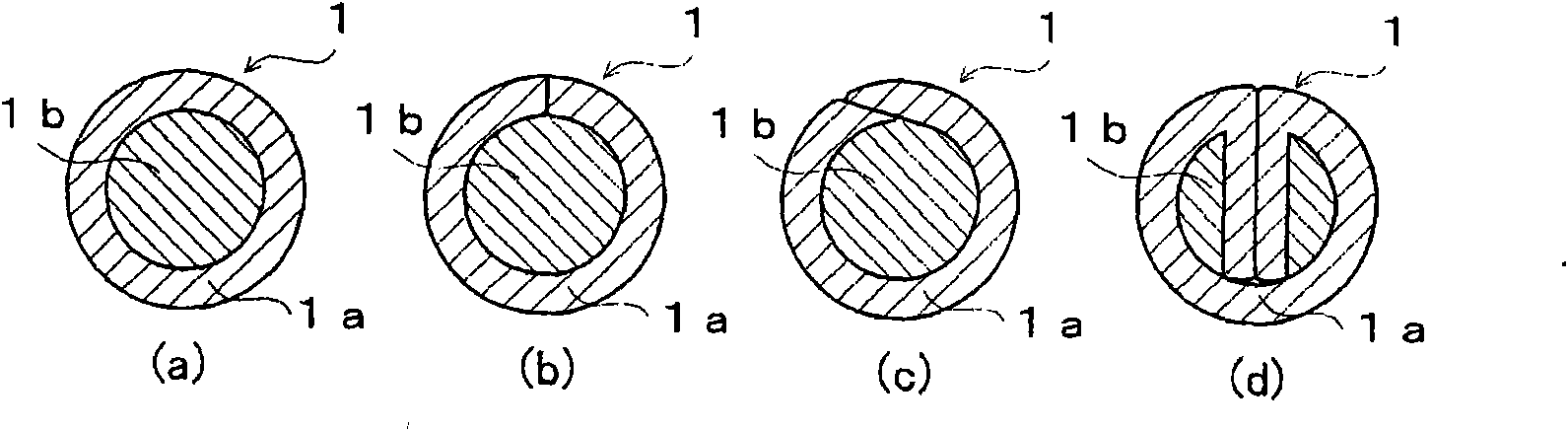

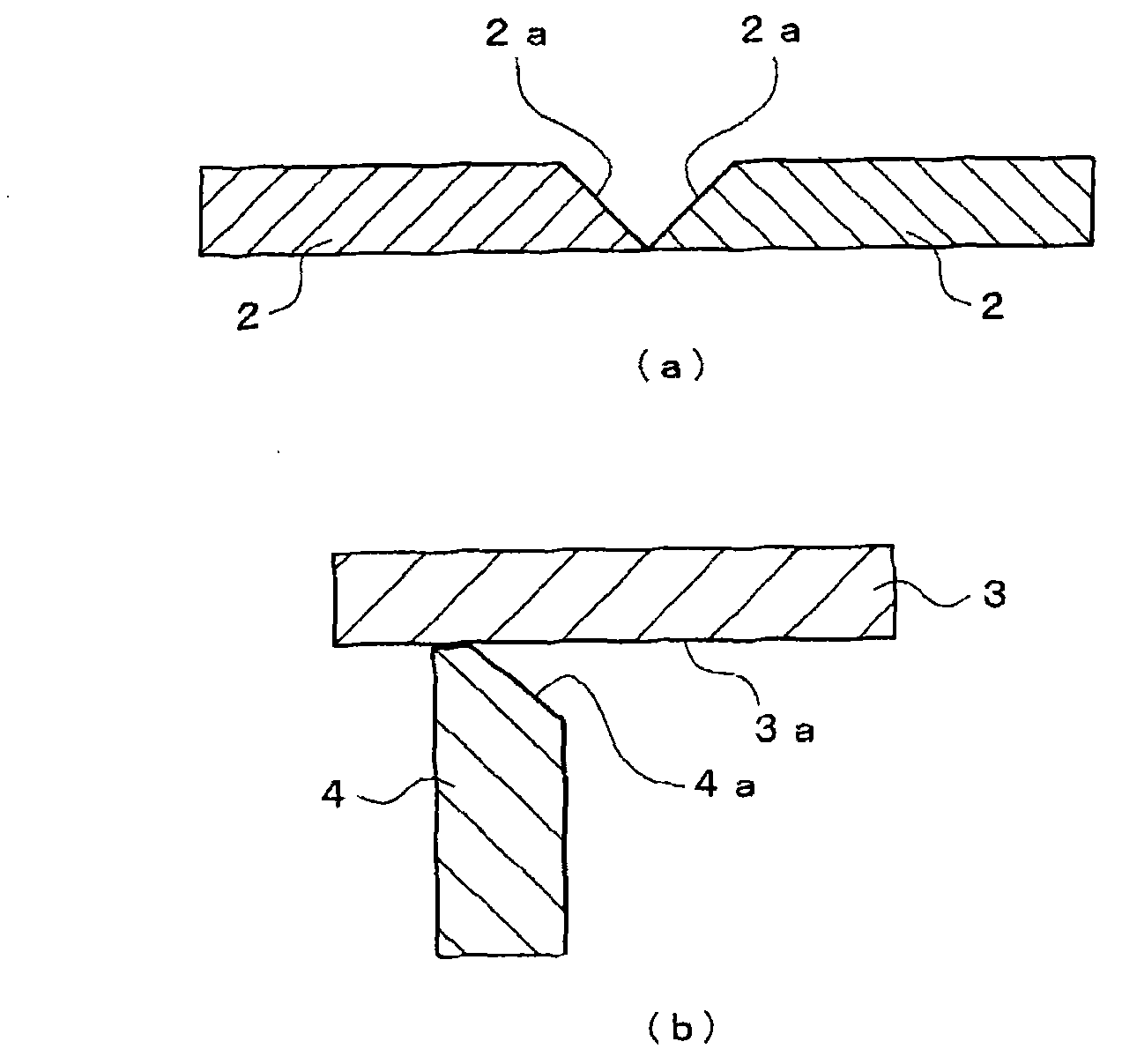

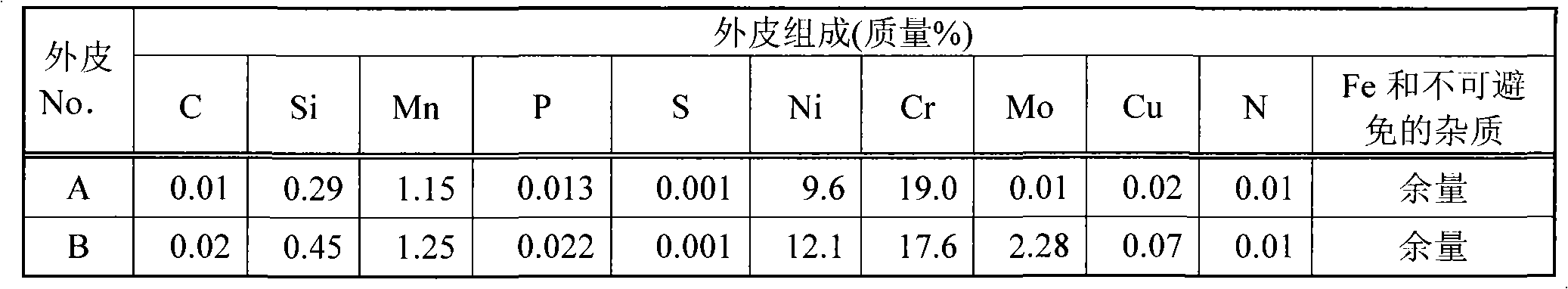

[0014] Hereinafter, the embodiments of the present invention will be specifically described. In order to obtain high pitting corrosion resistance in welded parts of duplex stainless steels, it has been conventionally done to add N, Cr, and Mo as components of flux-cored welding wires. However, adding a large amount of N can cause welding defects such as pits and gas grooves in the welded portion, and it is also easy to degrade the low-temperature toughness of the welded portion. Structural materials with degraded low-temperature toughness cannot be used in high-pressure and low-temperature environments such as sea trenches or the seabed. In order to solve the problems of the occurrence of welding defects and the deterioration of the low-temperature toughness of the welded portion caused by the addition of N to the flux-cored welding wire, the inventors of the present application conducted intense experimental research. Therefore, it was found that in order to maintain pitting ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com