Preparation method for graphene-316L stainless steel based on selective laser melting

A selective laser melting, -316L technology, applied in the field of additive manufacturing, can solve the problems of low processing dimensional accuracy, low utilization rate of raw materials, inability to meet the requirements of special-shaped complex parts shape, mechanical strength and corrosion resistance, etc. The effect of improving tensile strength and corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] In order to enable those skilled in the art to better understand the solution of the present invention, the technical solution of the present invention will be further described below in conjunction with specific examples.

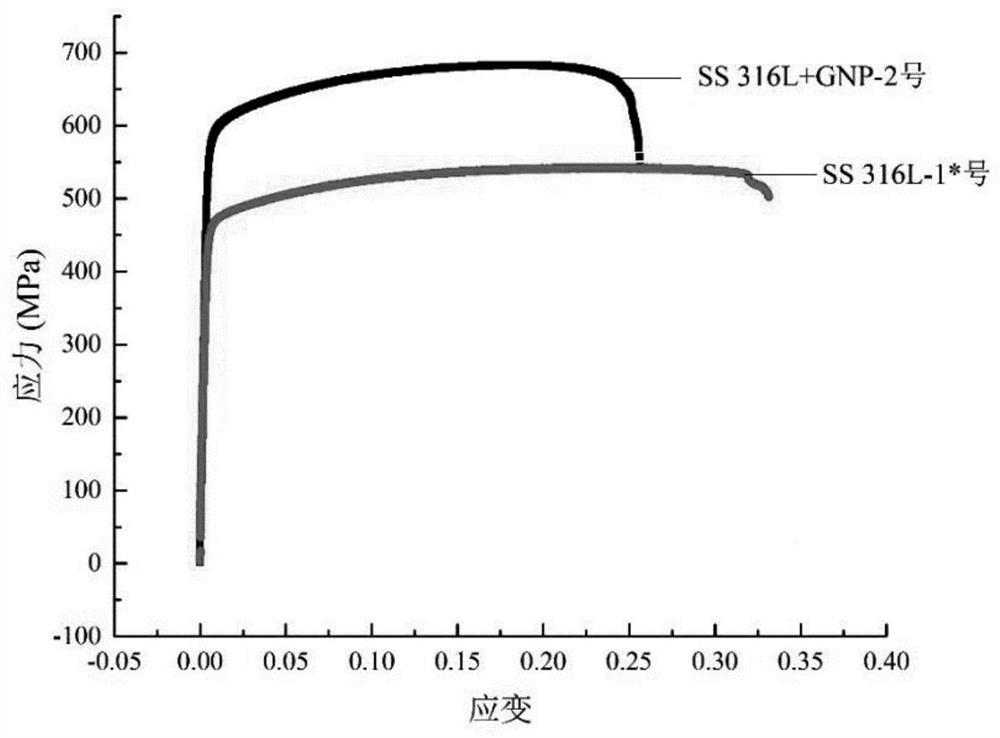

[0036] The average particle size of the manufacturing material 316L stainless steel powder is 15-45μm, and its main chemical composition is shown in the table below. The experiment uses graphene strengthening, that is, 0.1% graphene is added to the 316L stainless steel powder. The layer rate is ~80%, the purity is ~99%, and the specific surface area is 800-900m 2 / g. Mix the powder manually using absolute ethanol.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com