Low-cost austenitic stainless steel with excellent corrosion resistance

A technology for austenitic stainless steel and corrosion resistance, applied in the field of austenitic stainless steel, can solve the problems of poor pitting corrosion resistance and formability, limited improvement, poor pitting corrosion resistance, etc., to achieve cost reduction and excellent corrosion resistance The effect of high stability and good thermal processing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-4

[0031] Follow the steps below to manufacture:

[0032] (1) Use non-vacuum induction furnace, electric furnace + AOD dual process or electric furnace + AOD + VOD triple process for smelting and casting;

[0033] (2) Hot-rolled into hot-rolled coils with different specifications of 6-12 mm, solution heat treatment at 1080 ° C, and then pickling;

[0034] (3) The above pickled hot-rolled coil was further cold-rolled into a 2 mm cold-rolled sheet.

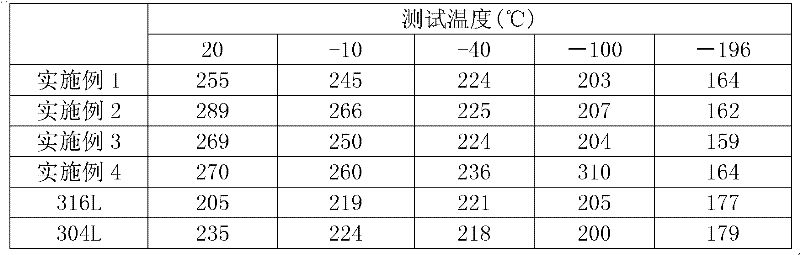

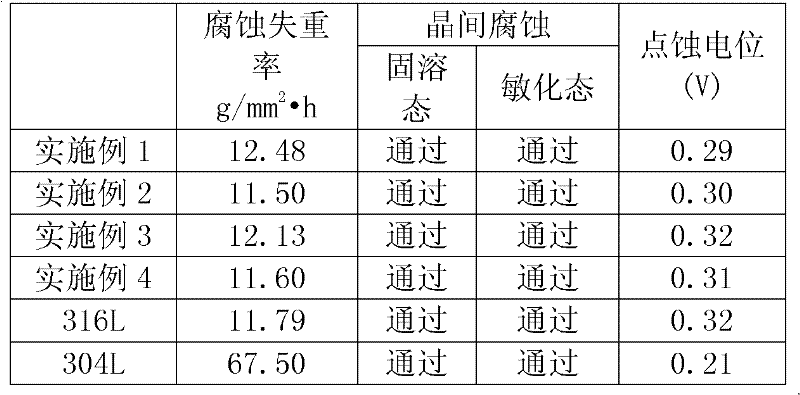

[0035] Table 1 is the chemical composition table of Examples 1-4 and conventional austenitic stainless steels 304L and 316L as comparative examples.

[0036] Table 1. Chemical composition (weight percent) of embodiment 1-4 and comparative example

[0037]

C

Si

mn

P

S

Cr

Ni

N

Mo

Cu

B

Val

(δ)

Si / M

no

Md3

0

Reality

Shi

example 1

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com