Welding rod additive containing cerium oxide and method for preparing welding rod additive containing cerium oxide

A technology containing cerium oxide and cerium oxide, applied in welding equipment, metal processing equipment, welding medium, etc., can solve the problem that the welding rod is difficult to meet the market demand.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

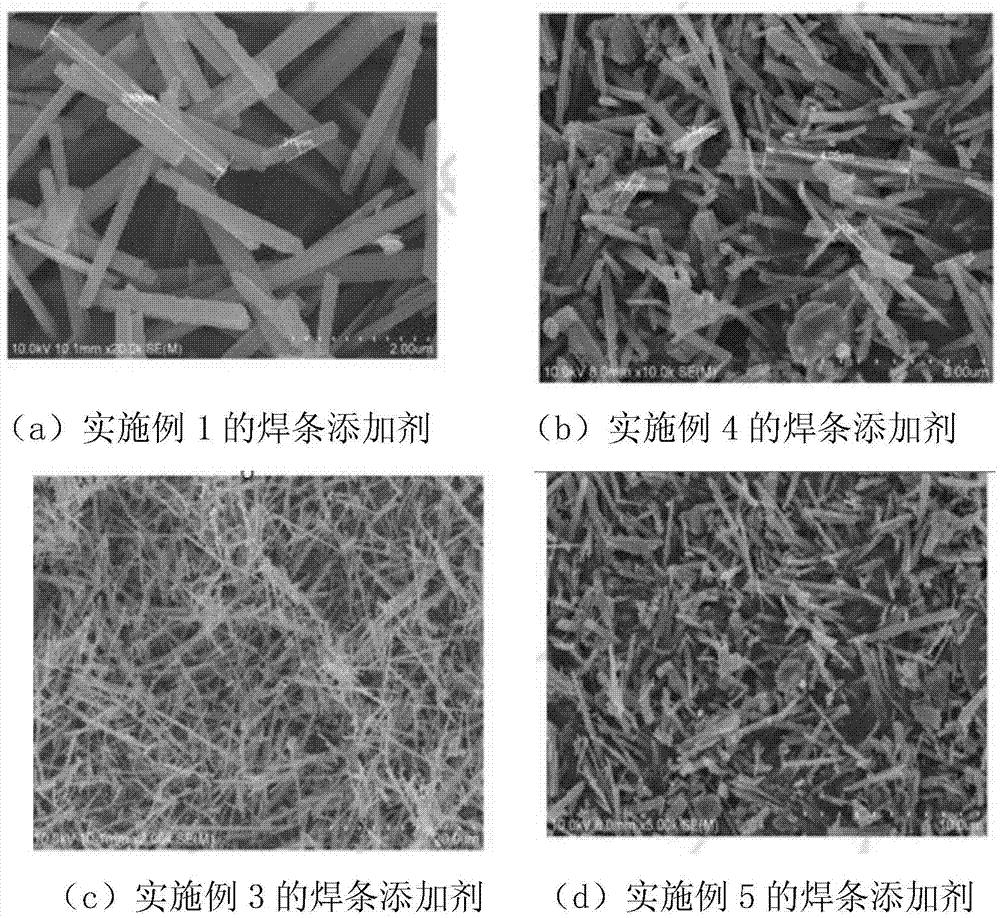

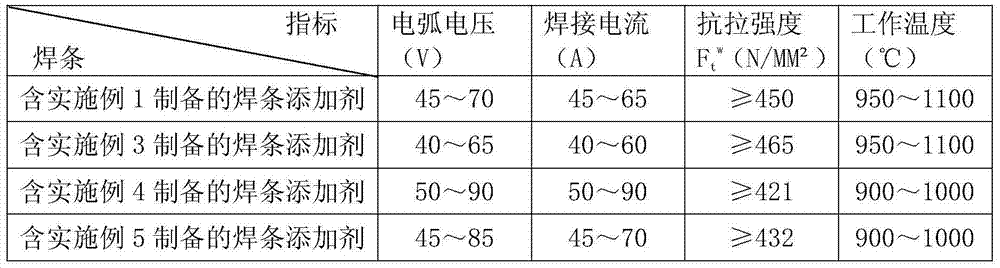

[0015] Embodiment 1: the preparation of welding rod additive

[0016] 1) Weighing high-purity titanium dioxide and electronic grade potassium carbonate according to a molar ratio of 3:2, then weighing 3% cerium oxide of the total mass of high-purity titanium dioxide and electronic grade potassium carbonate, and mixing the three to obtain a mixture;

[0017] 2) Put the mixture into a ball mill and mill it for 4 hours to obtain a mixed powder;

[0018] 3) Put the mixed powder in the mullite sagger, push it into the tunnel kiln, set the tunnel kiln to heat up to 1200°C at a heating rate of 250°C / h, keep it warm for 4 hours, and then turn off the heating system of the kiln , naturally cool down for 8 hours, and then take out the mullite sagger;

[0019] 4) After the block synthesized in the mullite sagger is naturally cooled to normal temperature, the block is crushed and ground until it passes through a 200-mesh sieve to obtain the electrode additive.

Embodiment 2

[0020] Embodiment 2: the preparation of welding rod additive

[0021] 1) Weigh high-purity titanium dioxide and electronic-grade potassium carbonate according to a molar ratio of 1:1, then weigh 5% cerium oxide of the total mass of high-purity titanium dioxide and electronic-grade potassium carbonate, and mix the three to obtain a mixture;

[0022] 2) Put the mixture into a ball mill and mill it for 4 hours to obtain a mixed powder;

[0023] 3) Put the mixed powder in the mullite sagger, push it into the tunnel kiln, set the tunnel kiln to heat up to 1195°C at a heating rate of 260°C / h, keep it warm for 4.5h, and then turn off the heating of the kiln system, cool down naturally for 8 hours, and then take out the mullite sagger;

[0024] 4) After the block synthesized in the mullite sagger is naturally cooled to normal temperature, the block is crushed and ground until it passes through a 100-mesh sieve to obtain the electrode additive.

Embodiment 3

[0025] Embodiment 3: the preparation of welding rod additive

[0026] 1) Take high-purity titanium dioxide, electronic-grade potassium carbonate and electronic-grade sodium carbonate according to the molar ratio of 3:1.5:1.5, then weigh 5% of the total mass of high-purity titanium dioxide, electronic-grade potassium carbonate and electronic-grade sodium carbonate Cerium oxide, mixing the four raw materials to obtain a mixture;

[0027] 2) Put the mixture into a ball mill and mill it for 4 hours to obtain a mixed powder;

[0028] 3) Put the mixed powder in the mullite sagger, push it into the tunnel kiln, set the tunnel kiln to heat up to 1200°C at a heating rate of 250°C / h, keep it warm for 4 hours, and then turn off the heating system of the kiln , naturally cool down for 8 hours, and then take out the mullite sagger;

[0029] 4) After the block synthesized in the mullite sagger is naturally cooled to normal temperature, the block is crushed and ground until it passes throu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com