Flux-cored wire

A technology of flux-cored welding wire and welding wire, which is applied in the direction of welding medium, welding equipment, welding/welding/cutting items, etc. It can solve the problems of not being able to meet high temperature crack resistance and high temperature crack resistance, and achieve excellent welding workability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

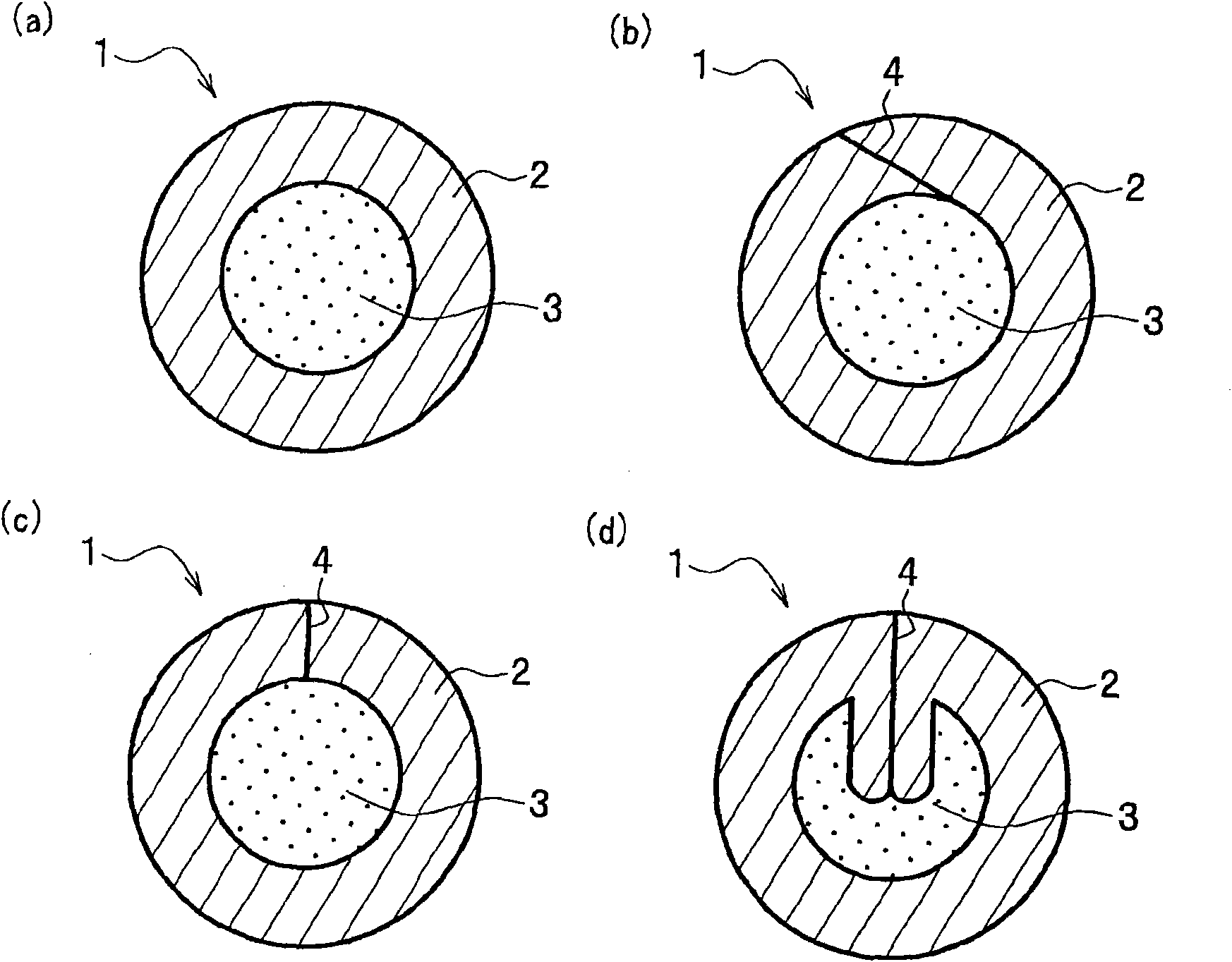

[0020] The flux-cored welding wire of the present invention will be described in detail. figure 1 (a)-(d) are cross-sectional views showing the structure of a flux cored wire.

[0021] Such as figure 1 As shown in (a) to (d), a flux-cored welding wire (hereinafter referred to as a welding wire) 1 is composed of a cylindrical steel sheath 2 and flux 3 filled in the cylinder. In addition, the welding wire 1 can also be in any of the following forms: figure 1 The tube of this jointless steel sheath 2 shown in (a) is filled with the seamless type of flux 3; The cylinder is filled with flux 3 seamed type.

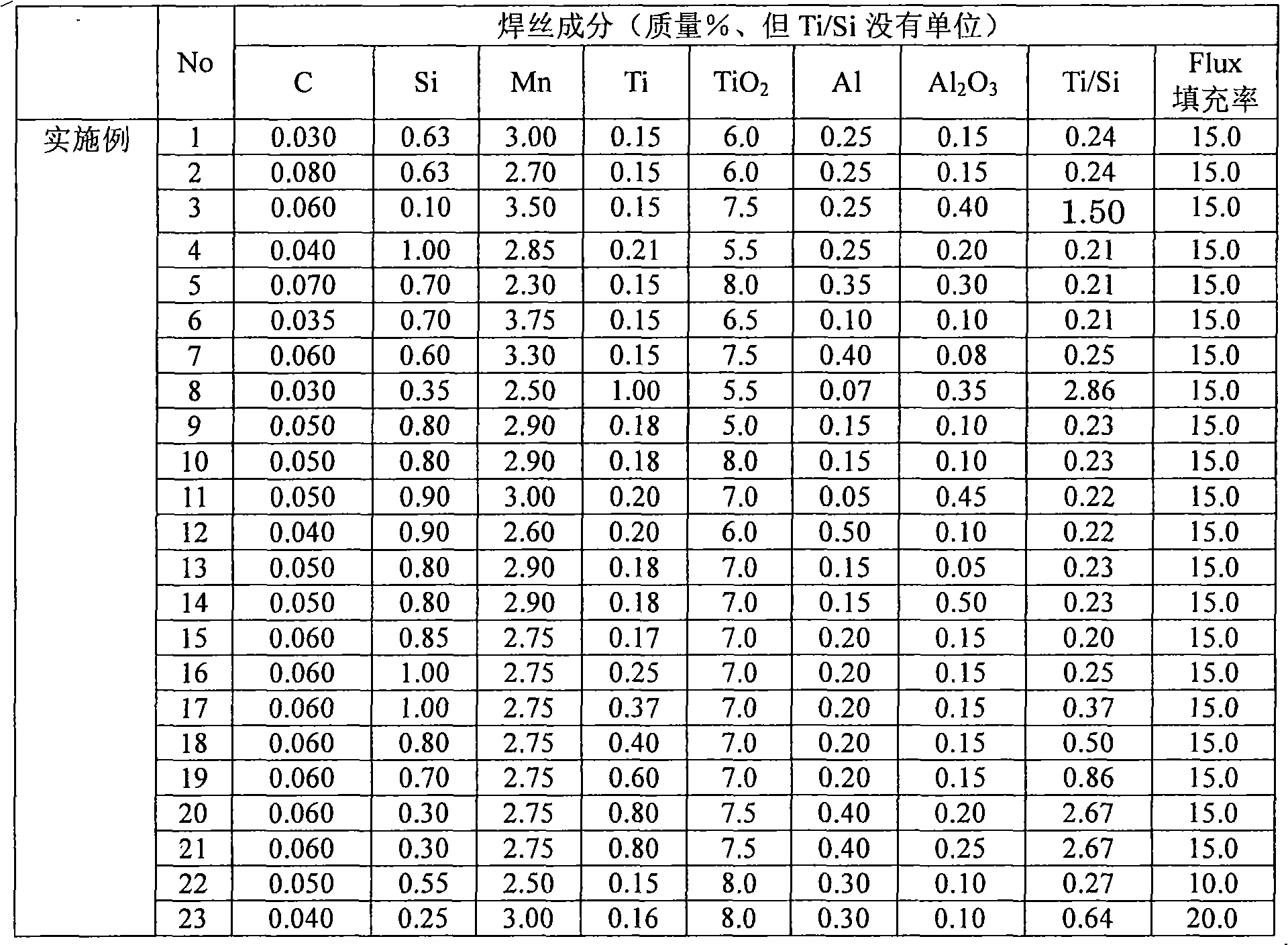

[0022] Furthermore, the welding wire 1 has a predetermined amount of flux filling rate and contains predetermined amounts of C, Si, Mn, Ti, TiO 2 , Al and Al 2 o 3 , the balance is composed of Fe and unavoidable impurities, and the calculated amount of Ti and the calculated amount of Si satisfy a prescribed relationship (specifically, (calculated amount of Ti / calculated am...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com