Solid welding wire for gas-shielded electric-arc welding of high-strength steel

A technology of solid welding wire and gas shielding, which is applied in the direction of welding medium, welding equipment, welding/cutting medium/material, etc., can solve the problems of increased welding wire production cost, and achieve excellent welding operability, excellent effect, and beautiful weld shape Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The specific application examples of the solid gas-shielded welding wire described in the present invention are as follows.

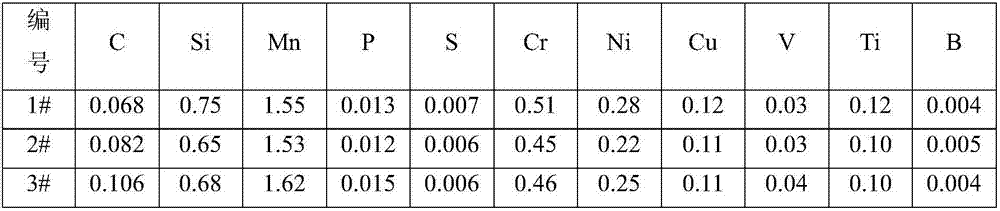

[0035] The main chemical composition of welding wire is listed in Table 1.

[0036] Table 1 Main chemical composition of welding wire in application examples, wt%

[0037]

[0038] 1. Welding process performance experiment:

[0039] In the welding parameter range of current 200-350A and voltage 30-35V, the welding process performance of the welding wire was tested. The diameter of the experimental welding wire was φ1.6mm. Less spatter, can meet the welding process requirements.

[0040] 2. Weld mechanical performance experiment:

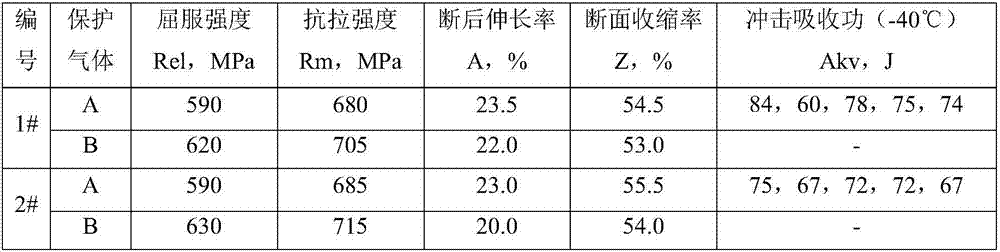

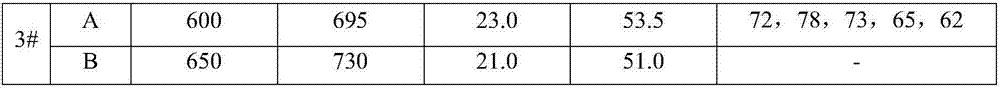

[0041] The shielding gas used in the experiment was 100% CO 2 (A) and 80% Ar 2 +20%CO 2 (B), the welding parameters are current 330-380A and voltage 32-35V. The mechanical properties of weld deposited metal were tested, and the results are shown in Table 2.

[0042] Table 2 Mechanical properties of welding wi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com