Package for electronic parts, lid thereof, material for the lid and method for producing the lid material

A technology of electronic components and packages, which is applied in the direction of electrical components, electric solid devices, semiconductor/solid device parts, etc., can solve the problems of insufficient effect, low productivity of packages, poor welding operability, etc., and achieve operation Excellent performance, excellent airtightness, and the effect of suppressing cracking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

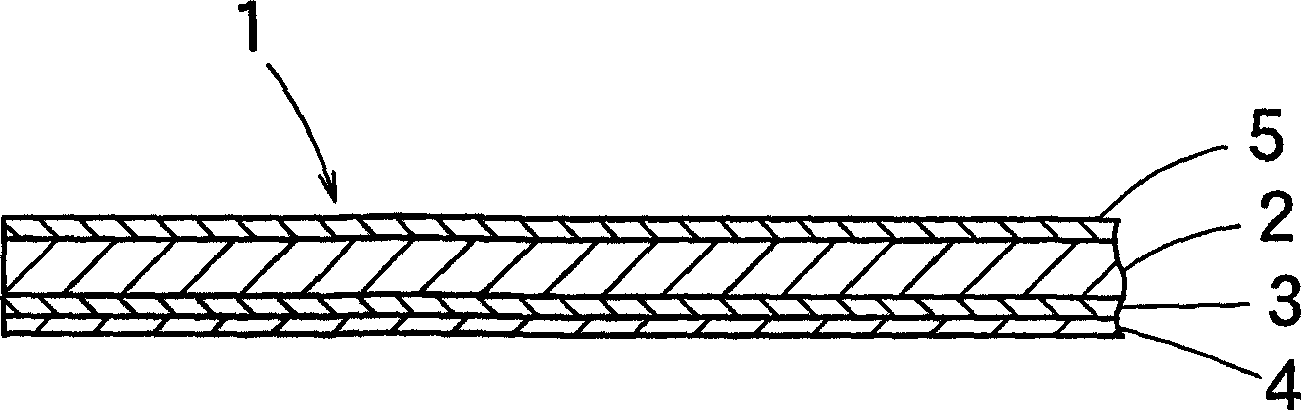

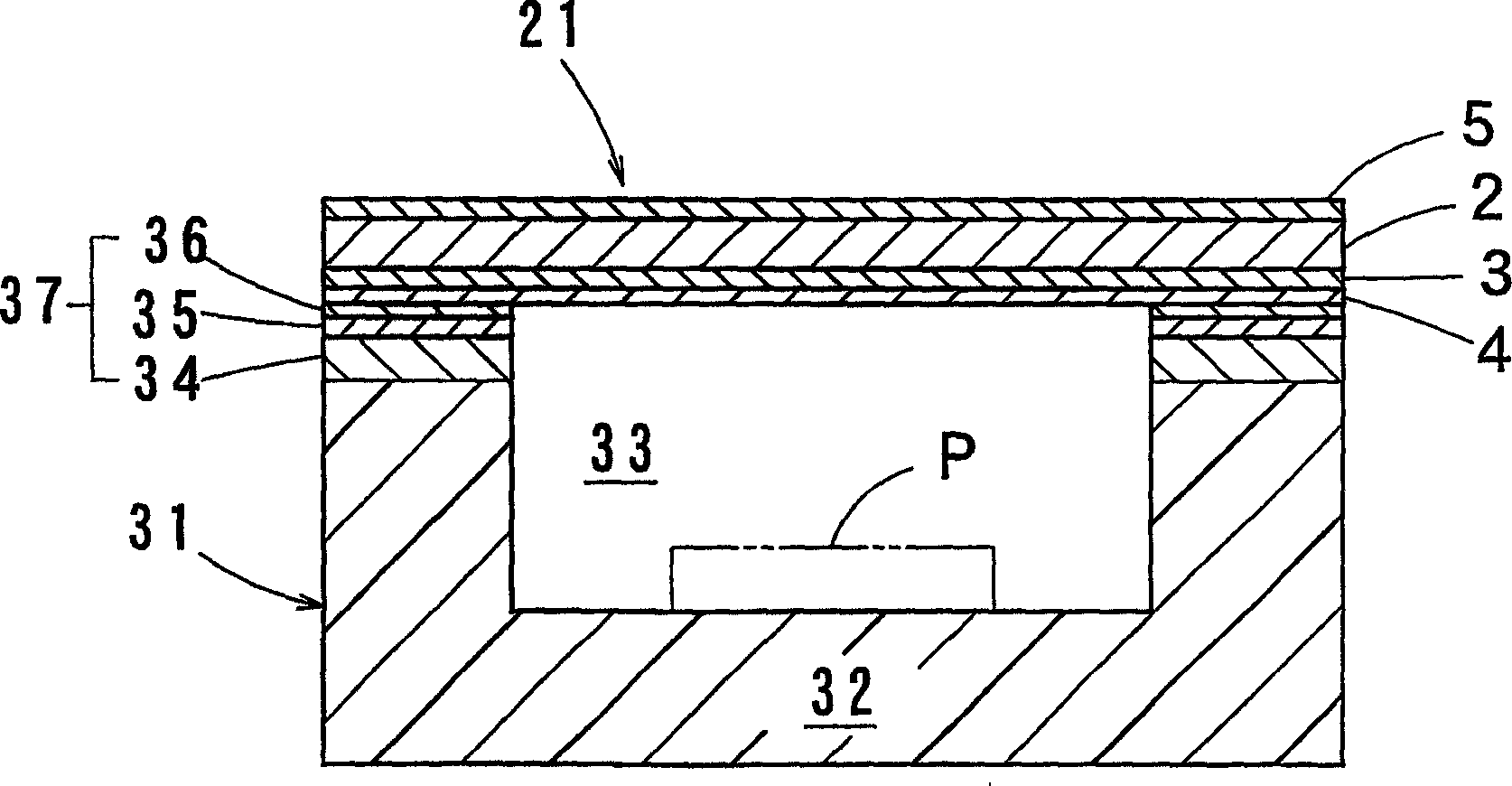

[0048] figure 1 The cover material sample of the shown 4-layer structure was produced by the following procedure. As the raw material of the substrate layer 2, a substrate sheet made of Fe-29 mass% Ni-17 mass% Co alloy with a width of 20 mm and a thickness of 1100 μm was prepared. As the Ni sheet made of Ni, a copper sheet made of oxygen-free copper (Cu: 99.95% by mass, O: 0.00006% by mass) with a width of 20 mm and a thickness of 600 μm was prepared as a raw material of the intermediate metal layer 3 . One surface of the base sheet is laminated with a nickel sheet, and the other surface is laminated with a copper sheet, and cold-compression bonding is carried out between rollers at a reduction rate of 60%, to obtain a copper bonded by pressure between adjacent materials. Layered layers. Furthermore, this copper laminate was held at 1000° C. for 3 minutes in an annealing furnace to perform diffusion annealing.

[0049] A solder material sheet formed of 85% by mass Ag-Cu (me...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com