Differential device and method of manufacturing the same

A technology of differential gear and differential gear, which is applied in the direction of differential gear, gear, gear parts, etc., to achieve the effect of improving bonding strength, improving efficiency, and preventing splashes from invading into the differential casing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0055] Embodiments of the present invention will be described below with reference to the drawings.

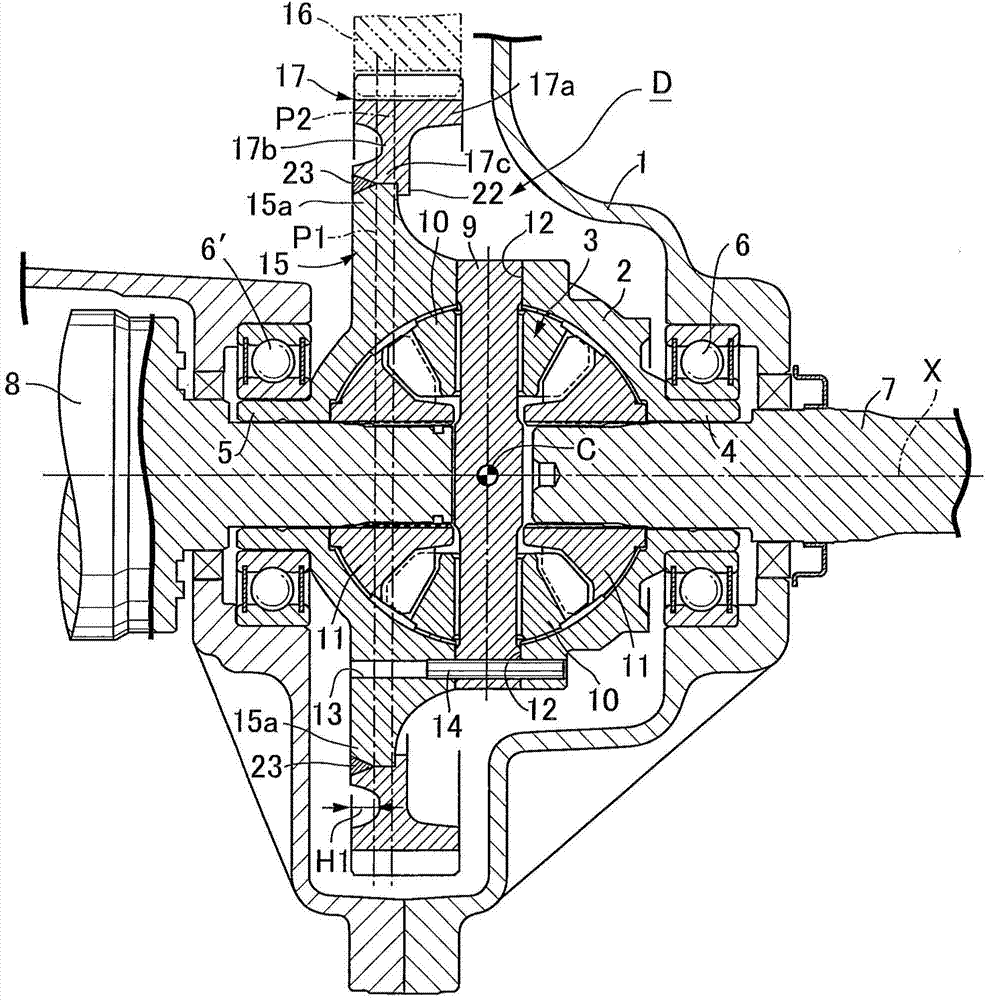

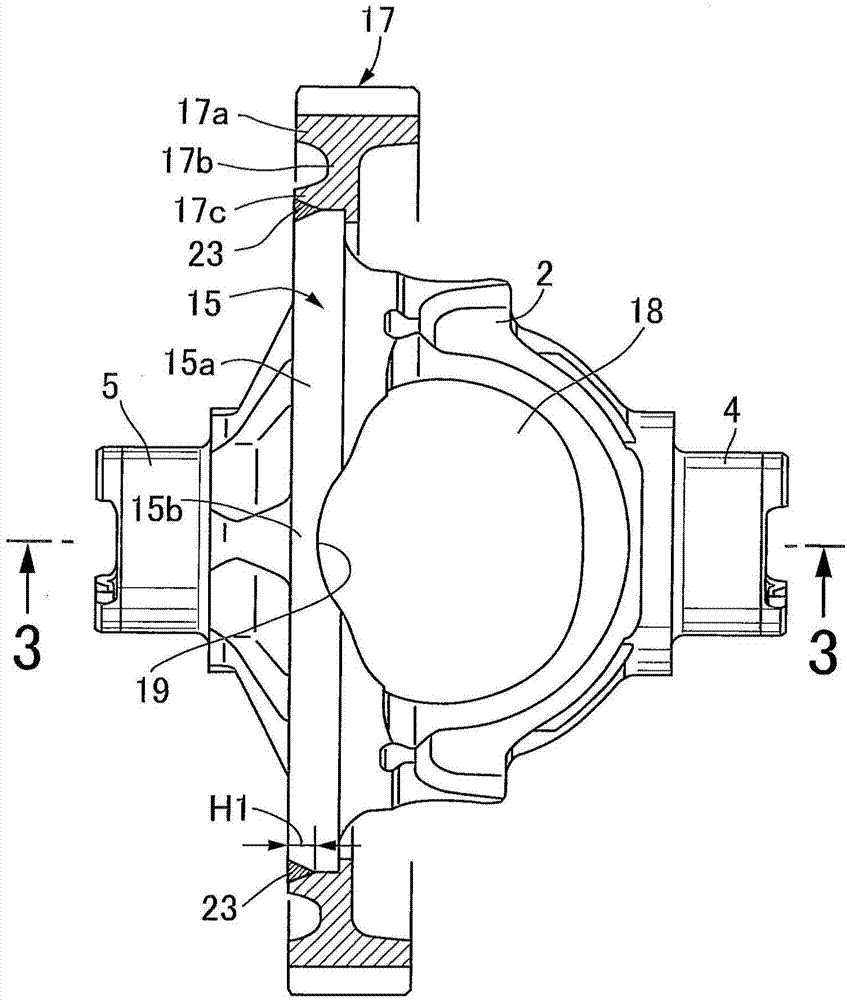

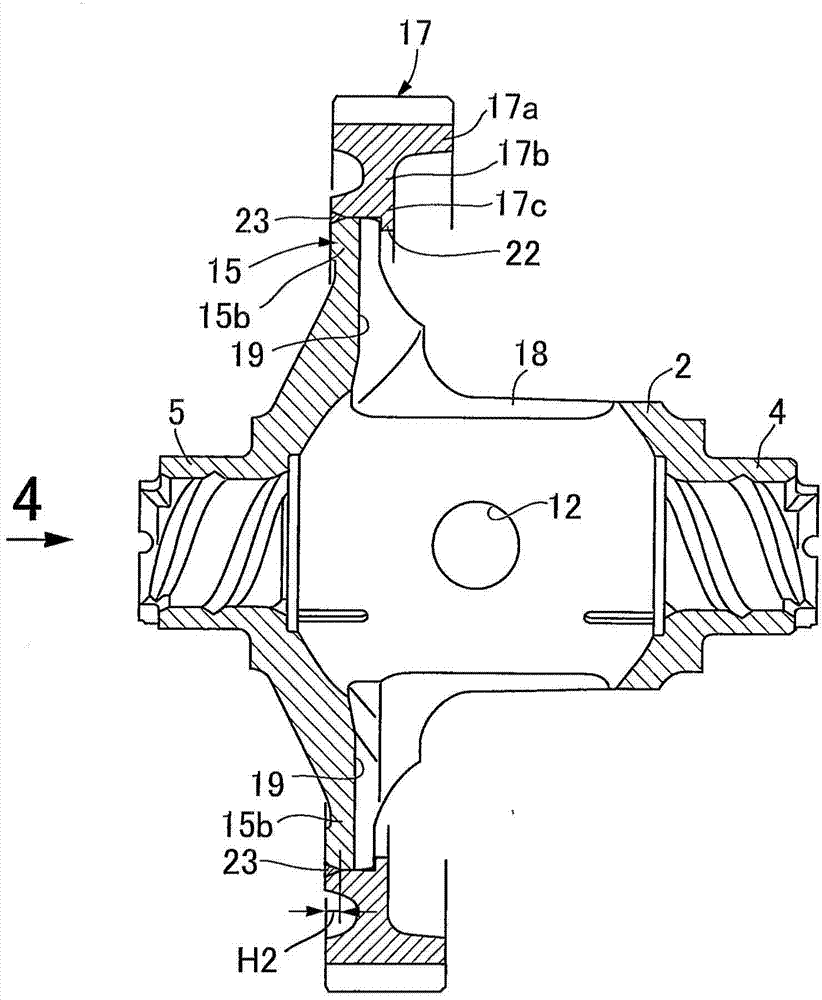

[0056] exist figure 1 Among them, the differential device D is accommodated in the transmission case 1 of the vehicle. This differential device D is composed of a differential case 2 and a differential mechanism 3 housed in the differential case 2 . A first bearing boss 4 and a second bearing boss 5 aligned on the same axis X are integrally formed on the right side and the left side of the differential case 2, and these first and second bearing bosses 4 , 5 are supported on the transmission housing 1 via bearings 6, 6', and support the right axle 7 and the left axle 8.

[0057] The differential mechanism 3 is composed of: a pinion shaft 9 held on the differential case 2 in a manner perpendicular to the axis X; a pair of pinion gears 10 supported by the pinion shaft 9; And a pair of side gears 11 are spline-coupled to the inner ends of the axles 7 and 8 and meshed with the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com