Method for housing solder wire and device thereof

A welding wire and reel technology, which is used in transportation and packaging, transportation of filamentous materials, thin material processing, etc., can solve the problems of difficulty in improving the efficiency of welding operations, residues, and unsatisfactory appearance, so as to improve the efficiency of welding operations and ensure quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

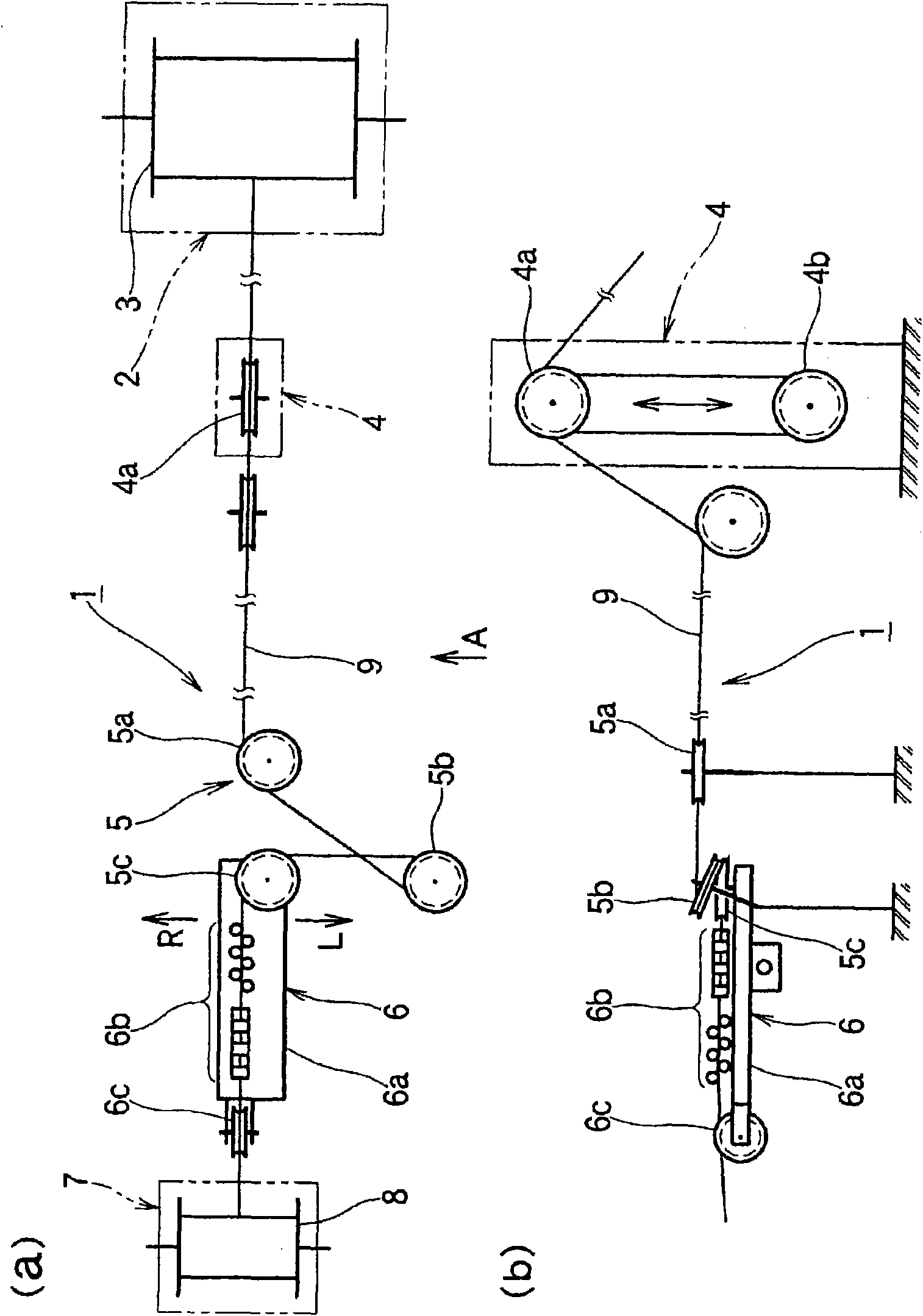

[0025] Next, for the wire winding device according to the embodiment of the present invention that implements the welding wire winding method of the present invention, reference will be made to the schematic plan view in order. figure 1 (a), and figure 1 (a) View from A figure 1 (b) Explain.

[0026] figure 1Indicated by reference numeral 1 is a wire winding device according to an embodiment of the present invention. This welding wire winding device 1 includes a welding wire extractor 2 provided with a relatively large-diameter bobbin 3 (rotating around a horizontal axis) formed by winding a welding wire 9 . In addition, a tension adjusting roller device 4 is provided. The tension adjusting roller device 4 includes a fixed side roller 4a around which the welding wire 9 drawn out from the bobbin 3 is wound, and a side roller 4a which winds the welding wire 9 while approaching and separating from the fixed side roller 4a. The tension of the moving side roller 4b is kept ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com