Welding machine for distributor welding

A distributor and welding machine technology, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve problems such as inability to air cooling and gas protection, poor quality of distributors, oxidation of welding parts, etc., to ensure beautiful appearance effect and quality, increasing efficiency and precision, ensuring efficient cooling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

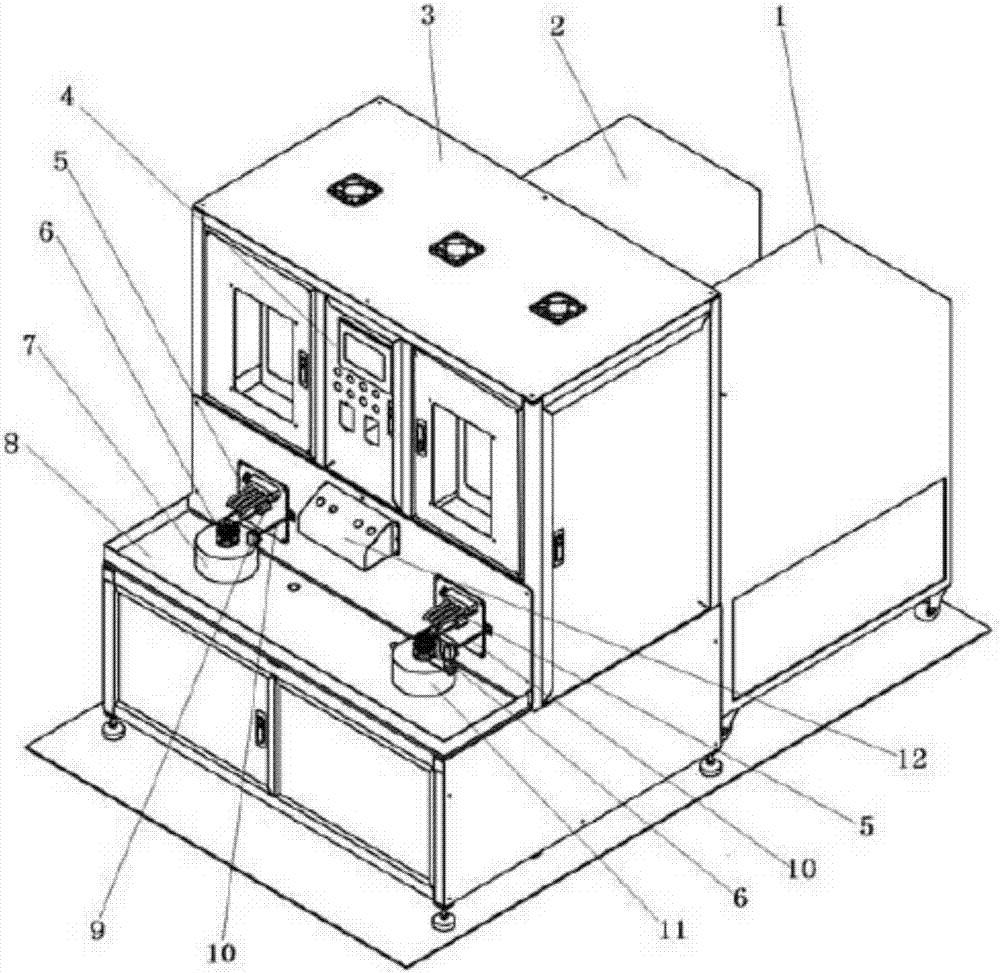

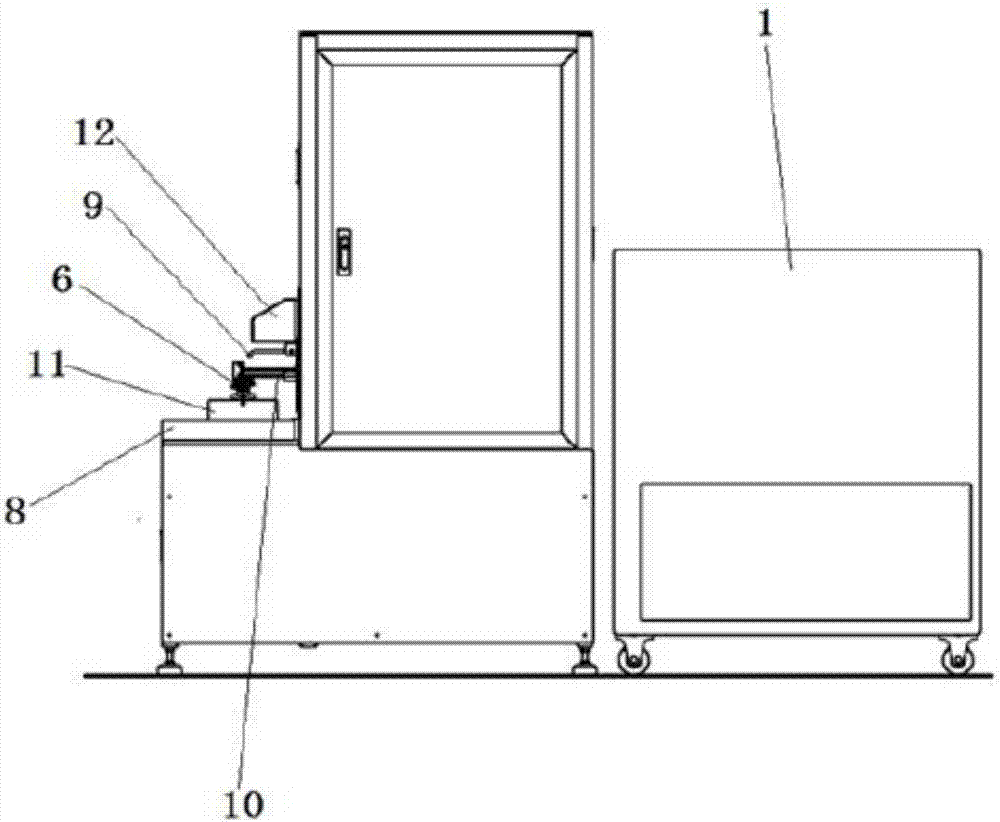

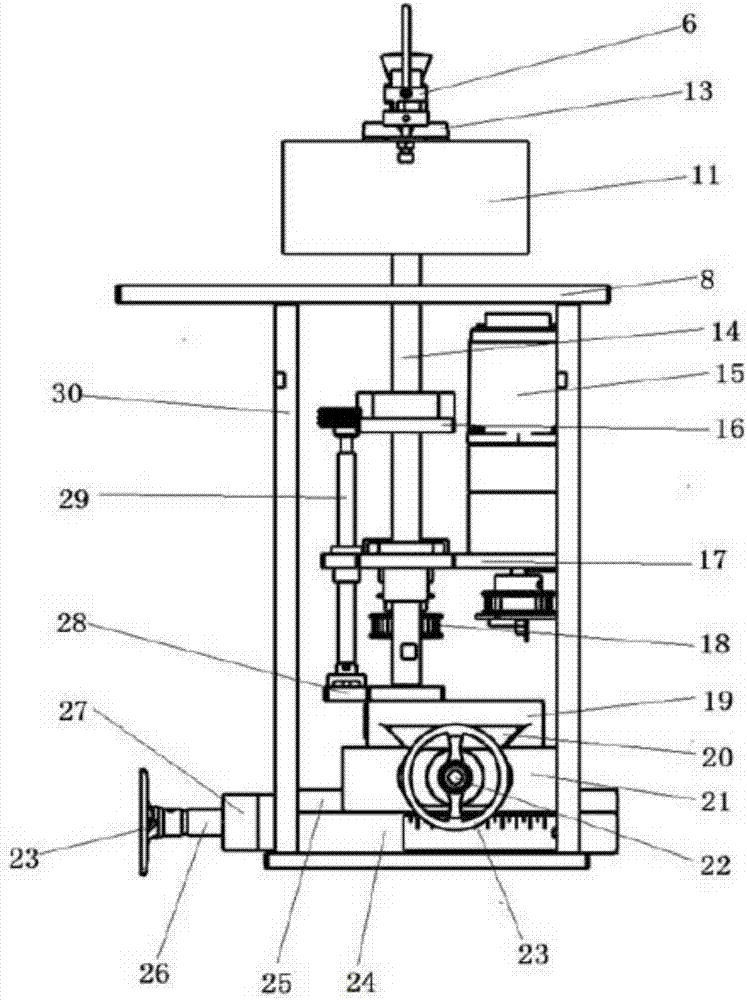

[0017] Such as Figure 1 to Figure 3 As shown, the present invention is a welding machine for welding distributors in the refrigeration and HVAC industry. The welding machine includes a protective cover 3 in the middle of the frame, and a horizontal welding platform 8 is provided on the frame at the front side of the protective cover 3. A nitrogen storage box 1 and a water-cooled circulation box 2 are arranged on the frame, and two stations are arranged side by side on the welding platform 8, which are respectively the first station 11 and the second station 7; Tool 13 is fixedly placed with welded distributor 6; the protective cover 3 on the upper side of each station is provided with nitrogen cooling head 5, brazing head 9 and water cooling head 10 that cooperate with the station, nitrogen cooling head 5 passes through The pipes and valves are connected to the nitrogen storage tank 1, and the water cooling head 10 is connected to the water cooling circulation tank 2 through ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com