A kind of box girder welding method

A welding method and technology for box beams, which are applied in welding equipment, welding/welding/cutting items, resistance welding equipment, etc., can solve the problems of low efficiency and poor welding quality of wide-flange box beams, and solve the problems of welding quality poor, the effect of improving welding strength and welding work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

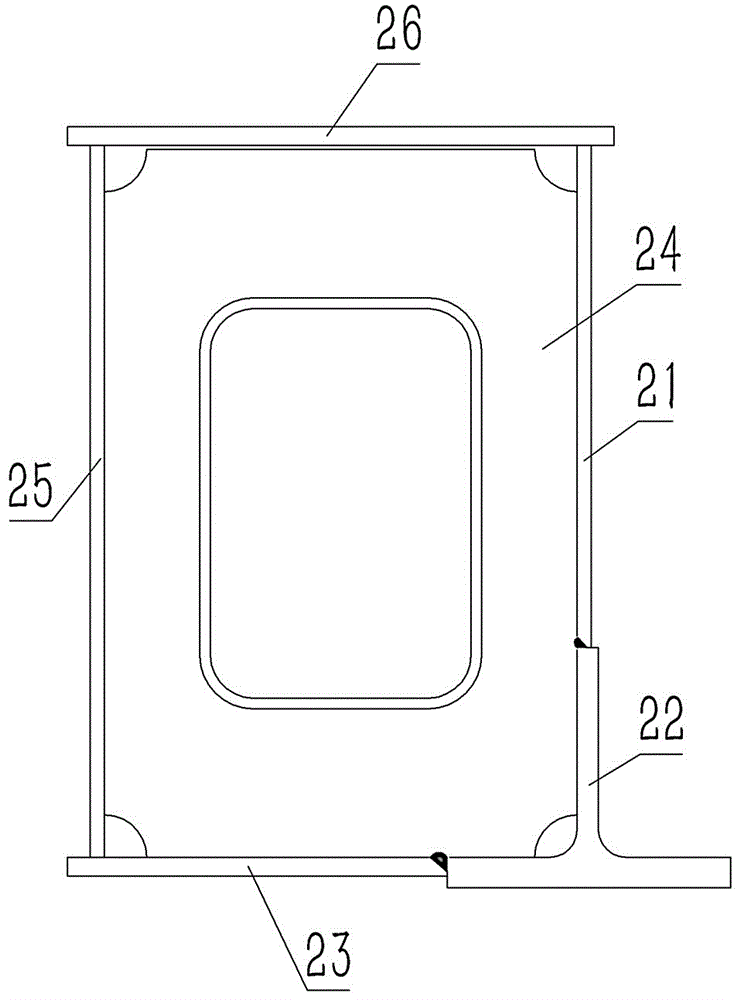

[0031] The embodiment of box girder welding method among the present invention: as Figure 6 to Figure 10 As shown, the method is a wide-flange box girder welding process consisting of the following steps:

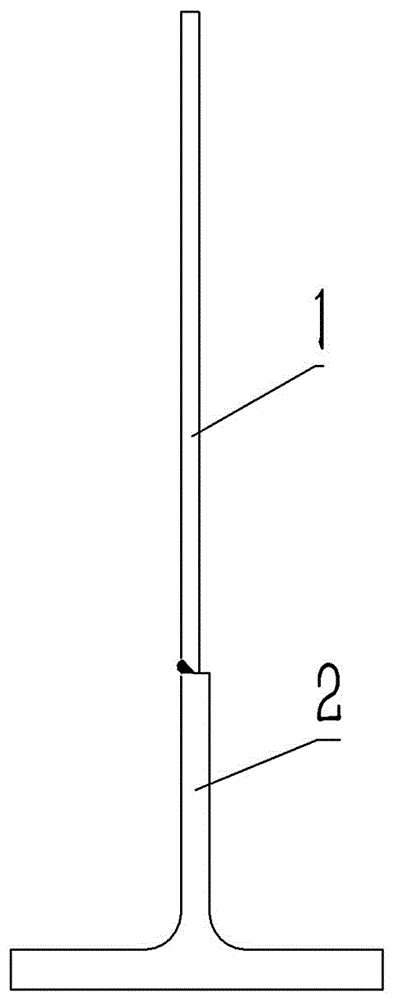

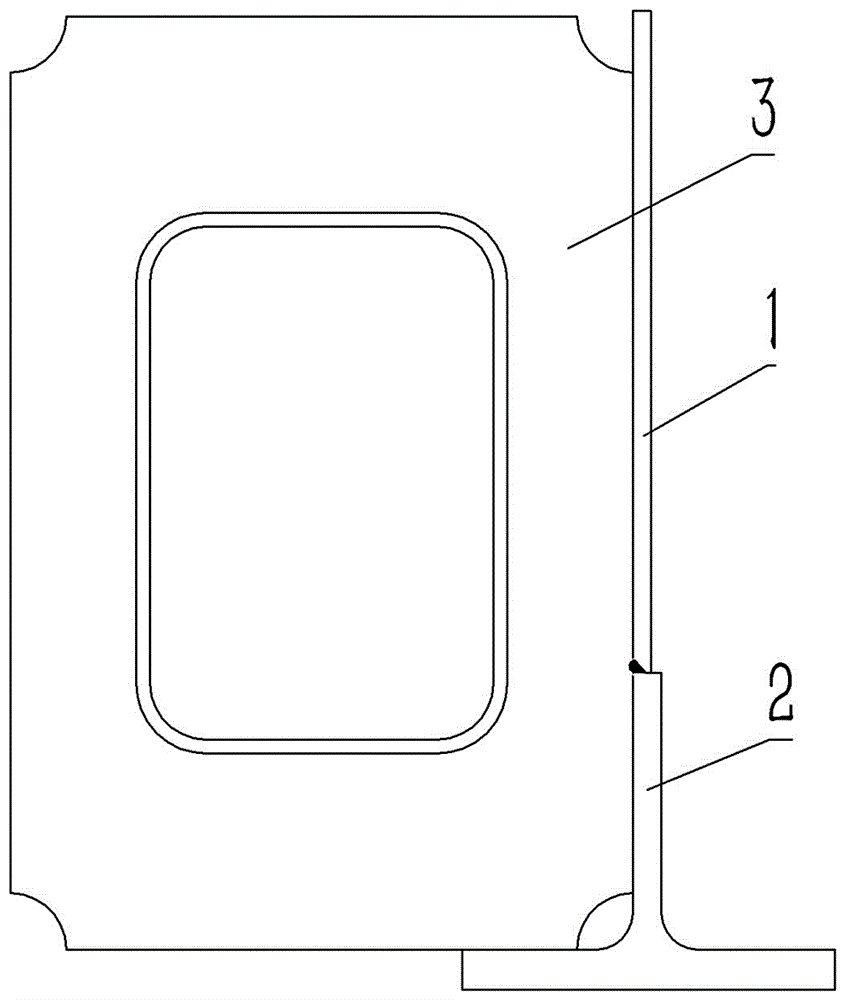

[0032] 1. Fix the T-shaped steel 22 and the main web 21 by spot welding. The lower edge of the main web 21 is butt-welded and fixed on the edge of the vertical wall of the T-shaped steel 22, and then the T-shaped steel 22 and the main web 21 are welded by submerged arc welding. Flat welds with straight extension;

[0033] 2. Fix the T-shaped steel 22 and the upper cover plate 23 by spot welding. The right edge of the upper cover plate 23 is butt-welded and fixed on the left flange edge of the T-shaped steel 22, and then the T-shaped steel 22 and the upper cover plate 23 are welded by submerged arc welding. Flat welds extending in straight lines to obtain L-shaped half-beam workpieces;

[0034] 3. Fix the half-beam workpiece and the rib plate 24 by spot welding, place eac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com