Ultrahigh-pressure pipeline system with combined type check valve

A pipeline system and one-way valve technology, applied in the direction of branch pipelines, pipes, pipes/pipe joints/pipe fittings, etc., can solve the problems of internal pressure relief, deformation, liquid leakage, etc., to reduce pressure, not Easy to damage and prolong the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described in detail below with reference to the embodiments of the accompanying drawings.

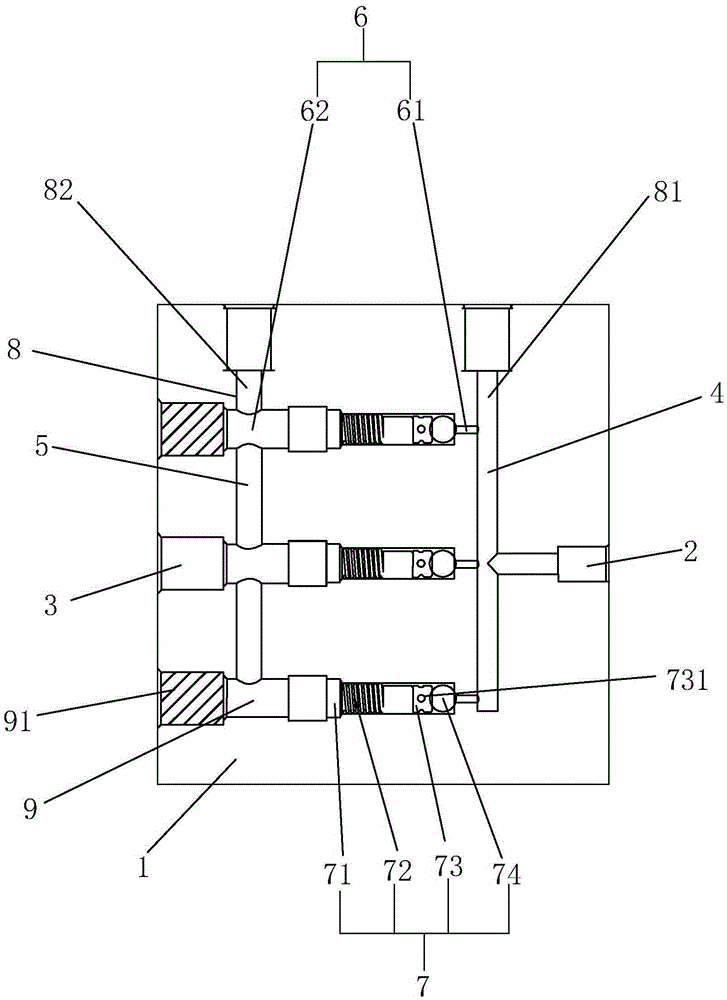

[0018] Such as figure 1 As shown, this embodiment is an ultra-high pressure pipeline system with a combined check valve, including a stainless steel base 1, and a main liquid inlet channel 2 and a main liquid outlet channel are respectively opened on both sides of the base 3. The main liquid inlet channel is connected with the external water pipe and the booster pump. The liquid can be pressed into the main liquid inlet channel under the action of the booster pump, and flows from the main liquid inlet channel to the main liquid outlet channel.

[0019] A first collecting channel 4, a second collecting channel 5 and a plurality of branches 6 are arranged between the main liquid inlet channel and the main liquid outlet channel, and the branches have a liquid inlet 61 and a liquid outlet 62 , the liquid inlet is connected to the first collectin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com