Patents

Literature

37results about How to "Guaranteed molding size" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Preparing method of GH4169 alloy large-scale special-shaped cross section annular blank

ActiveCN103447768AReduce forming pressureGuaranteed molding sizeMetal-working apparatusAlloyForming pressure

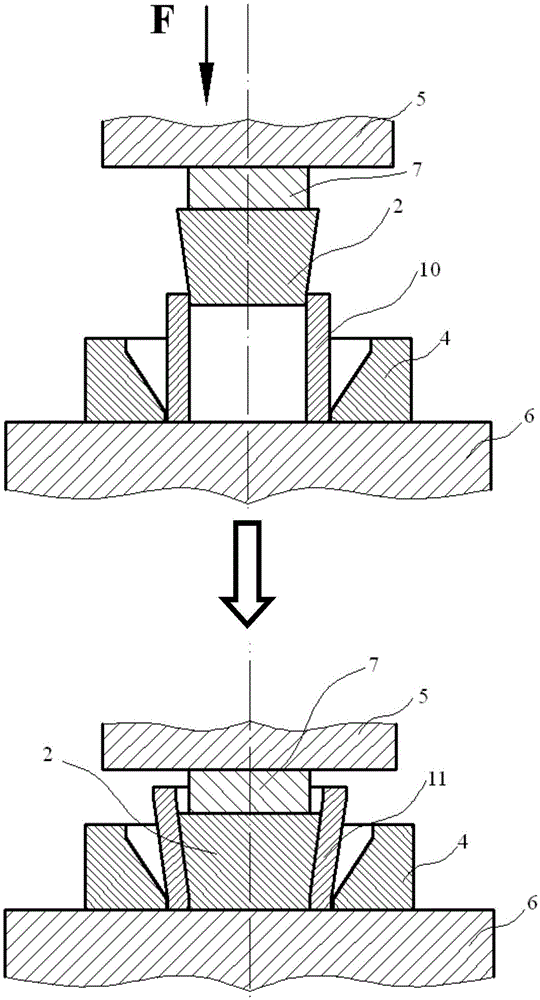

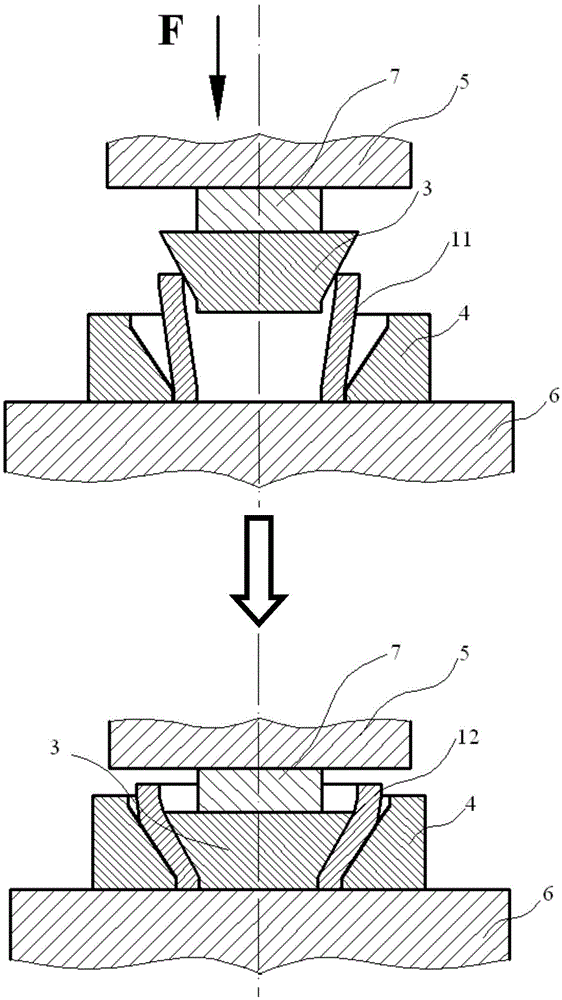

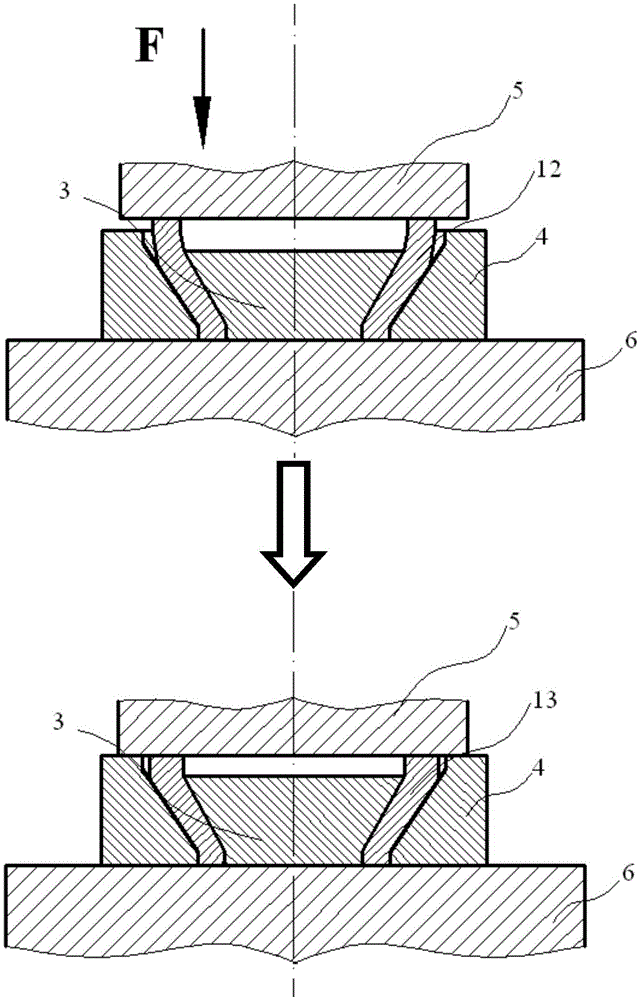

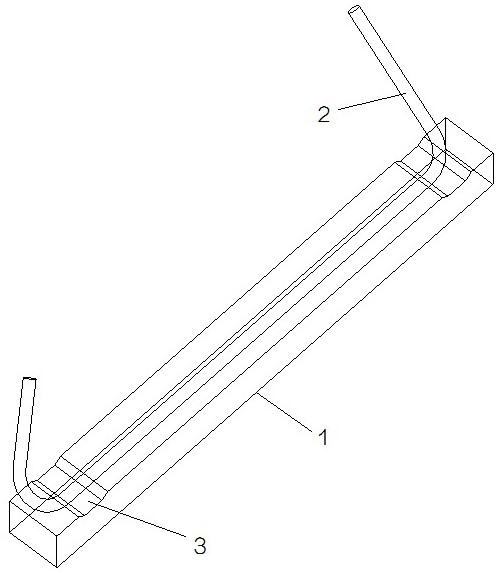

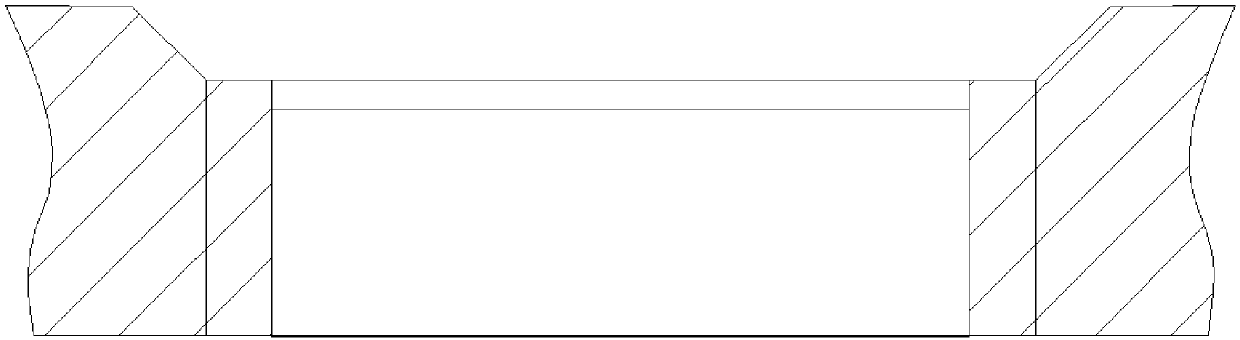

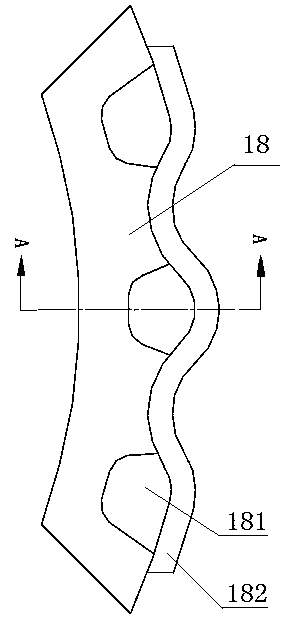

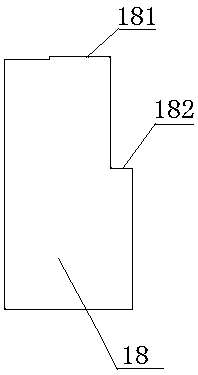

The invention discloses a preparing method of a GH4169 alloy large-scale special-shaped cross section annular blank. The preparing method comprises the steps that a GH4169 alloy bar is heated to be 1100+ / -10 DEG C in a certain heating mode, and is then subjected to upsetting, punching and rolling to become a rectangular cross section annular blank; then, the rectangular cross section annular blank is expanded into a primary special-shaped cross section annular blank at the pressure of 34 to 36MN; next, the primary special-shaped cross section annular blank is expanded into a secondary special-shaped cross section annular blank at the pressure of 32 to 35MN; then, the upper end of the secondary special-shaped cross section annular blank higher than a loose tooling is subjected to free upsetting to be flush with the loose tooling at the pressure of 20 to 26MN, and the final special-shaped cross section annular blank is obtained. The method has the advantages that the forming pressure required by the blank manufacturing can be effectively reduced, meanwhile, the flow direction of process excess materials can be effectively controlled, and the forming dimension of an intermediate blank is ensured. The method is applicable to the preparation of the intermediate blank of a large-scale special-shaped cross section annular blank element.

Owner:GUIZHOU ANDA AVIATION FORGING

Preparing method of TC4 alloy large-scale special-shaped cross section annular blank

InactiveCN103447769AGuaranteed molding sizeReduce forming pressureMetal-working apparatusAlloyAbnormal shaped

The invention discloses a preparing method of a TC4 alloy large-scale special-shaped cross section annular blank. The preparing method comprises the steps that a GH4169 alloy bar is heated to be 30 DEG C below the phase transformation point in a certain heating mode, and is then subjected to upsetting, punching and rolling to become a rectangular cross section annular blank; then, the rectangular cross section annular blank is expanded into a primary special-shaped cross section annular blank at the pressure of 32 to 34MN; next, the primary special-shaped cross section annular blank is expanded into a secondary special-shaped cross section annular blank at the pressure being 30 to 32 MN; then, the upper end of the secondary special-shaped cross section annular blank higher than a loose tooling is subjected to free upsetting to be flush with the loose tooling at the pressure of 20 to 24MN, and the final special-shaped cross section annular blank is obtained. The method has the advantages that the forming pressure required by the blank manufacturing can be effectively reduced, meanwhile, the flow direction of process excess materials can be effectively controlled, and the forming dimension of an intermediate blank is ensured. The method is applicable to the preparation of the intermediate blank of a large-scale special-shaped cross section annular blank element.

Owner:GUIZHOU ANDA AVIATION FORGING

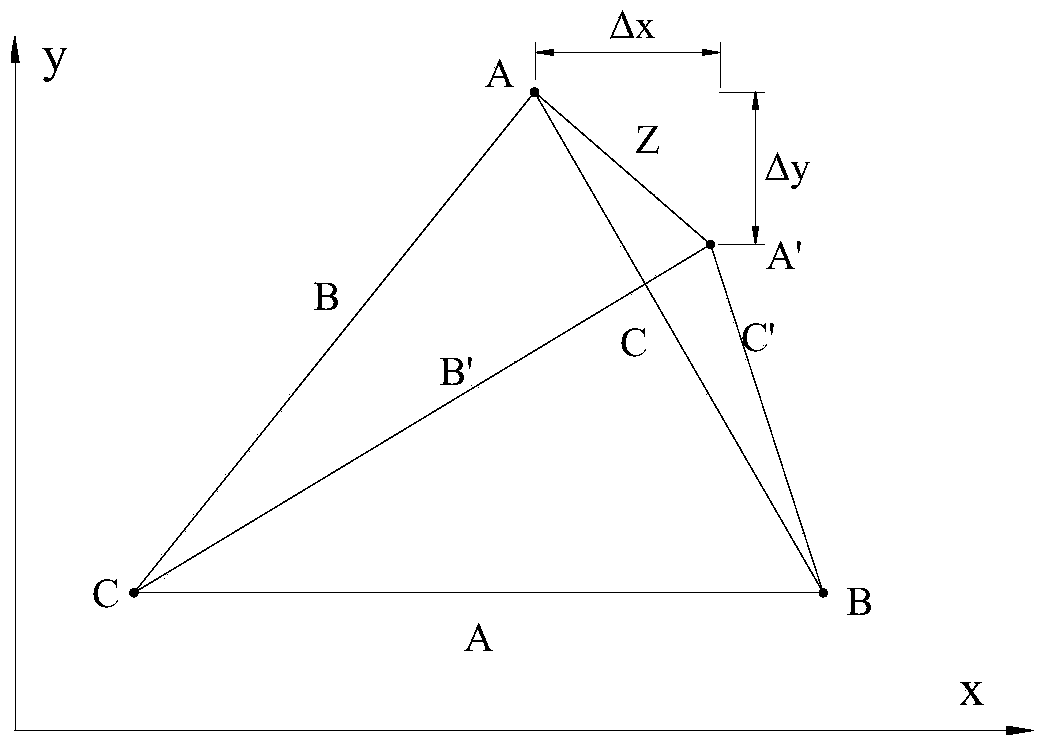

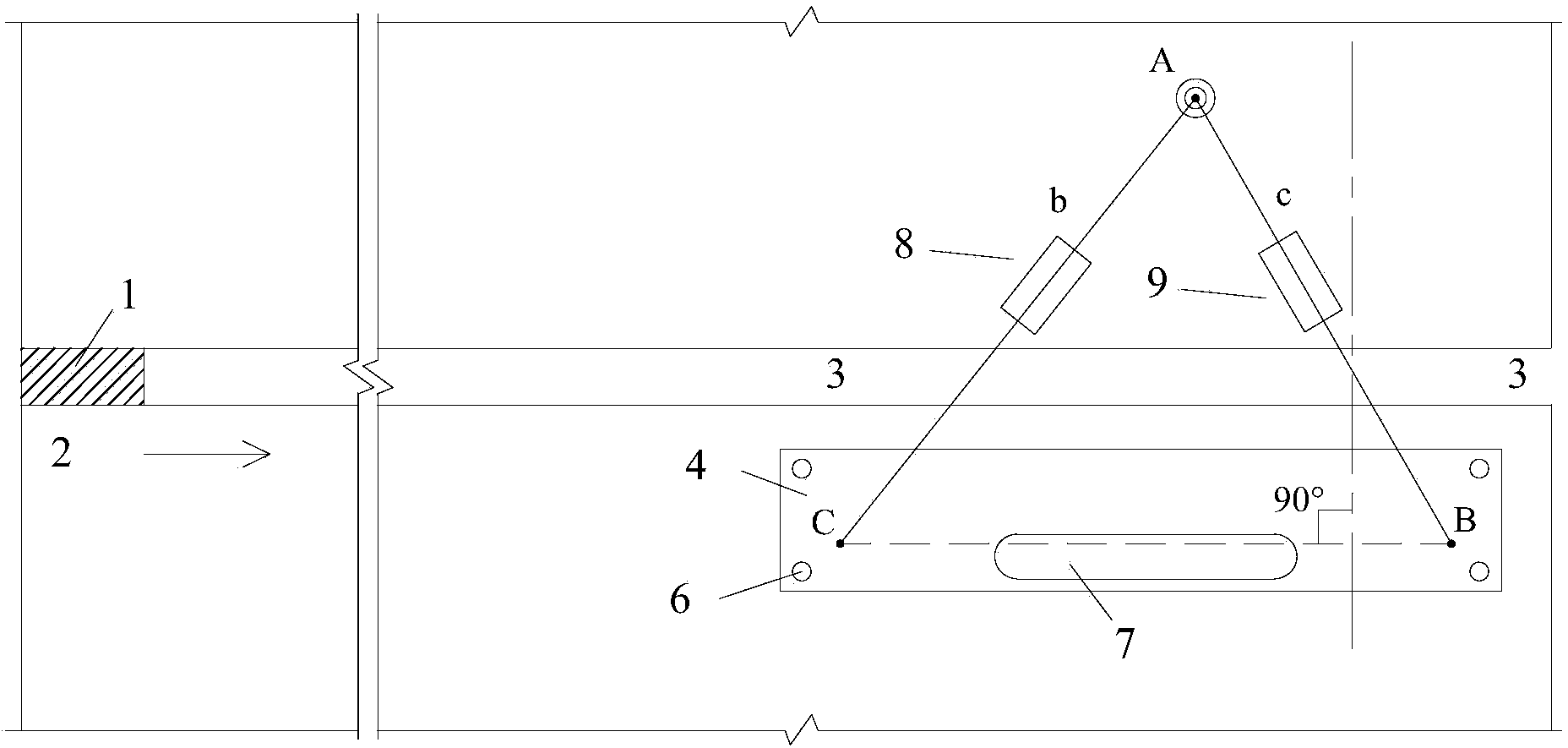

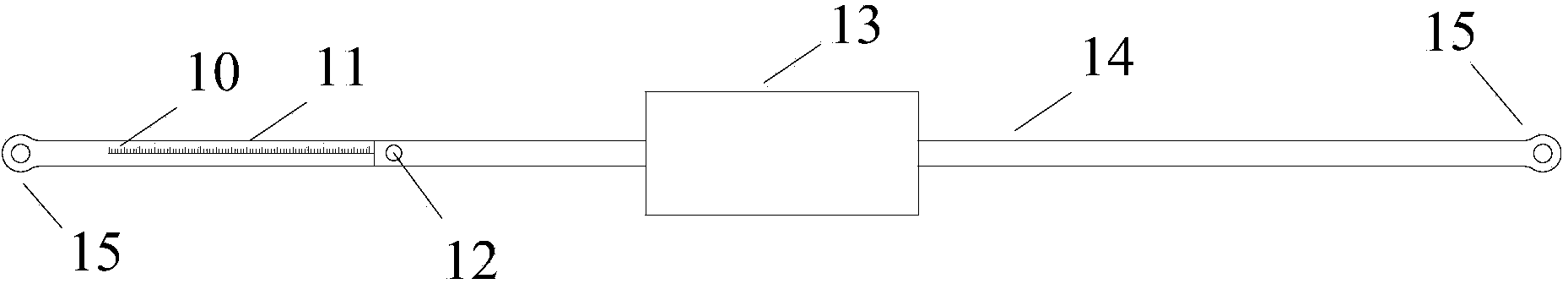

Method for automatically monitoring welding contraction deformation of steel structure

InactiveCN103586606AReduce labor intensityReal-time mastery of stabilityWelding/cutting auxillary devicesAuxillary welding devicesEngineeringUltimate tensile strength

The invention discloses a method for automatically monitoring welding contraction deformation of a steel structure. An inventor conducts theoretical deviation through a displacement sensor to obtain contraction deformation computational formulas seen from formula (1) to formula (6) and sets up the automatic monitoring method according to the formulas. The method is simple in device, easy to operate, high in automation degree, free of manual interference and capable of lowering the labor intensity of people. Contraction deformation values in two perpendicular directions and a total contraction deformation value can be displayed in real time, and real-time grasping of stability and quality of the welding technology can be facilitated. The monitoring result is higher in accuracy compared with the monitoring result obtained through a conventional method, and the accuracy can reach 0.01mm. When the method is applied to the steel structure welding field, the contraction deformation can be accurately, automatically and dynamically monitored in real time, reliability and stability of the welding technology can be conveniently distinguished, and the requirements of the steel structure for the forming size, the appearance and the bearing capacity are beneficially met.

Owner:GUANGXI UNIV +1

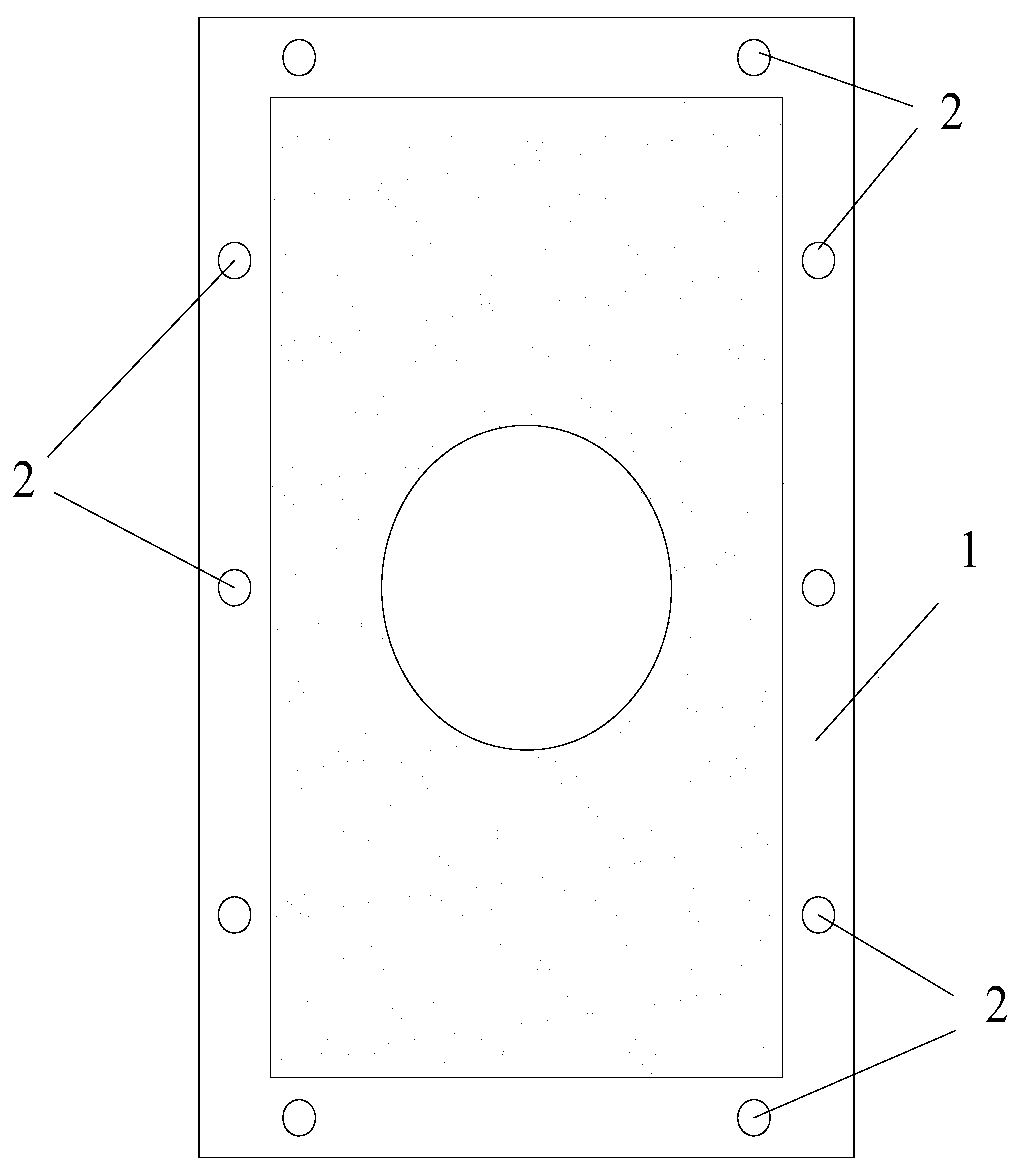

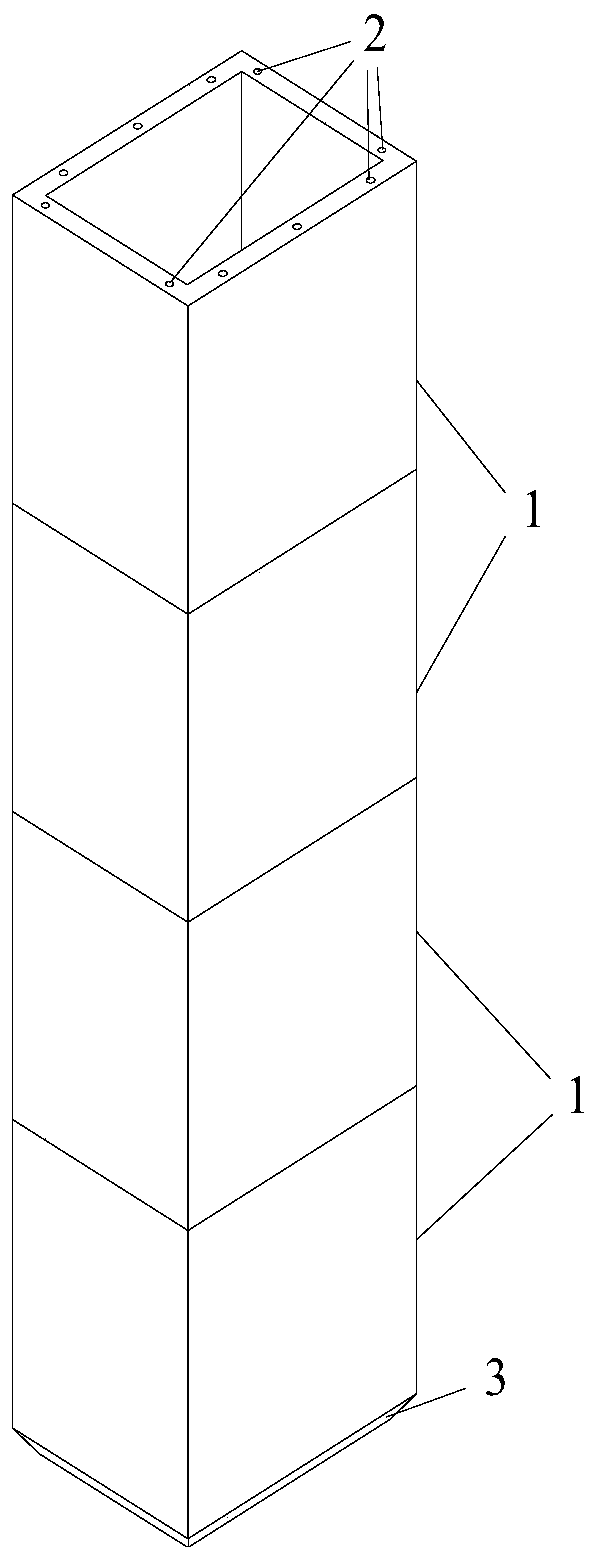

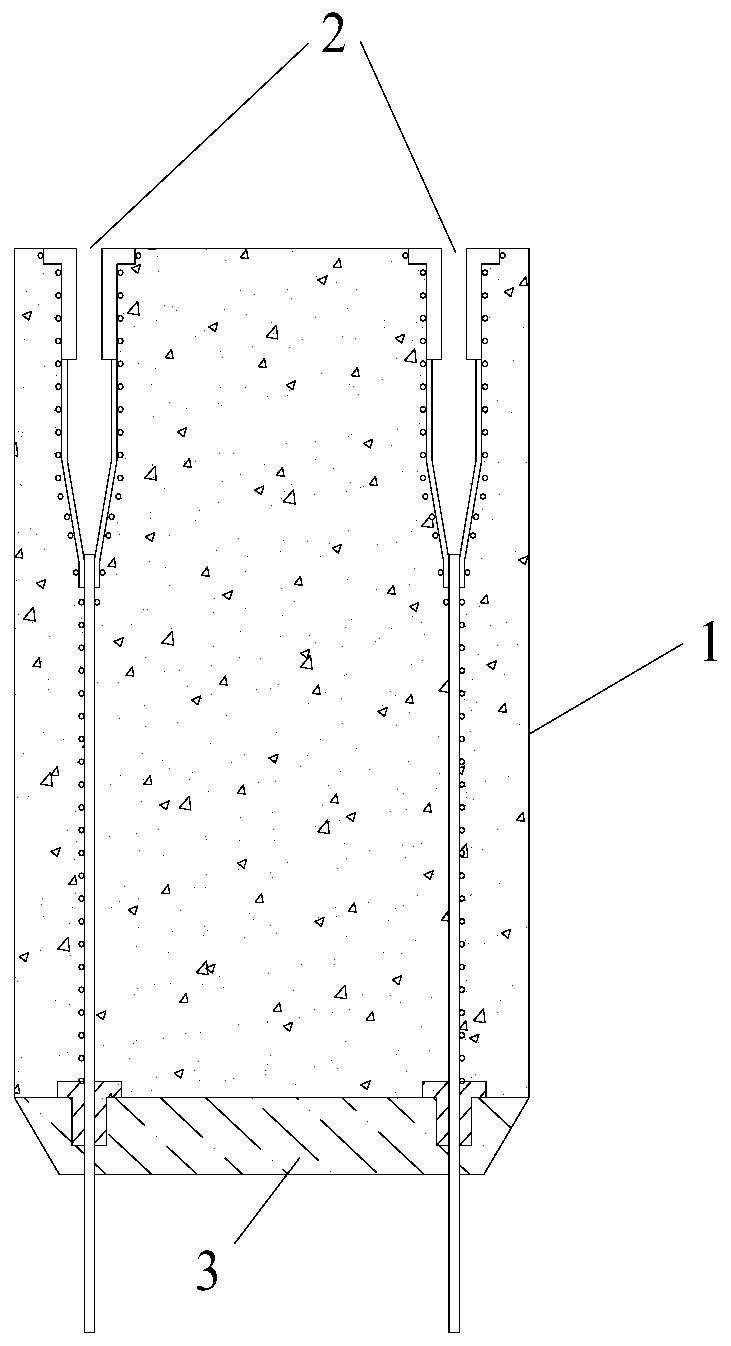

Prefabricated retaining wall and pile hole excavation method

PendingCN110438988ATo meet the needs of hole formationThe settlement process is easyExcavationsBulkheads/pilesLarge sizeInternal stress

The invention discloses a prefabricated retaining wall and a pile hole excavation method. The excavation method comprises the steps that first, guide-hole construction is carried out by using a machinery in an excavation area of a rectangular hole, after the internal opening is carried out, a soil body at the edges and corners of the rectangular hole is disturbed, internal stress is released, thedifficulty of subsequent excavation is greatly reduced, moreover, with the continuous increase of gravity of the prefabricated retaining wall, the settlement process of the prefabricated retaining wall is easier, and construction efficiency is conducive to be improved; and according to the excavation method, excavation of the rectangular hole can be carried out effectively, construction safety isimproved, construction difficulty is reduced, the requirement for forming a large-size rectangular hole is met, at the same time, prefabricated retaining wall structure is effectively installed to avoid the risk of hole collapse, hole digging and the retaining wall can be completed simultaneously, the construction period is conducive to be shortened, energy saving and environment production are achieved, the quality hidden danger of the retaining wall can be avoided effectively, and the excavation method is especially suitable for construction of an anti-slide pile in cold and high altitude areas such as the sichuan-tibet line.

Owner:CHINA RAILWAY ERYUAN ENG GRP CO LTD

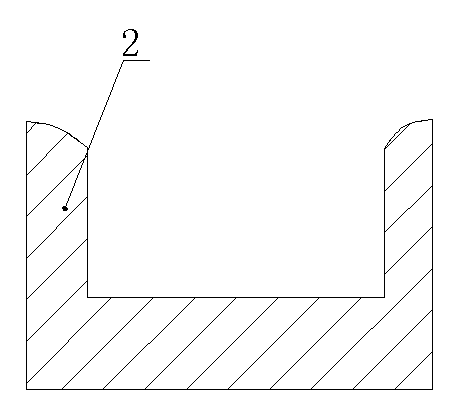

Easy-to-release anti-blocking original-side ceramic tile forming mould

ActiveCN104647573APrecise size controlPrevents stasis and even cloggingCeramic shaping apparatusBrickMaterials science

The invention discloses an easy-to-release anti-blocking original-side ceramic tile forming mould and belongs to the technical field of powder forming. The easy-to-release anti-blocking original-side ceramic tile forming mould comprises an upper mould core, side plates and a lower mould core which define a mould cavity. The easy-to-release anti-blocking original-side ceramic tile forming mould is characterized in that a ventilating path and a plurality of gas vent holes are formed in the upper mould core, wherein one end of each gas vent hole is communicated with the bottom surface of the upper mould core, the other end of each gas vent hole is communicated with the ventilating path, the ventilating path is connected with a gas exhausting branch and a gas blowing branch; the side plates comprise long side plates and short side plates which are enclosed in two adjacent long side plates, wherein first inclined positions which are outwards inclined from top to bottom are formed in the inner walls of the long side plates and the short side plates; second inclined positions are formed in the two ends of each short side plate; the long side plates and the short side plates can be tightly assembled together through the first inclined positions and the second inclined positions. A ceramic brick green body finished product pressed out by the forming mould does not need edging processing; moreover, in the pressing process, the gas exhausting system can be prevented from being blocked, the demoulding is easy to carry out and the mould is prevented from being blocked, so that the forming quality of the original-side ceramic tiles can be improved.

Owner:淄博沃德机械科技有限公司 +2

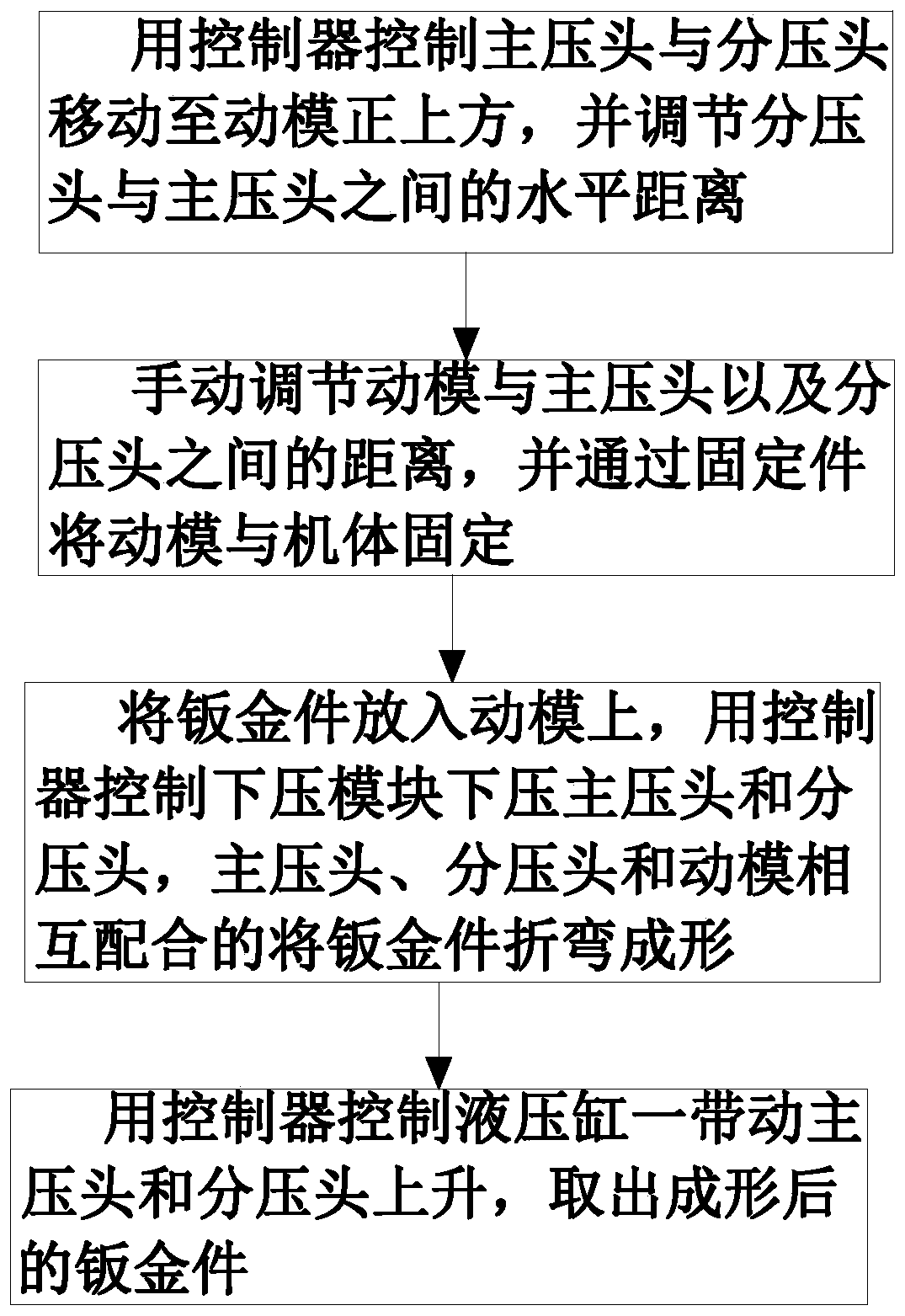

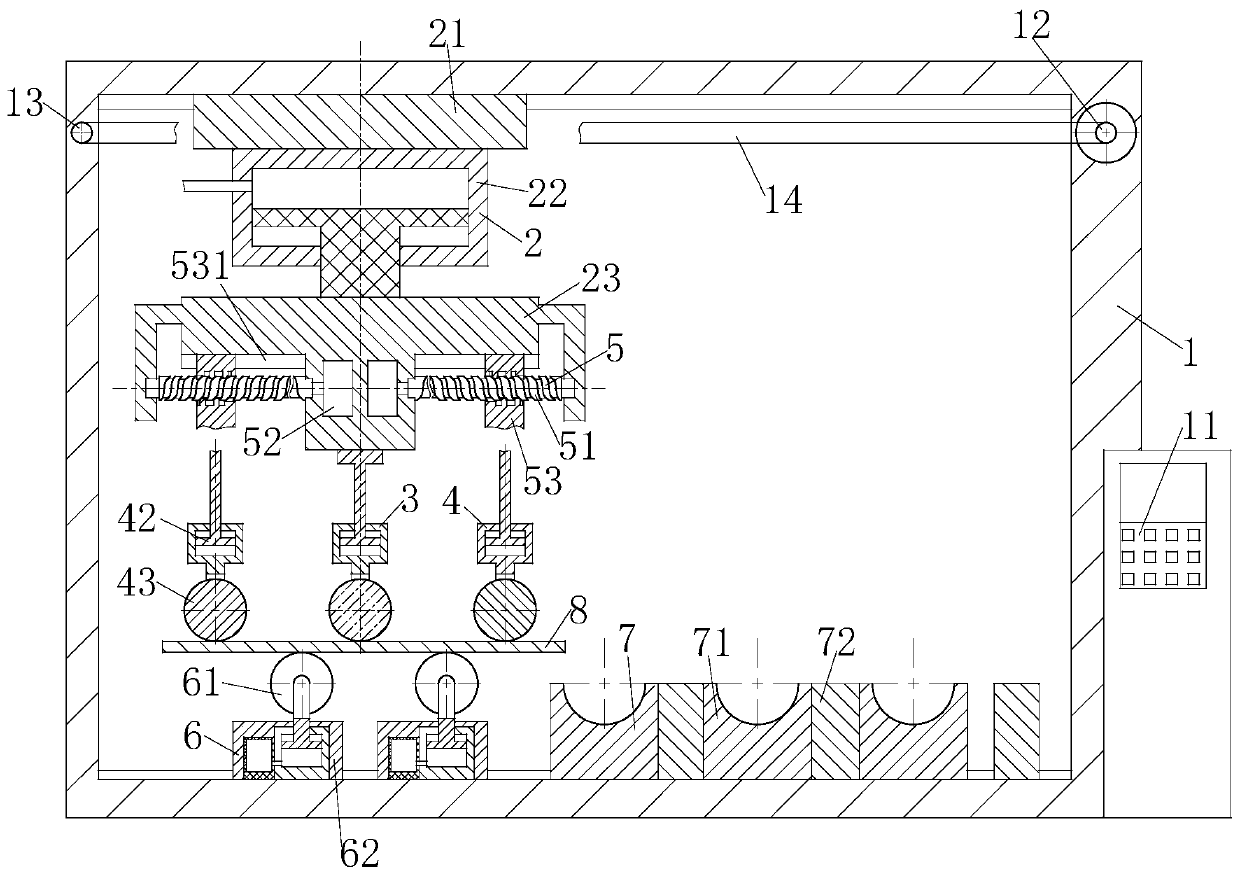

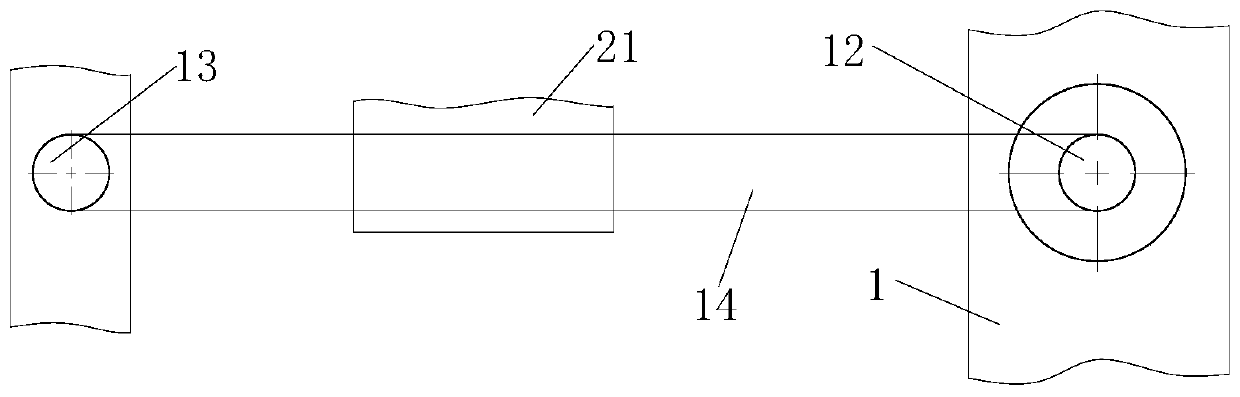

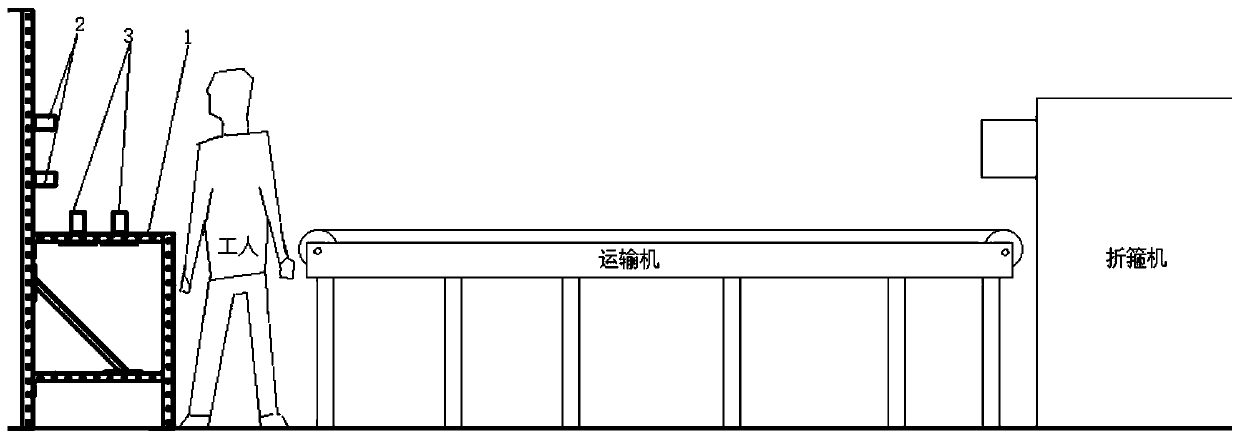

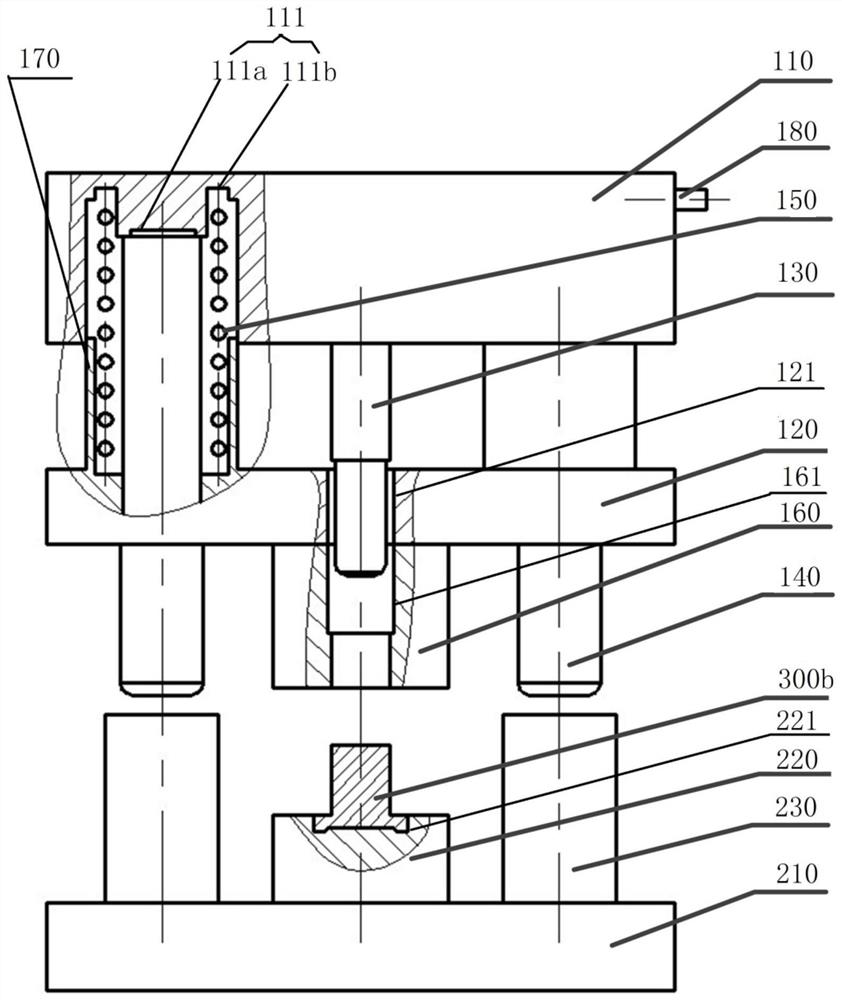

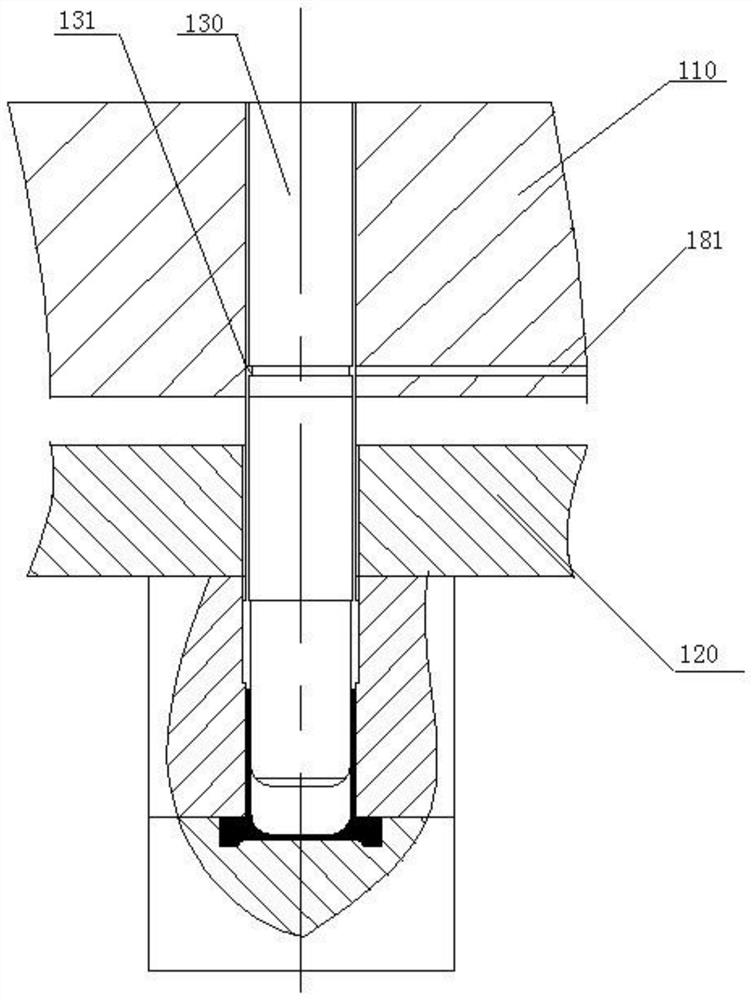

Bending forming method for sheet metal parts

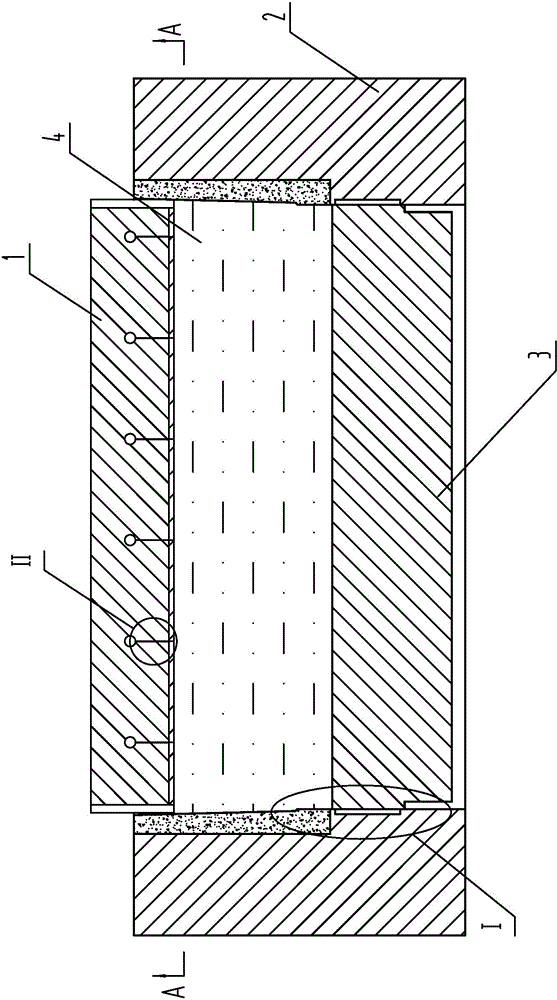

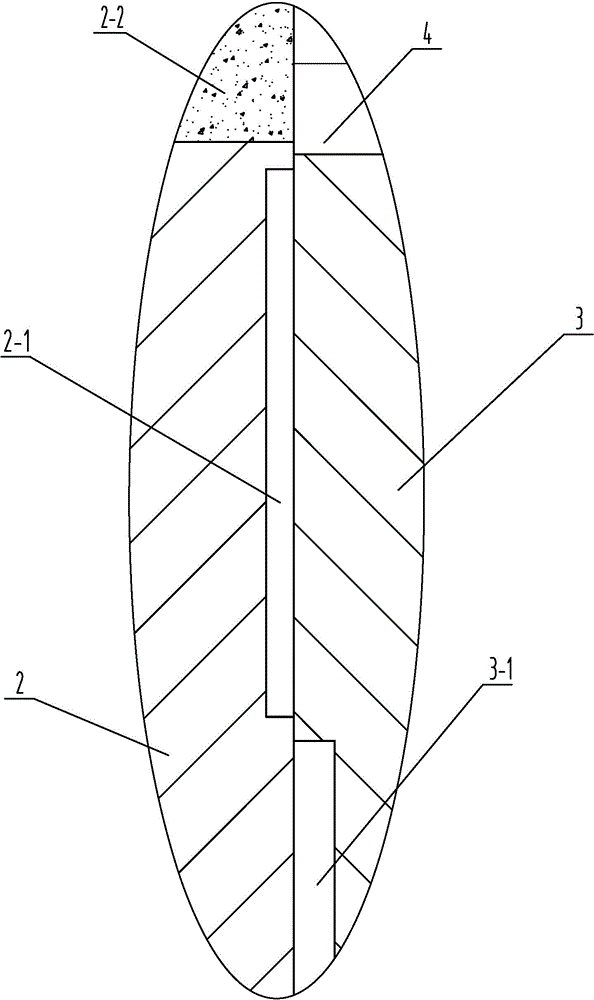

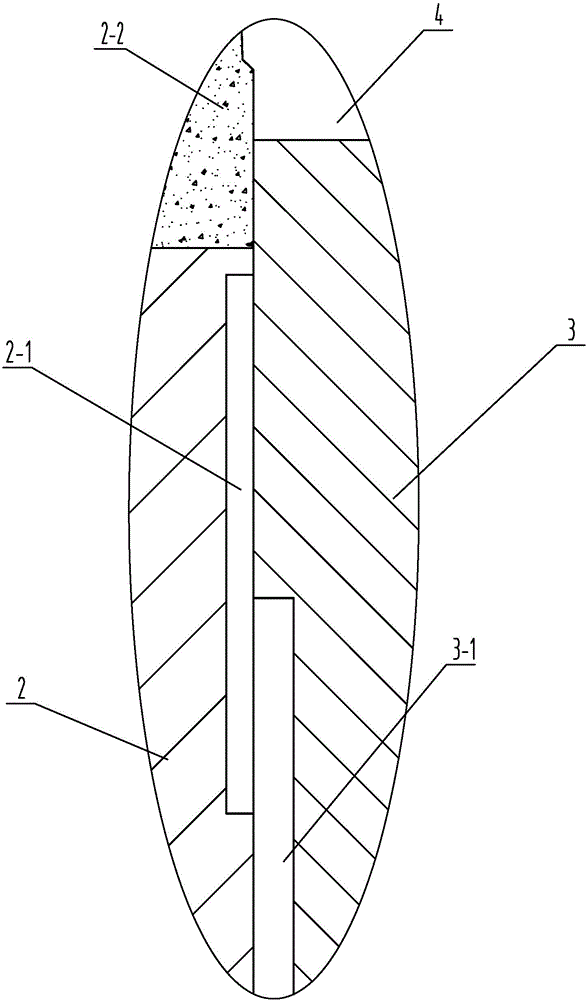

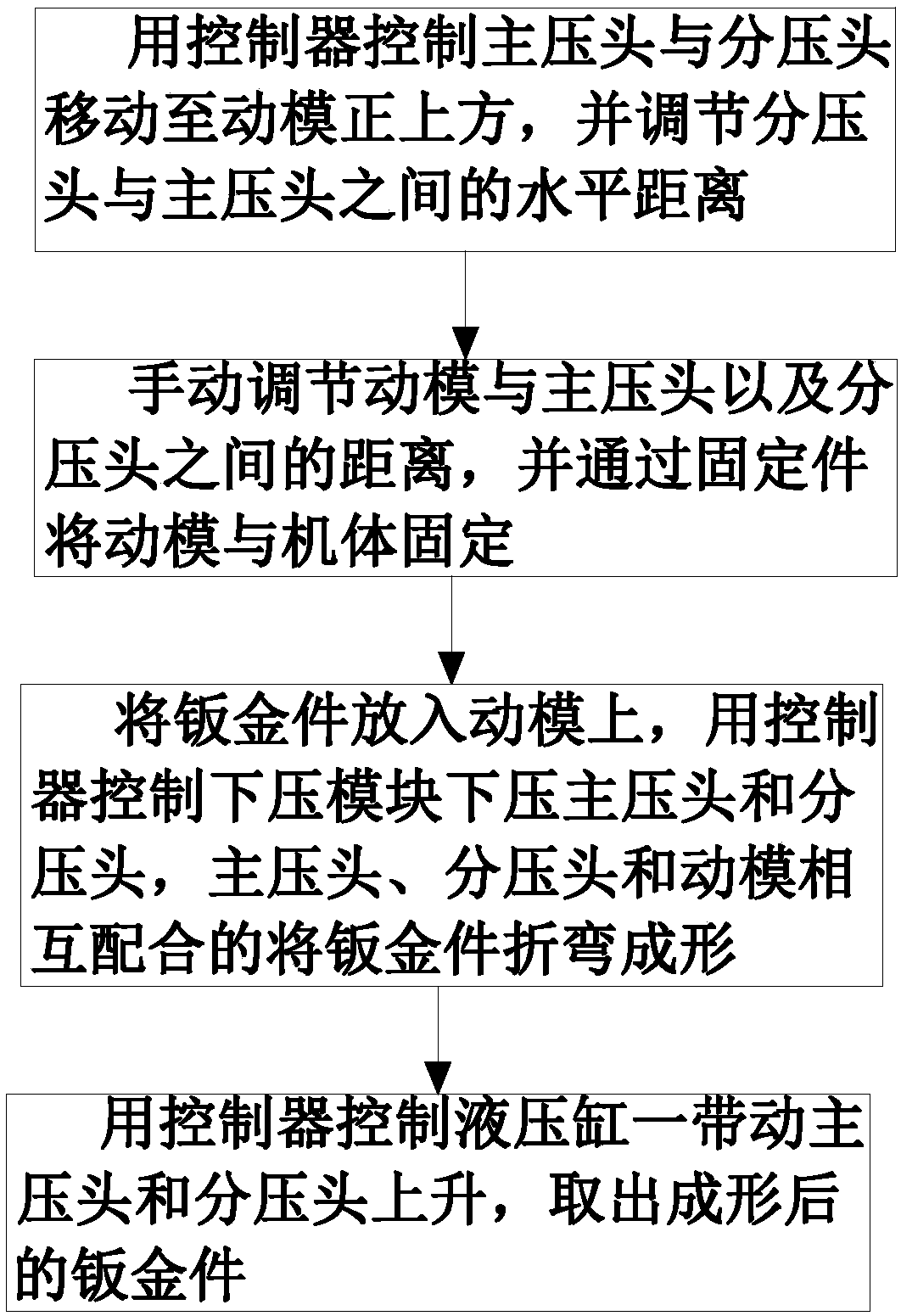

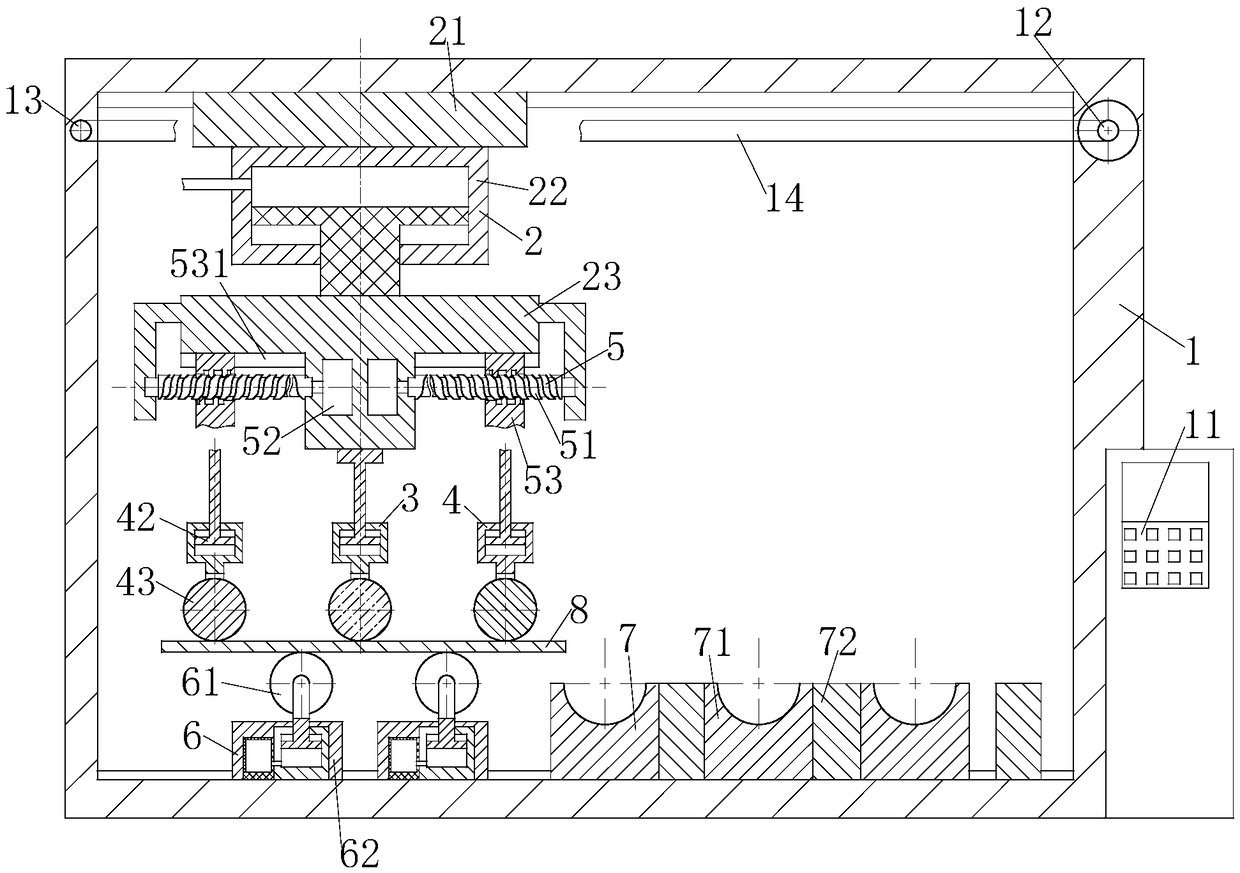

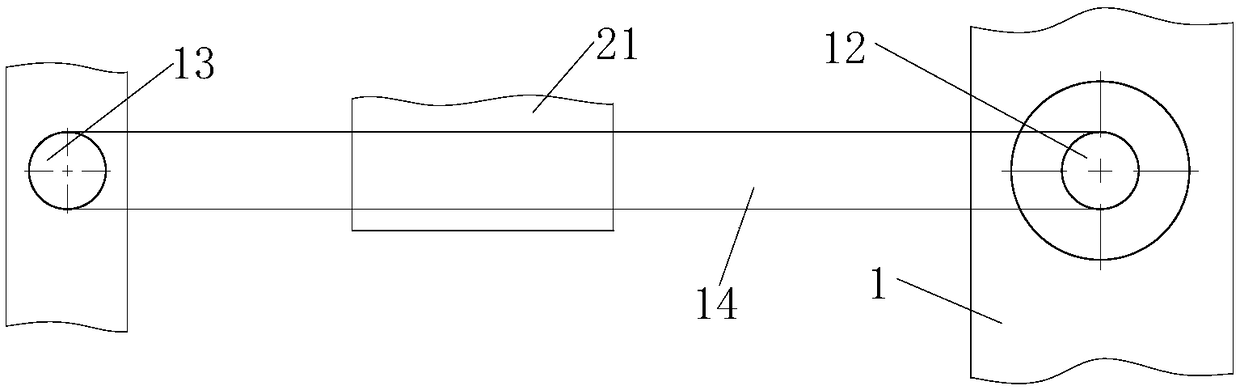

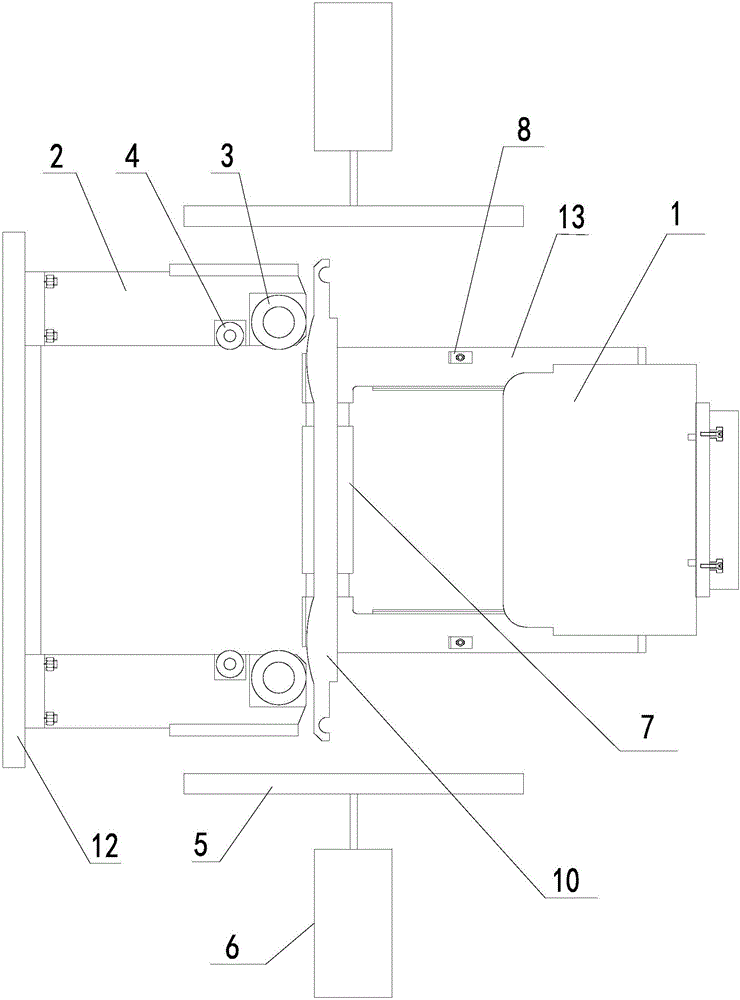

The invention belongs to the technical field of sheet metal processing, in particular to a bending forming method for sheet metal parts. The bending forming method adopts a multi-roller floating bending machine. The multi-roller floating bending machine comprises a machine body, a downward pressing module, a main pressure head, auxiliary pressure heads, an adjusting unit, movable dies and a fixeddie, wherein a controller is arranged on the machine body. The controller is located at one side of the machine body. The downward pressing module is located at the upper part of the machine body andis used to press down the main pressure head and the auxiliary pressure heads. The main pressure head is fixedly connected with the downward pressing module. The auxiliary pressure heads are of the same structure as the main pressure head, and the auxiliary pressure heads and the main pressure head are used for bending the sheet metal parts. The adjusting unit is positioned between the auxiliary pressure heads and the downward pressing module and is used for adjusting the auxiliary pressure heads to ascend or move left and right. The movable dies are located at one side of the lower part of the machine body and is in sliding connection with the machine body. The movable dies are used for bending the sheet metal parts. According to the bending forming method, the forming size of the sheet metal parts can be ensured by fine-adjusting the shapes of the sheet metal parts, and the forming qualification rate of the sheet metal parts is increased.

Owner:柳州盛盈装配有限公司

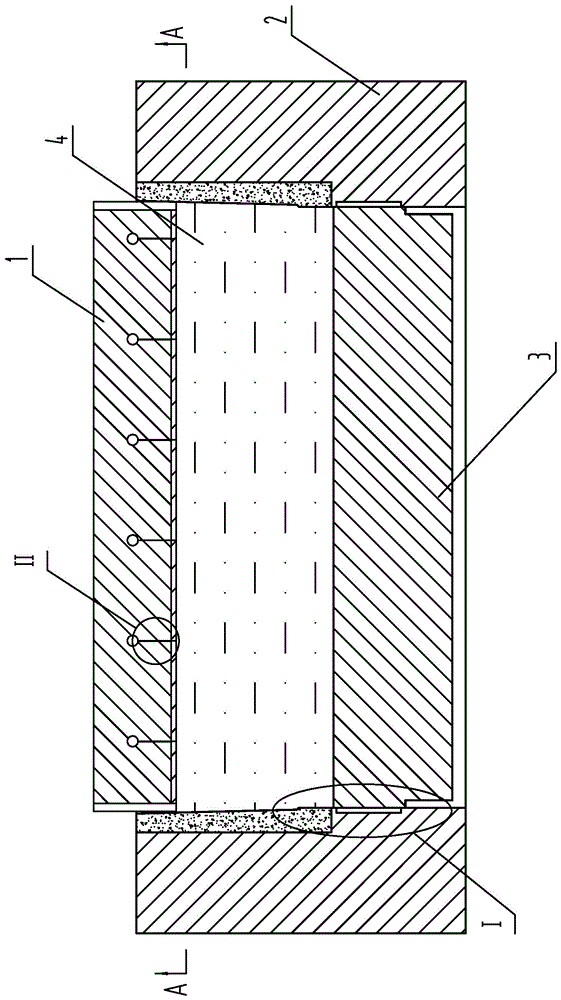

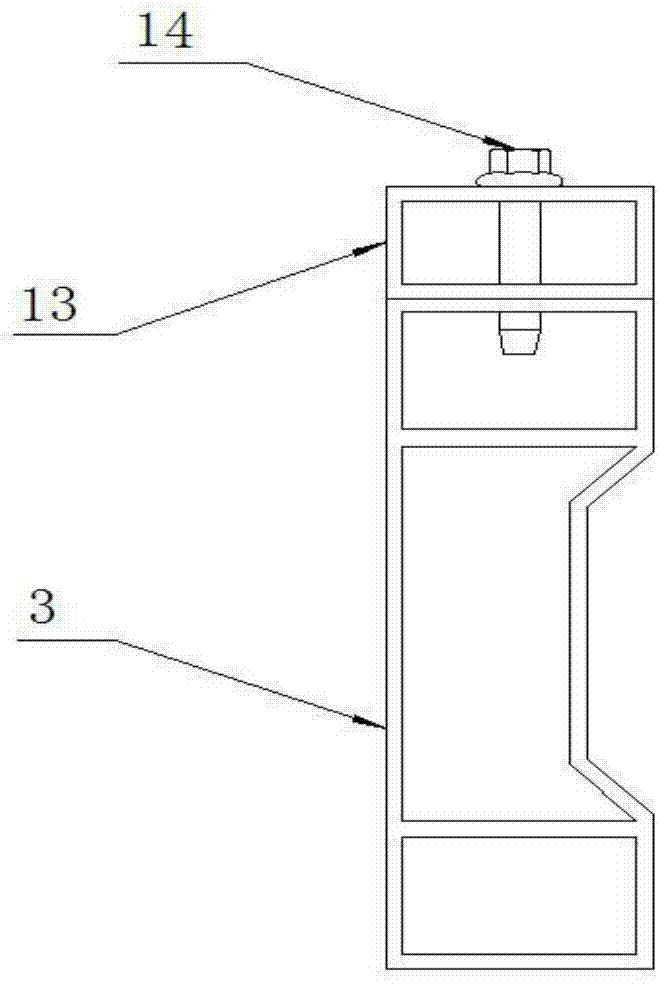

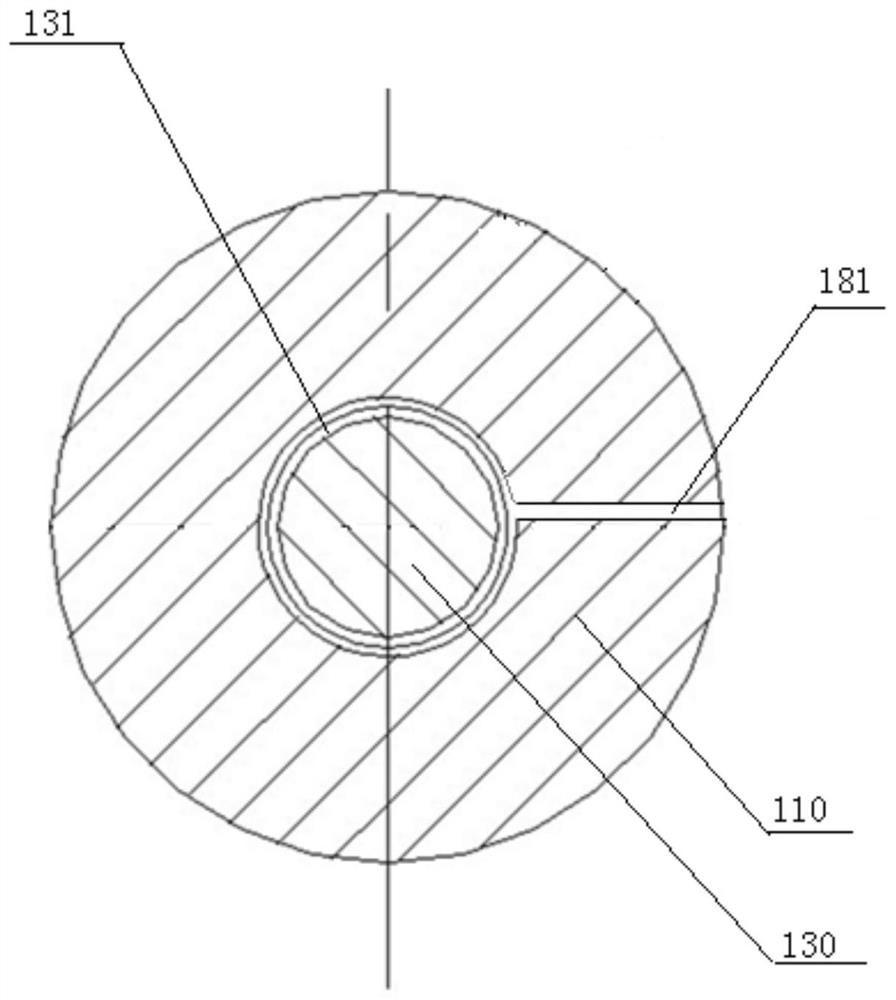

Steel mold for externally coating nodular cast iron pipe with cement mortar

InactiveCN106378867AGuaranteed molding sizeAvoid deformationSurface layering apparatusDetentCement mortar

The invention relates to a steel mold for externally coating a nodular cast iron pipe with cement mortar. The steel mold comprises a top die; the top die comprises a locating detent and a socket ring; the socket ring is supported by a socket adjusting ring positioned at the inner side of the socket ring; the locating detent is used for supporting an outer die which is positioned at the outer side of the positioning detent; the socket adjusting ring and the locating detent are arranged coaxially; the outer die comprises an outer die body and an outer die expansion body which is connected to the upper part of the outer die body; the outer die body is in transition connection with the outer die expansion body through an inverted cone; a material stop ring is arranged between the top die and the outer die; the material stop ring can be arranged on the locating detent and can also fall to be supported by the inverted cone in the outer die. The steel mold for externally coating the nodular cast iron pipe with cement mortar, disclosed by the invention, is simple in structure and capable of realizing quite good production of the nodular cast iron pipe.

Owner:江苏邦威机械制造有限公司

Preparing method of G10CrNi3Mo bearing steel large-scale special-shaped cross section annular blank

ActiveCN103447767AReduce forming pressureGuaranteed molding sizeMetal-working apparatusAlloyForming pressure

The invention discloses a preparing method of a G10CrNi3Mo bearing steel large-scale special-shaped cross section annular blank. The preparing method comprises the steps that a G10CrNi3Mo alloy bar is heated to be 1210+ / -20 DEG C in a certain heating mode, and is then subjected to upsetting, punching and rolling to become a rectangular cross section annular blank; then, the rectangular cross section annular blank is expanded into a primary special-shaped cross section annular blank at the pressure of 23 to 26MN; next, the primary special-shaped cross section annular blank is expanded into a secondary special-shaped cross section annular blank at the pressure of 20 to 25MN; then, the upper end of the secondary special-shaped cross section annular blank higher than a loose tooling is subjected to free upsetting to be flush with the loose tooling at the pressure of 8 to 12MN, and the final special-shaped cross section annular blank is obtained. The method has the advantages that the forming pressure required by the blank manufacturing can be effectively reduced, meanwhile, the flow direction of process excess materials can be effectively controlled, and the forming dimension of an intermediate blank is ensured. The method is applicable to the preparation of the intermediate blank of a large-scale special-shaped cross section annular blank element.

Owner:GUIZHOU ANDA AVIATION FORGING

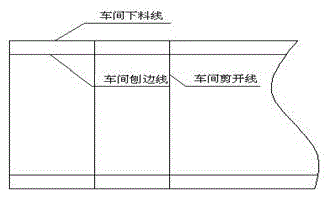

Novel tooth-like sealing plate manufacture technology

ActiveCN105631104AGuaranteed molding sizeGuarantee assembly and welding qualityDesign optimisation/simulationSpecial data processing applicationsEngineeringWelding

The invention relates to a novel tooth-like sealing plate manufacture technology. Key dimensions including tooth-like sealing plates, tooth-like lines, tooth root depth, bent lines and the like all have big deviations, so that an assembling gap between the sealing plate and a tube panel is overlarge, since the production process of the tooth-like sealing plate is in cold working processing and the manufacture precision of cold working is low, forming is poor, and the factors cause the problem that two ends are jacked and tooth spaces are overlarge during assembling so as to be difficult in realizing seal welding. The novel tooth-like sealing plate manufacture technology utilizes computer software to carry out three-dimensional entity authentication analysis, draws the assembling position relationship of the sealing plate and the tube panel, determines the key dimensions of the tooth-like lines, the tooth root depth and the bent lines, utilizes the computer software to carry out three-dimensional entity authentication analysis through theoretical calculation, givens the key dimensions of the tooth-like lines, the tooth root depth and the bent lines of 10 tooth-like sealing plates again, and formulates a new technology by a new tool. The invention is used for the novel tooth-like sealing plate manufacture technology.

Owner:HARBIN BOILER

Forming method for large concave forging

InactiveCN103203424AIncrease profitGuaranteed molding sizeMetal-working apparatusIngotWork in process

The invention discloses a forming method for a large concave forging. The forming method for the large concave forging comprises the following steps of A, performing heat preservation on a steel ingot for 6-7 hours at the temperature of 1220-1240 DEG C; B, performing upsetting drawing out for two times: firstly, performing necking, chamfering and secondary upsetting; then, performing stretching, tail cutting and indentation, pressing to form a concave part, and cutting to obtain a semi-finished product; and C, horizontally placing a low anvil on two mandrel supporters, and putting in the heated semi-finished product obtained in the step B. According to the forming method for the large concave forging disclosed by the invention, the concave forging which is complicated in shape is forged by utilizing a small-tonnage hydraulic press and the steel ingot, and therefore, not only is the quality of the forging satisfied but also the condition of traditional equipment is considered; the utilization rate of the steel ingot is improved, and the concave forging of which lugs are very big can be forged. The inherent quality of the forging can be ensured by a reasonable reheating schedule and enough forging ratio, and the forming and machining dimension of the forging is ensured by reasonable metal deformation and tool use.

Owner:LINZHOU HEAVY MACHINE CASTING AND FORGING CO LTD

Forming process of chromium-molybdenum-vanadium steel seamless taper pipe

The invention discloses a forming process of a chromium-molybdenum-vanadium steel seamless taper pipe. The forming process is characterized by comprising the following steps: an alloy tool steel material is selected, and following alloy elements in percentage by mass are added to carbon tool steel: 1.4%-1.6% of C, less than or equal to 0.60% of Mn, less than or equal to 0.60% of Si, less than or equal to 0.030% of P, less than or equal to 0.030% of S, 11.00%-13.00% of Cr, 0.70%-1.20% of Mo, less than or equal to 1.10% of V, and less than or equal to 1.00% of Co; and the hardness value HB of anequal-diameter straight pipe finished product material is less than or equal to 255. According to the forming process, taper pipe forming is conducted through a cold pressing type taper pipe formingdevice, and the pipe body change rate, the forming environment temperature and other technological means are kept; and the taper pipe is prevented from being formed in a material fatigue state in theforming process by controlling constant low temperature, cold pressing and compression ratio and designing roundness in a high-hardness state, so that not only are the forming sizes inside and outsidethe product ensured, but also the grains of the material inside the product are uniform and fine, and various good mechanical properties are achieved.

Owner:杭州淳通新材料科技有限公司

Expansion joint shaping mold device and construction method

InactiveCN112459129AIncrease stiffnessAvoid damageArtificial islandsProtective foundationSupporting systemRight triangle

The invention discloses an expansion joint shaping mold device and a construction method. The device comprises upper formwork, lower formwork and a steel edge rubber water-stop belt between the upperformwork and the lower formwork. The lower formwork is a right-angled triangular rigid supporting system formed by a welding keel, a formwork face plate, a shear-resistant steel bar hole, an angle steel keel, an inclined strut A, a support and a steel pipe sleeve; the upper formwork is arranged above the lower formwork, the upper formwork and the lower formwork are folded, a face plate and a bottom plate of the upper formwork are fixed through a reserved movable shear-resistant steel bar reserved hole, and the upper formwork and the lower formwork are fixed by tightening tension screws; A U-shaped groove A and a steel edge rubber water-stop belt horizontal positioner are arranged on the angle steel keel of the lower formwork, a U-shaped groove B is formed in the bottom of the target face plate of the upper formwork, and a steel edge rubber water-stop belt is arranged between the U-shaped groove A and the U-shaped groove B. According to the device, shaping and geometric dimension of concrete can be effectively ensured, the position of the steel edge rubber water-stop belt is prevented from displacement, and the shaped expansion joint is smooth and straight and is not bent.

Owner:CHINA FIRST METALLURGICAL GROUP

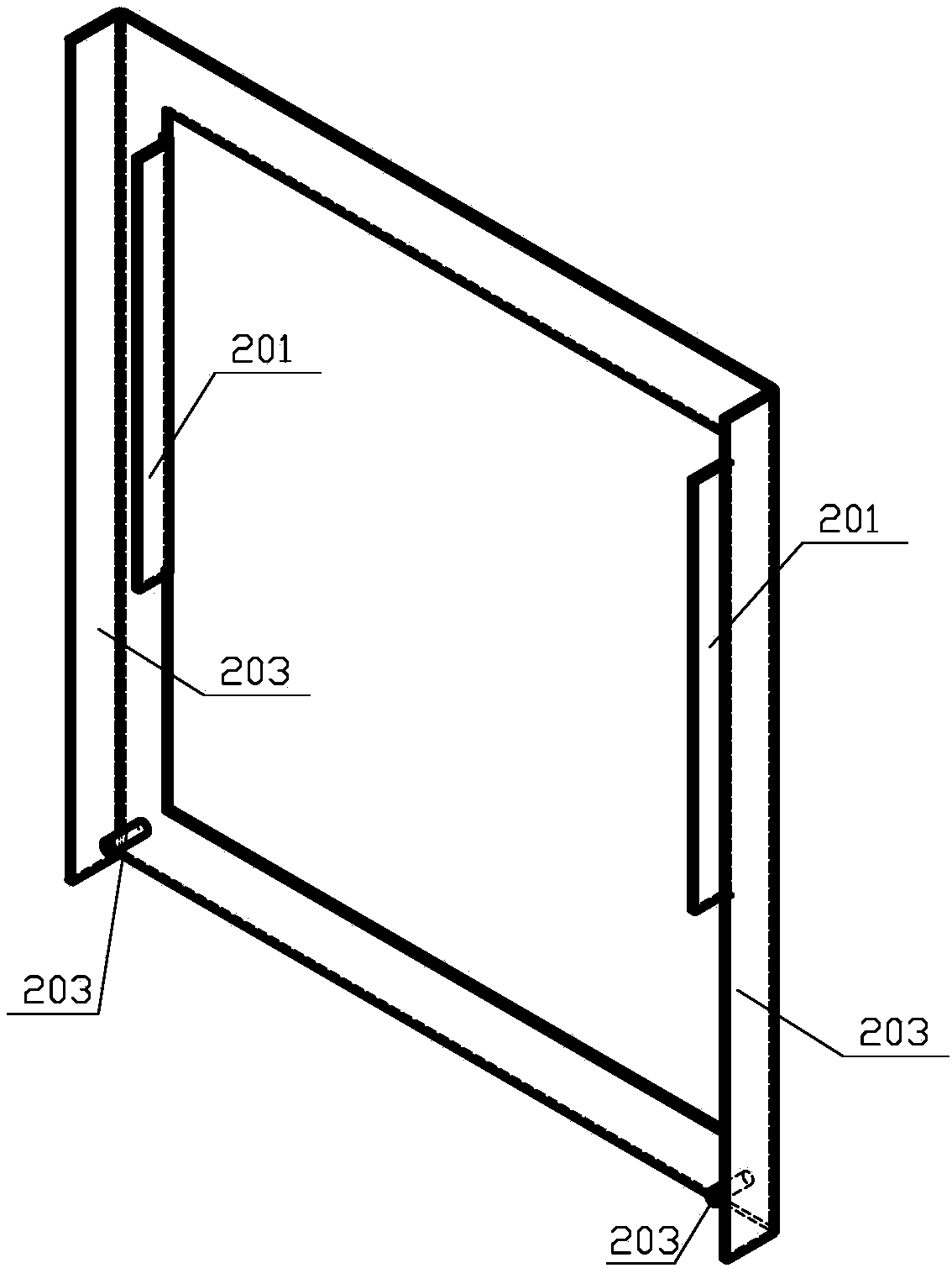

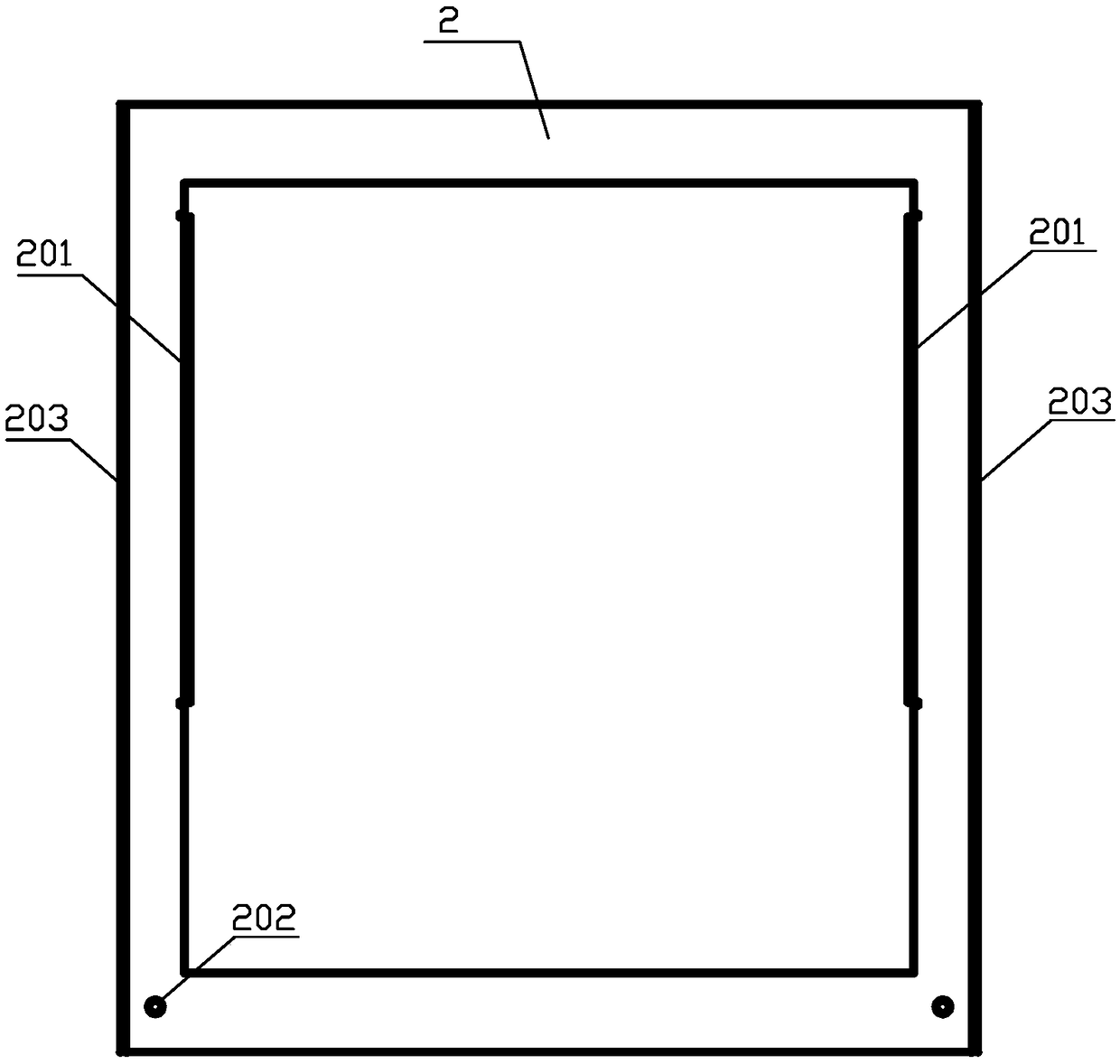

Self-positioning tool structure for assembling loop network switchgear cubicle instrument box

PendingCN108406648AGuaranteed molding accuracyGuaranteed molding sizeWork holdersEngineeringSwitchgear

The invention relates to a self-positioning tool structure for assembling a loop network switchgear cubicle instrument box. The tool structure comprises a positioning bottom plate, a positioning coverplate, a positioning rear connecting plate, a left side plate and a right side plate; a positioning bolt is fixed on the positioning bottom plate, the positioning cover plate comprises a positioningfolding edge, the contact part among the left side plate, the right side plate and the positioning bottom plate is provided with an along edge, and a positioning hole is formed in the along edge; andduring installation, the positioning folding edge is folded into the inner frame of the left side plate and the inner frame of the right side plate, during installation, the positioning bolt on the positioning bottom plate is inserted into the positioning hole of the left side plate and the positioning hole of the right side plate, a bent covering edge is bent on the positioning bottom plate, during installation, the left side plate, the right side plate and the positioning rear connecting plate are installed on the inner side of the bent covering edge, during installation, the positioning bolt on the positioning bottom plate is inserted into the positioning hole of the left side plate and the positioning hole of the right side plate, positioning and connecting effects are achieved in thepositioning holes, the folding edge of the positioning cover plate is pressed into the left side plate and the right side plate of the instrument box to ensure the inner forming size of the box body,after the forming precision of the instrument box is guaranteed, the tool structure is disassembled, and after the instrument box is installed, disassembling is carried out.

Owner:SHANGHAI NAJIE COMPLETE SETAB OF ELECTRIC

A method for bending and forming sheet metal parts

The invention belongs to the technical field of sheet metal processing, in particular to a bending forming method for sheet metal parts. The bending forming method adopts a multi-roller floating bending machine. The multi-roller floating bending machine comprises a machine body, a downward pressing module, a main pressure head, auxiliary pressure heads, an adjusting unit, movable dies and a fixeddie, wherein a controller is arranged on the machine body. The controller is located at one side of the machine body. The downward pressing module is located at the upper part of the machine body andis used to press down the main pressure head and the auxiliary pressure heads. The main pressure head is fixedly connected with the downward pressing module. The auxiliary pressure heads are of the same structure as the main pressure head, and the auxiliary pressure heads and the main pressure head are used for bending the sheet metal parts. The adjusting unit is positioned between the auxiliary pressure heads and the downward pressing module and is used for adjusting the auxiliary pressure heads to ascend or move left and right. The movable dies are located at one side of the lower part of the machine body and is in sliding connection with the machine body. The movable dies are used for bending the sheet metal parts. According to the bending forming method, the forming size of the sheet metal parts can be ensured by fine-adjusting the shapes of the sheet metal parts, and the forming qualification rate of the sheet metal parts is increased.

Owner:柳州盛盈装配有限公司

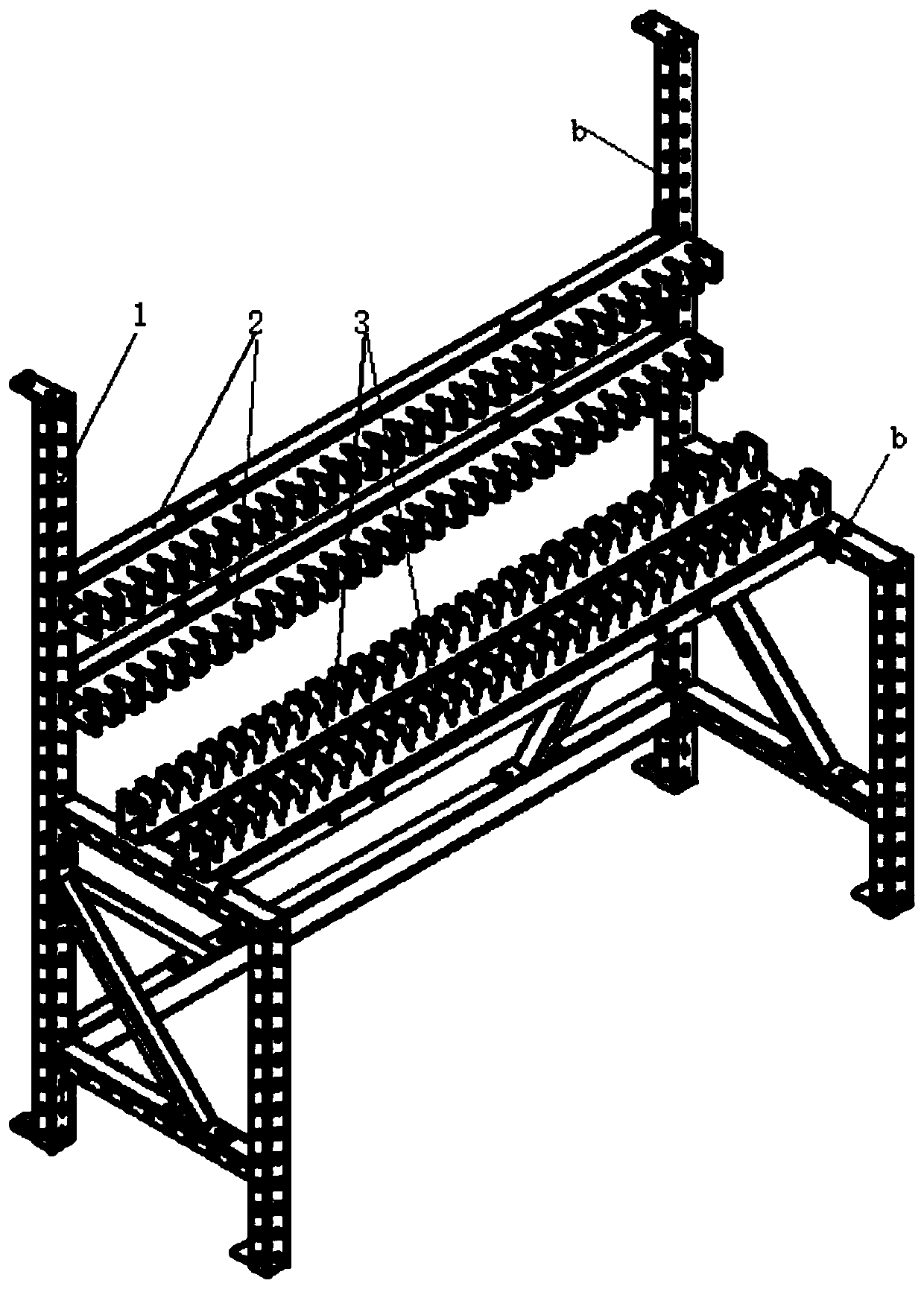

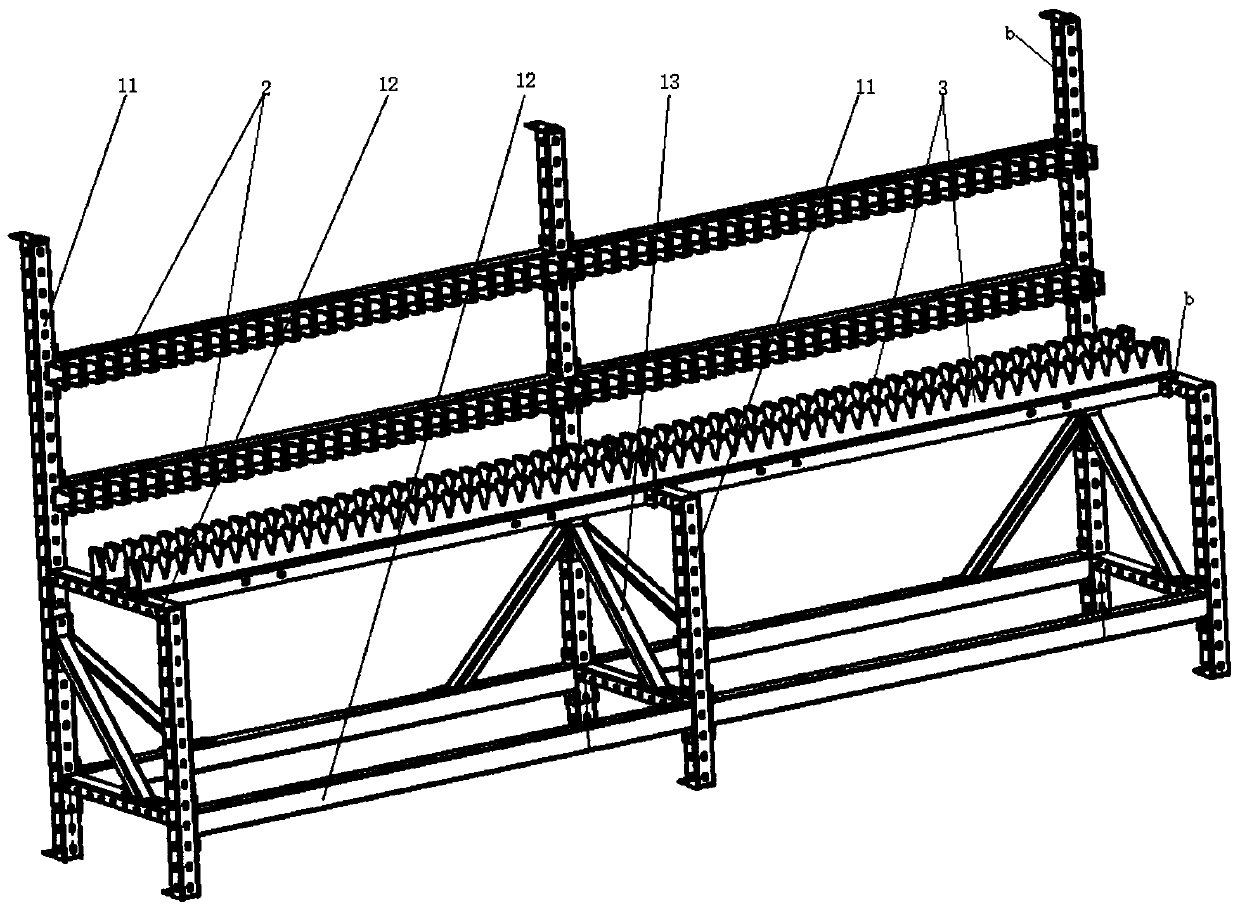

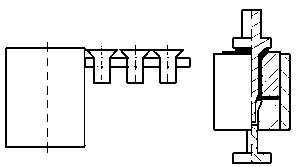

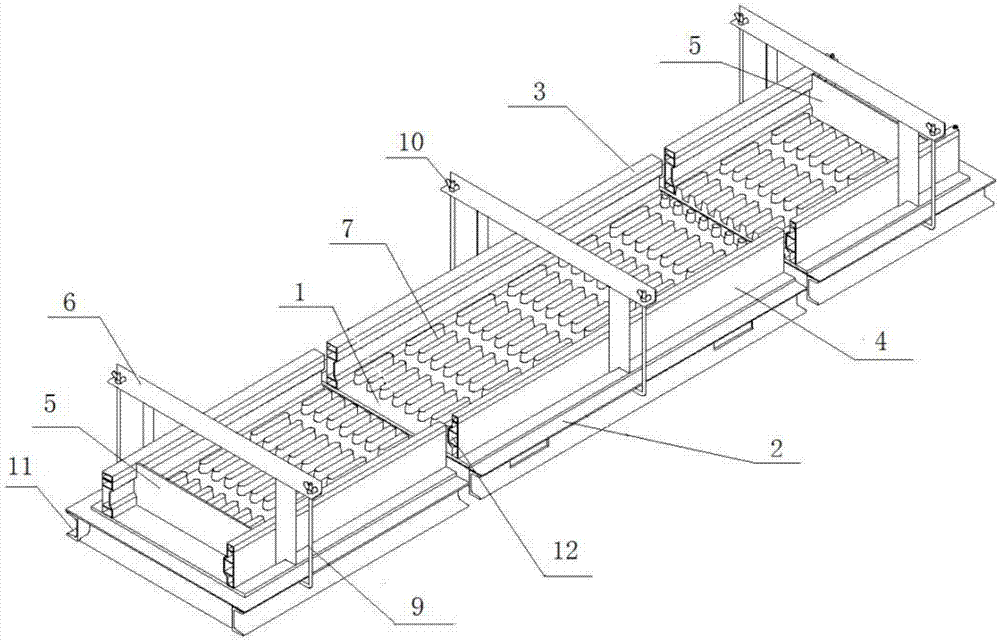

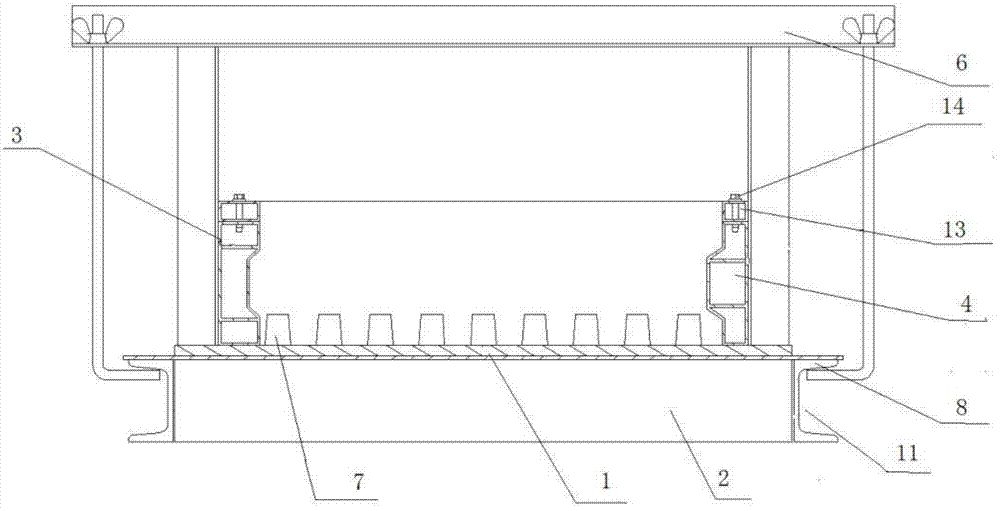

Steel reinforcement cage machining method and system

The invention discloses a steel reinforcement cage machining method and system. A conveyor is arranged between a steel reinforcement cage machining site and a stirrup folding machine, and stirrups made by the stirrup folding machine fall on the conveyor and are directly conveyed to the steel reinforcement cage machining site; and spacing strips are designed, positioning grooves are uniformly distributed in the length direction of the spacing strips, and the distance between every two adjacent positioning grooves is equal to the minimum distance between the stirrups. The multiple parallel spacing strips which are provided with the positioning grooves with aligned notches are arranged, when a steel reinforcement cage is shaped, the bottoms and one sides of the stirrups are respectively clamped in the positioning grooves, the stirrups are simultaneously matched with at least three spacing strips and do not fall vertically, and the distance between the stirrups is controlled by adjusting the stirrups to be placed in the different positioning grooves, the vertical position and the horizontal position and the input number of the spacing strips are adjusted to adapt to the size of the stirrups, when the spacing strips are shorter than longitudinal bars, the size requirements of the longitudinal bars are met by lengthening the spacing strips, and all the stirrups and the longitudinal bars are fixed and formed at a time after being matched. The forming size of a steel reinforcement cage is guaranteed, efficiency is improved, and workload is reduced.

Owner:美好建筑装配科技有限公司

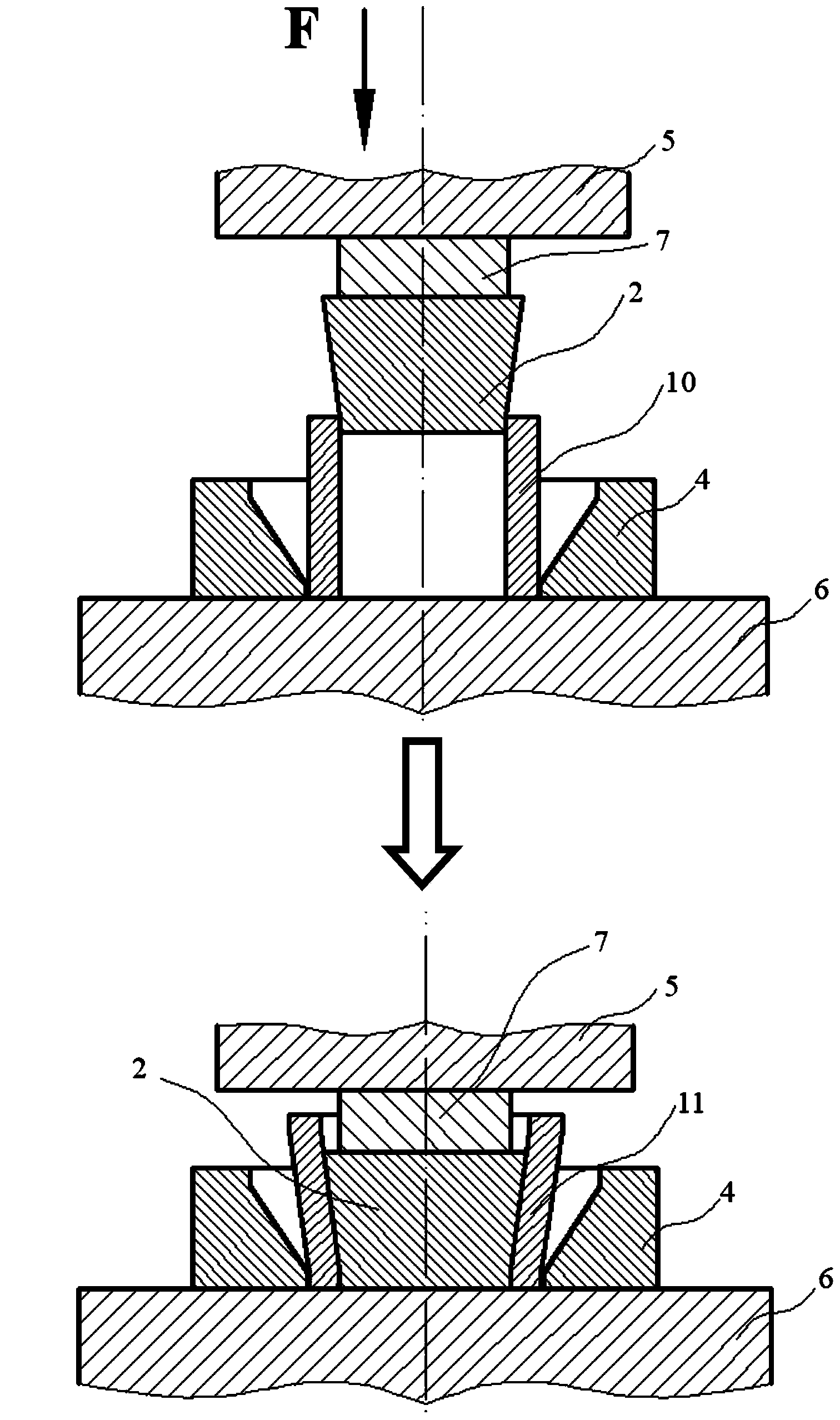

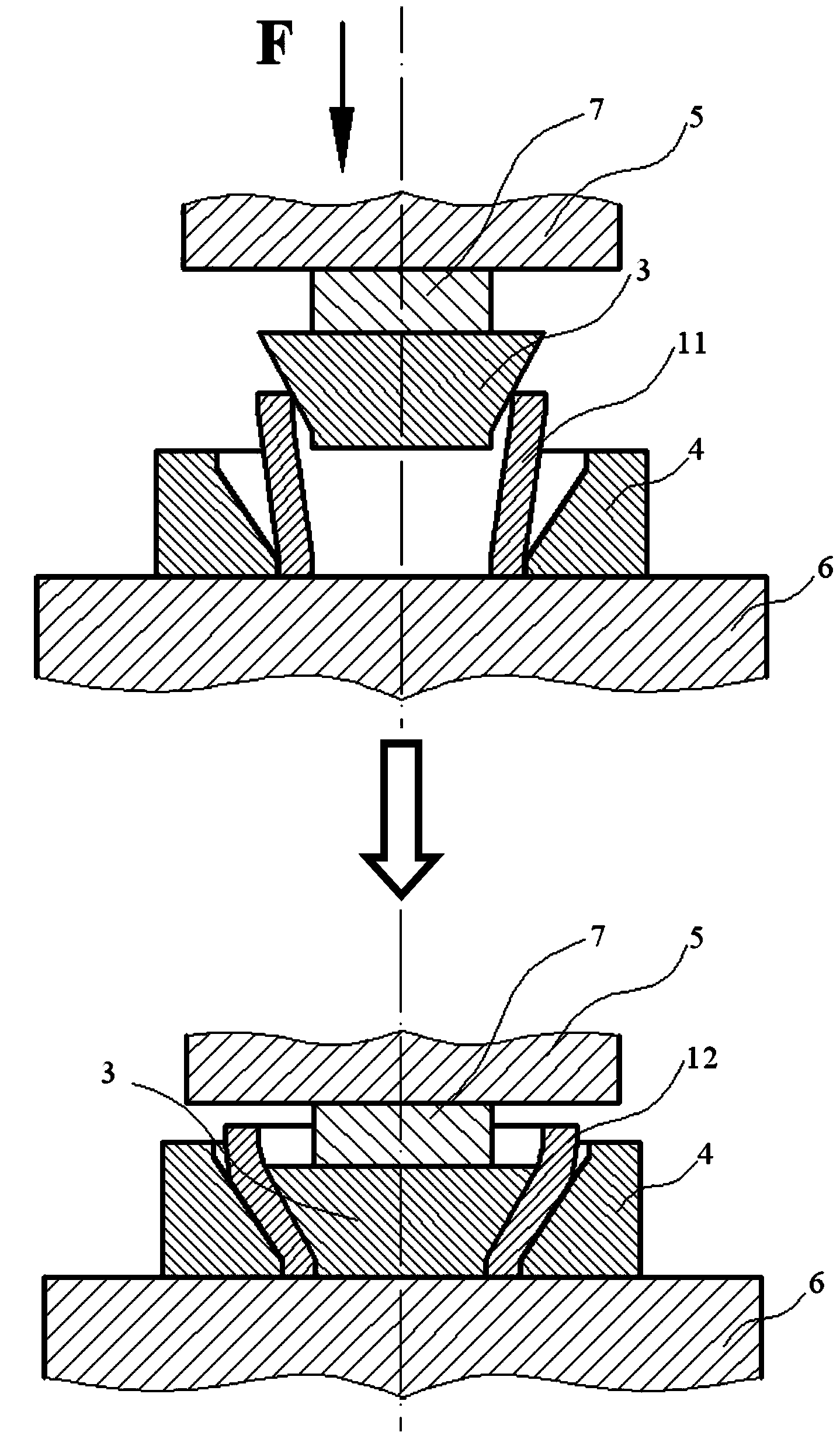

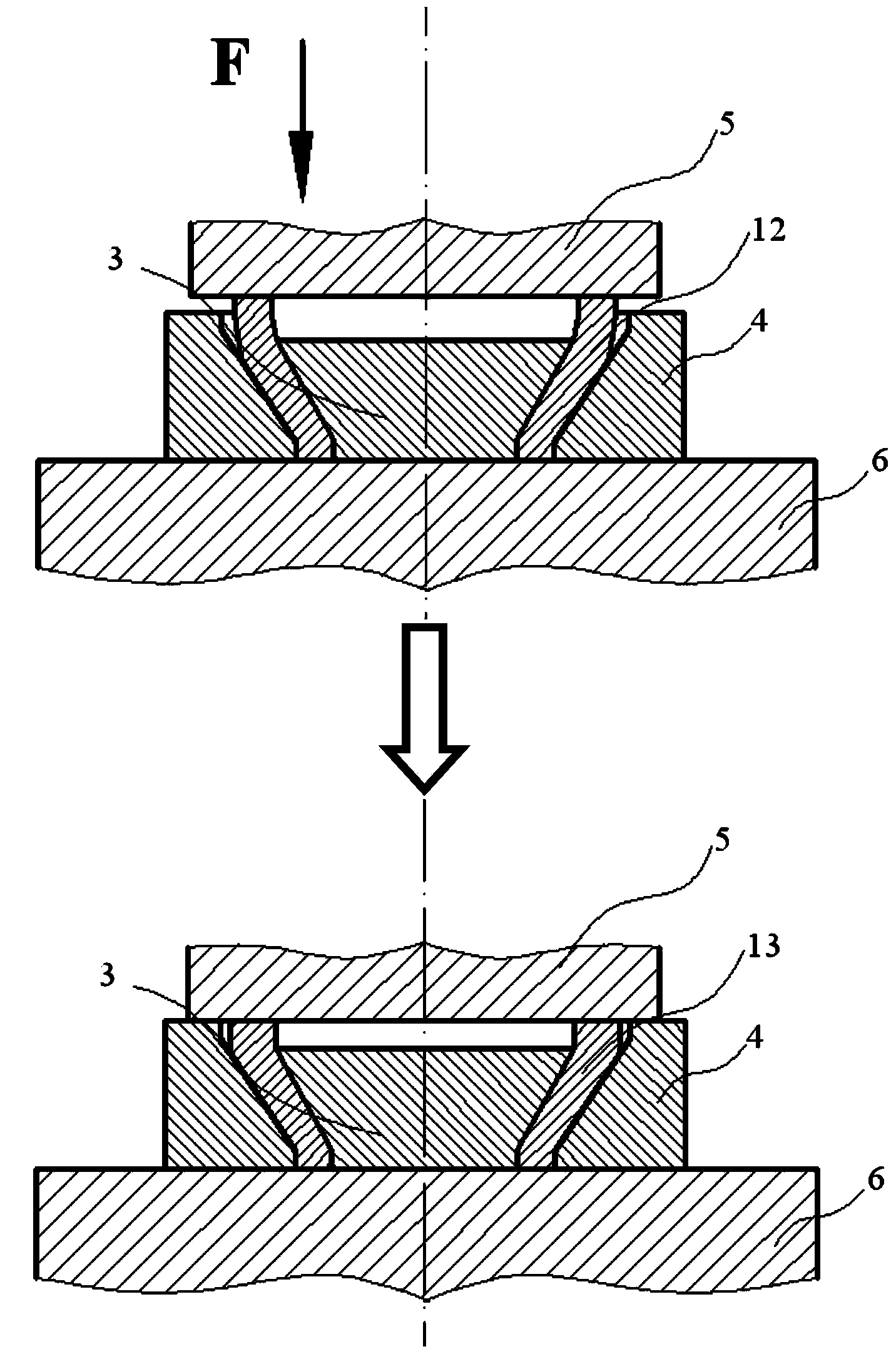

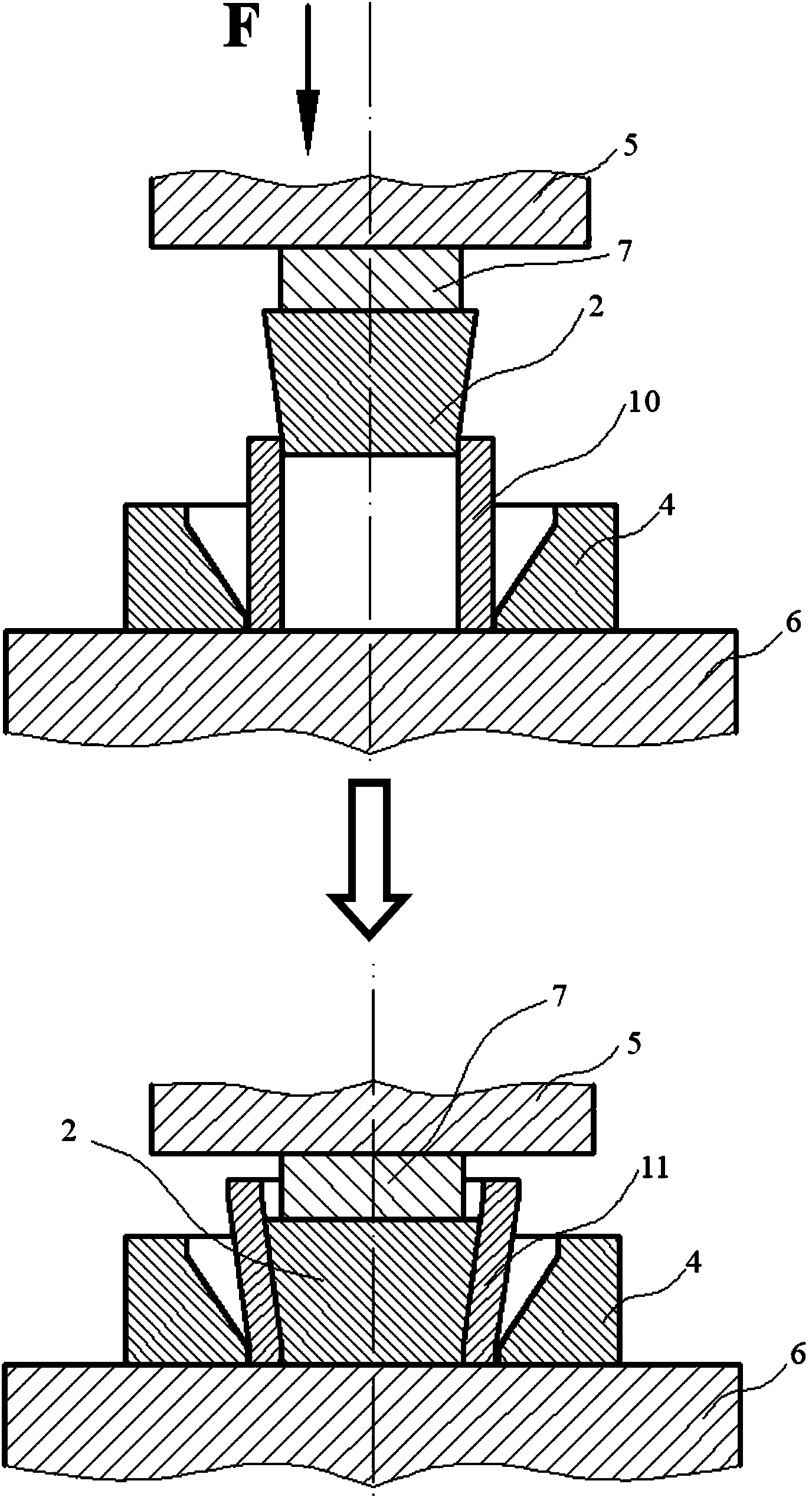

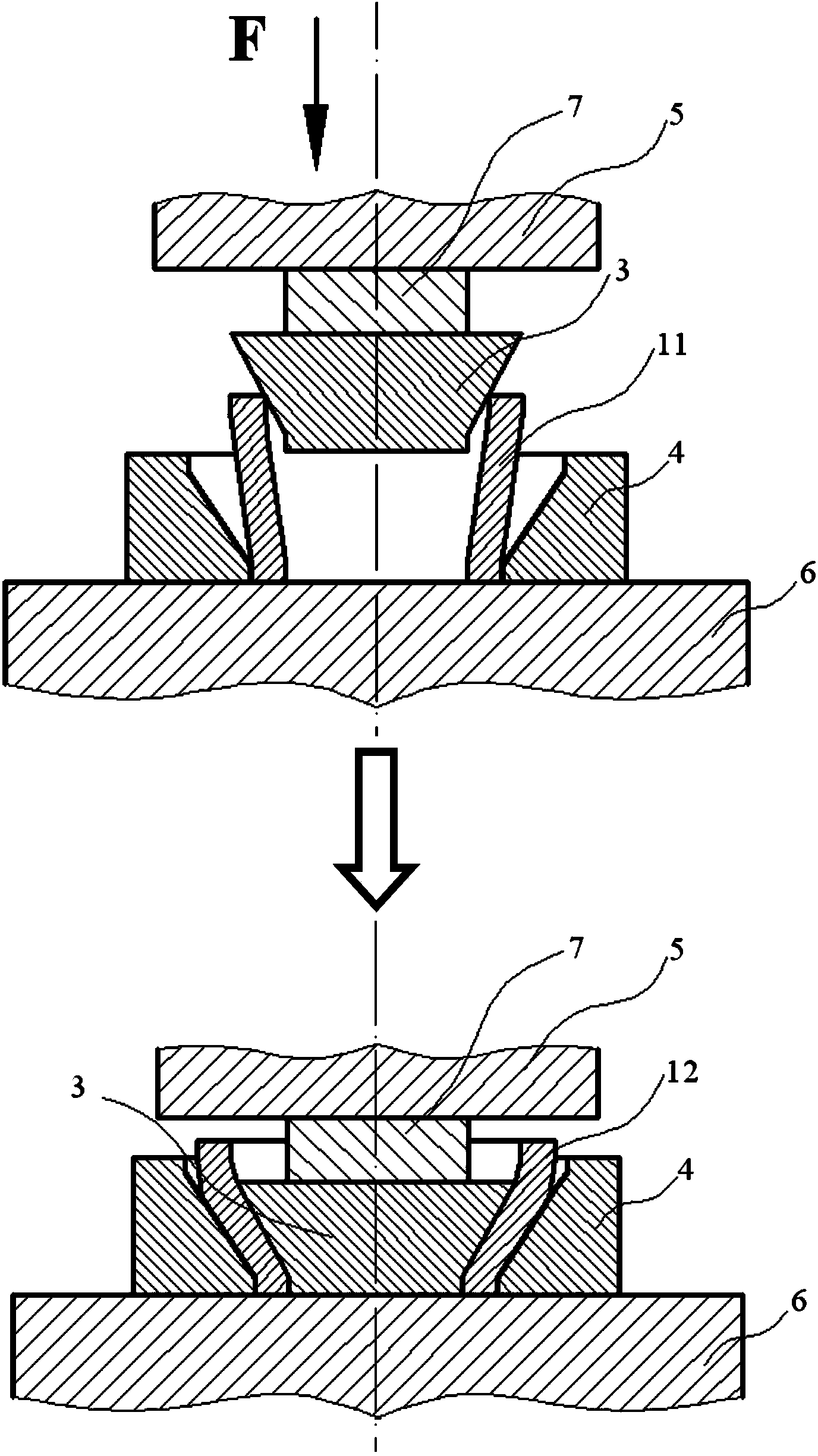

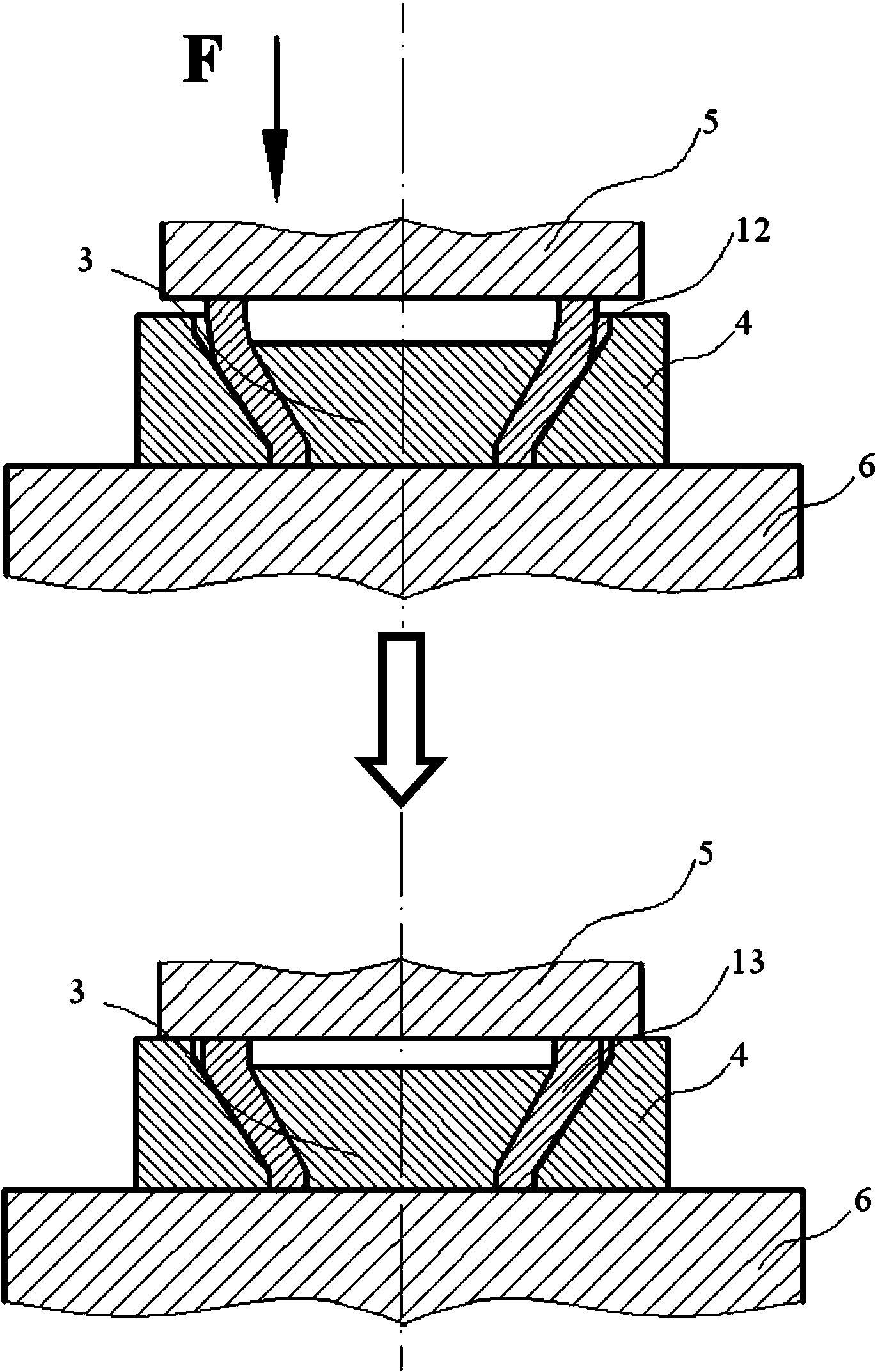

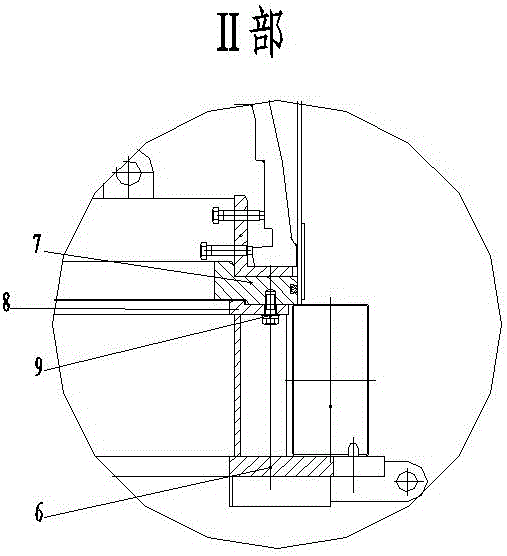

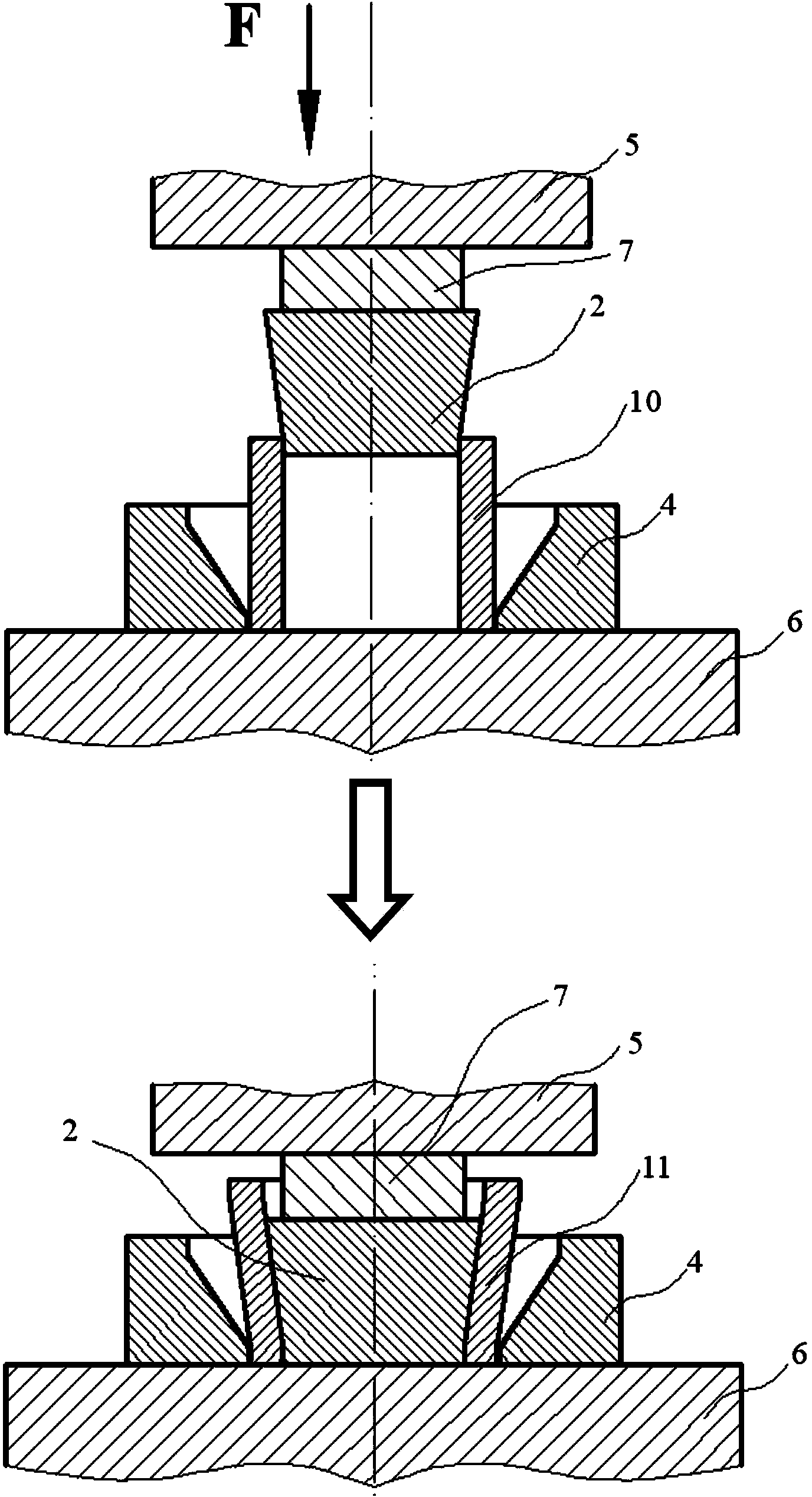

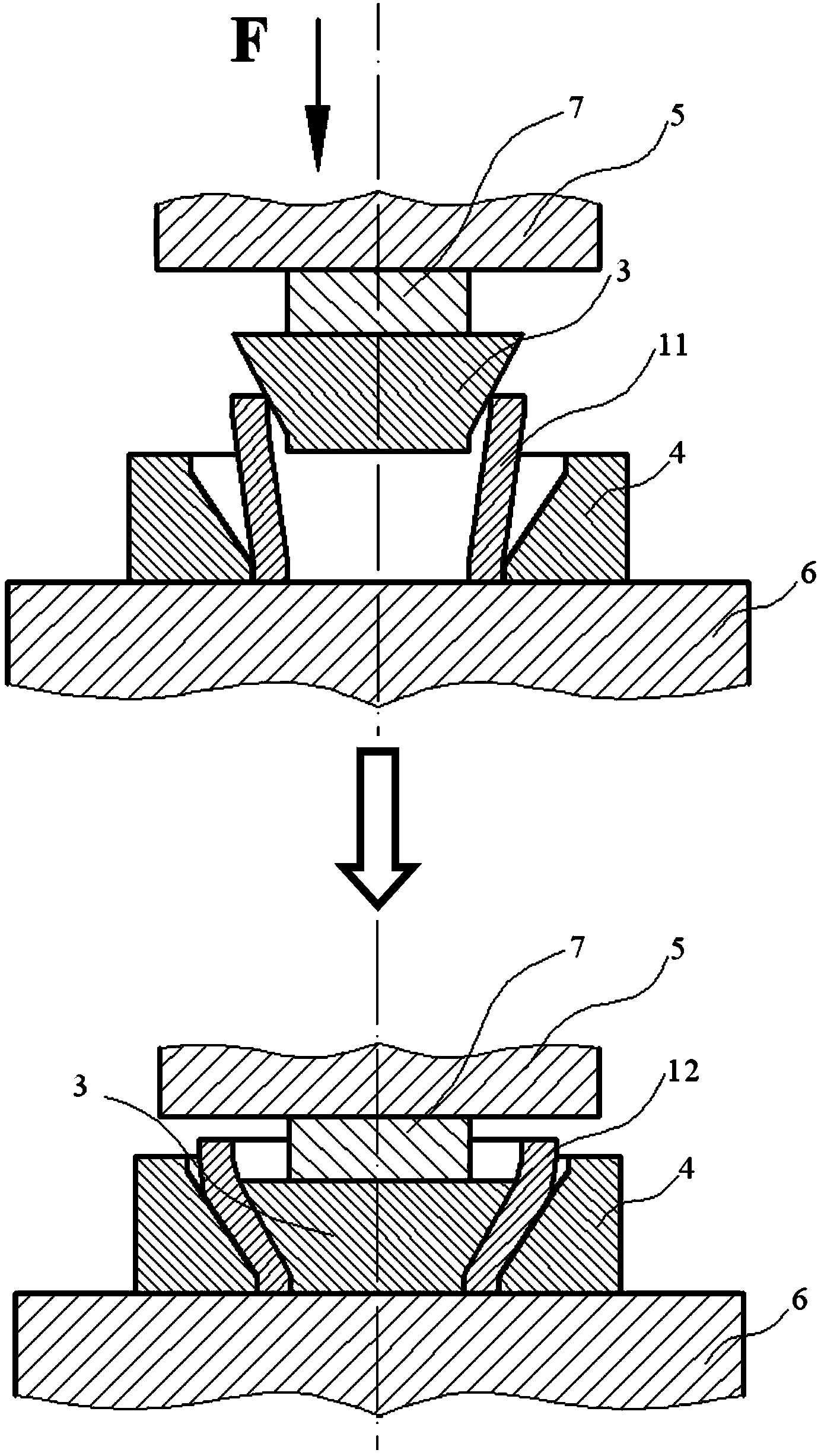

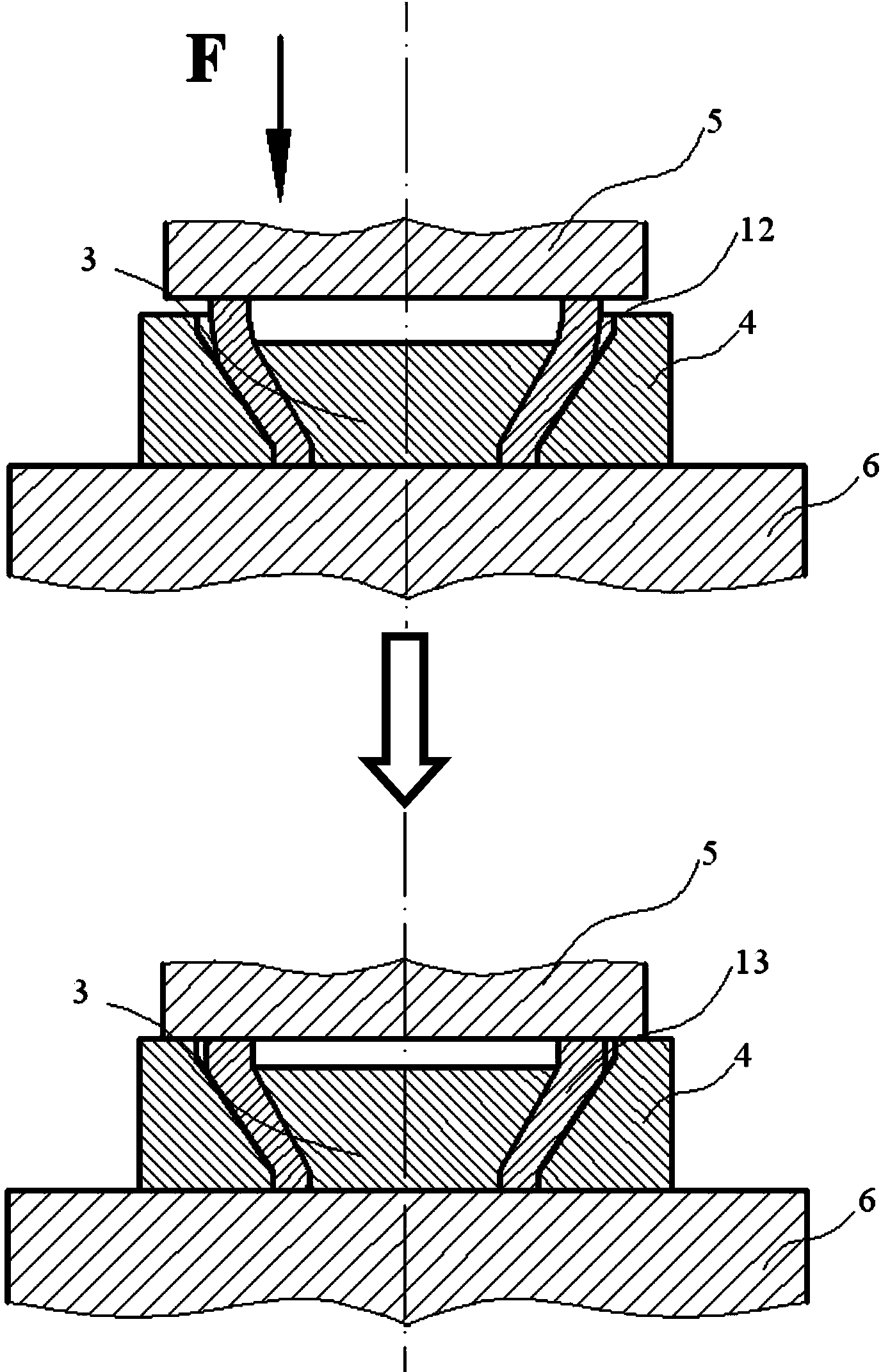

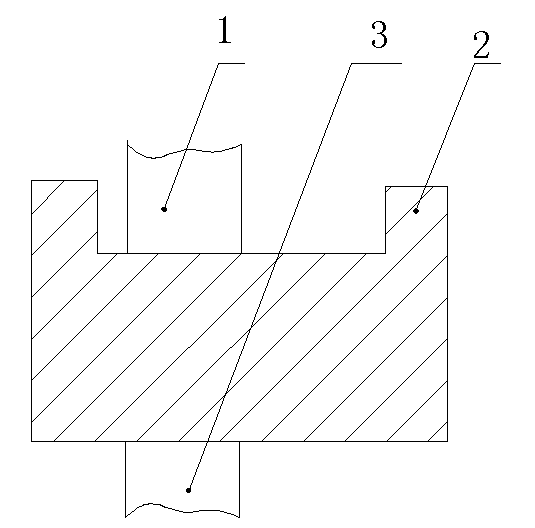

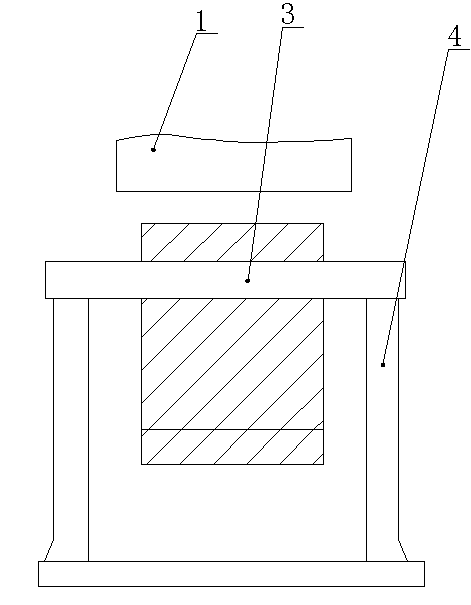

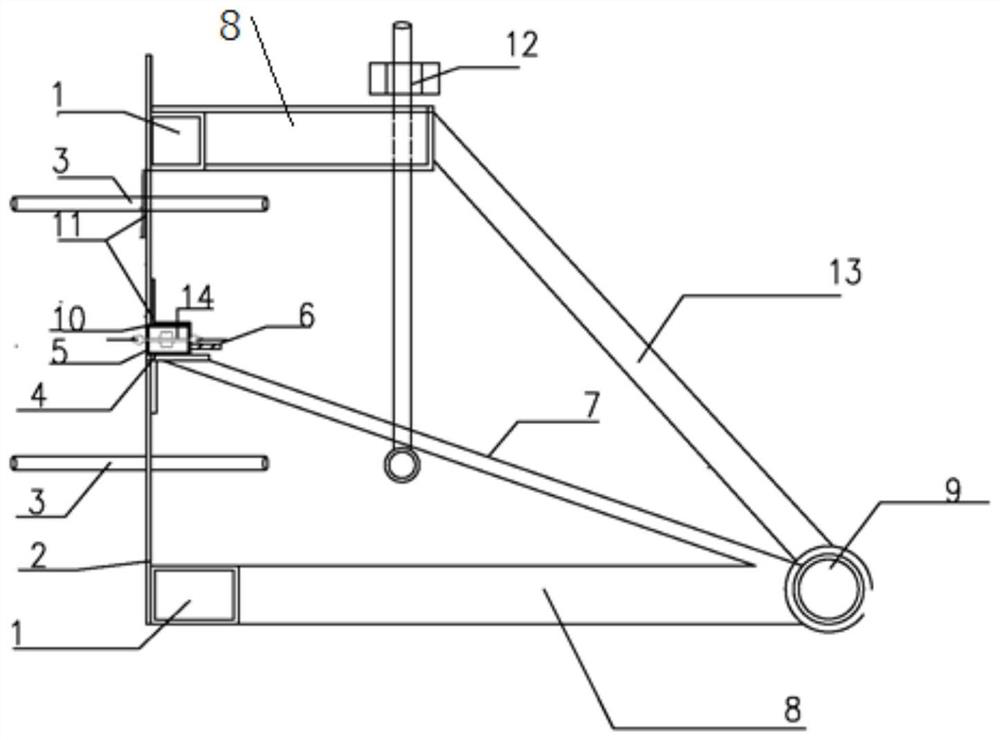

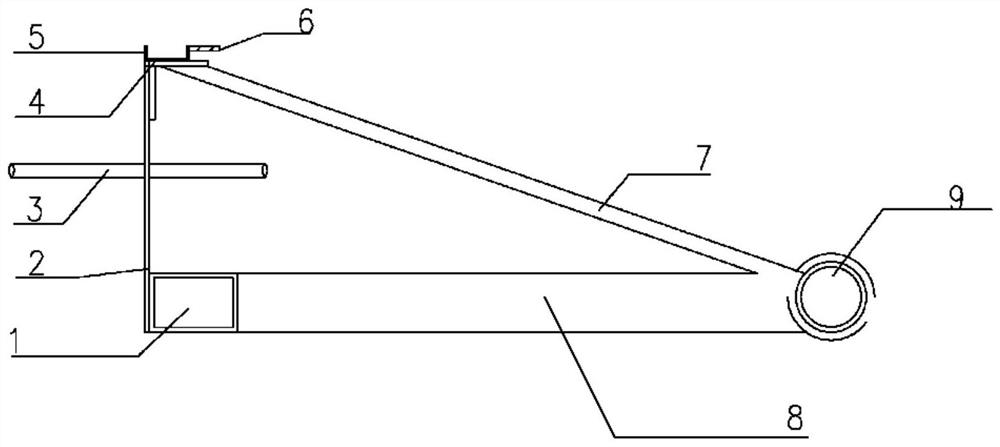

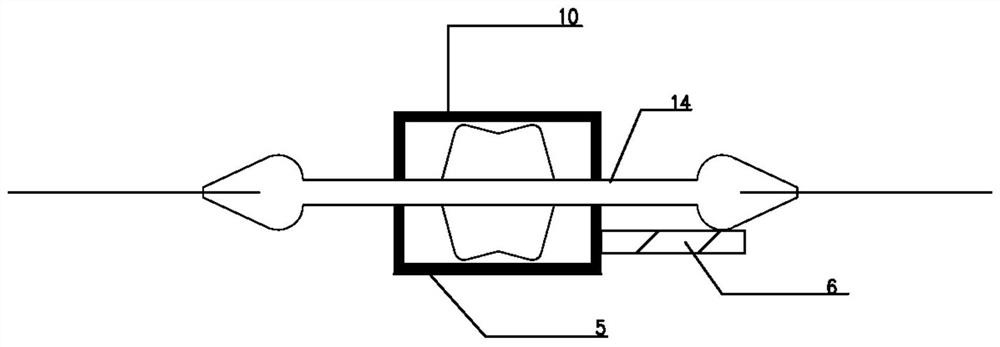

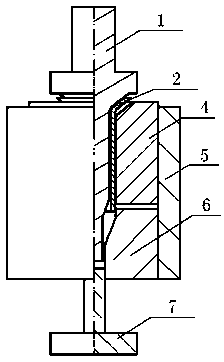

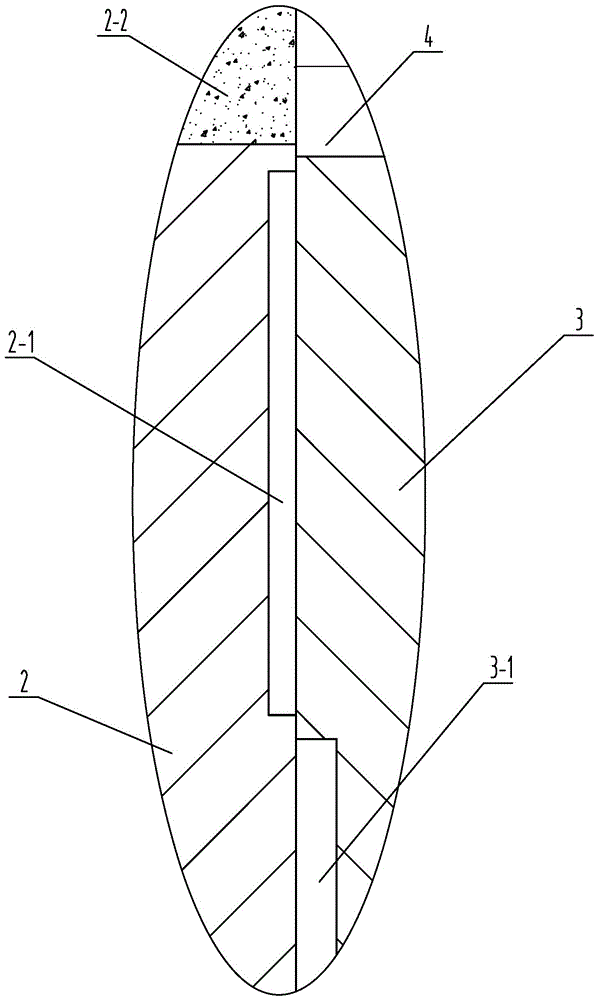

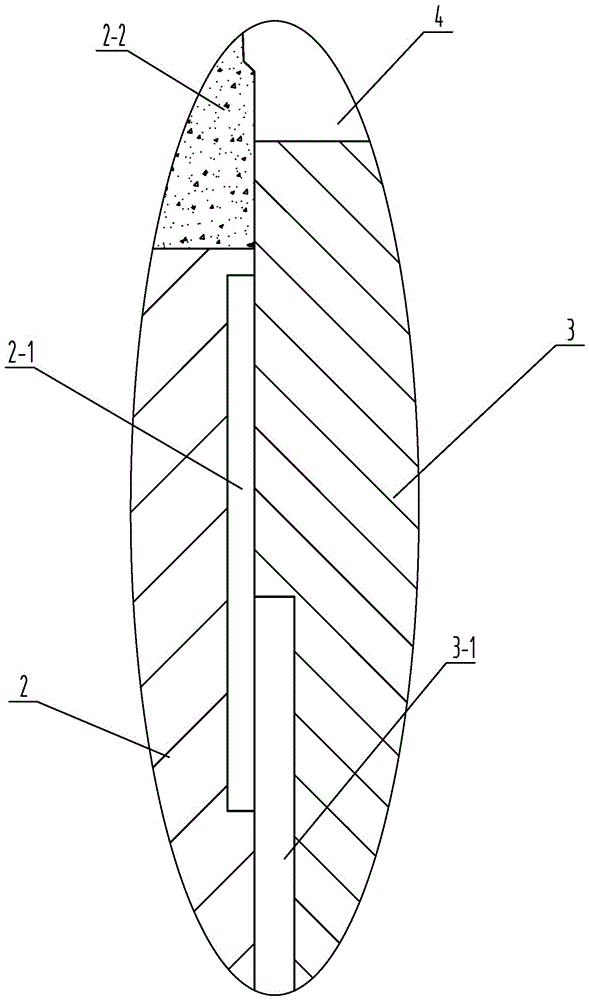

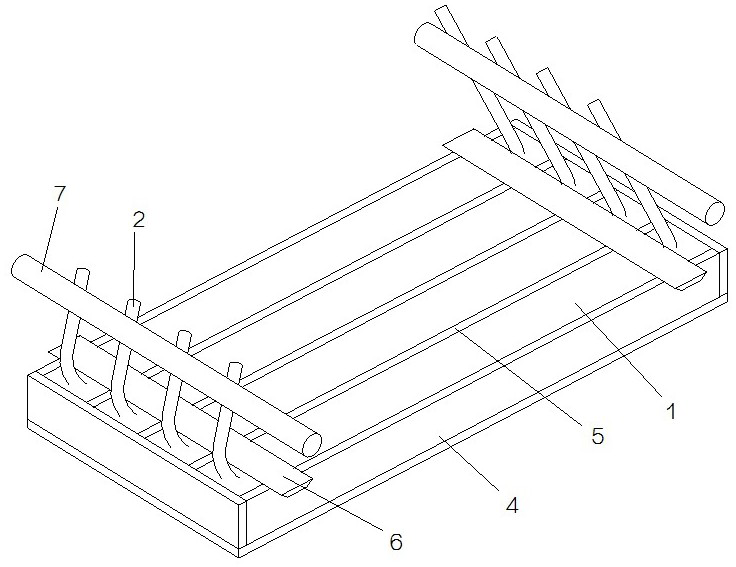

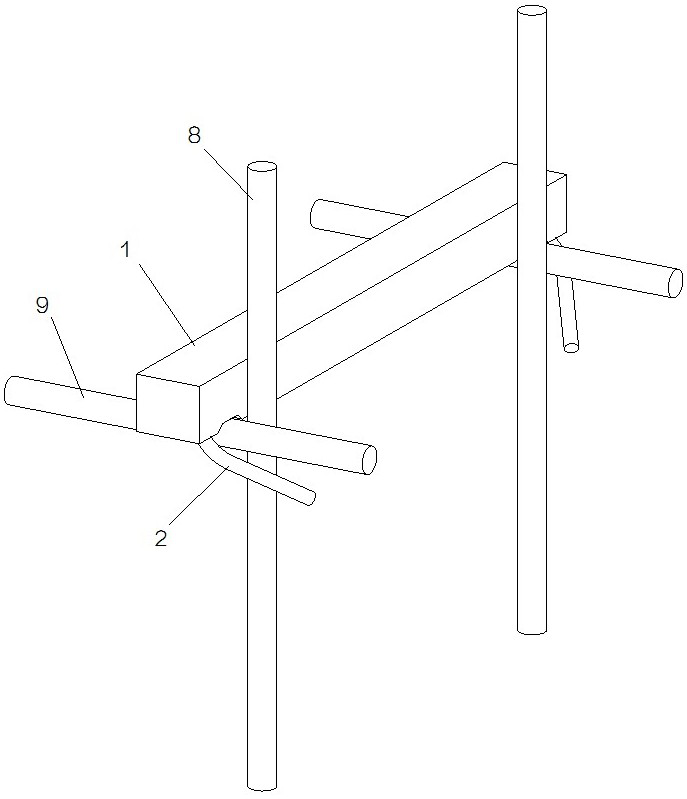

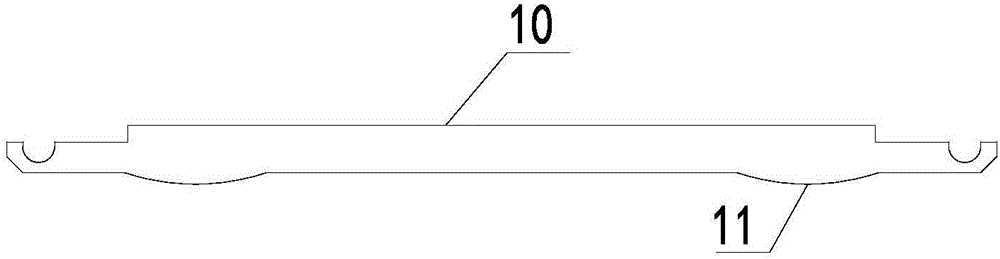

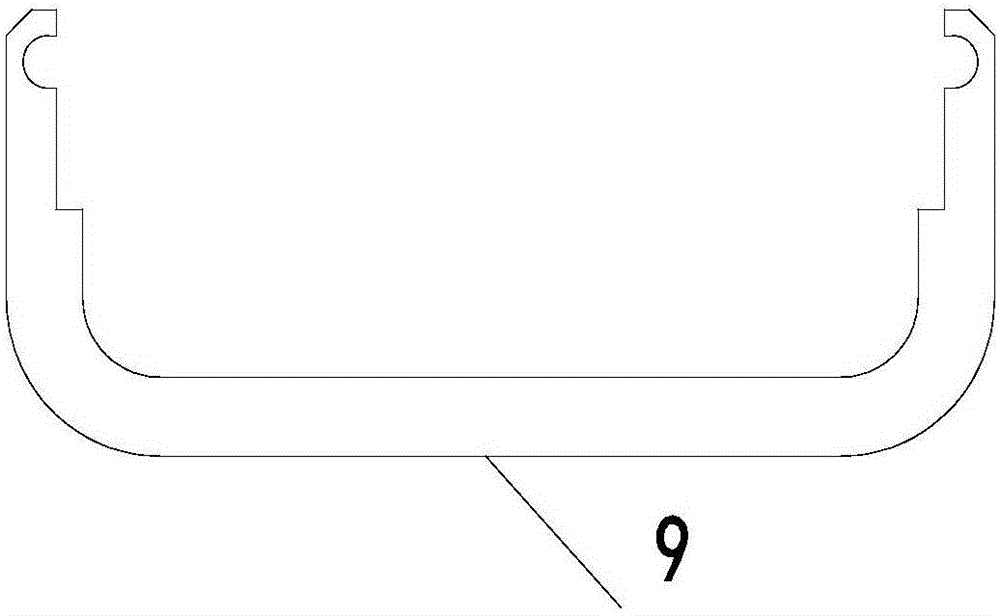

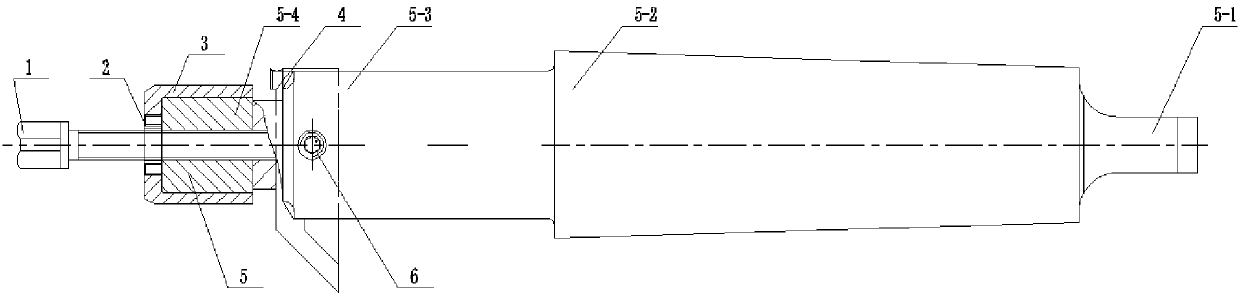

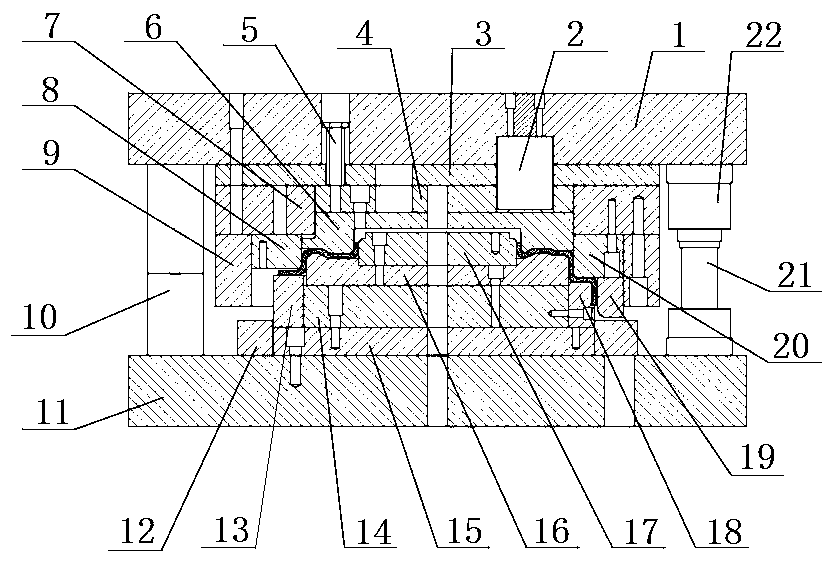

Lower cone forming tool and method for intervention nail pulling dual-taper bush

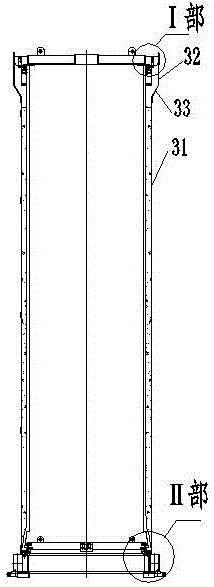

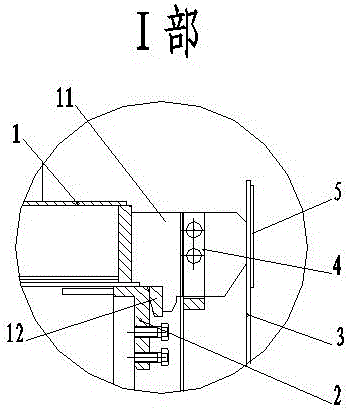

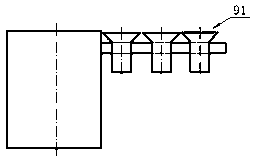

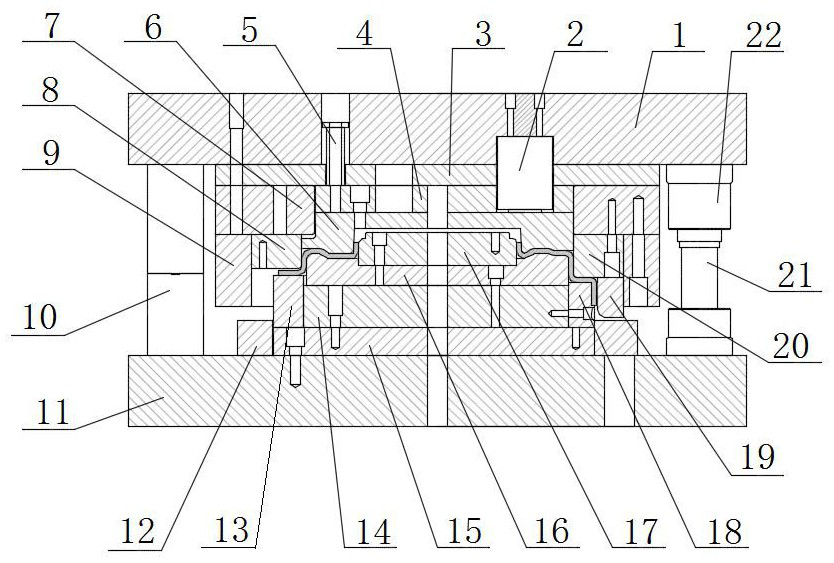

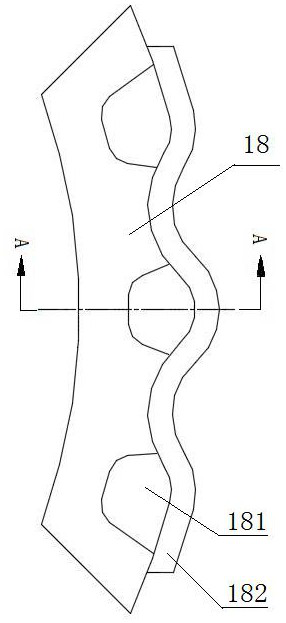

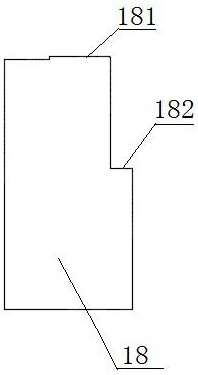

ActiveCN107866496AImprove fatigue lifeImprove machining accuracyShaping toolsEjection devicesThin walledAirplane

The invention discloses a lower cone forming tool and method for an intervention nail pulling dual-taper bush. The forming tool comprises a feeding mechanism, a lower cone forming mechanism and an unloading mechanism; the automatic feeding mechanism comprises a workpiece (91), a material guiding groove (92) and a vibration material disc (93); the lower cone forming mechanism comprises an inner cavity molded surface pressure head (1) of the dual-taper bush, a blank (2) of the dual-taper bush, an outer molded surface interlayer cover (4) of the dual-taper bush, a guide cover (5) and a lower conefemale die (6); and the unloading mechanism is an unloading rod (7). According to the lower cone forming tool and method, a whole set of combined forming tool is designed, the size of a molding die cavity is precisely controlled, the match between sizes of the die and the workpiece is realized, the instability of the workpiece is limited by inner and outer molded surfaces of the die, a sectionalcombined die is adopted, the lower cone is formed in a forming manner of limiting and necking down, the formation of the lower cone of a 100-degree countersunk head or flat head thin-wall interventionbush is met, and the lower cone forming tool can be used for precisely controlling an intervention connection structure of a plane composite material with precise interference amount.

Owner:AVIC BEIJING AERONAUTICAL MFG TECH RES INST

A cover mold used to cancel the phosphating process

Owner:GUILIN FUDA

A kind of easy-off and anti-blocking original edge ceramic tile forming mold

ActiveCN104647573BPrecise size controlPrevents stasis and even cloggingCeramic shaping apparatusBrickMaterials science

The invention discloses an easy-to-release anti-blocking original-side ceramic tile forming mould and belongs to the technical field of powder forming. The easy-to-release anti-blocking original-side ceramic tile forming mould comprises an upper mould core, side plates and a lower mould core which define a mould cavity. The easy-to-release anti-blocking original-side ceramic tile forming mould is characterized in that a ventilating path and a plurality of gas vent holes are formed in the upper mould core, wherein one end of each gas vent hole is communicated with the bottom surface of the upper mould core, the other end of each gas vent hole is communicated with the ventilating path, the ventilating path is connected with a gas exhausting branch and a gas blowing branch; the side plates comprise long side plates and short side plates which are enclosed in two adjacent long side plates, wherein first inclined positions which are outwards inclined from top to bottom are formed in the inner walls of the long side plates and the short side plates; second inclined positions are formed in the two ends of each short side plate; the long side plates and the short side plates can be tightly assembled together through the first inclined positions and the second inclined positions. A ceramic brick green body finished product pressed out by the forming mould does not need edging processing; moreover, in the pressing process, the gas exhausting system can be prevented from being blocked, the demoulding is easy to carry out and the mould is prevented from being blocked, so that the forming quality of the original-side ceramic tiles can be improved.

Owner:淄博沃德机械科技有限公司 +2

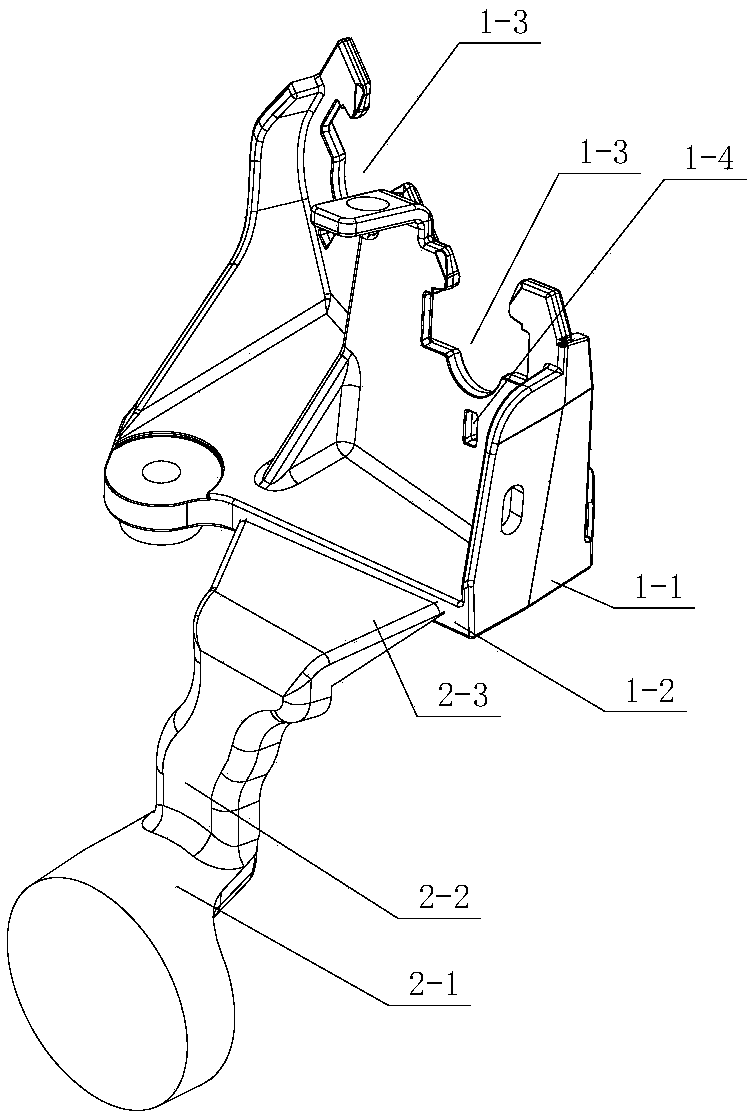

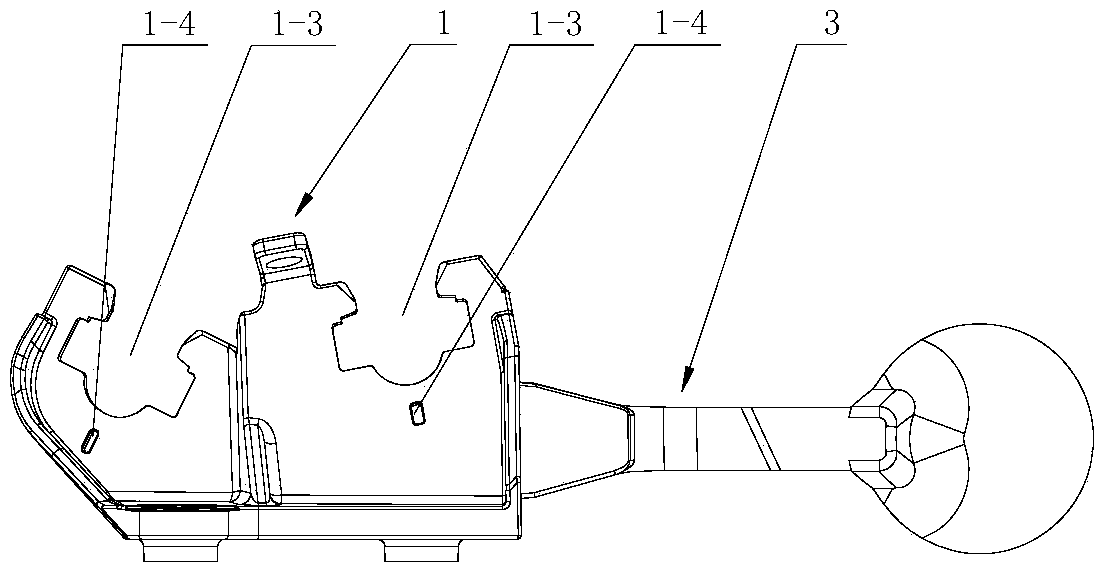

Improved runner system of automobile brake wire bracket

The invention relates to an improved runner system of an automobile brake wire bracket. The runner system is arranged outside the bottom connected with the planar end of a die-casting mold cavity of the automobile brake wire bracket and is located outside the side away from plastic clip mounting grooves to be die-cast; the runner system comprises a straight runner and a transverse runner connectedwith the tail end of the straight runner; a sprue part communicating with the die-casting mold cavity is arranged at the tail end of the transverse runner; the transverse runner is of a curved runnerstructure; an included angle is formed between the transverse runner and the sprue part. According to the runner system, the positions and the shapes of the runners are changed, so that the erosion of metal liquid to the casting mold cavity is reduced; the size of mounting holes under the plastic clip mounting grooves is ensured; the service life of a mold is also prolonged.

Owner:TIANJIN HUIDE IND & TRADE

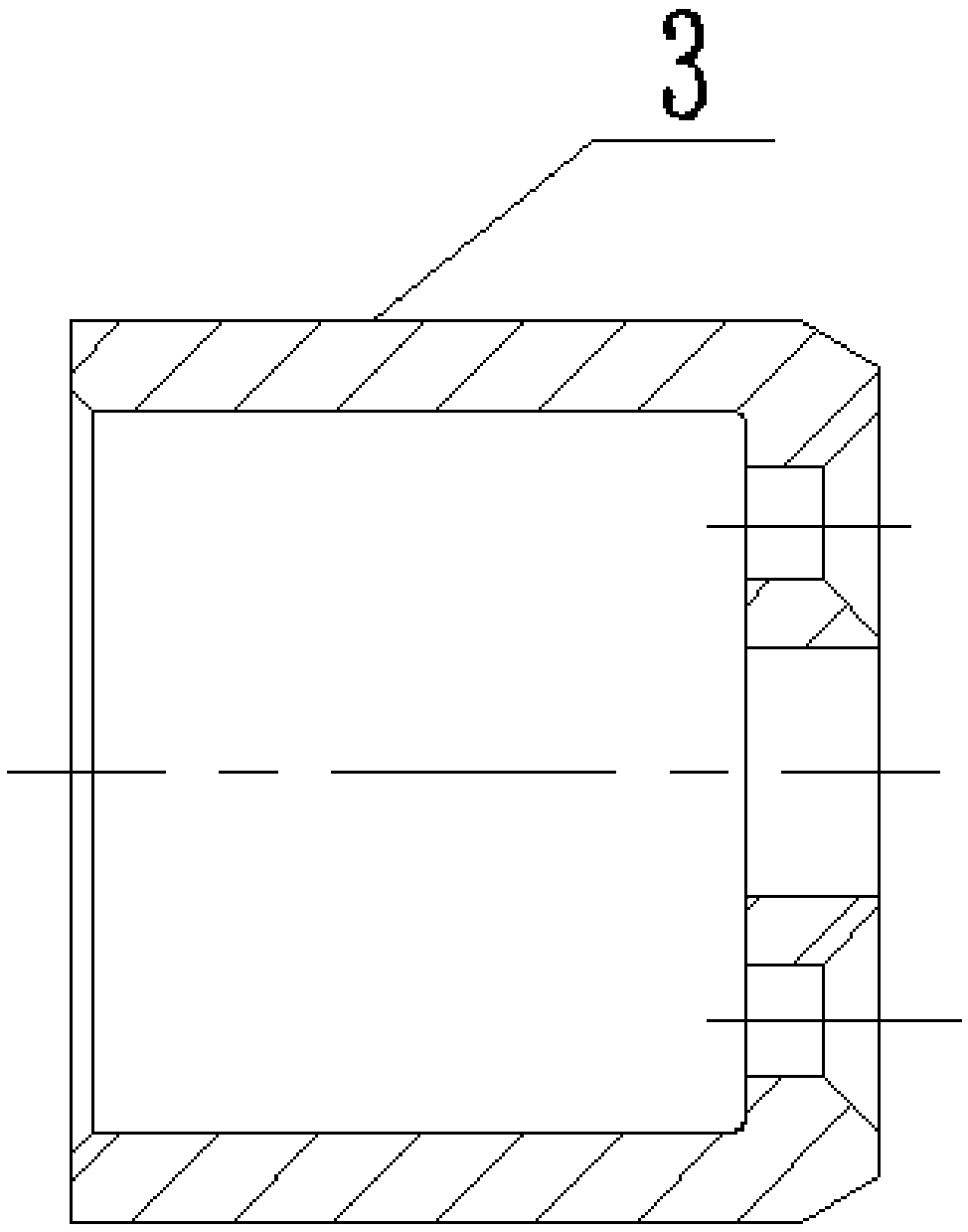

Pipe orifice mould-withdrawing tool for container

InactiveCN106270070ANot easy to wear and deformGuaranteed molding sizeShaping toolsEngineeringMechanical engineering

The invention relates to a pipe orifice mould-withdrawing tool for a container. The tool is composed of a mould-withdrawing barrel, a barrel pipe-withdrawing lower mould, a pipe-withdrawing upper mould, inner hexagonal screws, mould placing platforms, a hydraulic machine connecting screw rod, a mould-withdrawing seal head and a seal head pipe-withdrawing lower mould. The tool is suitable for pipe orifice mould-withdrawing mould forming production of sanitary grade equipment, and belongs to the technical field of an innovative process of manufacturing the sanitary grade equipment. A reasonable mould operating mode is as follows: a mould is driven hydraulically; a workpiece is placed on a hydraulic platform by a worker, upper and lower moulds are assembled, a hydraulic device is started, and a step of withdrawing the mould can be finished only by an operation of a single worker, so that the labor intensity of the worker is alleviated.

Owner:FEATURE-TEC (WUXI) FILTRATION TECH CO LTD

Preparation method of gh4169 alloy large-scale special-shaped cross-section ring billet

ActiveCN103447768BReduce forming pressureGuaranteed molding sizeMetal-working apparatusAlloyAbnormal shaped

The invention discloses a method for preparing a GH4169 alloy large-scale special-shaped cross-section ring blank. The steps are: heating the GH4169 alloy bar to 1100±10°C in a certain heating method, and then forming a rectangular shape through upsetting, punching and rolling. Cross-section ring billet; then expand it into a ring billet with a special-shaped cross-section with a pressure of 34-36MN; then expand it into a secondary ring billet with a special-shaped cross-section with a pressure of 32-35MN; The upper end of the secondary special-shaped cross-section ring blank is freely upset until it is flush with the tire mold, and the final special-shaped cross-section ring blank is obtained. The method can effectively reduce the forming pressure required for billet making, and at the same time can effectively control the flow direction of the remaining material in the process to ensure the forming size of the intermediate billet. The method is suitable for the preparation of intermediate blanks of large rings with special-shaped cross-sections.

Owner:GUIZHOU ANDA AVIATION FORGING

Shear wall formwork inner stay and tie bar combined component and method

ActiveCN108843016BReduce space occupancyReduce hindranceAuxillary members of forms/shuttering/falseworksArchitectural engineeringRebar

The invention belongs to the technical field of building construction, and in particular relates to a combined member of a shear wall formwork inner stay and a tie bar, which includes a cement inner stay and a tie bar, and both ends of the tie bar are bent upwards to form a A hook, one end of which is a 90° hook, and the other end is a hook greater than 90° and less than 180°; the cement inner stay is a long strip structure, and a notch is provided on the upper surface of its two ends; The middle part of the tie bar is pre-buried in the cement inner stay, the hooks at both ends of the tie bar face upward and are located outside the notch of the corresponding end, and the hooks at both ends of the tie bar are connected to the upper part of the cement inner stay. Surfaces are angled at an angle. In the present invention, the cement inner stays and tie bars are made into one component to form a whole, which not only satisfies the function of formwork inner support and steel bar tie, but also reduces the space occupancy of the transverse member in the shear wall, and reduces the time when the vibrating rod is inserted. The obstruction reduces the difficulty of on-site construction; greatly saves labor and improves construction efficiency.

Owner:CHINA FIRST METALLURGICAL GROUP

Forming die device used for U-shaped bar materials

InactiveCN105642760AGuaranteed molding sizeGuaranteed flatnessShaping toolsMetal-working feeding devicesEngineeringMechanical engineering

Owner:HEFEI PRESSURE MACHINERY

A Boiler Header Tube Hole Processing Tool

ActiveCN106216744BReduce processing timeGuaranteed molding sizeTransportation and packagingTrepanning drillsEngineeringScrew thread

The invention discloses a boiler header pipe hole machining tool, relates to a pipe hole machining tool, and aims to solve the problems of time waste due to need of triple machining, need of frequent replacement of a cutter bar and a blade, incapability of guaranteeing the pipe hole size precision in manual operation and difficult guarantee of the pipe hole size requirements in pipe hole machining in traditional boiler head pipe hole machining. The boiler header pipe hole machining tool comprises a bolt, a guide sleeve, a blade, a cutter bar, blade ejecting screws and two guide sleeve fixed screws; the cutter bar includes a flat section, a conical section, a blade mounting section and a guide sleeve fixed section; the flat section, the conical section, the blade mounting section and the guide sleeve fixed section are fixedly connected in sequence; a plane and a blade mounting hole are machined on the blade mounting section; blade ejecting screw thread holes are formed from the plane to the blade mounting hole; the guide sleeve coats the guide sleeve fixed section; the blade is mounted in the blade mounting hole; and the blade ejecting screws are arranged in the blade ejecting screw thread holes. The boiler header pipe hole machining tool is used for header pipe hole machining.

Owner:HARBIN HAGUO BOILER ENG TECH

Manufacturing method of toothed seal plate

ActiveCN105631104BGuaranteed molding sizeGuarantee assembly and welding qualityDesign optimisation/simulationSpecial data processing applicationsManufacturing technologyComputer software

The invention relates to a novel tooth-like sealing plate manufacture technology. Key dimensions including tooth-like sealing plates, tooth-like lines, tooth root depth, bent lines and the like all have big deviations, so that an assembling gap between the sealing plate and a tube panel is overlarge, since the production process of the tooth-like sealing plate is in cold working processing and the manufacture precision of cold working is low, forming is poor, and the factors cause the problem that two ends are jacked and tooth spaces are overlarge during assembling so as to be difficult in realizing seal welding. The novel tooth-like sealing plate manufacture technology utilizes computer software to carry out three-dimensional entity authentication analysis, draws the assembling position relationship of the sealing plate and the tube panel, determines the key dimensions of the tooth-like lines, the tooth root depth and the bent lines, utilizes the computer software to carry out three-dimensional entity authentication analysis through theoretical calculation, givens the key dimensions of the tooth-like lines, the tooth root depth and the bent lines of 10 tooth-like sealing plates again, and formulates a new technology by a new tool. The invention is used for the novel tooth-like sealing plate manufacture technology.

Owner:HARBIN BOILER CO LTD

Cover plate mold for cancelling phosphating process

ActiveCN110355275AReduce processing stepsReduce pollutionShaping toolsAgricultural engineeringEngineering

The invention discloses a cover plate mold for cancelling a phosphating process. The cover plate mold is mainly composed of an upper template, a compression spring, an upper baseplate, an upper mold core baseplate, fixing screws, an upper mold core, a fixing plate, an upper transmission piece pressure block, a mold frame, a limiting mechanism, a lower template, a discharging plate, a lower transmission piece pressure block, a lower mold core baseplate, a lower baseplate, a lower mold core, a locating block, a step structure mounting surface pressure block, a flanging pressure block, an upper mounting surface pressure block, a guide pillar and a guide sleeve. According to the cover plate mold, through regulation of the cover plate mold structure and a clearance, formation after phosphatingis not required; a cover plate is directly subjected to stretch forming, and destructive treatment to the surface is not required; the surface strength of the cover plate can be improved, and meanwhile the production efficiency is improved; and the production cost, labor intensity and environmental pollution are reduced.

Owner:GUILIN FUDA

A processing mold for concrete composite sound-absorbing and insulating panels for sound barriers

InactiveCN105500503BIncrease productionReduce processing timeMouldsMould auxillary partsSound barrierRebar

The invention discloses a machining mold for a concrete composite sound absorbing and insulating board for a sound barrier for high speed railways. The machining mold is of a rectangle and comprises a convex mold, a concave mold, an end mold, a rubber bottom mold, a base and a mold fixing bracket, wherein the convex mold and the concave mold are respectively fixed on two long sides of the rubber bottom mold, the end mold is arranged at the end part of the rubber bottom mold through the convex mold and the concave mold, and inclined bar-shaped teeth are arranged on the surface of the rubber bottom mold; the mold fixing bracket comprises an angle iron, L-shaped threaded steel bars and fastening components; grooves are formed in two sides of the base; the mold fixing bracket is fixed to the base welded to the outer sides of the convex mold and the concave mold and is reinforced and fixed through the L-shaped threaded steel bars and the fastening components; movable connecting components for adjusting the length of the machining mold are arranged at two end parts of the rubber bottom mold. The machining mold can be randomly adjusted according to required length, and multiple machining molds can be matched in use, so that the machining time can be greatly saved, the yield of the concrete composite sound absorbing and insulating board can be increased, and the labor cost and the material cost can be saved.

Owner:四川云路科技有限公司

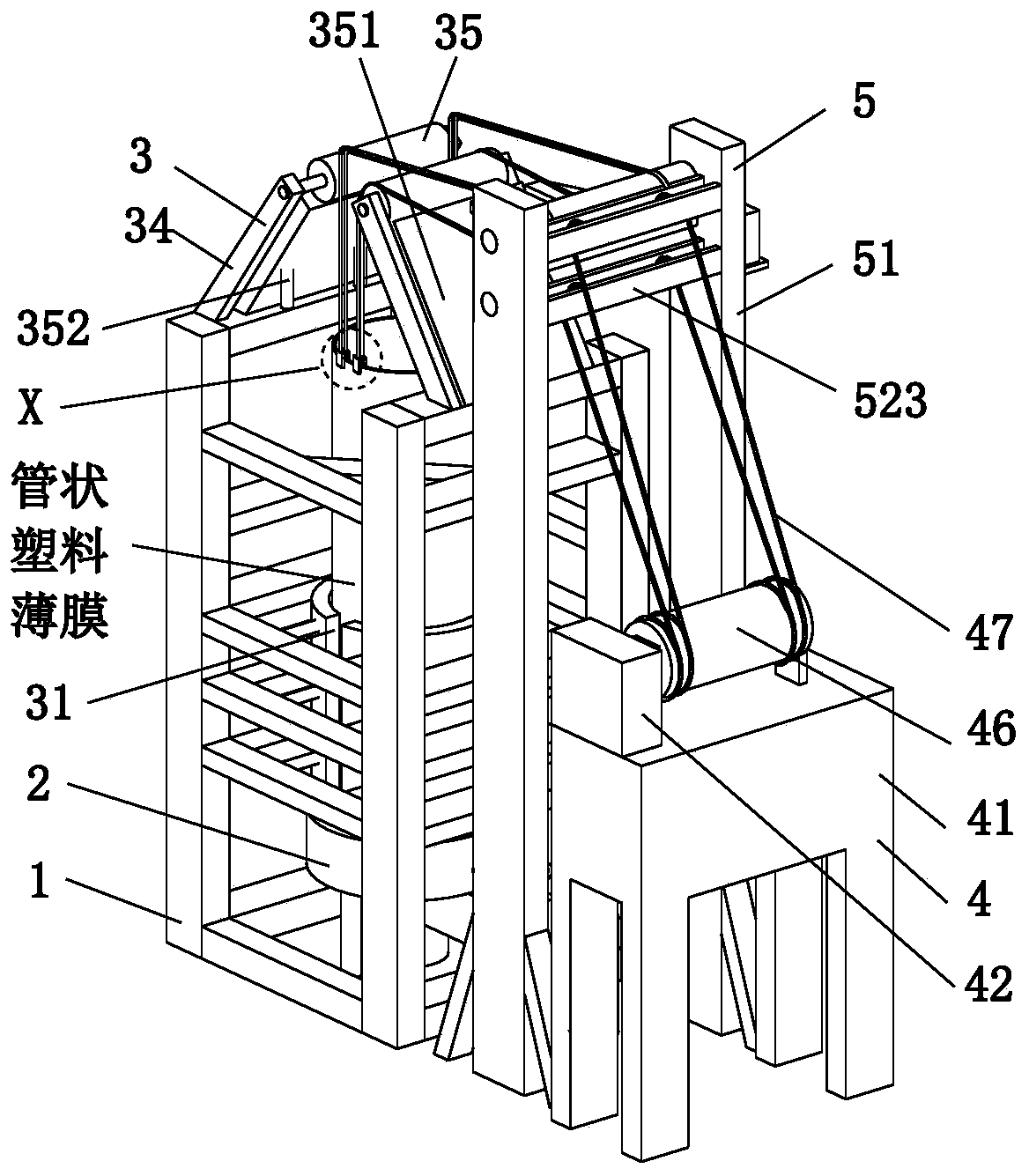

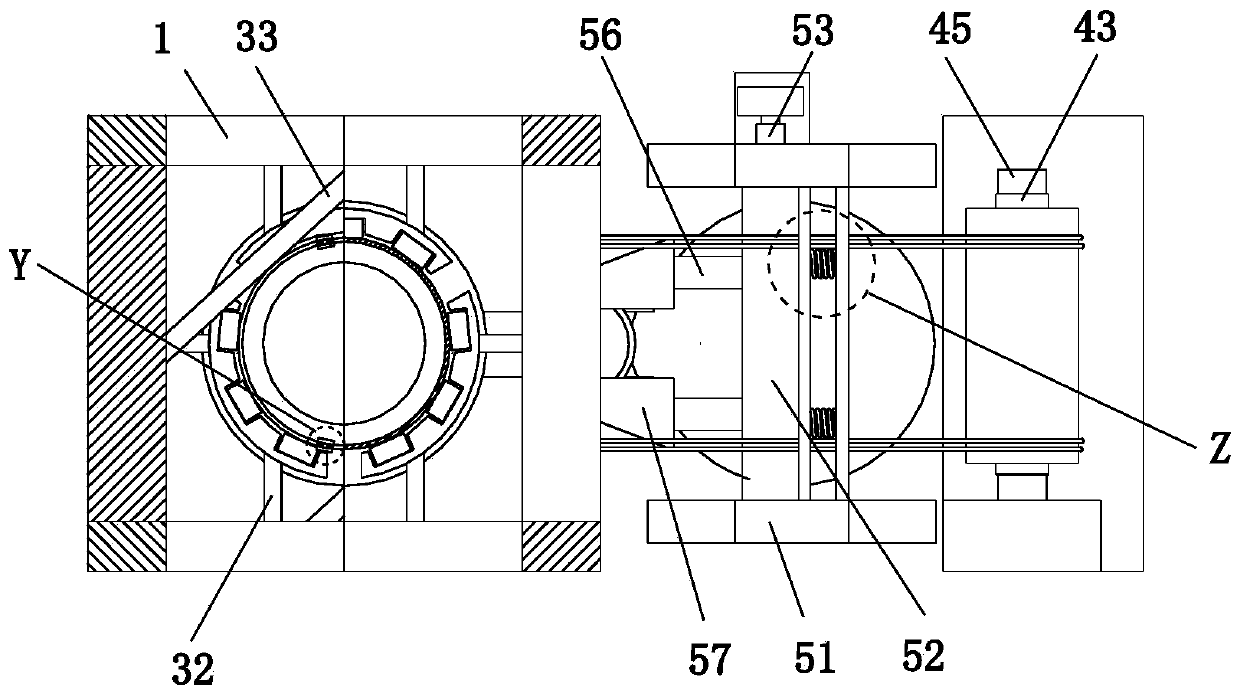

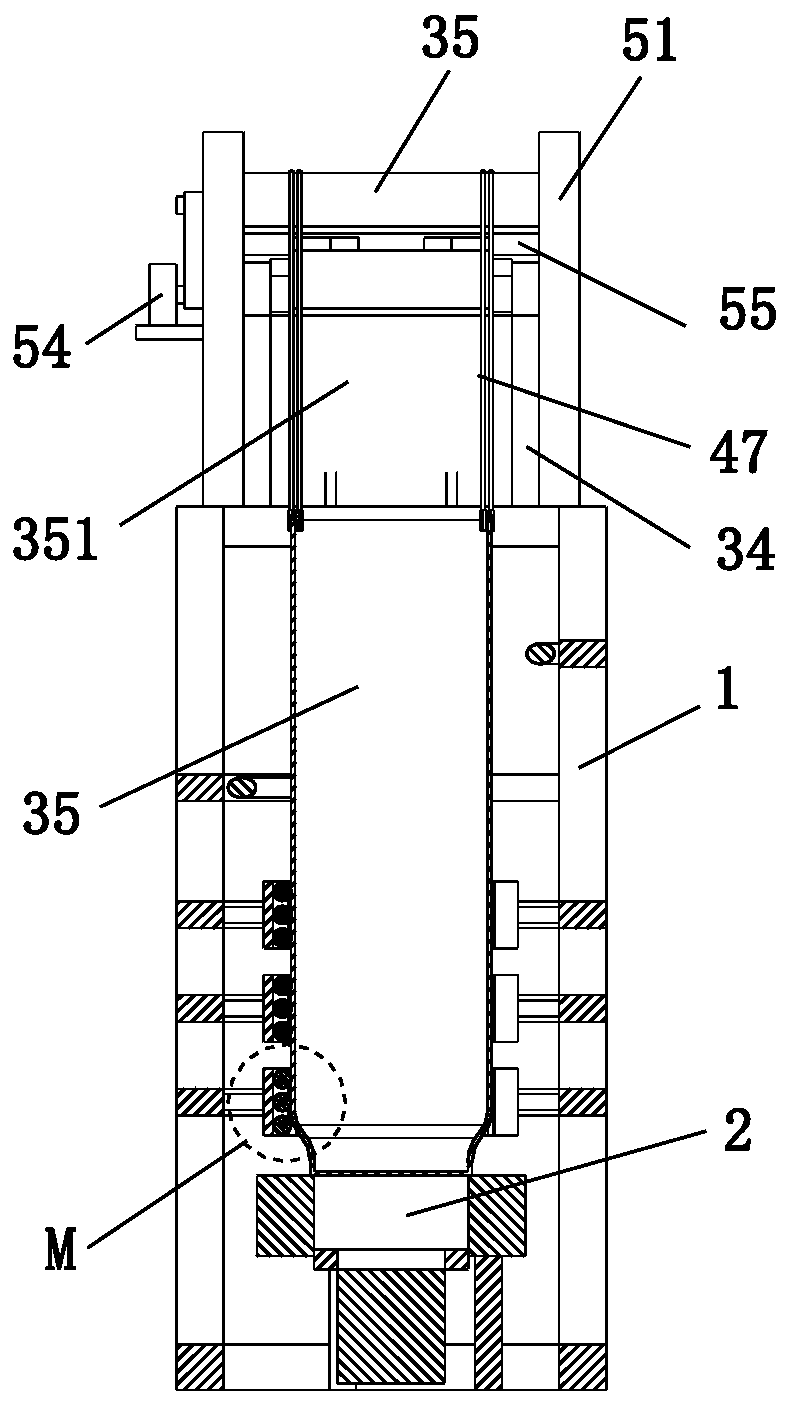

Blow molding preparing method for plastic film

The invention relates to a blow molding preparing method for a plastic film. A blow molding preparing device for the plastic film is used. The blow molding preparing device for the plastic film comprises a guide frame, an extruding machine, a guiding and fixing device, a traction device and a cutting device. The extruding machine is installed at the lower end of the interior of the guide frame. The guiding and fixing device is arranged above the extruding machine. The traction device is arranged on the right side of the guiding and fixing device. The cutting device is arranged between the traction device and the cutting device. By means of the blow molding preparing method for the plastic film, a multiple guiding and fixing design concept is adopted for conducting plastic film production,an adaptive guiding, clamping and fixing structure is adopted for the upper and the lower end of the initial-stage tubular plastic film, the forming size of the tubular plastic film and the completeness of the whole body of the plastic film are ensured, and the forming quality of the tubular plastic film is improved.

Owner:陈铭军

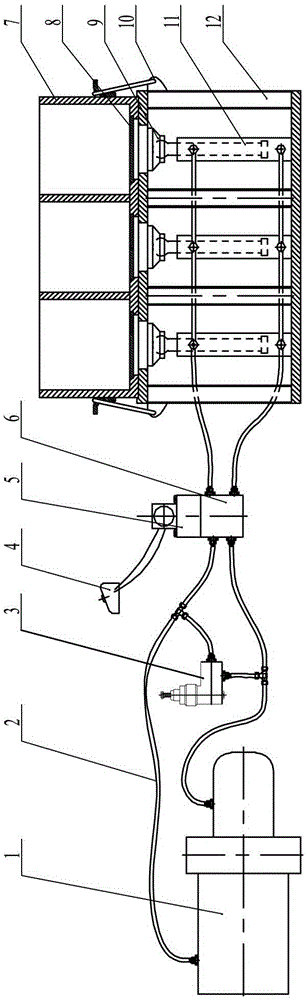

Automatic demoulding device and method for concrete test block

The invention relates to a demoulding device and a demoulding method, in particular to a concrete briquette automatic demoulding device and a demoulding method. The device comprises a forming test mould, a demoulding support base, three hydraulic oil cylinders and a hydraulic power device, wherein the forming test mould is a three-connection mould, test mould support boards are arranged in the centers of the baseboards of the forming test mould, sealing rings are arranged around the test mould support boards, a positioning groove is formed in the upper surface of the demoulding support base, the side wall of the groove is provided with a hinged buckle which tightly clamps the three-connection mould, a basket-like nut is arranged in the middle part of the hinged buckle, the three hydraulic oil cylinders are arranged in parallel, top blocks are hinged to the upper ends of the hydraulic oil cylinders, the lower ends of the hydraulic oil cylinders are fixed with a demoulding support, an electromagnetic reversing valve pinboard and a direct-acting overflow valve are respectively connected onto the oil inlet and the oil outlet of the hydraulic power unit, the electromagnetic reversing valve pinboard is connected with the three hydraulic oil cylinders in parallel, an electromagnetic reversing valve is installed on the electromagnetic reversing valve pinboard, and the electromagnetic reversing valve and the hydraulic power unit are electrically connected with an electrically controlled box. The concrete briquette automatic demoulding device is simple in mould and high in forming precision, the automatic demoulding does not be damaged easily.

Owner:CHONGQING CONSTR ENG NEW BUILDING MATERIALS +1

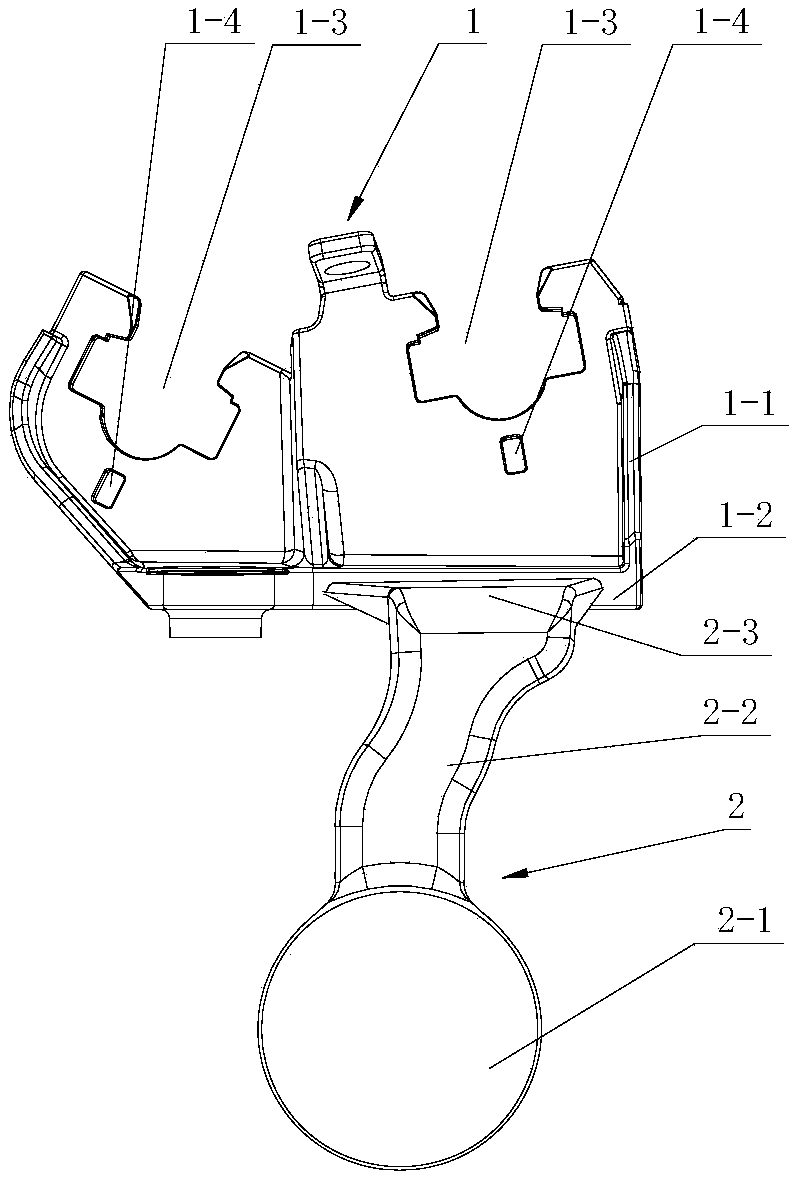

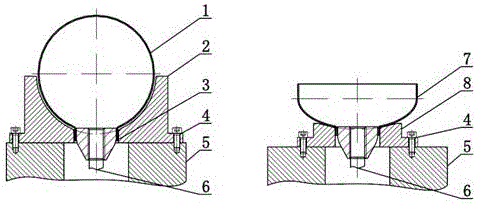

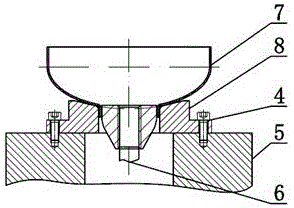

Neck tube supporting structure of vehicle LNG cylinder and forming die and forming method thereof

ActiveCN112077162AGuaranteed molding sizeGuaranteed stabilityExtrusion diesUnderstructuresIn vehicleEngineering

The invention discloses a neck tube supporting structure of a vehicle LNG cylinder and a forming die and a forming method thereof. The forming die comprises a first die base plate; an extrusion core rod, one end of which is fixedly connected to the first die base plate; a second die base plate parallel to the first die base plate, and the first die base plate is connected with the second die baseplate through a plurality of springs; the two guide columns symmetrically arranged on the two sides of the extrusion core rod; wherein the second die base plate is provided with two guide through holes, the guide through holes and guide columns are arranged in a one-to-one correspondence mode, and the guide columns can move in the axial direction of the guide through holes; a backward extrusion upper die fixedly connected to the second die base plate; a second extrusion through hole is arranged on the backward extrusion upper die, and the second extrusion through hole and a first extrusion through hole are coaxially arranged; a base; a backward extrusion lower die fixedly mounted on the base and arranged opposite to the backward extrusion upper die; and two guide sleeves fixedly connectedto the base, and the two guide sleeves and the two guide columns are arranged in a one-to-one correspondence mode.

Owner:JILIN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com