Steel mold for externally coating nodular cast iron pipe with cement mortar

A technology of cement mortar and steel mold, which is applied in the direction of ceramic molding machines, manufacturing tools, surface layering devices, etc., can solve the problems of lack, small fluid resistance, etc., and achieve the effects of high concrete density, reduced flow velocity, and small flow resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

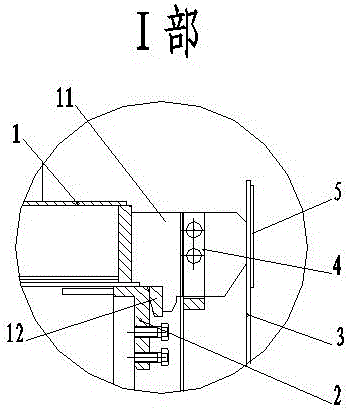

[0023] The present invention includes a top mold 1, the top mold 1 includes a positioning claw 11 and a socket ring 12, the socket ring 12 is supported by a socket adjustment ring 2 inside the socket ring 12, and the positioning claw 11 is supported in the socket ring 12. The outer mold 3 on the outside of the positioning claw 11, the socket adjustment ring 2 and the positioning claw 11 are coaxially arranged;

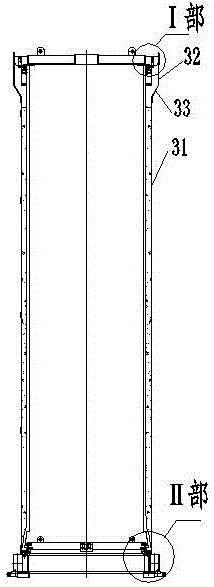

[0024] The outer mold 3 includes an outer mold body 31 and an outer mold expansion body 32 connected to the top of the outer mold body 31, and the outer mold body 31 and the outer mold expansion body 32 are transitionally connected by an inverted cone 33;

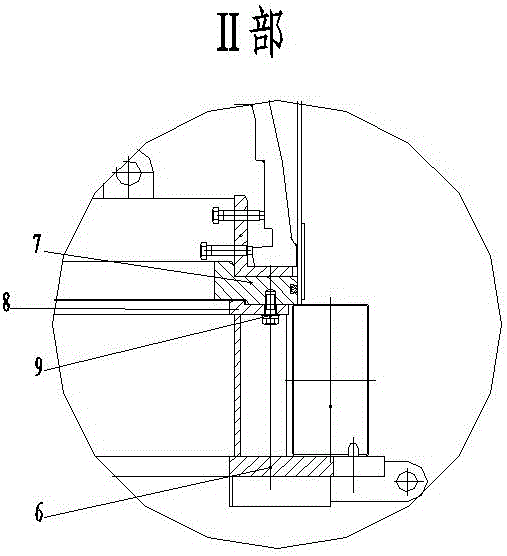

[0025] A retaining ring 4 is arranged between the top mold 1 and the outer mold 3, and the retaining ring 4 can be arranged on the positioning claw 11, and the retaining ring 4 can also drop to the bottom of the outer mold 3. The inverted cone 33 is supported.

[0026] The outer mold 3 is a single-opening type, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com