Neck tube supporting structure of vehicle LNG cylinder and forming die and forming method thereof

A technology for supporting structures and forming dies, applied in substructures, metal extrusion dies, vehicle parts, etc., can solve problems such as low production efficiency, achieve the effects of improving quality, ensuring stability, and solving low production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0061] The present invention will be further described in detail below in conjunction with the accompanying drawings, so that those skilled in the art can implement it with reference to the description.

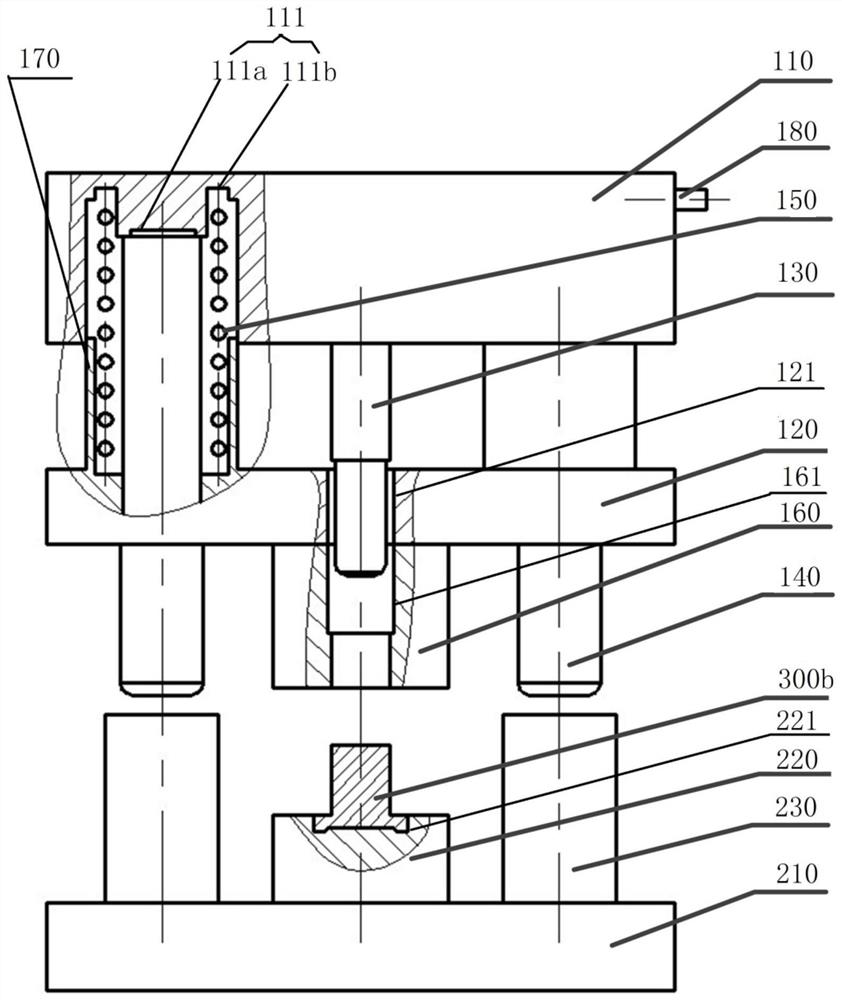

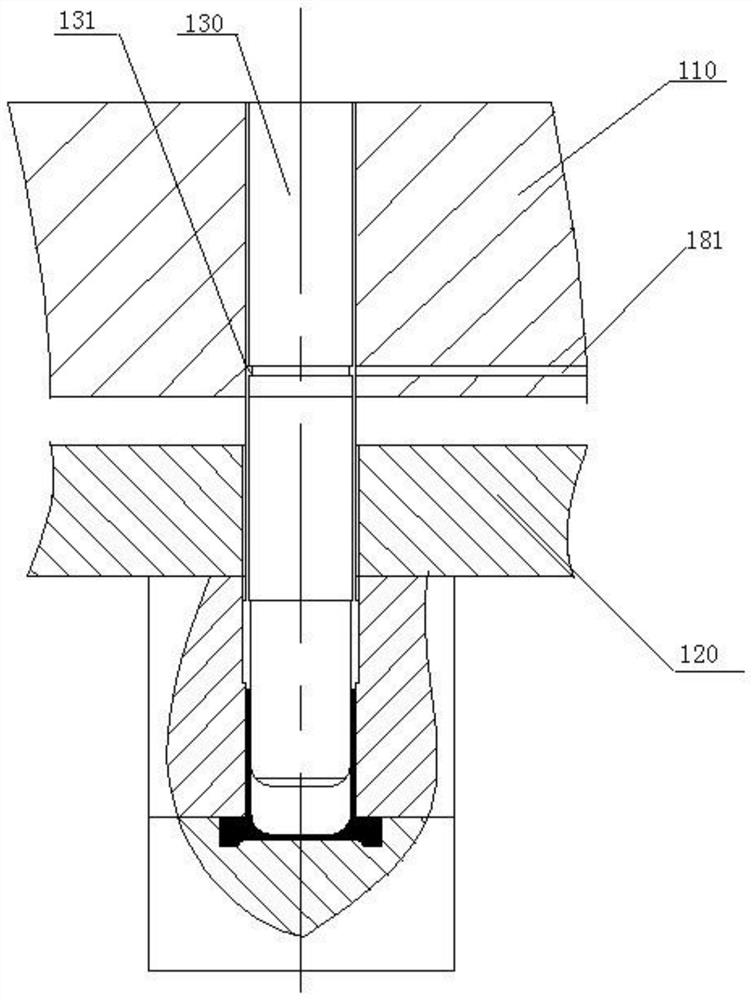

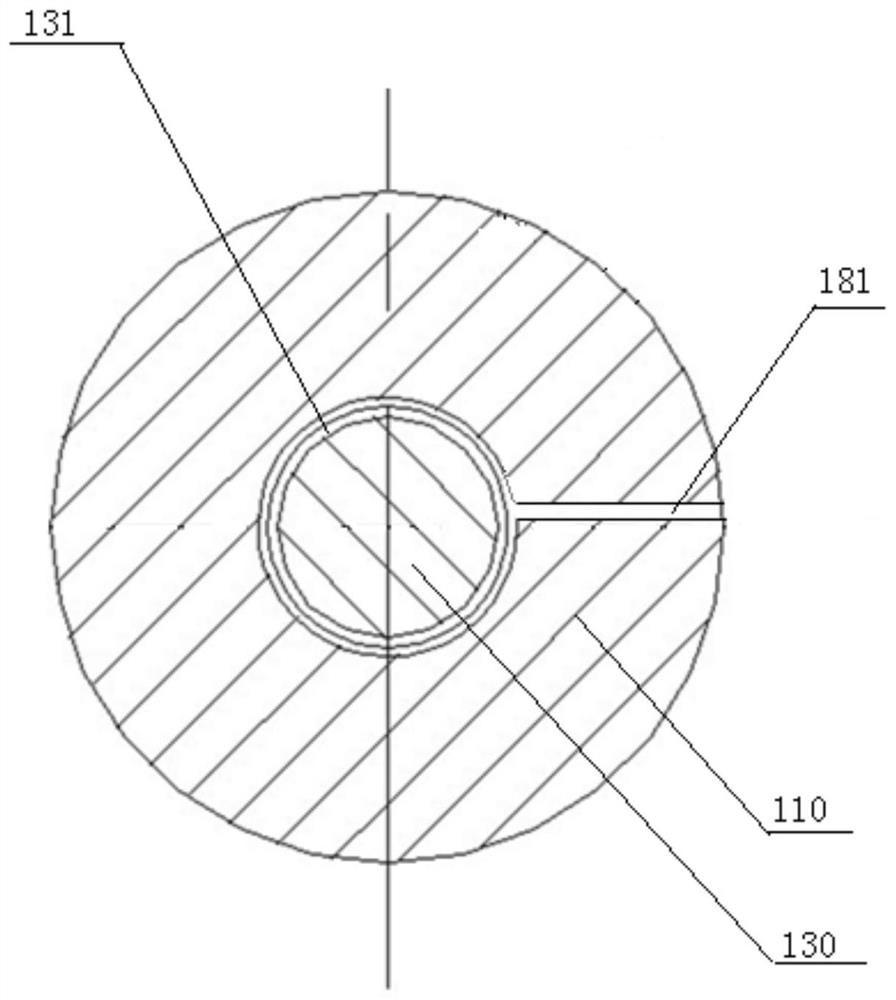

[0062] Such as figure 1 As shown, the present invention provides a molding die for the neck tube support structure of a vehicle-mounted LNG gas cylinder, which mainly includes: a first mold base plate 110, a second mold base plate 120, an extrusion mandrel 130, a guide column 140, a spring 150, reverse extrusion upper die 160, base 210, reverse extrusion lower die 220 and guide sleeve 230.

[0063] The first mold base plate 110 is arranged horizontally, and the upper end of the extrusion mandrel 130 is fixedly connected to the first mold base plate 130; the second mold base plate 120 is arranged in parallel with the first mold base plate 130, and the first mold base plate 110 It is connected with the second die base plate 120 through two springs 150 ; wherein, the two spring...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com