A Boiler Header Tube Hole Processing Tool

A technology for boiler headers and processing tools, which is applied in the direction of manufacturing tools, metal processing equipment, drilling accessories, etc., can solve the problems that it is difficult to ensure the size requirements of the tube holes, the size accuracy of the tube holes cannot be guaranteed, and waste of time, etc., to achieve Save processing time, ensure molding size, and reduce processing times

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

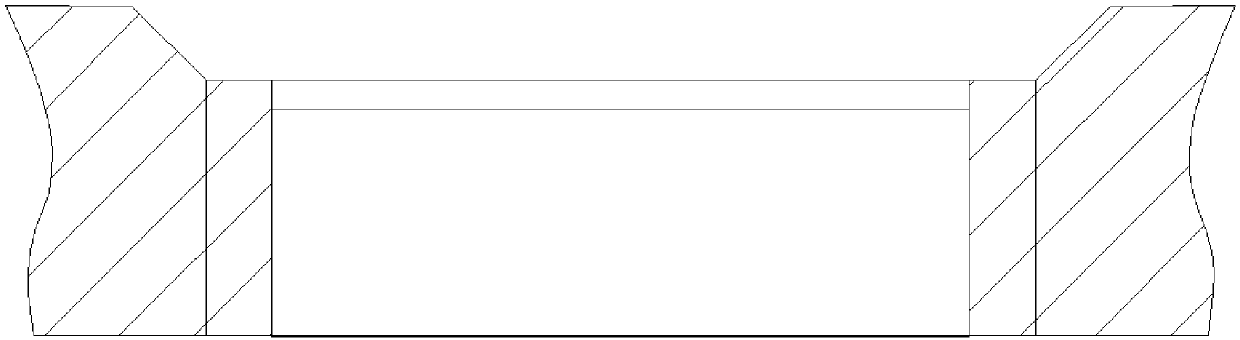

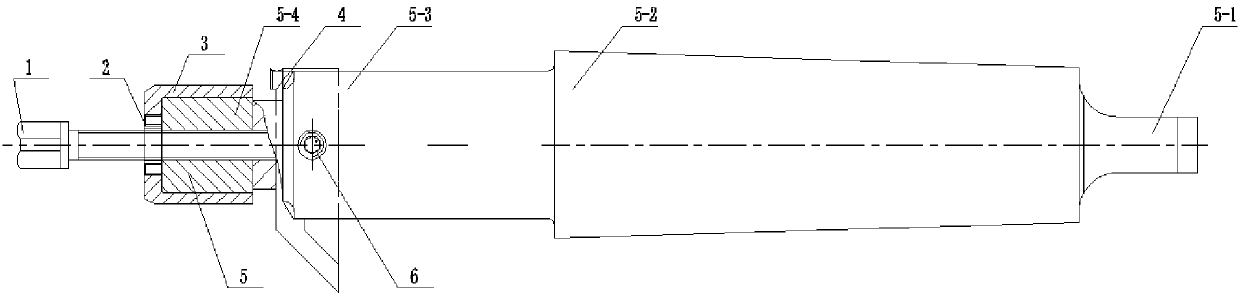

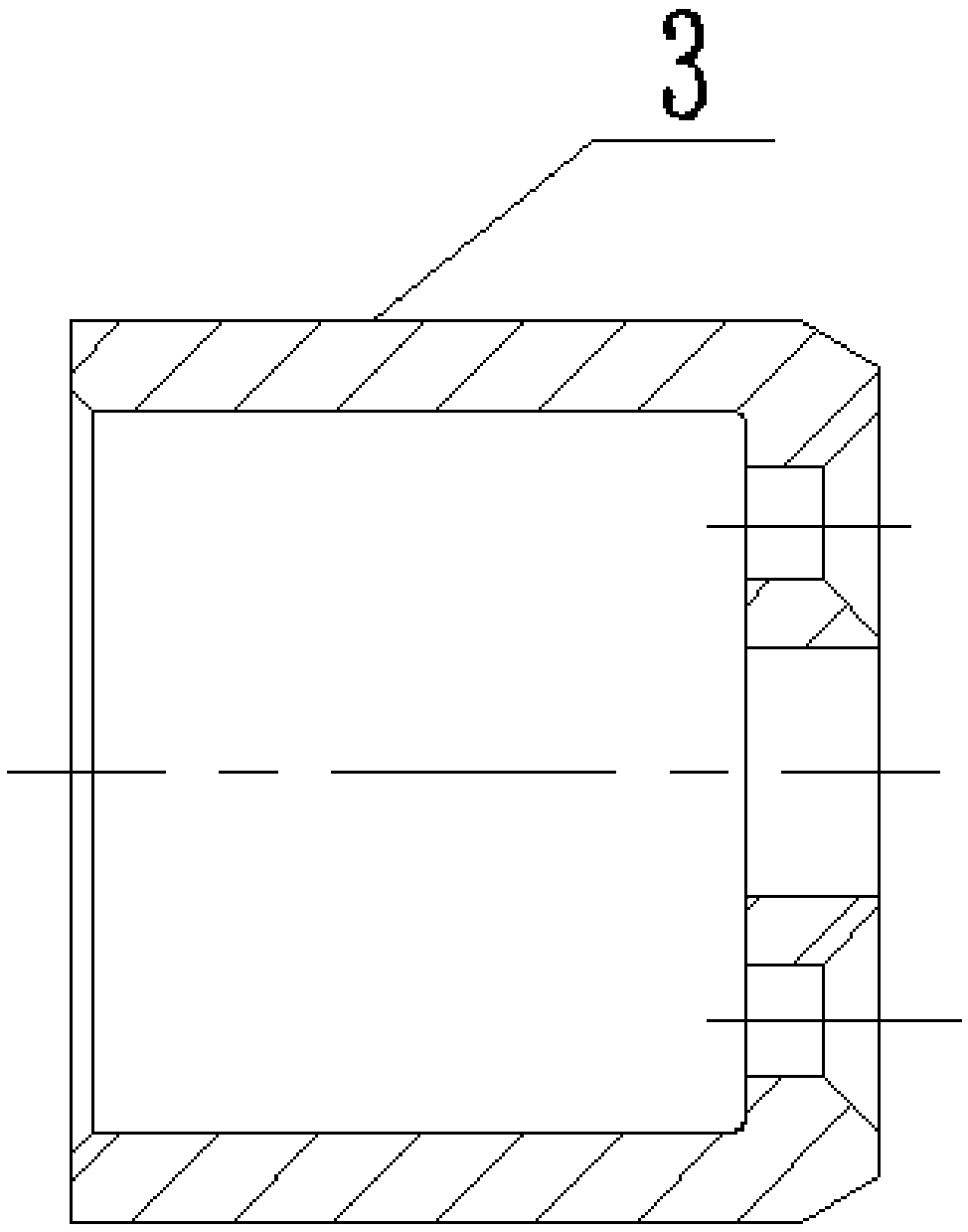

[0008] Specific implementation mode one: combine Figure 2-Figure 10 Describe this embodiment, a boiler header pipe hole processing tool described in this embodiment, it includes a bolt 1, a guide sleeve 3, a blade 4, and a cutter bar 5, a blade tightening screw 6 and two guide sleeve fixing screws 2 , the tool bar 5 includes a flat section 5-1, a conical section 5-2, a blade installation section 5-3 and a guide sleeve fixing section 5-4, and the flat section 5-1, a conical section 5-2, and a blade installation section 5- 3 and the guide sleeve fixed section 5-4 are fixedly connected in sequence, and the guide sleeve fixed section 5-4 is processed with two guide sleeve fixing screw threaded holes along the length direction of the cutter bar 5, and the blade installation section 5-3 is close to the guide sleeve The fixed section 5-4 is processed with a plane 5-5 and the blade installation hole 5-6, and the blade top tightening screw thread hole is processed on the plane 5-5 to ...

specific Embodiment approach 2

[0009] Specific implementation mode two: combination figure 2 , Figure 4-Figure 8 Describe this embodiment, a boiler header tube hole processing tool described in this embodiment, the blade 4 includes a first blade portion 4-1, a second blade portion 4-2 and a cutter body 4-3, the first blade portion 4 -1 is positioned at the top of the front end face 4-4 of the cutter body 4-3, and the second blade portion 4-2 is positioned at the bottom end of the cutter body 4-3, and the main blade of the second blade portion 4-2 is connected to the front end face 4 The angle formed by the vertical planes of -4 is c, the first chip flute is processed on the first blade portion 4-1, the rake angle of the first blade portion 4-1 is a1, the first blade portion 4-1 The relief angle is b1, the second flute is processed on the second blade portion 4-2, the rake angle of the second blade portion 4-2 is a2, the relief angle of the second blade portion 4-2 is b2, and the first The distance betwe...

specific Embodiment approach 3

[0010] Specific implementation mode three: combination figure 2 , Figure 4-Figure 8 Describe this embodiment, a boiler header pipe hole processing tool described in this embodiment, the value of a1 is 8°, the value of b1 is 12°, the value of a2 is 12°, and the value of b2 is 8°, The value of c is 45°, the value range of L is 2mm-4mm, and other components and connections are the same as those in the second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com